Flat product freezer for hamburger patties

Optimize your freezing process with a high-speed freezer that cuts costs in half by using high-velocity air jets to rapidly chill and preserve hamburgers and other flat products.

Freezes and Chills Flat Food Products

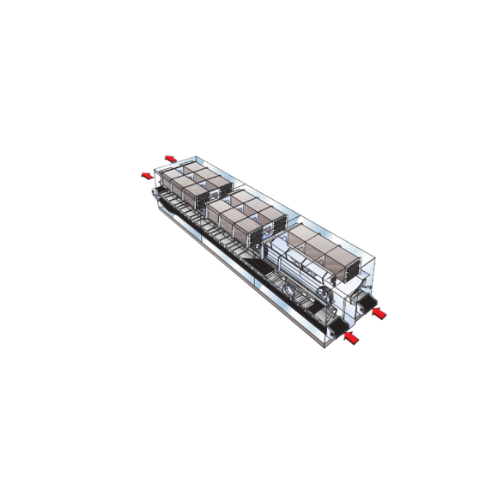

The Frigoscandia Flat Product Freezer from JBT is specifically designed to enhance freezing efficiency in high-speed, continuous processing lines, especially for poultry, meat, and seafood sectors. Utilizing impingement freezing technology, it rapidly chills flat food products such as chicken nuggets, beef patties, and fish fillets through thousands of high-velocity air jets. This innovative method effectively removes the boundary layer of air, enabling faster freezing at significantly reduced costs compared to traditional cryogenic systems. Capable of processing large volumes, its modular design ranges from 2 to 8 pre-manufactured modules, accommodating various production demands with ease.

This equipment boasts dual parallel stainless steel mesh belts boasting a usable width of 27.5 inches each, ensuring that products remain flat and aligned throughout the freeze. Constructed with stainless steel and an aluminum fin heat exchanger, it prioritizes hygiene with a design that minimizes bacteria build-up via stainless steel enclosures and smooth, sloped surfaces. The freezer incorporates a patented low volume refrigerant feed system, optimized for energy efficiency and superior product yield, delivering juicier, more tender results than alternatives. Enhancements such as an integrated wash-down system and options for extremely low temperature operations further streamline maintenance and cleaning while ensuring robust performance and reliability.

Benefits

- Cuts operational costs with rapid, low-energy freezing compared to cryogenic systems.

- Enhances product quality by preserving moisture, resulting in juicier, more tender end-products.

- Increases hygiene standards with an easy-to-clean stainless steel design that minimizes bacteria buildup.

- Boosts production efficiency through continuous operation with minimal product handling.

- Offers scalable solutions with modular design for flexible production capacities.

- Applications

- Seafood, Meat, Hamburger patties, Poultry

- End products

- Chicken nuggets, Turkey burgers, Beef patties, Shrimp, Fish fillets

- Steps before

- Hamburger patty formation, Meat portioning, Grinding, Mixing

- Steps after

- Packing, Storing, Distribution

- Input ingredients

- raw hamburger patties, raw meat products

- Output ingredients

- frozen hamburger patties, frozen meat products

- Market info

- JBT is known for manufacturing industrial ETO equipment, specializing in food processing and airport ground support systems. They are reputed for innovative solutions and reliable service in industries requiring sophisticated automated systems and machinery.

- Freezing Method

- Impingement freezing

- Module Length

- 13.55 ft.

- Impingement Zone Range

- 27.1 ft. to 108.1 ft.

- Belt Width

- 27.5 in. per belt

- Material

- Stainless steel

- Refrigerant Feed System

- Patented low volume (LVS) system

- Freezer Style

- Linear, mechanical

- Temperature

- Extremely Low Temperature (100°F)

- Working Mechanism

- Impingement Freezing

- Integrated Steps

- Freezing two raw hamburger lines into one

- Flow Type

- Linear, Mechanical Style

- Freezing Efficiency

- Energy-efficient compared to cryogenic tunnels

- Cleaning Method

- Integrated Wash Down System

- Cleanability

- Stainless steel freezing zone, rounded corners, and sloped surfaces

- Corrosive resistance

- Stainless steel construction

- Product Alignment

- Flat and aligned freezing

- Product Type

- Hamburger patties

- Modular design

- 2 to 8 pre-manufactured modules

- Module length

- 13.55 ft – 108.1 ft

- Belt width

- 27.5 in. per belt

- Construction material

- Stainless steel, aluminum fin

- Enclosure panels

- Internally welded stainless steel

- Discharge method

- Dual parallel mesh belts

- Modular design

- 2 to 8 pre-manufactured modules

- Module length

- 13.55 ft. – (Minimum impingement zone of 27.1 ft. to maximum of 108.1 ft.)

- Belt width

- 27.5 in. per belt

- Enclosure material

- Stainless steel

- Heat exchanger materials

- Stainless steel tube and aluminum fin

- Options

- Stainless steel finish caulked enclosure panels, Integrated wash down system, ELT Extremely Low Temperature refrigeration system (100°F)