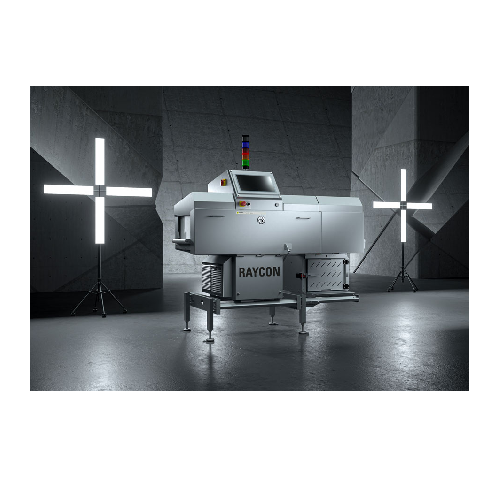

X-ray inspection system for packaged meat

Ensure packaged food safety by seamlessly detecting contaminants such as metals, glass, and stone in meat products and ready-made meals with this advanced inspection system.

Detects and Removes Contaminants in Packaged Foods

The RAYCON series from Sesotec offers specialized X-ray inspection systems designed for detecting and eliminating contaminants in packaged foods and meat products. This equipment features precision inspection techniques that utilize advanced X-ray technology for the detection of metals, glass, ceramics, and other impurities. Perfectly suited for high-speed production environments, this robust solution delivers exceptional operational efficiency with a modular design facilitating easy installation and integration into existing lines. The RAYCON systems are engineered for continuous operation, ensuring compliance with food industry standards such as BRCGS, IFS, and HACCP. Featuring user-friendly interfaces, these systems simplify the inspection process while maintaining flexible configurations to accommodate various packaging formats. With options like dual-energy technology, RAYCON systems provide superior detection capabilities, even for low-density contaminants, ensuring rigorous quality control across applications like frozen meals, vacuum-packed meats, and pasta products. Installation supports seamless integration with PLC systems for enhanced automation, while the hygienic design ensures easy cleaning and maintenance, reducing downtime and preserving product integrity.

Benefits

- Enhances product safety by reliably detecting contaminants down to 0.3 mm.

- Streamlines operations with seamless integration into high-speed production lines.

- Reduces product wastage through precise separation of defective items.

- Lowers maintenance costs with hygienic, tool-free serviceability.

- Meets stringent food safety standards, safeguarding against recalls and customer complaints.

- Applications

- Meat products, Ready-made meals, Pasta, Processed food products, Packaged meat, Packaged sausages, Packaged foods

- End products

- Frozen lasagna trays, Packaged turkey breast slices, Corned beef cans, Ravioli cans, Vacuum-packed sliced ham, Vacuum-sealed bacon strips, Spaghetti packages, Frozen chicken nuggets, Microwavable pasta pots, Packaged salami

- Steps before

- Cutting, Mixing, Forming, Cooking

- Steps after

- Packing, Labelling, Sterilization, Storage

- Input ingredients

- packaged foods, meat products, pasta, ready-made meals

- Output ingredients

- inspected packaged foods, contaminant-free meat products, defect-free pasta, quality assured ready-made meals

- Market info

- Sesotec is known for specializing in the development and manufacturing of innovative machine technology, particularly for metal detection, sorting, and separation systems used across industries such as food, plastics, and recycling, ensuring product quality and safety.

- Detection type

- X-ray

- Contaminant detection

- Metals, Glass, Ceramic, Stones, Bone fragments, PVC, Teflon, Rubber, Glass-fibre-reinforced plastics

- Smallest detectable contaminant size

- 0.3 mm

- Automation

- Intuitive user interface, PLC-controlled

- Inspection speed

- High-speed thanks to innovative analysis software

- Compliance with standards

- BRCGS, IFS, HACCP

- Radiation protection

- Excellent, in line with German X-ray Regulation (Röntgenverordnung − RöV)

- Installation

- Modular design, hassle-free

- Contaminant detection capability

- Metals, glass, ceramics, stones, bone fragments, PVC, Teflon, rubber, glass-fibre-reinforced plastics

- Inspection type

- X-ray

- Automation level

- Intuitive user interface

- Cleaning method

- Easy cleaning and maintenance

- Modular design

- Hassle-free installation

- Product removal

- Integrated separation systems for defective products

- Inspection speed

- High speeds with innovative analysis software

- Batch vs. continuous operation

- Inline Continuous

- Cleanability

- Easy cleaning and maintenance

- Biological compatibility

- Food safe materials

- Corrosive resistance (e.g. acids)

- Yes

- Density/particle size

- Compatible with varying densities

- Packaged Product Suitability

- Meat, Pasta, Ready-Made Meals

- Machine footprint

- Compact/Space-saving

- Conveyor belt type

- Flat conveyor belt

- Control panel type

- Intuitive touchscreen

- Design

- Hygienic/Easy-to-clean

- Installation

- Hassle-free/Modular design

- X-ray tube

- Electrically generated, fan-shaped beam

- Detector unit

- Linear above conveyor

- Weight check system

- Integrated

- Control panel type

- Intuitive user interface

- Integration possibilities

- Merge multiple packaging lines into single inspection system

- Design flexibility

- Modular design for easy installation

- Software features

- Special analysis software for digital imaging

- Product handling

- Conveyor belt system