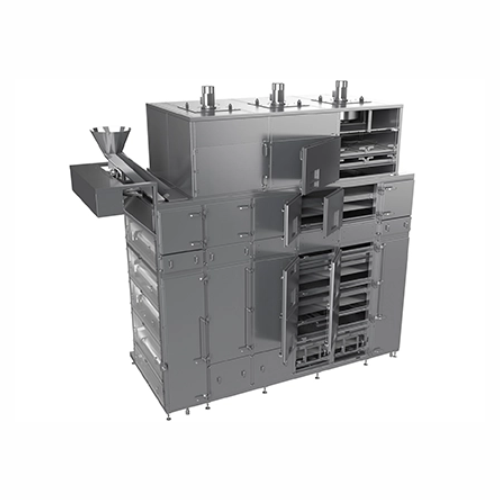

Continuous belt dryer for large-scale drying applications

Optimize your production with a continuous belt dryer, engineered for precise moisture removal and homogenous drying, ensuring product stability and quality across diverse applications.

Continuously Dries and Dehumidifies Various Products

The Bandtrockner from HARTER drying solutions offers a versatile, automatic drying system designed for continuous moisture removal in industries such as food, pharmaceuticals, and packaging. Its closed system employs precise air guidance and adjustable band speeds to optimize drying conditions and product integrity. Applications include drying surface coatings, pet food, and medicinal cannabis, facilitating end-products from paint coatings to sterile medical devices. Engineered for high throughput, it efficiently processes large volumes with a speed-sensitive conveyor belt, all while maintaining low energy consumption through optimized airflow control. This equipment integrates smoothly into existing production lines, supported by PLC automation and is available in materials suitable for various industrial uses. HARTER provides customization options and thorough engineering support to tailor solutions for specific operational needs, ensuring compliance with industry standards and streamlined maintenance through adaptable design features.

Benefits

- Enhances production efficiency with continuous operation and minimal downtime.

- Optimizes energy use, reducing consumption costs with precise air flow control.

- Supports large-scale drying processes, increasing throughput capacity.

- Maintains product quality with homogeneous and gentle drying.

- Provides flexible integration options for diverse industrial applications.

- Applications

- Animal feed, Medical devices, Industrial sludge, Surface coatings, Sewage sludge, Packaging materials, Food products, Medicinal cannabis, Pharmaceuticals

- End products

- Printed labeling, Pet kibble, Sterile surgical instruments, Dried cannabis flowers, Fruit slices, Vegetable crisps, Paint coatings, Corrugated cardboard, Degreased industrial waste, Dried sewage pellets, Cattle feed pellets, Herbal medicines

- Steps before

- Purification, Grinding, Emulsification

- Steps after

- Packing, Coating, Sterilization

- Input ingredients

- Lebensmittel, Tierfutter, Pharma / Medizintechnik, Medizinalcannabis, Verpackungen, Industrieschlamm, Klärschlamm

- Output ingredients

- getrocknete Lebensmittel, getrocknetes Tierfutter, getrocknete Pharmazeutika / Medizintechnik, getrocknetes Medizinalcannabis, getrocknete Verpackungen, getrockneter Industrieschlamm, getrockneter Klärschlamm

- Market info

- HARTER Drying Solutions is known for its expertise in energy-efficient drying technology, particularly using heat pump-based systems. They provide customized drying solutions for various industrial applications, focusing on energy savings and improved product quality.

- Automation

- Fully automatic

- Capacity

- Large production volumes

- Band length

- Customizable

- Band speed

- Adjustable

- Temperature control

- Precise

- Airflow direction

- Product-specific

- Moisture removal efficiency

- High

- System design

- Closed

- Working mechanism

- Continuous belt drying

- Automated process

- Fully automatic

- Product-specific air guidance

- Custom air flow design

- Batch vs. continuous operation

- Continuous

- Airflow control

- Optimized for product characteristics

- Parameter determination

- In-house testing

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Compact

- Band length

- Customizable

- Band speed

- Customizable

- Schütthöhe (bed height)

- Flexible

- Fallstufen and Auflockerungseinrichtungen

- Available for specific applications

- Feed/discharge method

- Continuous

- System enclosure

- Closed with minimal openings

- Airflow control

- Customizable to product

- Control panel type

- Available

- Material Handling

- Fallstufen / Auflockerungseinrichtungen

- Band Configuration

- Bandlänge / Bandgeschwindigkeit / Schütthöhe

- Airflow Design

- Produktabhängig ausgelegt

- System Type

- Vollautomatisch

- System Enclosure

- Geschlossenes System

- Parameter Testing

- Trocknungstests im hauseigenen Technikum