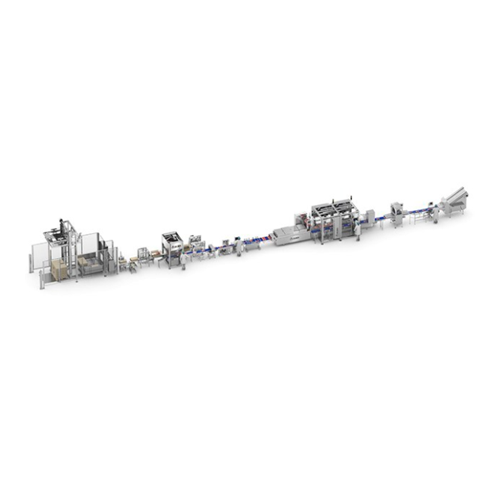

Automated sliced meat packaging solution

Ensure seamless and efficient packaging of sliced meat products with a fully automated line that integrates slicing, thermoforming, inspection, and palletizing, streamlining your production process from start to finish.

Automates Slicing, Packaging, and Palletizing Process

The ULMA Packaging Thermoforming Line is a fully automated solution designed for high-speed processing of sliced meats, ideal for meat processing and food packaging companies. This comprehensive line begins with precision slicing and loading, incorporates hygienic design thermoformers for packaging, and integrates metal detection with automated labeling to ensure product integrity. A robotic case packing system organizes the packages into carton boxes, followed by a mechanical palletizing operation to ready the products for distribution. This system enhances efficiency with PLC control for seamless integration into existing operations, reducing labor costs and maximizing throughput. Constructed from durable materials, it supports continuous, high-speed operation while ensuring compliance with industry standards. Custom engineering support is available, ensuring the equipment fits specific production needs.

Benefits

- Enhances operational efficiency by fully automating slicing to palletizing processes.

- Reduces labor costs with robotic loading and case packing automation.

- Ensures product safety with integrated metal detection and rejection systems.

- Optimizes packaging consistency and quality through precise thermoforming technology.

- Streamlines production flow with seamless integration into existing facilities.

- Applications

- Meat products, Packaged foods, Protein products, Sliced meat

- End products

- Packaged pepperoni slices, Salami slices, Deli meat packages, Packaged cooked sausages, Roast beef slices, Packaged prosciutto, Turkey breast slices, Ham slices, Packaged bacon strips, Chicken breast slices

- Steps before

- Slicing, Product Accumulation

- Steps after

- Inspection, Labeling, Case Packing, Palletizing

- Input ingredients

- sliced meat products, raw meat slices

- Output ingredients

- sealed packages of sliced meat, packaged sliced meat, case-packed cartons, palletized boxes

- Market info

- ULMA Packaging Spain is renowned for designing and manufacturing innovative, customized packaging solutions for the food, pharmaceutical, and non-food industries, emphasizing advanced automation technology, sustainability, and high-quality service.

- Automation Level

- Fully Automated

- Thermoforming Machine Type

- Hygienic Design TFS

- Packaging Type

- Sliced Meat Products

- Metal Detection

- Included with Rejection

- Labeling System

- Automatic Labeling

- Case Packing System

- Robotized Casing Cell

- Box Closing Equipment

- Included

- Palletizing System

- Mechanical Palletizing System

- Robotic Loading Cell

- Two Robots

- Slicer Type

- Automatic Slicer with Product Accumulation Buffer

- Automation level

- Fully automated

- Batch vs. continuous operation

- Continuous

- Cleaning method

- Manual/CIP

- Changeover time

- Fast

- CIP/SIP

- CIP capable

- Energy efficiency

- Optimized for high efficiency

- Working mechanism

- Thermoforming, inspection, labeling, packing, palletizing

- Product type

- Sliced meat

- Machine footprint

- Compact design for factory integration

- Discharge method

- Single row alignment

- Control panel type

- Automated interface

- Compact footprint

- Optimized for limited space

- Slicer design

- Automatic slicer with product accumulation buffer

- Packaging system

- Thermoforming for sliced products

- Structure material

- Hygienic design

- Control panel type

- HMI/Touchscreen

- Integration possibilities

- Robotic integration

- Footprint design

- Compact/hygienic