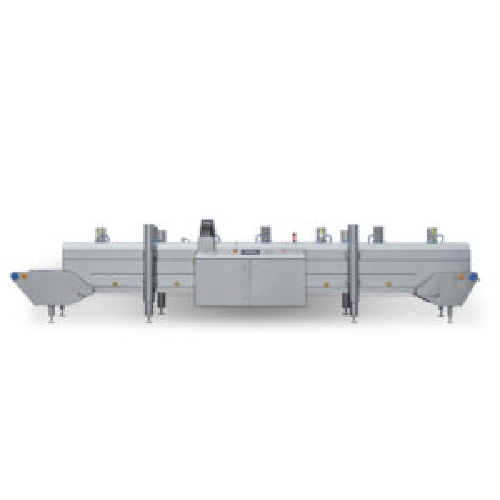

High performance tunnel freezer for industrial food processing

Maximize your floor space while achieving rapid freezing with enhanced air velocity, ensuring minimal product dehydration for high surface-to-volume items like flat and small products, all with a compact, efficient design.

Freezes and Preserves Food Products Efficiently

The High Performance Cryogenic Tunnel Freezer from Dohmeyer is an innovative solution designed for efficient freezing of food products within space-constrained environments. Using specially designed turbulence fans, it increases gas flow and creates high-velocity, turbulent conditions that swiftly eliminate insulating air layers from product surfaces. This results in reduced dehydration and faster freezing times, ideal for flat and small products like pancakes, beef patties, and tortellini. With a compact design, it maximizes freezing capacity per square meter, ideal for operations in food processing, industrial bakeries, and meat processing plants. Capable of continuous, high-speed operations, it integrates seamlessly into production lines, optimizing throughput without compromising product quality. The freezer’s stainless steel construction ensures durability and compliance with hygiene standards, offering easy cleaning and maintenance features. Its bespoke engineering options provide customization to meet specific industrial requirements, supported by comprehensive technical assistance for seamless integration.

Benefits

- Optimizes space usage, elevating freezing capacity per square meter.

- Minimizes product dehydration, preserving quality and texture.

- Integrates effortlessly into high-speed production lines, enhancing efficiency.

- Provides custom engineering solutions for specific industrial needs.

- Facilitates easy cleaning and maintenance, ensuring uninterrupted operation.

- Applications

- Pasta, Pancakes, Flat products, Hamburgers, Small products

- End products

- Sliced vegetables, Beef patties, Tortellini, Nuggets, Dumplings, Spring rolls, Crepes, Frozen pancakes, Flatbread, Ravioli, Mini pizzas

- Steps before

- Preparation, Temperature Control, Product Layout

- Steps after

- Packing, Storage, Distribution

- Input ingredients

- pancakes, hamburgers, pasta, flat products, small products

- Output ingredients

- frozen pancakes, frozen hamburgers, frozen pasta, frozen flat products, frozen small products

- Market info

- Dohmeyer is renowned for manufacturing advanced cryogenic equipment, specializing in ultra-low temperature applications for various industries, including pharmaceuticals and food processing. They are recognized for their innovation, quality, and customer-focused engineered-to-order solutions.

- Freezing capacity

- High

- Floor space efficiency

- Compact design

- Residence time

- Low

- Air velocity

- High

- Gas flow control

- Patented strategy

- Surface-to-volume efficiency

- High for flat/small products

- Dehydration rate

- Reduced

- Working mechanism

- Cryogenic gas flow with turbulence fans

- Compact design

- Fits into limited floor space

- Batch vs. continuous operation

- Inline Continuous

- Freezing capacity

- Highest for given floor space

- Residence time

- Lowest possible

- Automation level

- Patented control strategies for temperature and gas flow

- Biological compatibility

- Yes

- Corrosive resistance (e.g. acids)

- Yes

- Cleanability

- Easy to clean

- Abrasion resistance

- High resistance

- Density/particle size

- Variable depending on product

- Product type

- Flat or small products

- Compact footprint

- Yes

- Machine footprint

- Small

- Discharge method

- Inline

- Control panel type

- PLC-controlled

- Design

- Tailor-made

- Control strategies

- Patented control strategies for temperature and gas flow

- Compact design

- Tailor-made to fit limited space

- Turbulence fans

- Specially designed to increase gas flow and freezing efficiency

- Freezing modules

- High performance for surface freezing