Mustard Production Technology

Find innovative production technology for making mustard and connect directly with world-leading specialists

White, black and brown seeds from the mustard plant are the key constituents of this colorful and classic condiment. The various mustard production technology includes a mixer that mixes the mustard seeds with a handful of other ingredients and a mill that finely grinds the seeds to impart their characteristic flavor.

Stories about mustard

Select your mustard process

Tell us about your production challenge

Making mustard, seeding your success with mustard production technology

Mustard seeds are the star ingredient of mustard sauces. When it comes to flavor, dark seeds are generally the hottest, while lighter colors indicate milder varieties. The enzyme myrosinase interacts with various glucosinolates to form mustard oil, responsible for the pungent spiciness of mustard sauces. The enzymes of the seeds go dormant when dried, so it is the addition of liquid that reawakens them to produce their spicy flavor.

Mustard production technology includes first a mixing tank where you mix your dry ingredients with water and vinegar. You then pump this mixture into the stone mill, where a rotating stone grinds the mustard seeds into a fine paste. This grinding also generates a fair amount of heat which thickens the mustard to the desired consistency.

White seeds and turmeric powder for your yellow mustard production

Yellow mustard is produced with white mustard seeds and incorporates turmeric and paprika for its characteristic color. This is added with salt to a solution of water and white vinegar and contrasts with Dijon mustard which uses white and cider vinegar. You use brown mustard seeds to produce Dijon, with more seeds and less water than in yellow mustard. The preliminary mixture must also ferment for about 12 hours before processing to develop the stronger flavors it is known for. Altogether, it takes about 20 hours to produce yellow mustard, but 32 hours to produce Dijon. The seed makes all the difference when producing mustard.

Dijon mustard production: let it rest for the best

The production process of Dijon mustard takes advantage of fermentation to create a unique taste. Brown mustard seeds, salt, white vinegar, cider vinegar, and water are brought together in a fermentation tank to provide some time for friendly microbes to introduce the robustness that Dijon is known for.

More adventurous producers may include additional ingredients such as red wine to further develop that signature taste. This process requires significantly more time than yellow mustard to complete but compensates with an abundance of flavor.

Mustard powder as a flavoring agent

Mustard powder is a readily available milled form of mustard seeds that provides the essence of mustard without the added body of mustard sauce. It is often used as a flavoring agent, such as in the seasoning of meats or the brine of pickling. Mustard powder is also commonly used as an ingredient in mayonnaise and vinaigrettes, due to its unique pungency of spice.

Processing steps involved in mustard making

Which mustard technology do you need?

High shear emulsifier for mayonnaise production

Streamline your production of high-quality emulsions with this high-capaci...

High shear emulsifier for food and pharmaceutical products

Optimize your production line with precise emulsification, ho...

Heat exchangers for efficient heat transfer in industry

Achieve precise temperature control across diverse viscosities wi...

Precise liquid cooling solution for food processing

Ensure high-quality preservation of flavors and textures in liquid fo...

Continuous nut paste production line

Elevate your production efficiency with a versatile preparation line designed to seaml...

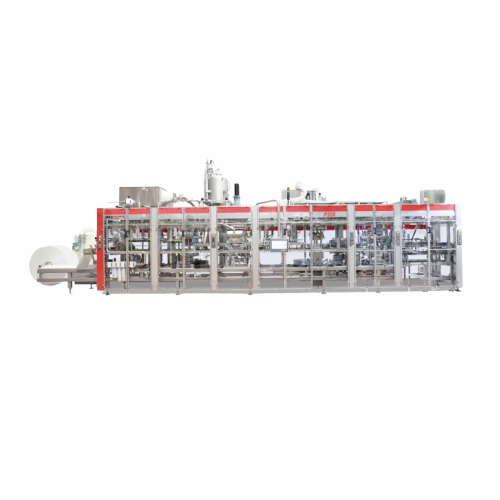

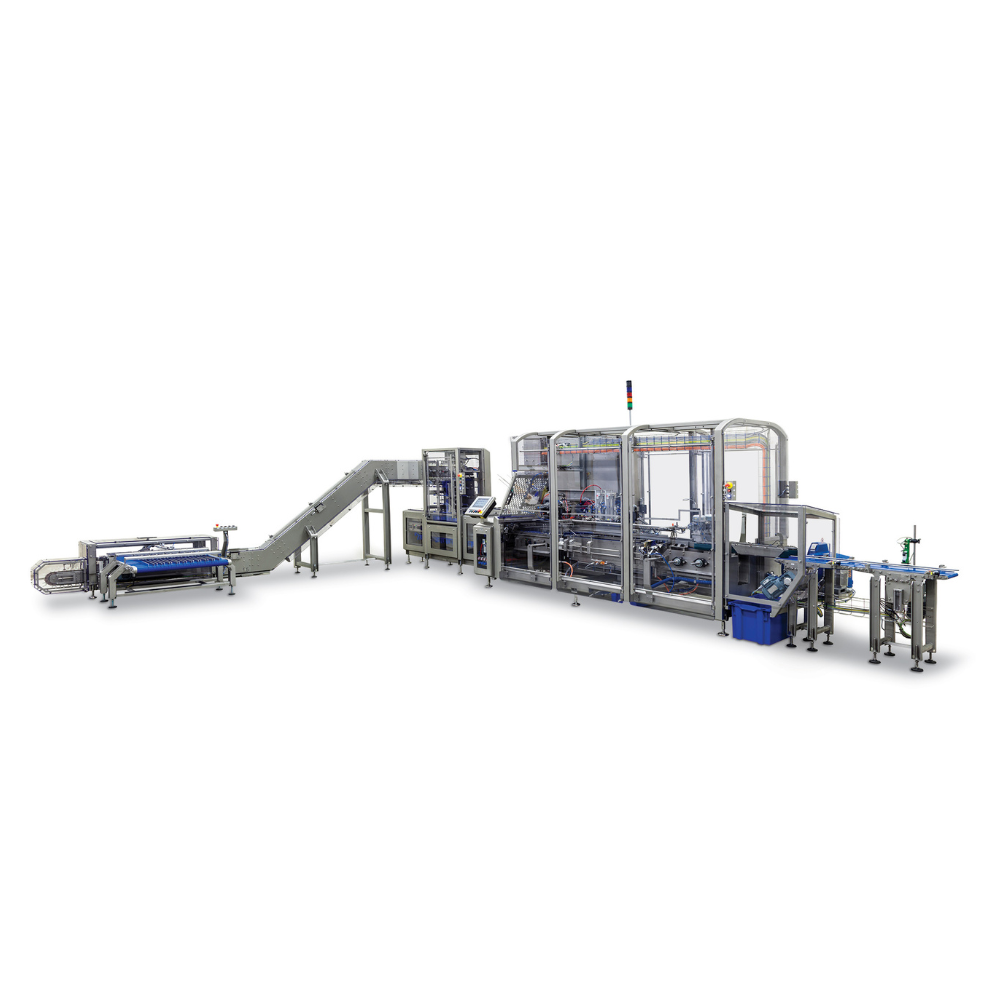

Continuous mustard production line

Optimize your condiment production with precision-engineered systems capable of transfor...

Cheese blending and heating line for processed cheese

Optimize your processed cheese production with a solution that seam...

Continuous caramel production line

Optimize your caramel production with seamless integration, achieving precise fat meltin...

Industrial cooker for sauces and stews

When producing diverse culinary delights such as sauces and stews, achieving even he...

Continuous heat exchanger for soups and sauces

Optimize your soup and sauce production with a continuous heat exchanger th...

Efficient cooling and cooking systems for food processing

Streamline your production with integrated cooling and cooking...

Industrial cutting system for fine emulsions

Optimize your production line with precision cutting and emulsifying, ensurin...

Vacuum deaeration system for mustard and liquid detergents

Ensure optimal product quality by effectively removing air fr...

Cleaning systems for food, pharmaceuticals, and cosmetics

Ensure optimal hygiene and safety with advanced cleaning syste...

Continuous caramel process line

Optimize your continuous food processing with an engineered-to-order line tailored for preci...

Continuous cheese line

Achieve precise temperature control and seamless product transitions with this equipment, ideal for en...

Continuous mustard line

Streamline mustard production with high-capacity continuous processing that reduces air pockets and e...

Continuous tahina production line

Streamline your tahina production with precise grinding and controlled cooling, ensuring ...

Vacuum de-aeration unit for liquid to pasty products

Optimize your product consistency and stability with continuous de-a...

Laboratory homogenizer for viscous products

Achieve ultra-fine textures and improved consistency in pasty and semi-pasty p...

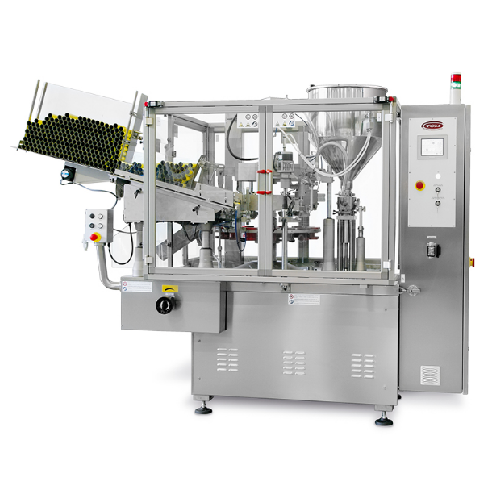

Tube filling machine for cosmetics and food products

Achieve precise and efficient packaging with this advanced twin-head...

Tube filling solution for plastic and laminate tubes

Ensure precise tube filling and sealing with quick changeovers, enha...

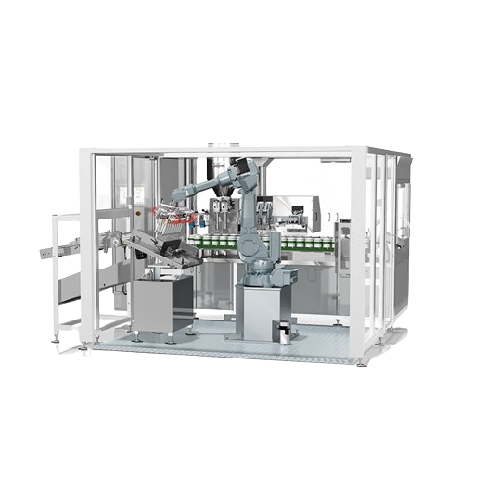

Pick & place robot for packing tubes in boxes

Efficiently streamline your packaging line with this compact case packer, de...

Tube filling station for plastic, laminate, and aluminum tubes

Efficiently seal and fill various tube materials, ensurin...

High capacity filling line for jars and bottles

Need to streamline your packaging line? This high-capacity solution proces...

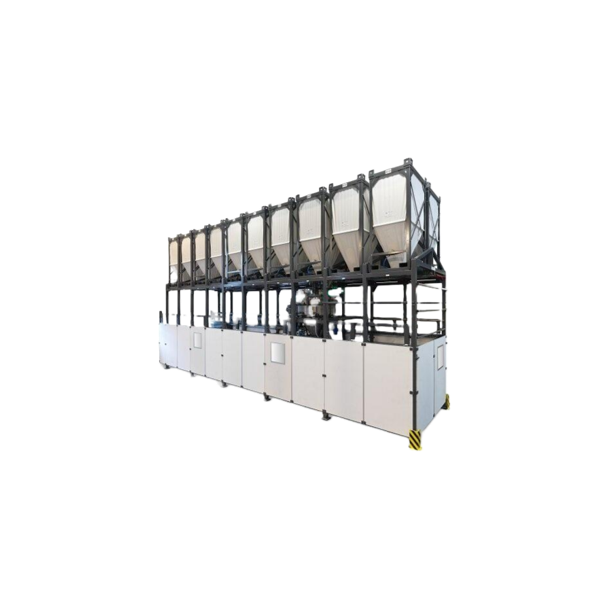

Large container filling line

Optimize your production line with a seamless solution for efficiently filling large containers...

2-head liquid and viscous product filling system

Streamline your filling operations with precision and versatility designe...

8 head liquid and viscous product filling system

When precision and speed are crucial, this 8 head filling machine ensures...

Blending system for fine adjustment of original gravity in beer

Ensure precise control over your beer’s original gravity...

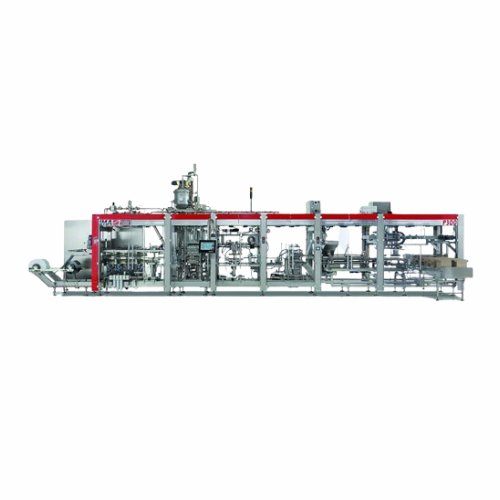

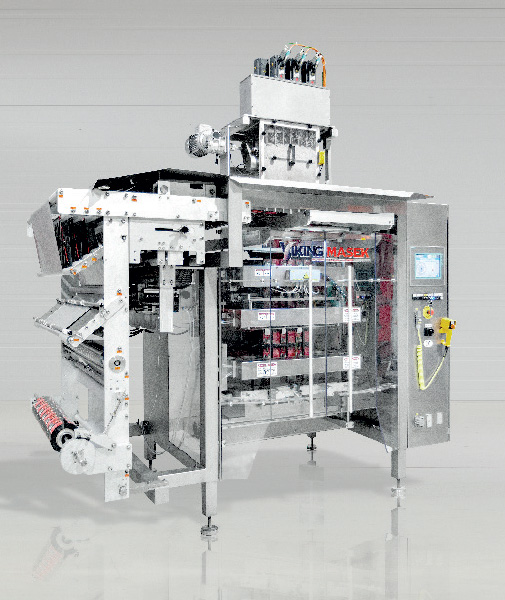

Form fill and seal machine for portion packs

Streamline your portion packaging with a compact system that efficiently form...

Form fill and seal solution for dairy portion packs

Optimize your production with precision portion packing, reducing mat...

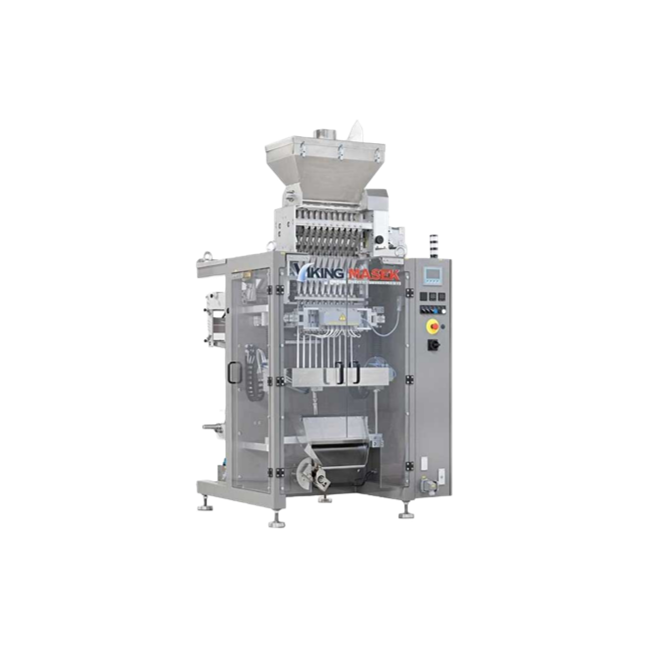

Stick pack forming, filling, and sealing solution

Enhance packaging efficiency with a high-speed solution designed for pr...

High-shear mixer for high viscosity products

Achieve consistent, homogeneous mixtures of high-viscosity products with a ve...

Vacuum high shear mixer for medium to high viscosity products

Achieve flawless blending and air-free consistency in visc...

Bigbag filling system for powder and bulk materials

Ensure precise and dust-free bigbag filling with this versatile syste...

High-precision rotary weight filler for edible oils and sauces

Achieve exceptional filling precision with solutions desi...

Pneumatic dosing system for dense and semi-dense products

For precise dosing of dense and semi-dense liquids, this pneum...

Vacuum cooker-cooler for jams and sauces

Optimize your food production with a vacuum cooker-cooler that enhances flavor whi...

Inline wet mill for mayonnaise emulsions

Eliminate the challenges of achieving stable, uniform emulsions in your sauces and...

Efficient tube filler and sealer

Optimize your production line with a semi-automatic tube filling and sealing solution, desi...

Automatic positive displacement bottle filler

Streamline your liquid filling operations with precision and flexibility, id...

Vacuum juicing for fruits and vegetables

Achieve superior juice quality with minimal oxidation and maximum nutrient retenti...

Rotary piston fillers with plunger for viscous products

Optimize your filling process with high-speed, rotary piston fill...

Rotary cup filling and closing system

Maximize production efficiency with a system that offers precision filling and secure...

Automatic tube filling for multi-color products

Achieve precision in multi-color product packaging with seamless co-extrus...

Automatic tube filling solution for medium to high volume production

Boost your production line efficiency with a robus...

Colloid mills for shearing and mixing in food processing

Optimize your liquid formulations with precise colloid mills, en...

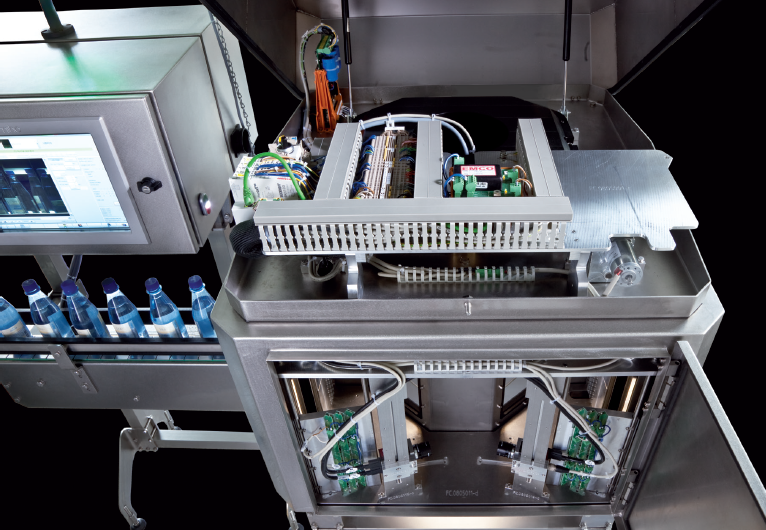

In-line metal detector for liquids & pastes

Ensure product safety by seamlessly integrating a metal detection system into ...

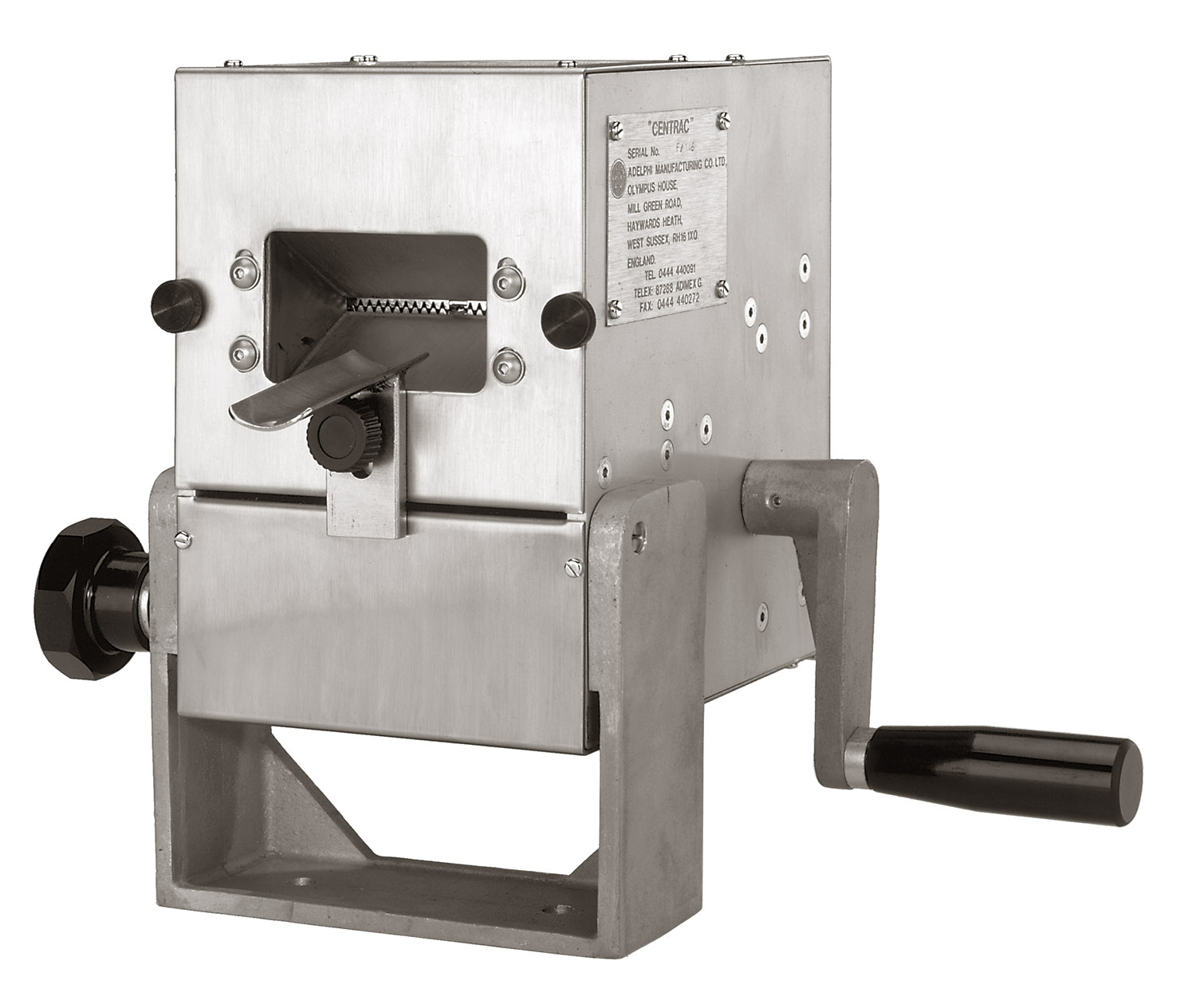

Manual metal tube sealing equipment

For small-batch productions where you utilize metal tubes as containers for your produc...

Linear automatic bottling machine for liquids

Autonomous filling systems are a very widely utilized solution for the consi...

Vacuum and pressure cooker for fruits and vegetables

When producing fruit-based products such as marmalades or ice cream ...

Bottle filling and capping monobloc

Spillage and overfilling are common problems in most production lines for bottled produ...

Centrifugal mixer for batters and creams

Batters, creams and other delicate sauces and emulsions take time to mix, reducing...

Automatic bottling machine for beverage

One of the biggest challenges when bottling beverage drinks is that many of the bot...

Automatic filling machine for sauce

Traditional sauce filling units can struggle to maintain a high quality of output in ca...

Flexible pasteurizer for packaged food

Autoclaves for sterilising and cooking food products are a mainstay of many producti...

Universal Mixer and Cooker for Sauces

Sauce cookers and mixing machines have traditionally been designed to suit one proces...

Versatile bottle sorting system

Quality bottle sorting machine and inspection system which can be put to use not only after ...

Stickpack Machine

If you are looking to pack your product into stick packs from 17 x 40 mm to 100 x 200 mm in size, you may b...

Sachet Machine

If you want to pack into eye-catching 4-side sealed sachets between 40×50 mm and 250×200 mm in size, ...

Vacuum cooker for concentrating sauces and purees

When producing high quality prepared food, concentrating products for s...

Industrial sous vide cooker

High temperatures, oxidation and evaporation from long sessions of conventional cooking can impa...

Cone mill machine

When your raw materials include agglomorated suspensions of grainy or crystalline solids and your process n...

Smart Industrial Sauce Cartoning System

Large volume producers of sauces and ready meals continuously pack different produc...

Versatile stone mill machine

In the food industry, when it comes to milling a wide range of products such as seeds and nuts ...