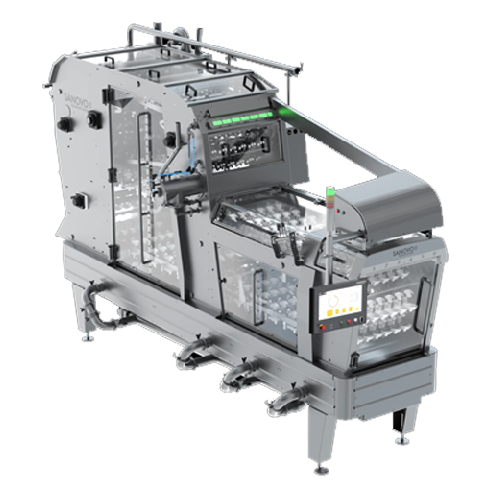

High-yield egg breaking system

Achieve unprecedented efficiency and sustainability in your egg processing operations with a high-capacity machine designed for optimal yield and minimal environmental impact.

Maximizes Egg Yield and Ensures Product Quality

The BreakerPro 6 from SANOVO Technology is designed to revolutionize the efficiency and sustainability of industrial egg breaking. It features an optimized gripper design and an egg white recovery unit, producing up to 75,600 eggs per hour while achieving a 1% higher yield. The machine caters to food processing, industrial egg breaking, and egg-cultured vaccine production industries, delivering liquid egg whites, yolks, and heat-stable powders. Its automation is enhanced by servo motors and an advanced touch panel, ensuring seamless integration into high-speed production lines. The green CIP system reduces water and chemical usage, meeting stringent food safety and environmental standards.

Benefits

- Enhances yield by up to 1% through optimized egg handling and cracking.

- Minimizes environmental impact with a green CIP design, reducing water and chemical use.

- Ensures high product quality with advanced scanning and yolk separation.

- Reduces maintenance effort with servo motors and reliable operation.

- Provides a safe and ergonomic operator environment with intuitive controls.

- Applications

- Industrial egg breaking, Food safety, Food processing, Egg processing, Egg products, Egg-cultured vaccine production

- End products

- Liquid egg whites, Liquid egg yolks, Egg-based vaccines, Pasteurized liquid egg products, Heat-stable egg yolk powder

- Steps before

- Egg loading, Destacking of egg trays, Egg handling, Conveyor belt loading

- Steps after

- Egg white recovery, Eggshell disposal, Egg product storage, Packing

- Input ingredients

- eggs, egg trays

- Output ingredients

- egg white, yolk, shells, egg products, processed eggs, edible egg whites

- Market info

- Sanovo is renowned for manufacturing ETO industrial equipment, specializing in egg handling, processing, and packaging machinery. They hold a strong market reputation for innovative solutions and reliable, high-quality systems tailored to the food and egg industry.

- Capacity

- 75, 600 eggs/hour

- Automation

- Advanced multi-color touch panel

- Yield Maximization

- Up to 1% higher yield

- Environmental Impact

- Optimized CIP system, reduction in water and chemical use

- Location/Suitability

- Fits processors in need to produce up to 75, 600 eggs/hour

- Egg White Recovery

- Optional recovery unit, up to additional 0.5% yield

- Power Consumption

- Up to 40% lower due to lighter drive chain

- Noise Level

- Lower noise during production

- Operator Environment

- Enhanced, eliminates loose covers

- Servo Motors

- Reliability and minimized downtime

- Egg Cracking Optimization

- Controlled shell cracking, higher yield

- Material of Yolk Cup

- Food grade polyethylene

- Scanning System

- Enhanced scanner system for better product quality

- Yield Maximization

- Up to 1% higher yield

- Production Capacity

- Up to 75, 600 eggs/hour

- Environmental Impact

- Low environmental impact with green design

- Automation Level

- Advanced multi-color touch panel and LED bars

- Cleaning Method

- Optimized CIP system

- Energy Efficiency

- Reduced power consumption with servo motors

- Integration

- In-line with OptiLoader Plus 6

- Changeover Time

- Faster machine adjusting for increased uptime

- Operational Simplicity

- Improved operator experience with reduced manual adjustments

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine Footprint

- Customizable based on model

- Frame Length

- Longer machine frame for optimization

- Gripper Design

- Optimized gripper design for higher yield

- Control Panel Type

- Advanced multi-color touch panel

- Discharge Method

- Optimized egg crackers for better shell draining

- Yolk Cup Material and Design

- Re-designed food-grade polyethylene cups

- Control panel type

- Multi-color touch panel

- Integration possibilities

- Optional egg white recovery unit

- Design type

- Optimized CIP system

- Gripper design

- Optimized gripper design

- Additional features

- Servo motors instead of belts

- Operating interface

- Multi-function LED bars