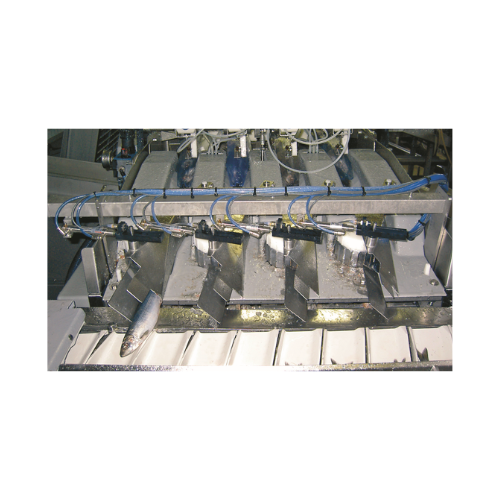

Camera-operated fish sorting system for filleting machines

Streamline your fish processing line with a system that optimizes filleting efficiency through advanced image recognition, ensuring precise sorting and quality control for herring and mackerel fillets.

Optimizes and Sorts Fish for Filleting

The Cabinplant Vision System is an innovative camera-operated solution designed for enhancing the filleting process in fish and seafood production lines. By integrating seamlessly with existing Baader or VMK filleting machines, it ensures precise sorting and surveillance of fish infeed, optimizing the conveyor’s pocket distribution to prevent bottlenecks. This system deftly identifies fish species, size, and positioning, using a self-teaching method that allows for continuous operation without the need for manual intervention, reducing the number of operators from one to zero. It is capable of processing herring and mackerel fillets with a throughput of up to 320 trays per minute. Optional features include a dry feeding conveyor for enhanced feeding efficiency. The vision system’s PC-based control supports software upgrades, allowing for flexible adaptability and detailed statistical monitoring of each fish processed. Built for demanding fish processing environments, it offers robust operational reliability and can be customized to fit various production needs, ensuring optimal yield and quality in fish filleting operations.

Benefits

- Increases productivity by automatically sorting and optimizing fish feed on the filleting line.

- Reduces labor expenses by elimination of manual operator requirements through self-teaching technology.

- Enhances product quality by accurately identifying and rejecting improperly positioned fish.

- Maintains continuity and efficiency with up to 320 trays per minute processing capacity.

- Provides comprehensive production insights via full statistical monitoring of each fish processed.

- Applications

- Seafood, Fish

- End products

- Herring fillets, Mackerel fillets

- Steps before

- Feeding, Sorting, Positioning

- Steps after

- Filleting, Waste Handling, Recirculation

- Input ingredients

- herring, mackerel, whole fish, half fish

- Output ingredients

- processed fish, filleted fish, waste fish

- Market info

- Cabinplant is known for designing and manufacturing tailored processing solutions for the food industry, specializing in fish, seafood, fruits, and vegetables. They are reputed for their innovative technology and efficiency in delivering customer-specific engineered-to-order equipment.

- Capacity

- Up to 320 trays per minute

- Automation

- Self-teaching method

- Detection type

- Vision system

- Species Detection

- Herring, Mackerel

- Detection functionality

- Belly-turned fish, foreign species, double fish

- Operating Environment

- Existing filleting machine setup

- Operator Requirement

- Reduction from 1 to 0 operators

- Control System

- PC-based control with software upgrade

- Automation level

- Self-teaching, Camera-operated

- Changeover time

- Fast

- Batch vs. continuous operation

- Inline Continuous

- Energy efficiency

- Optimized feeding

- Cleaning method

- Minimal changes required

- Capacity

- Up to 320 trays/minute

- Feeding method

- Optional dry feeding conveyor

- Detection capabilities

- Belly-turned, foreign species, double fish

- Input output control

- Surveillance of infeed and outfeed

- Operator reduction

- From 1 to 0 operators

- Biological compatibility (fish species)

- Herring, Mackerel

- Corrosion resistance

- Yes (suitable for processing environments)

- Machine footprint

- Compact, mounts on existing lines

- Control panel type

- PC-based control

- Discharge method

- Pocket conveyor

- Control panel type

- PC-based control

- Integration possibilities

- Existing filleting machine set-up