Air drying solution for leafy vegetables

Achieve optimal moisture reduction with precision air drying, ideal for maintaining the quality and freshness of delicate leafy vegetables in high-speed food processing operations.

Dries and Cools Leafy Vegetables Efficiently

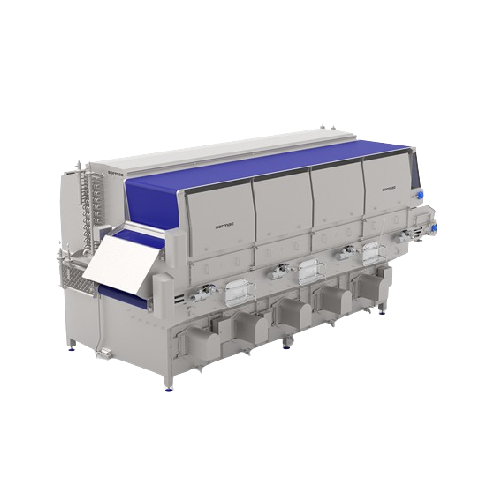

The Air Drying Tunnel LDT-140 from Sormac is a specialized solution for drying and cooling delicate leafy vegetables like spinach, baby leaf, and shredded iceberg lettuce. This innovative equipment uses an upward air stream to gently remove moisture without damaging the produce. The drying tunnel operates with a two-stage heat exchange system, cooling and then reheating the air to optimize moisture absorption, resulting in moisture levels below 2% on the product surface. Designed for continuous high-speed processing, it handles up to 2,550 units per hour and integrates seamlessly with existing dewatering and washing systems for a streamlined production line. With a closed system to prevent energy loss and an integrated cooling section to reach desired packaging temperatures, the LDT-140 ensures efficient energy usage and minimal environmental impact. Its hygienic design facilitates easy cleaning, maintaining high standards of food safety, and allowing customization to fit specific production needs.

Benefits

- Enhances product freshness by achieving ultra-low moisture levels.

- Preserves the integrity of delicate greens, minimizing product damage.

- Reduces energy costs through efficient closed-system design.

- Supports quick transition to packaging temperatures for immediate processing.

- Facilitates easy maintenance with accessible, hygienic construction.

- Applications

- Spinach, Baby leaf, Fresh produce, Iceberg lettuce, Leafy vegetables

- End products

- Bagged spinach, Shredded iceberg lettuce, Ready-to-eat salad mixes, Baby leaf salad packs, Packaged leafy greens

- Steps before

- Dewatering, Washing

- Steps after

- Cooling, Packaging

- Input ingredients

- delicate leafy vegetables, spinach, baby leaf, cut iceberg lettuce

- Output ingredients

- dried leafy vegetables, moisture reduced spinach, dried baby leaf, dried cut iceberg lettuce

- Market info

- Sormac is known for its expertise in manufacturing high-quality vegetable processing equipment, particularly peeling, washing, and slicing machines, with a strong reputation for innovation, reliability, and customer-focused solutions in the food processing industry.

- Drying Temperature

- 25–30°C

- Cooling Temperature

- Approx. 5°C

- Capacity

- Up to 2, 550 kg/hour

- Moisture Percentage

- Less than 2%

- Air Speed

- Product floats

- Cooling Medium

- Glycol solution

- Heat Exchanger Temperature

- Approx. 0°C and 33°C

- System Type

- Closed system

- Process Type

- Thermal drying

- Working mechanism

- Thermal air drying

- Integrated steps

- Dewatering via conveyor, air drying, cooling section

- Batch vs. inline flow

- Inline continuous

- Cleaning method

- Hygienic design for easy cleaning

- Automation level

- PLC controlled

- Biological compatibility

- Delicate leafy vegetables

- Feed method

- Dewatering conveyor

- Discharge method

- Transport conveyor

- Integration possibilities

- With dewatering conveyor, salad washer, transport conveyor

- Cooling medium supply

- Client-supplied glycol solution or separate cooling installation

- Heat exchanger customization

- Adaptable to specific client temperature requirements