Turkey halver for poultry processing

Effortlessly halve turkeys while maximizing yield and flexibility in your poultry processing line, ensuring seamless integration with existing systems for optimized production.

Efficiently Halves and Separates Turkey Parts

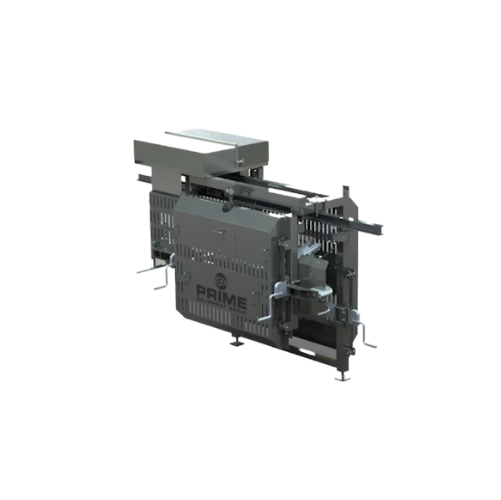

The HM-1T Turkey Halver from Prime Equipment Group is engineered to streamline your poultry processing line by effectively halving and separating turkey parts with precision. With its line-driven operation, this machine uses a fully automatic cutting system to ensure consistent and accurate separation of the front half from the saddle. This equipment excels in enhancing yield by allowing for adjustments to remove more rib bones or saddle, tailored to your production needs. It’s ideally suited for the production of turkey halves, saddle cuts, and front half portions, serving poultry processors, meat facilities, and food companies efficiently.

The HM-1T can integrate seamlessly with your existing overhead lines and operates continuously, requiring no additional power or operator intervention. Capable of processing up to 50 toms per minute or 60 hens per minute, it maximizes throughput without compromising on quality. This machine is compatible with the BSC-Series Back Skin Cutter, providing flexibility in how front halves are managed post-separation. Constructed to handle solid product types, it supports both whole turkey processing and the creation of boneless fillets and turkey ribs. The HM-1T offers customizability and engineering support to adapt to various production environments, ensuring reliability and efficiency in operations.

Benefits

- Increases yield with adjustable cutting for optimal separation.

- Minimizes labor requirements with fully automatic, line-driven operation.

- Enhances production flexibility, accommodating various processing options.

- Maintains high processing speeds, handling up to 60 hens per minute.

- Integrates seamlessly with existing overhead lines, optimizing workflow.

- Applications

- Seafood, Meat, Poultry

- End products

- Turkey saddle cuts, Whole turkey processing, Boneless turkey fillets, Front half turkey portions, Turkey halves, Turkey ribs

- Steps before

- Poultry Processing - Primary, Whole Bird Chilling, Skinning

- Steps after

- Cooking, Freezing, Chilling, Proofing, Portioning, Slicing, Packaging

- Input ingredients

- whole turkey, turkey carcass

- Output ingredients

- front half of turkey, saddle of turkey, rib bones, back skin

- Market info

- JBT is known for manufacturing innovative industrial machinery and solutions, particularly in the food processing and air transportation sectors, renowned for their advanced technology, reliability, and customer-focused engineered-to-order solutions tailored to specific industry needs.

- Automation

- Line-driven, no motor

- Electrical Requirements

- 480V, 3 ph, 60 Hz

- Net Weight

- 1, 200 lbs (544 kg)

- Production Rate

- Up to 50 toms/min

- 60 hens/min

- Working Mechanism

- Line-driven, no motor required

- Production Flexibility

- Adjustable for product requirements

- Automation Level

- Manual / Line-driven

- Integration Capability

- Works with BSC-1 Back Skin Cutter

- Yield Improvement

- Works with various overhead lines

- Maintenance Requirement

- No additional power or operator

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Compact footprint

- Line-driven, no motor required

- Net Weight

- 1, 200 lbs (544 kg)

- Discharge method

- Adjustable to remove more rib bones or saddle

- Production rate

- Up to 50 toms/min

- 60 hens/min

- Operating configuration

- Works with BSC-Series Back Skin Cutter

- Control mechanism

- Line-driven, no additional power or operator required

- Adjustability

- Adjustable for different processing options

- Integration with equipment

- Works with BSC-1 Back Skin Cutter

- Production flexibility

- Designed for production flexibility

- Automation requirement

- Line-driven, requires no additional power

- Front half processing option

- Front half can be dropped by back skin