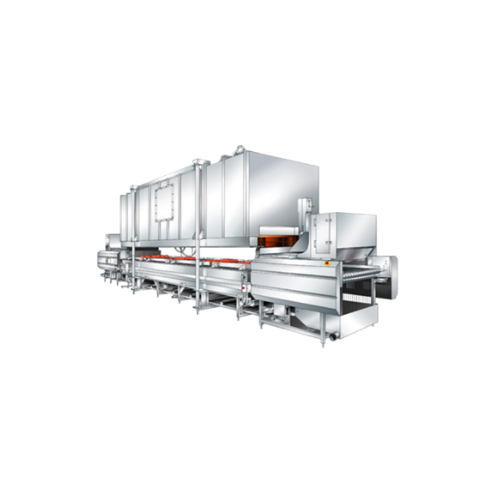

High velocity impingement oven for food processing

Optimize your cooking operations with a high velocity impingement oven that ensures rapid heat transfer and exceptional cooking uniformity, enhancing both product quality and production capacity in continuous food processing.

Delivers Rapid, Uniform Cooking with High Velocity Airflow

The Stein JSO-IV Jet Stream® Impingement Oven by Stein stands out as a versatile solution for food processing companies, particularly those in poultry, meat, and seafood industries. Featuring VaporJET® technology, it combines thermal fluid heating with high velocity vertical impingement airflow for unparalleled cooking uniformity. This oven excels in delivering rapid heat transfer and excellent color development, ensuring optimal product yield for items like chicken nuggets, roasted chicken breasts, and smoked salmon fillets. Designed with two thermal fluid heat exchangers, the oven offers distinct temperature zones and removes combustion by-products from the product zone. It supports continuous and high-speed operations, tailored for automation with ProLINK® PLC controls, and integrates seamlessly with upstream finishing and downstream cooling processes. Energy efficiency is enhanced through variable frequency drives for air circulation fans, while the fully automatic Clean-in-Place system ensures minimal downtime and contamination risk. Modular in design, the oven accommodates various product heights with adjustable upper plenums, making it adaptable for different processing requirements.

Benefits

- Maximizes production capacity with fast, uniform heat transfer.

- Enhances product quality with precise humidity and temperature control.

- Decreases downtime with a fully automatic Clean-in-Place system.

- Ensures flexible processing with variable speed air circulation fans.

- Integrates seamlessly into existing production lines for continuous operation.

- Applications

- Seafood, Meat, Ready meals, Poultry

- End products

- Chicken nuggets, Cooked beef patties, Grilled sausages, Prepared lasagna, Roasted chicken breast, Breaded fish sticks, Pre-cooked chicken wings, Baked seafood kebabs, Smoked salmon fillets, Ready-to-eat meatloaf

- Steps before

- Preparation, Portioning, Coating, Injection, Marination

- Steps after

- Cooling, Freezing, Packing, Portioning, Slicing

- Input ingredients

- coated food substrates, uncoated food substrates, poultry, meat, seafood

- Output ingredients

- cooked food products, cooked poultry, cooked meat, cooked seafood

- Market info

- JBT is known for manufacturing innovative industrial machinery and solutions, particularly in the food processing and air transportation sectors, renowned for their advanced technology, reliability, and customer-focused engineered-to-order solutions tailored to specific industry needs.

- Heat Transfer Rate

- Extremely fast

- Production Capacity

- Maximum

- Humidity Control

- Automatic

- Belt Width

- 40 in.

- Modular Design

- 22 ft. oven box

- Plenum Adjustment

- 2 to 6 in.

- Air Circulation Fans

- Variable speed (VFD)

- Electric Drives

- Available

- Thermal Fluid Heat Exchangers

- Two

- Infeed Section Length

- 8.5 ft. standard, options up to 20.5 ft.

- Automation

- Fully automatic CIP

- Impingement Velocity Control

- Yes

- PLC Controls

- ProLINK®

- Cooking Method

- High velocity impingement

- Temperature Control

- Two thermal fluid heat exchangers

- Humidity Control

- Humitrol-III® automatic humidity control

- Cleaning

- Fully automatic Clean in Place (CIP) system

- Adjustable Upper Plenums

- Two to six inches

- Impingement Velocity Control

- Two variable speed (VFD) air circulation fans

- Automation Level

- ProLINK ® PLC controls

- Loading Mechanism

- 40 in. wide usable belt width

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Product Yield

- Highest possible product yield of impingement ovens

- Machine footprint

- 22 ft. long oven box

- Modular design

- Yes, with clam shell hood design

- Belt width

- 40 in. wide usable belt width

- Steam heated infeed section

- 8.5 ft. long

- Automatic hood lift

- Yes

- Control panel type

- ProLINK ® PLC controls

- Impingement velocity control

- Variable speed (VFD) air circulation fans

- Plenum adjustment

- Automatic adjustment from two to six inches

- Steam heated infeed section length

- 8.5 ft standard, options up to 20.5 ft

- Transition chambers

- Two or four ft. for multiple box installations