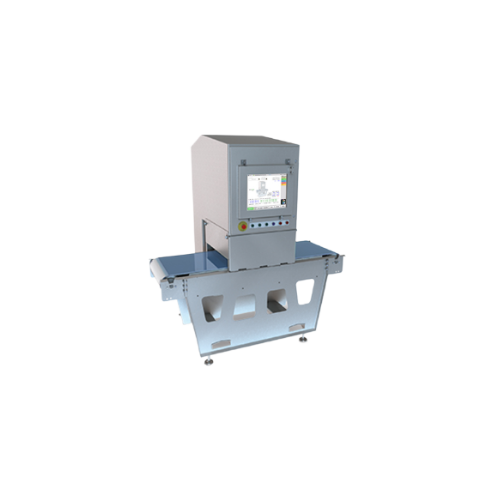

Inspection system for portioning precision in food processing

Enhance your production line with an advanced inspection system that ensures precision portioning, optimizing resource use while improving end-product quality. Ideal for continuous, high-speed operations where detailed scanning and sorting increase efficiency without compromising performance.

Inspects and Sorts Poultry, Meat, and Seafood Products

The DSI J-Scan Inspection System from JBT FoodTech is an advanced inspection and sorting solution tailored for poultry, meat, and seafood processing lines. Designed as an in-line scanner, it excels in high-speed, continuous operations, ensuring 100% product inspection. Leveraging DSI’s industry-proven portioning systems, the J-Scan uses a combination of scanning and sorting technologies to handle varying product inputs effectively, enhancing product consistency and quality. The system integrates effortlessly with upstream and downstream equipment, supporting applications such as chicken breast fillets, pork loin chops, and fish fillets. Equipped with customizable sorting criteria, it adjusts dynamically to match portioner capacity and incoming product variation. Its modular design allows for seamless integration with existing systems, and it can operate with a weigh scale for comprehensive scan and weight applications. For maintenance, the J-Scan offers a streamlined interface for operators, ensuring efficient operation and quicker adjustments.

Benefits

- Enhances product quality by ensuring precise inspection and sorting for varied inputs.

- Boosts operational efficiency with continuous, high-speed scanning and portioning.

- Reduces waste through adaptive sorting criteria that optimize portioner capacity.

- Simplifies integration with modular design compatible with existing systems.

- Minimizes labor intervention with easy-to-use touch screen interface.

- Applications

- Seafood, Meat, Poultry

- End products

- Chicken breast fillets, Processed chicken nuggets, Beef steak cuts, Turkey slices, Shrimp portions, Salmon portions, Pork loin chops, Fish fillets, Deli meat slices

- Steps before

- Injection, Marination

- Steps after

- Sorting, Packing

- Input ingredients

- poultry, meat, seafood, raw products

- Output ingredients

- sorted products, sliced portions, inspected products

- Market info

- JBT is known for manufacturing industrial ETO equipment, specializing in food processing and airport ground support systems. They are reputed for innovative solutions and reliable service in industries requiring sophisticated automated systems and machinery.

- Inspection Type

- In-line product scanning

- Sorting System

- High-speed precision sorting

- Interface

- Touch screen

- Control System

- DSI Q-LINK™ Portioning Software

- Modular Design

- Yes, modular and expandable

- Integration Capability

- Compatible with upstream processing equipment

- Data Storage

- Statistical process control data and trend analysis

- Automation level

- High/PLC integration

- In-line inspection

- 100% product scanning

- Feedback mechanism

- Corrective feedback to operators

- Control interface

- Touch screen, DSI Q-LINK™ Platform

- Sorting capability

- High-speed precision sorting

- Integration flexibility

- Modular and expandable design

- Cleanability

- High

- Abrasion resistance

- Yes

- Corrosive resistance (e.g. acids)

- Yes

- Biological compatibility

- Food-grade materials

- Density/particle size

- Varied

- Product inspection type

- In-line

- Modular and expandable design

- Control an integrated sort system

- Stand-alone scanner

- In-line product scanning

- Interface type

- Touch screen

- Modular design

- Expandable

- Integration possibilities

- Control signals to existing sorters

- Scan and sort capabilities

- Upstream or downstream

- Control interface

- Touch screen (DSI Q-LINK™ Portioning Software)

- System integration

- With weigh scale for scan + weight application