Food Inspection Equipment

Find production technology for inspecting food, and connect directly with leading machine manufacturers worldwide.

In the food industry, ensuring product quality and safety is of utmost importance. This is where industrial food inspection equipment comes into play. With advanced inspection technology, food inspection equipment can help detect contaminants and defects, such as metal, glass, and plastic in food products, to prevent contamination and ensure consumer safety. Food inspection technology can be used throughout the production process, from raw materials to packaging. Automated inspection equipment, such as metal detectors and x-ray inspection systems, can quickly and accurately detect any foreign objects that may be present in food products. These technologies can also help identify any defects or inconsistencies in the product.

One of the most important aspects of food inspection is ensuring proper packaging. Containment detection and checkweighers are commonly used in the packaging process to ensure that the correct amount of product is being packaged and that the packaging itself is free from defects. This ensures that the final product meets quality assurance standards and is safe for consumption. Food inspection technology is critical for both food and beverage manufacturers. With increased awareness of food safety, consumers expect high-quality and safe products. The use of food inspection equipment not only ensures consumer safety, but it also helps protect the reputation of food companies by preventing recalls and ensuring compliance with regulatory standards.

Which food inspection technology do you need?

Sanitary cover for visual inspection

Ensure optimal hygiene and easy access in your production line with a transparent cove...

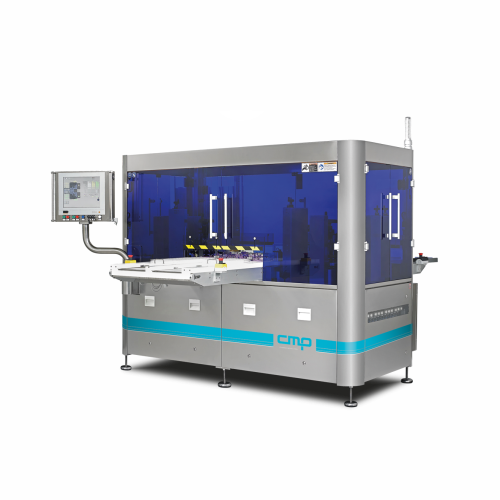

Visual inspection systems for packaging quality control

Detect and eliminate packaging and labeling faults early in your ...

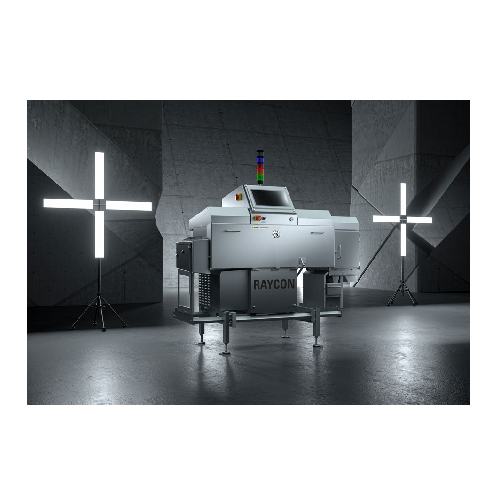

X-ray inspection system for food packaging

Ensure product integrity and safety with advanced detection of foreign bodies i...

Glass container Inspection line

Ensure precise quality control with a high-speed inspection line designed for glass containe...

Glass container inspection system

Ensure product integrity with precision inspection for glass containers, detecting partic...

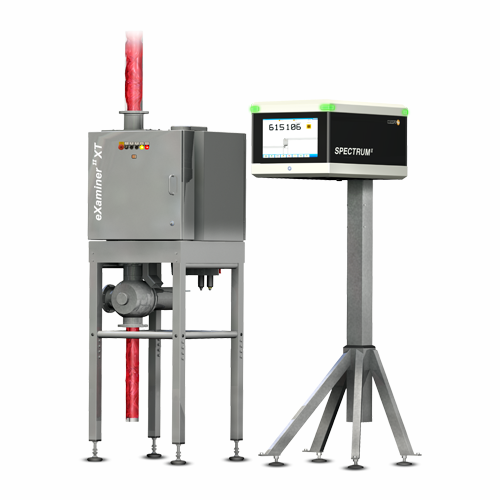

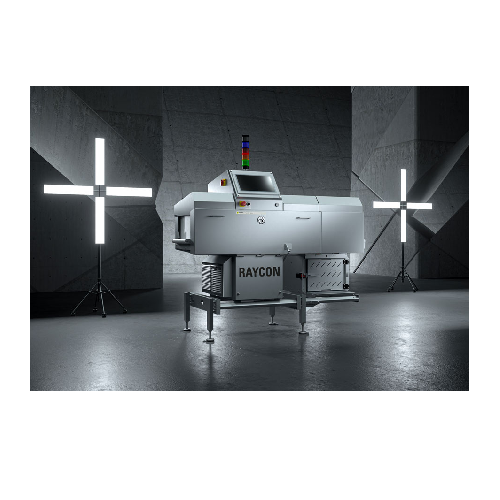

X-ray inspection system for large bulk products

Ensure consumer safety and product quality by efficiently detecting contam...

X-ray food inspection system for loose products

Ensure contaminant-free loose products by integrating a versatile inspecti...

Curtainless x-ray inspection for small lightweight packaged food products

Eliminate product damage and false rejects w...

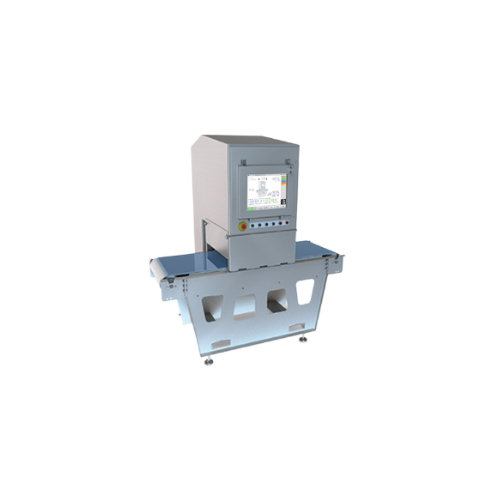

Compact x-ray inspection system for food safety

Enhance food product safety with advanced x-ray inspection, targeting both...

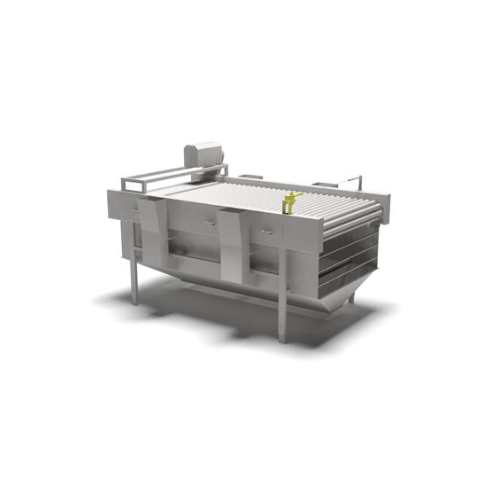

Inspection table for vegetables and fruits

Streamline your quality control with an efficient inspection table designed for...

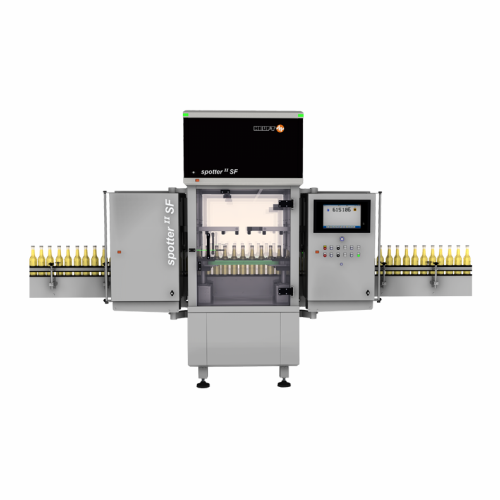

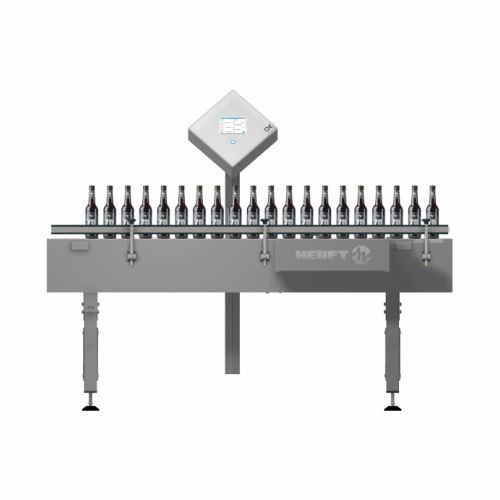

Inspection system for returnable glass containers

Ensure the safety and quality of your beverage containers with a precis...

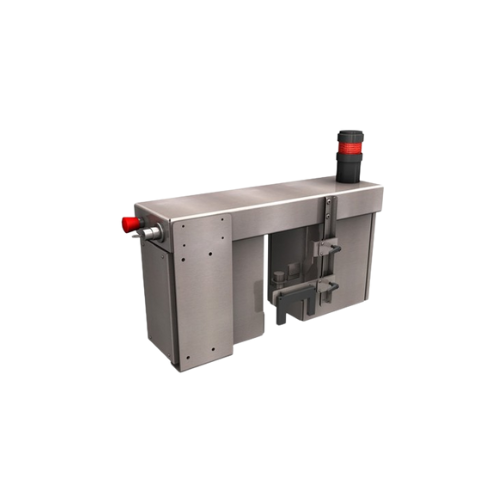

Compact fill level and cap inspection system

Ensure flawless beverage quality by integrating a compact system for precise ...

Empty bottle inspector with deep learning

Ensure that every beverage container in your production line is pristine with cu...

Inspection systems for fillers and cappers

Ensure precise fill levels and secure cap placements with advanced inspection s...

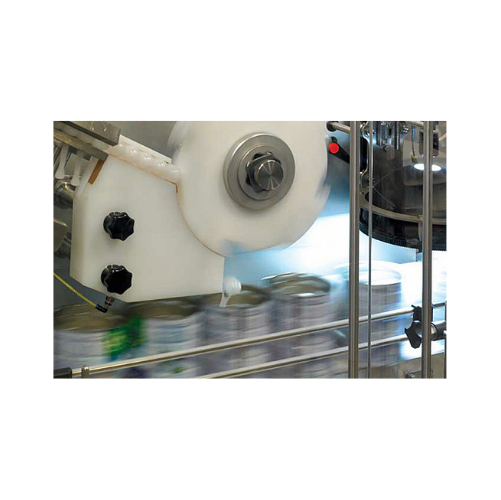

Closure inspection system for crown corks and metal caps

Ensure product integrity with high-speed 360° closure inspection...

Label inspector for beverage and food containers

Ensure precise label application with high-speed inspection, crucial for ...

Pallet inspection system

Ensure the stability and integrity of diverse pallets with a high-speed inspection system that minim...

Inspection systems for poultry and seafood processing

Enhance the quality control of your food production with cutting-ed...

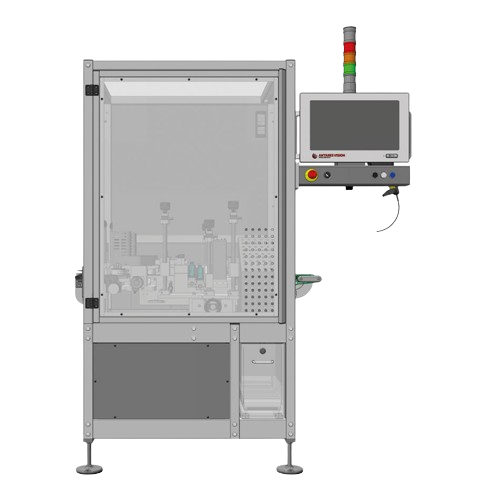

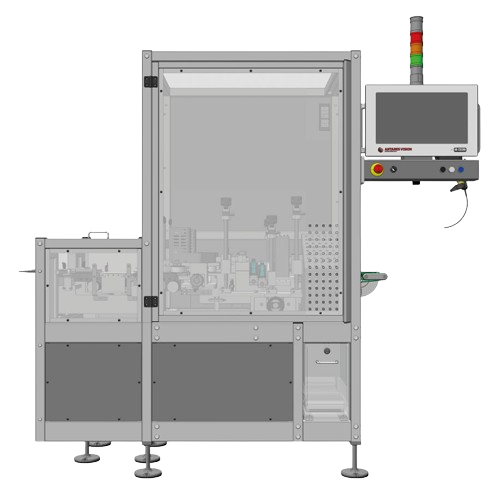

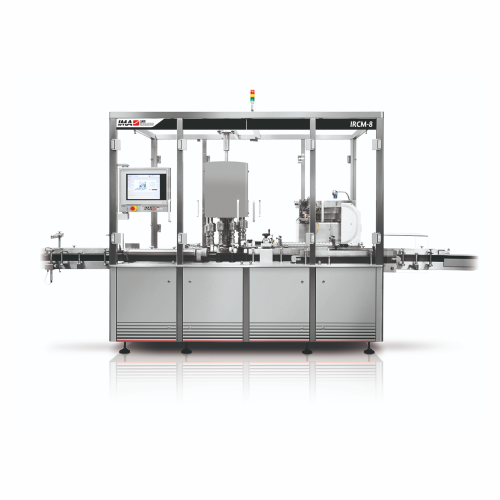

Compact full product inspection system for pharmaceuticals

Easily detect fill level inaccuracies, closure misalignments,...

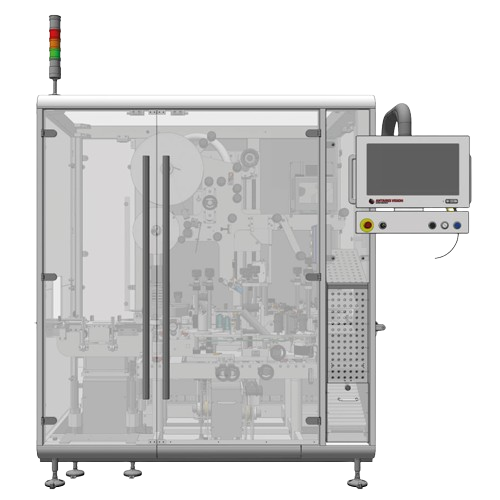

Empty container inspection for pharma packaging

Ensure ultra-clean packaging by detecting glass faults and contaminants be...

Full case inspection for food, beverage, and pharma industries

Ensure flawless packaging integrity with this inspection ...

Full container check for fill level and closure inspection

Ensure the integrity of your liquid products with this advanc...

Top-down inspector for food and packaging

Ensure seamless product safety and quality assurance with advanced top-down insp...

Pulsed x-ray foreign object inspection for food packaging

Ensure your packaged goods are free from dangerous contaminant...

Pipeline inspection for liquid and paste-like products

Ensure your liquid and paste-like products are free from foreign o...

Final product inspection system for pharmaceutical containers

Ensure the integrity and precision of packaged pharmaceuti...

Full container inspection for pharma and food industries

Ensure precise fill levels and secure closures in your productio...

Full container inspection for glass and Pet bottles

Ensure the highest product quality by detecting foreign objects and m...

Closure inspection for beverage containers

Ensure the integrity of your bottled products with precision closure inspection...

Empty can inspection system for food industry

Ensure seamless production flow by detecting faulty cans before filling, pre...

X-ray assisted empty container inspection system

Detect low-density foreign objects and micro-cracks in empty containers w...

Foreign object inspection for full containers

Detect and remove minute foreign objects from liquid and paste-like products...

Empty crate inspection system

Ensure flawless quality by inspecting empty crates for damage and design faults, offering high...

X-ray assisted empty bottle inspection

Enhance your production line with advanced X-ray and optical technology to ensure pr...

Fill level and closure inspection system

Ensure precise fill levels and secure closures in high-speed liquid packaging envi...

Final container inspection for beverages

Ensure flawless product presentation and secure branding by detecting misaligned l...

Advanced foreign object inspection for full beverage containers

Ensure consumer safety and brand protection with advance...

Full case inspection for beverage packaging

Ensure quality packaging with precise inspection of full containers, detecting...

Full container inspection system

Ensure the quality and safety of your products with a compact solution that performs precis...

Empty bottle inspector for beverage industry

Ensure flawless quality control by thoroughly inspecting empty bottles for de...

X-ray inspection system for contaminant detection

Detect and eliminate foreign contaminants in a wide range of food produ...

X-ray inspection system for low-density foreign objects

Enhance your inspection capabilities with advanced X-ray technolo...

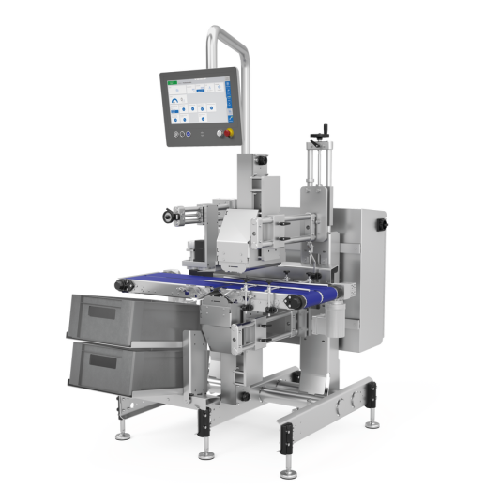

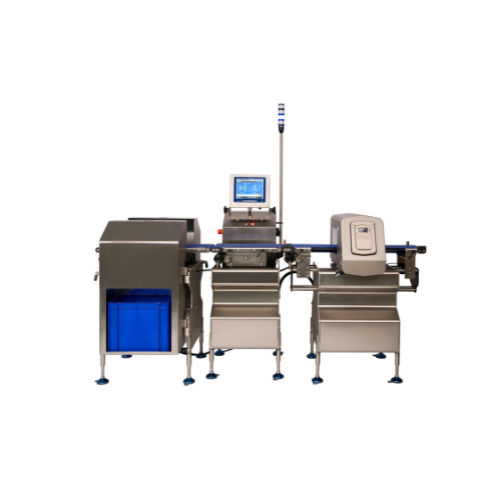

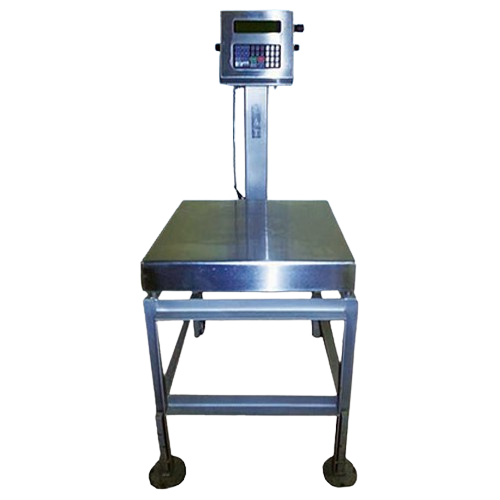

Checkweigher for packaged goods inspection

Ensure precision and compliance with this high-speed checkweigher, perfect for ...

X-ray inspection system for identifying foreign bodies in food products

Ensure precise detection of foreign materials i...

X-ray inspection system for detecting foreign objects in food products

Ensure product safety and quality by detecting e...

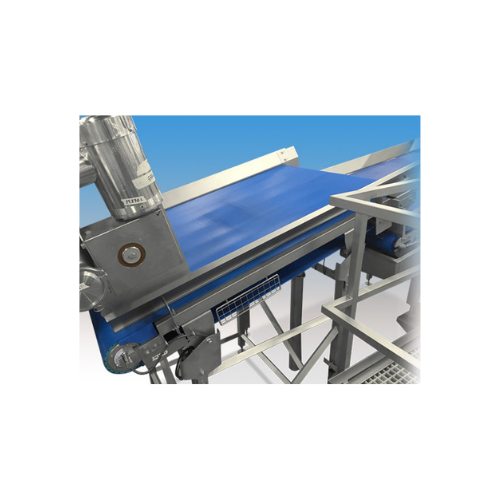

Inspection conveyor for potatoes and vegetables

Streamline your defect removal and trimming process with a conveyor system...

Label inspection for vertical products

Ensure label quality and accuracy with advanced inspection technology designed for p...

All-in-one inspection system with leak detection, x-ray, and weighing

Optimize your production line with a compact syst...

Cap and fill level inspection system for bottles

Ensure precise cap placement and accurate fill levels in your bottling li...

Checkweighers for medium-large product inspection

Ensure precise weight and quality compliance in high-speed production l...

Empty bottle inspection system for food industry

Detect subtle defects in empty bottles before filling to ensure product s...

Empty can inspection system for defect detection

Ensure the integrity and quality of your canned products by swiftly detec...

Preform inspection system for blown containers

Ensure defect-free blown containers and minimize line jams with a robust pr...

Combi x-ray inspection and checkweighing for small products

Optimize your production line’s quality control with a...

Dual lane x-ray inspection system for cosmetics

Optimize your production line with dual-lane x-ray technology that ensures...

X-ray inspection for contaminants in horizontal products

Ensure your packaged and unpackaged products are contaminant-fre...

Code inspection system for beverage industry

Ensure accurate labeling and avoid costly recalls with a high-speed code insp...

Empty bottle inspection system for beverage industry

Enhance your production line’s efficiency by detecting defects...

Food x-ray inspection system for contaminant detection

Ensure the purity and safety of your food products with advanced x...

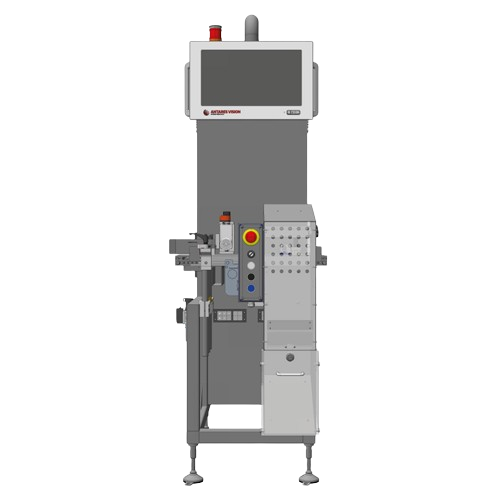

Inspection system for portioning precision in food processing

Enhance your production line with an advanced inspection s...

3-in-1 food package inspection system

Ensure your packaged food products meet safety and regulatory standards with a system...

Tray weight inspection system

Ensure accurate and efficient quality control by seamlessly integrating a high-speed tray weig...

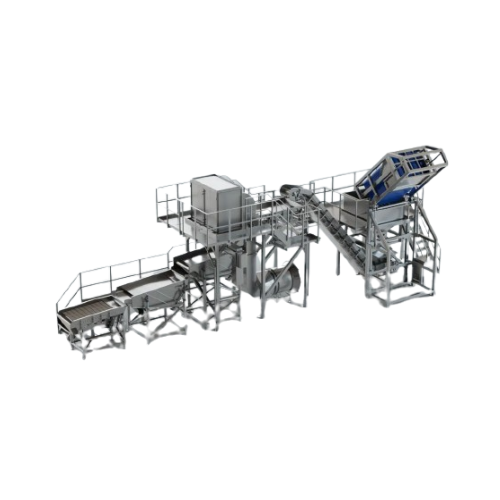

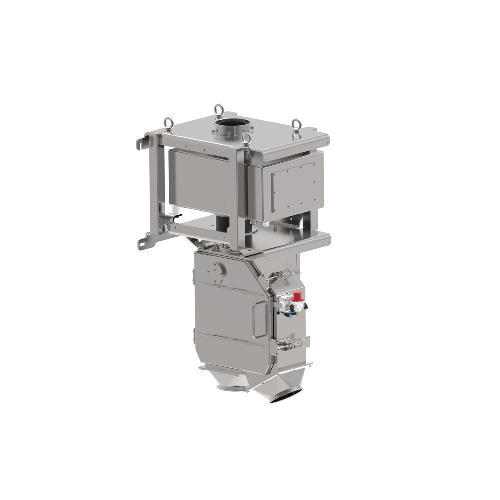

X-ray scanner for bulk material inspection

Ensure product safety and minimize downtime by intercepting foreign contaminant...

X-ray scanner for sealed container inspection

Ensure the integrity and quality of sealed containers while seamlessly integ...

Dual view x-ray inspection for canned goods

Enhance your production line with advanced dual-view X-ray inspection, ensurin...

X-ray and optical inspection system for product safety

Ensure the safety and integrity of your products with a single sys...

X-ray inspection system for wet environments

Ensure unparalleled product inspection under extreme cleaning conditions with...

Integrated x-ray, checkweighing, and vision inspection unit

Ensure product safety and compliance by seamlessly detecting...

Label printing and inspection system

Ensure flawless label application with meticulous inspection and verification, prevent...

Bottle and vial inspection and coding system

Ensure seamless coding and inspection of vials and bottles with rapid 360° ev...

Industrial x-ray inspection for quality assurance

Ensure product integrity with real-time x-ray inspection that detects c...

Omnidirectional inspection system for bottles and vials

Ensure precise serialization and aggregation with a 360° inspecti...

Product inspection systems for contamination control

Ensure product safety and compliance with precision inspection techn...

Conveyor x-ray inspection for large food packaging

Ensure the safety and quality of your packaged food products by detect...

X-ray inspection for tall packages in cans and bottles

Ensure your production line detects foreign objects in tall packag...

X-ray detection for food inspection

Ensure product integrity in high-speed packaging lines by detecting metallic and non-me...

X-ray inspection system for packaged meat

Ensure packaged food safety by seamlessly detecting contaminants such as metals,...

X-ray inspection system for unpackaged bulk products

Ensure product purity and safety in high-speed production lines with...

Dairy Equipment Crack Inspection

Dairy producers rely on equipment like spray dryers, silos, and different tanks for the sto...

Cartoning solution for tube applications

Streamline your cartoning operations with a machine designed for flexible size cha...

Camera quality control for industrial production

Ensure flawless product quality by integrating a precision optical inspec...

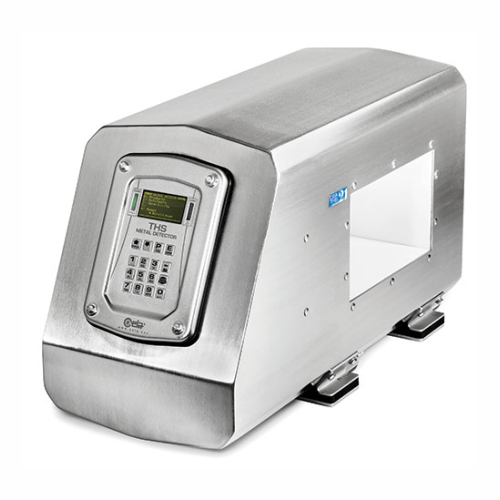

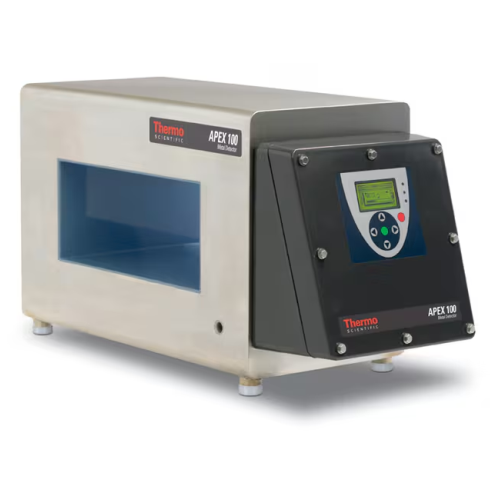

Industrial metal detector for packaging lines

Ensure product safety and compliance by detecting metallic contaminants in p...

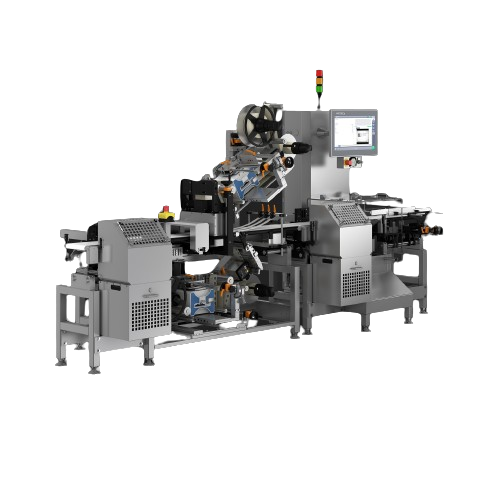

Labelling solution for thermoformed packaging

Ensure flawless labeling integration with high-speed, continuous production....

Mbs belt systems for seamless packaging integration

Optimize your packaging line with a system that seamlessly merges mul...

Automatic checkweighers for precise weight control

Ensure accurate weight compliance and enhance quality control with adv...

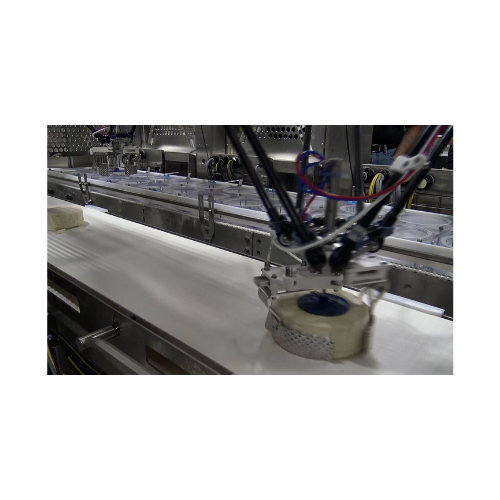

Intermittent pick and place solution for stackable items

Optimize your production line with high-speed, intermittent oper...

Horizontal continuous motion cartoner

Streamline your packaging process with a high-speed cartoning solution that ensures p...

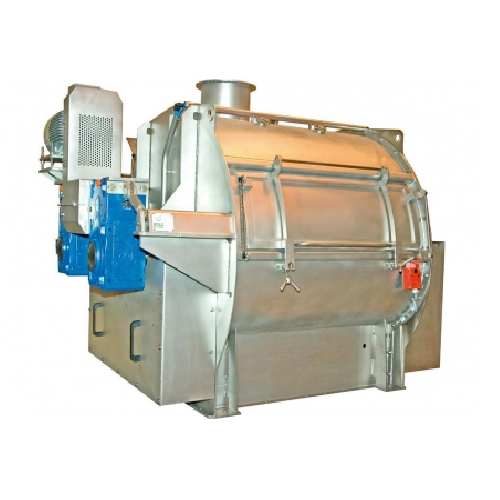

Industrial mixer-grinder for food processing

Streamline your processing line with a robust mixer-grinder that combines eff...

Metal detector checkweigher combination system for food products

Simultaneously detect metal contaminants while ensuring...

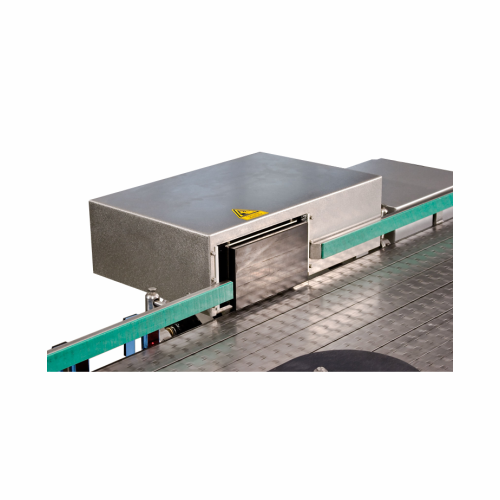

Metal detector conveyor system for food safety

Ensure product integrity across high-speed production lines with robust met...

Six-axis industrial robot for high-speed precision tasks

Designing compact automation systems? This solution excels in hi...

Modular labeling system for beverage containers

Easily adapt to evolving labeling needs with this flexible system, designe...

Industrial code verification system for product packaging

Ensure flawless packaging integrity with high-speed code verif...

High-precision fill level checker for beverages and containers

Ensure precise fill levels and prevent product wastage by...

Container rejection system for high-speed operations

Ensure product safety by swiftly removing defective containers at hi...

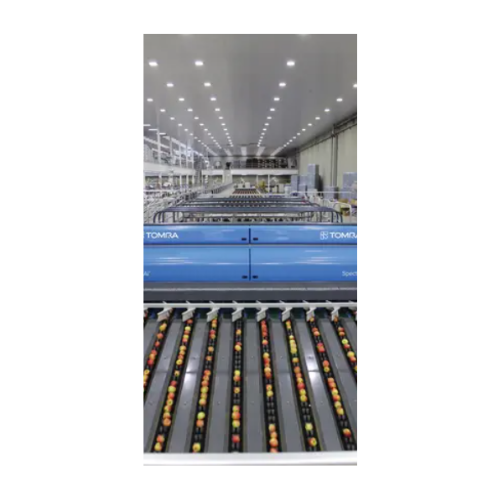

Optical sorting platform for food processing

For manufacturers aiming to enhance quality control, this platform offers pre...

Optical sorter for food processing

Enhance your production line with advanced sorting technology that meticulously inspects...

Optical potato sorter

Ensure precise sorting with advanced optical technology that identifies and separates defects in a wide...

Labelling solution for cylindrical containers

Achieve precise and efficient labelling for cylindrical containers with a sy...

Linear labelling system for vials and bottles

Streamline your labelling process with a compact solution designed for preci...

Metal detector for small to medium-sized products

Ensure product integrity and compliance by seamlessly integrating metal...

Leak detection for pharmaceutical containers

Ensure the integrity of your liquid products in high-speed production by dete...

Leak detection system for plastic containers

Ensure product integrity and prevent costly recalls with this advanced system...

Foreign object detection for packaged and unpackaged food

Ensure the integrity of packaged and unpackaged foods by detec...

Foreign matter detection for syrup and medicine bottles

Ensure the quality and safety of your liquid products with precis...

Automatic leakage detection for Pet bottles

Ensure the integrity of bottled beverages by detecting even the smallest leaks...

Semi-modular labeller for precise beverage bottle labelling

Achieve millimeter-precision bottle labelling with seamless ...

Labelling solution for food and beverage containers

Optimize your packaging line with precision labelling technology that...

Full container check system for beverage industry

Streamline your quality assurance process with advanced detection techn...

Pharmaceutical filter dryer

Achieve precise moisture control and efficient drying of sensitive materials with this advanced ...

Pharmaceutical horizontal peeler centrifuge

Optimize product consistency and purity with precise separation and filtration...

Ferrous-in-foil metal detection system

Enhance quality control for foil-packaged goods with precise ferrous metal detection...

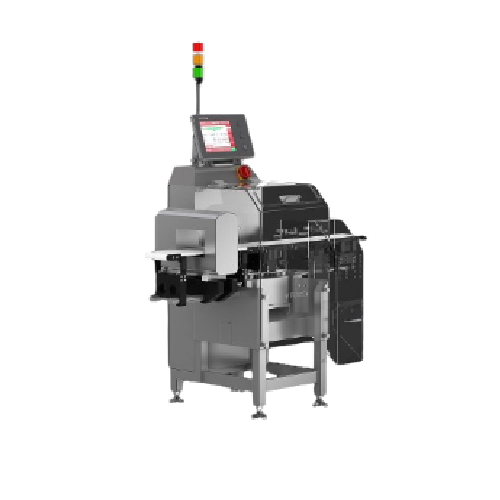

Metal detection and weight verification system

Optimize space and boost inspection accuracy by combining metal detection a...

Conveyor belt metal detection system for food processing

Enhance product safety and ensure compliance with the most strin...

Multi-lane checkweigher for mixed-application production lines

Achieve precise weight verification across multiple lanes...

Self-adhesive labeling system for unstable cylindrical containers

Ensure precise labeling of unstable cylindrical conta...

Linear labeller for self-adhesive labels in pharma

Ensure precise labelling with integrated inspections and traceability ...

Linear self-adhesive labeller for cylindrical and flat containers

Optimize your labelling process with precision applic...

Fast screen exchange grinding solution for medium-hard products

Maximize your milling efficiency with a solution that al...

High-speed continuous motion horizontal cartoner

Achieve seamless high-speed cartoning with precision cartoner systems des...

Industrial rice cooker

Enhance rice processing with an engineered solution that ensures precise cooking and cooling, optimizi...

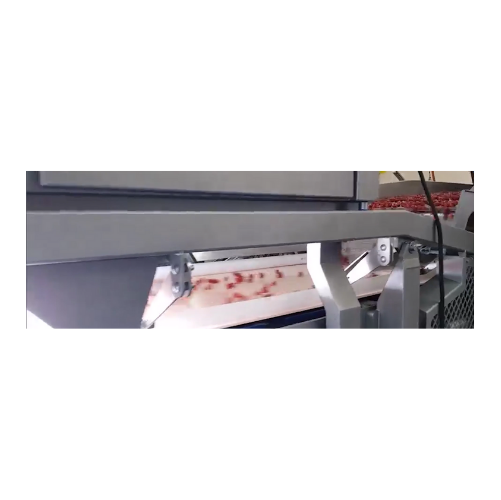

Pre-cleaning system for Iqf berries

Ensure the purity of your IQF berries with advanced pre-cleaning technology that expert...

Optical sorter for frozen fruit and vegetable processing

Enhance your processing line’s efficiency with high-speed ...

Roller table for sorting and cleaning pome fruit

Ensure thorough inspection and cleaning of pome fruits with rotating roll...

Citrus sorting table

Ensure optimal citrus fruit quality by manually sorting and removing defects before processing, enhancin...

Scraped surface sterilizer for high viscosity liquid products

Optimize your production of high viscosity liquids with a ...

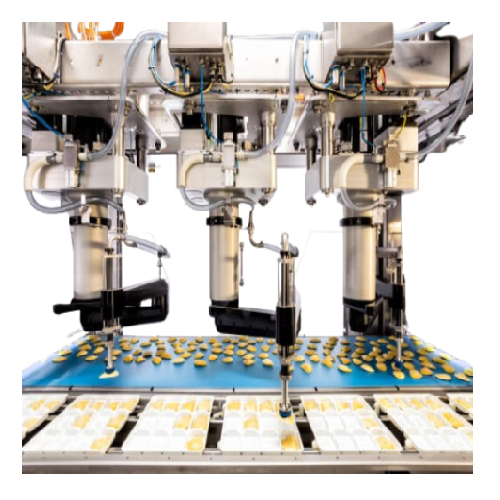

Vision-guided variety pack solution for confectioneries

Achieve seamless variety pack assembly by dynamically loading var...

Soft gel encapsulation system

Efficiently produce high-quality soft gel capsules with precision encapsulation, rapid drying,...

Serialization system for printing and verifying carton codes

Ensure accurate serialization with high-speed printing and ...

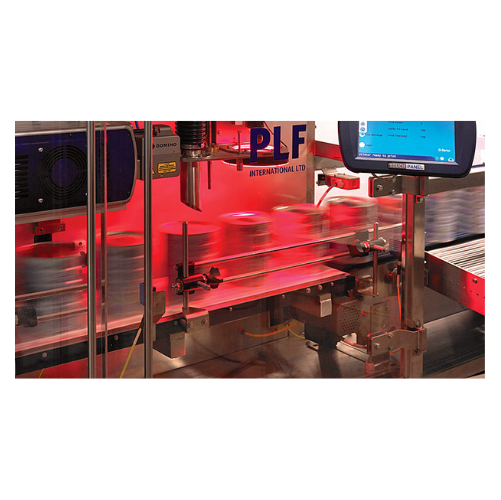

Print and verify cartons packaging systems

Streamline your packaging line with a versatile solution that prints, verifies,...

In-line checkweighing and printing system for cartons

Ensure precision and efficiency in your packaging line with a compa...

Automated quality control for food packaging

Ensure seamless quality control with real-time inspections, serialization, an...

Pressure measurement system for bottle leak detection

Ensure the integrity and quality of your packaged products by accur...

X-ray and checkweigher combination for medium horizontal products

Streamline your packaging line with integrated checkw...

Checkweighers for medium and small products

Ensure precise weight control in high-speed production lines with advanced che...

Industrial checkweighers for medium-large products

Manage large and heavy packagings with precision and efficiency, ensur...

Combi x-ray and checkweigher for vertical products

Ensure accurate weight control and safety by detecting foreign bodies ...

Combi x-ray and checkweigher for vertical products

Ensure precise weight control and contamination detection for vertical...

Integrated metal detector and checkweigher for small/medium formats

Ensure precise quality control and contaminant-free...

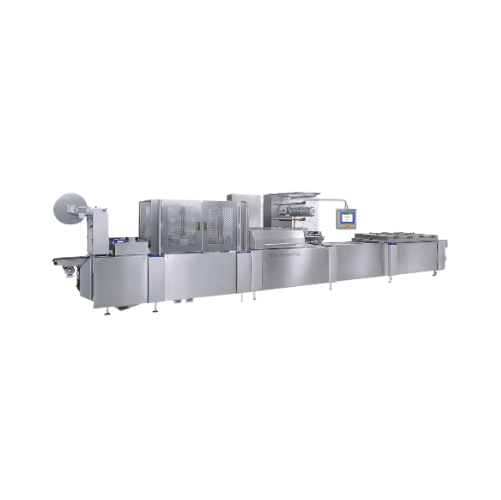

4-side seal horizontal form-fill-seal packaging system

Streamline your confectionery and snack packaging with high-speed,...

Compact industrial boiler for steam and hot water applications

Experience reliable steam and hot water generation with t...

Laser date and batch coder for product identification

Ensure precise product traceability and enhance packaging quality w...

Gizzard repeeling station for chicken and turkey

Enhance worker safety and production efficiency by automating the peeling...

X-ray guided waterjet portioning system for pork ribs

Optimize your poultry and meat processing with precise, efficient p...

Finished product storage silos for industrial applications

Optimize your storage capabilities with silos that ensure saf...

Customizable self-stacking solution for spiral freezers

Enhance your freezing process with a customizable self-stacking s...

Thermoforming packaging for skin applications

Enhance your packaging line’s versatility with a solution designed for...

Air conveyor for empty Pet bottles

Optimize your bottling line with an advanced air conveyor that reduces energy consumptio...

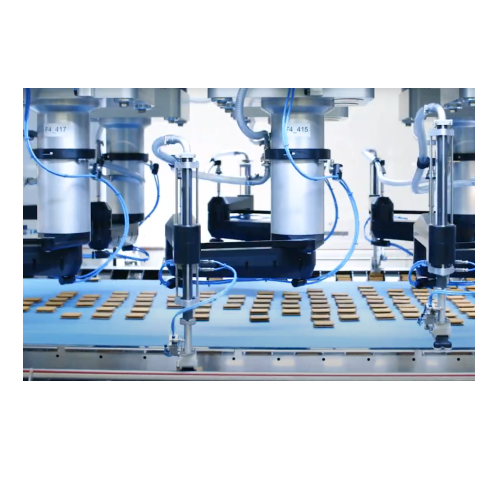

Robotic pick and place system for cookies

Streamline your bakery production with a flexible robotic system that seamlessly...

Screw belt mixer for dry materials

Achieve uniform mixing of bulk dry materials with variable speed control, ensuring preci...

X-ray scanner for contaminant detection in packaging

Ensure your products remain contamination-free with advanced X-ray s...

Intermediate dough proofer for soft and pre-fermented dough

Optimize your proofing process with a solution that gently h...

Compact serialisation solution for cartons

Optimize your packaging line with a versatile serialisation solution designed t...

Compact x-ray scanner for foreign body detection

Ensure product quality with a space-saving x-ray scanner designed for hig...

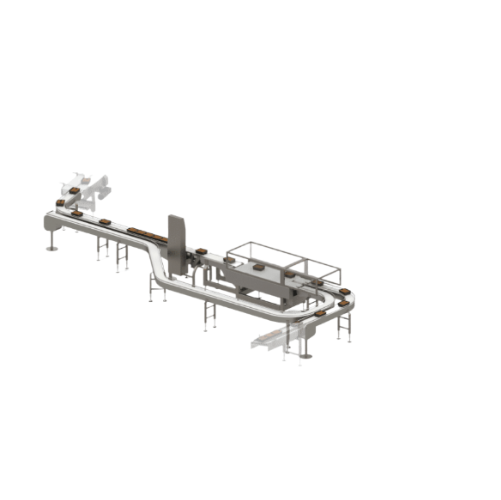

Modular end-of-line system for quality control

Streamline your end-of-line operations with seamless integration of weighin...

Checkweigher with integrated metal detector for food industry

Ensure comprehensive quality control in your production li...

Checkweigher and metal detector for heavy loads

Streamline your inspection process by combining precision weighing with co...

continuous leak tester for aerosol cans

Ensure the integrity of your aerosol cans with high-speed leak testing designed to ...

Inline leak tester for aerosol cans

Ensure the integrity of your aerosol cans with precise leak detection, achieving regula...

High capacity vertical conveying for flour

For consistent, high-speed handling of delicate and powdery materials, this eng...

Cucumber sorting and grading solution

Optimize cucumber handling with precise diameter, length, and shape sorting, enhancin...

Hazelnut sorting and quality selection system

Optimize your hazelnut processing with a system designed to detect defects a...

Blueberry sorting for consistent quality control

Ensure your blueberries meet market standards with precise sorting and gr...

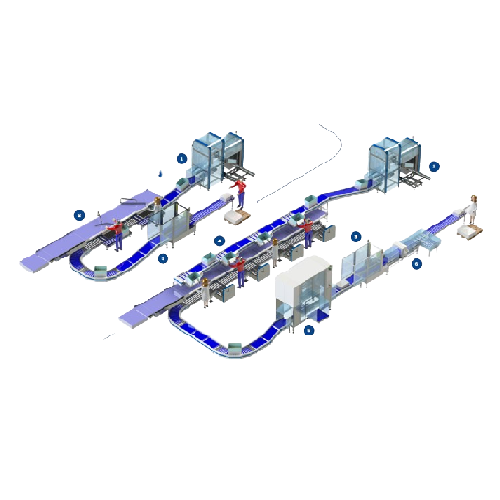

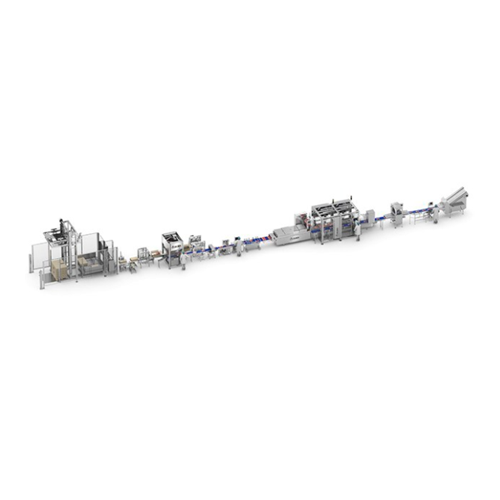

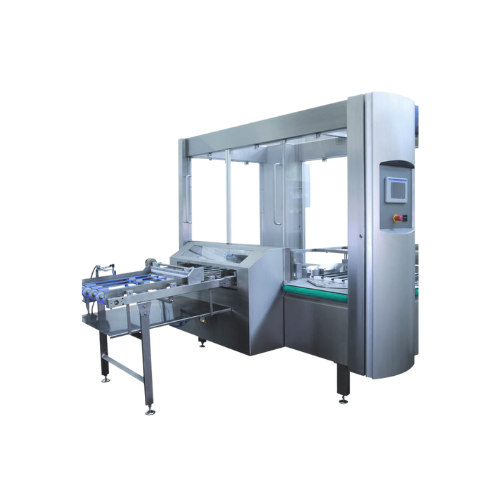

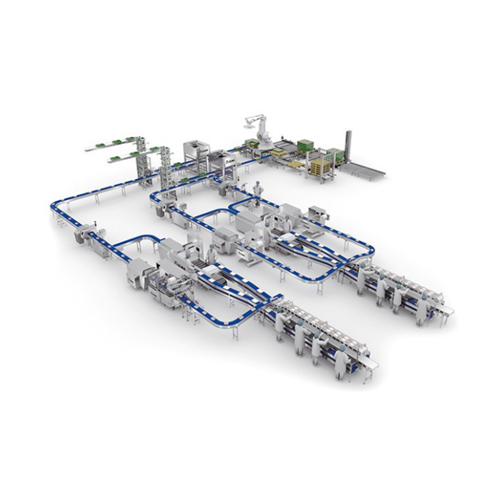

Automated packaging line for meat fillets

Streamline your meat fillet packaging with this fully automated system, designed...

Automated sliced meat packaging solution

Ensure seamless and efficient packaging of sliced meat products with a fully autom...

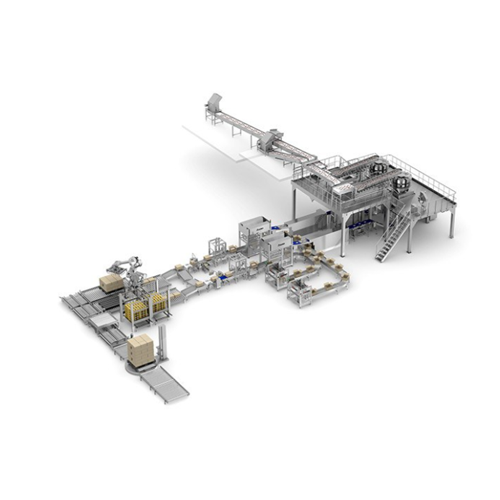

Traysealing system for chicken breasts packaging

Streamline your poultry packaging with a fully automated traysealing solu...

Frozen chicken cut-ups packaging solution

Maximize your poultry packaging efficiency with a solution that seamlessly integ...

Belt sorter for potatoes and leafy vegetables

Enhance the precision and efficiency of your sorting process with a system d...

Single and dual lane sorters for fresh produce

Optimize your food processing line with precision defect detection and vers...

Intelligent optical fruit sorting and grading system

Enhance product quality and reduce waste with cutting-edge optical s...

Blueberry sorting and grading system

Enhance your fruit processing line with a cutting-edge system designed for precision s...

Checkweigher for pharmaceutical and food industries

Ensure precise weight measurement and reliable product rejection in h...

Versaweigh checkweigher for precise weight control

Ensure your packaging accuracy and maintain quality standards with hig...

High-speed industrial checkweigher for cartons and bottles

Ensure precise weight control and reject non-compliant packag...

Food production metal detector

Ensure your packaged food products are free from metal contamination with efficient detection...

Industrial metal detector for packaged food products

Ensure the safety and compliance of your packaged food products by d...

Inline flash cooler for sweetened condensed milk

Optimize your sweetened condensed milk production with a continuous flash...

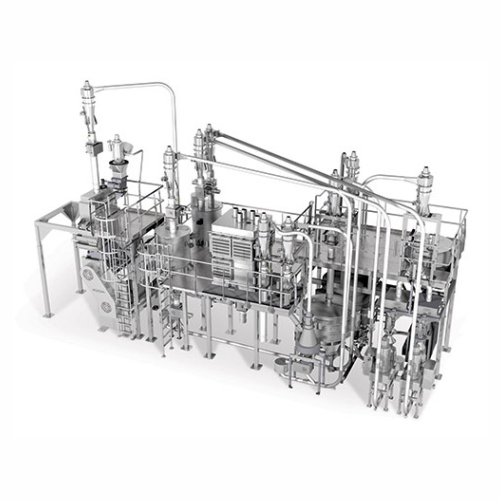

Tomato paste processing line

Streamline your tomato processing with our comprehensive production line, ensuring high-quality...

Small egg grader for farms

Efficiently sort eggs by weight with precision and speed, ensuring each egg meets quality standar...

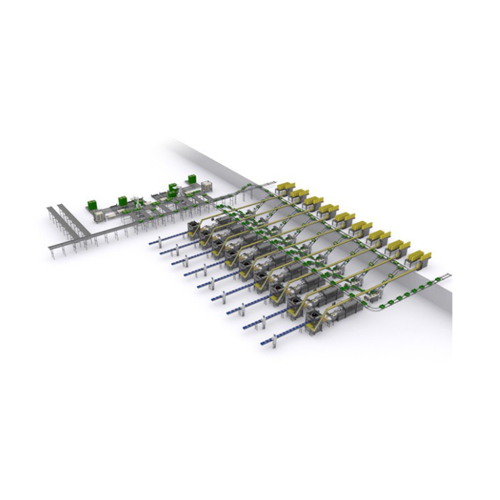

Robotic pick and place platform for food packaging

Enhance your packaging efficiency and product quality with a scalable ...

Twin shaft paddle mixer for bulk materials

Achieve precise blend consistency with a twin shaft paddle mixer designed to ha...

Vertical scraped surface heat exchanger for food processing

For continuous production that demands consistent texture an...

Wet bunker for potato buffering

Efficiently buffer and rinse pre-peeled potatoes and other potato products using a wet bunke...

Continuous roller peeler for root vegetables

Optimize peeling efficiency with precision-controlled roller systems engineer...

Industrial onion peeler for efficient onion processing

Achieve high-yield onion processing and perfect peeling quality wi...

Pick & place vision system for packaging quality control

Ensure flawless product packaging with a vision system that enha...

Sausage cutting solution for natural and artificial casings

Achieve precise sausage cuts at high speeds with solutions f...

Non-Destructive Crack Detection Vessel Testing

Using traditional types of inspection methods when inspecting vessels may p...

Spray Dryer Crack Testing Services

Spray dryers undergo multiple thermal cycles and may develop cracks as the metal becomes...

Conveyor belt metal detector for food products

Inspecting and rejecting finished food products for metal contamination is ...

Metal detector for bottles

For metal contamination detection in finished products that are bottled, traditional solutions re...

Entry-level high volume package seal tester

Manufactured food products need to be packed in gas-filled pouches to ensure t...

High-capacity bulk weighers

A checking weigher recognized for receiving and shipping bulk materials, typically in mills and ...

Spray dryer performance optimization system

Achieve unparalleled spray drying efficiency with real-time monitoring and con...

High pressure extruder for expanded snacks

Enhance your snack production with precise control over texture and shape throu...

Precise liquid cooling solution for food processing

Ensure high-quality preservation of flavors and textures in liquid fo...

Pig systems for product recovery in food and beverage industry

Maximize yield and minimize waste with advanced PIG syste...

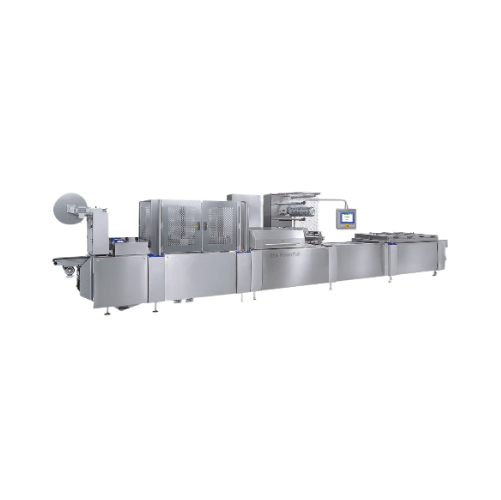

Thermoforming packaging for high-output segment

Enhance your production efficiency with advanced thermoforming technology,...

High-precision slicing for cheese and sausage products

Experience unparalleled slicing precision and efficiency with high...

Label dispenser integration for packaging lines

Streamline labeling operations with precision and flexibility, ensuring yo...

Marking solutions for traysealers

Ensure precise labeling and data printing on tray-sealed packages with integrated solutio...

Flowpackers for efficient food packaging

Achieve seamless packaging with flowpackers designed for high-speed, sustainable o...

Robotic loading systems for packaging applications

Enhance your production line with versatile robotic loading systems, d...

Checkweigher for food processing compliance

Ensure accurate package weights while preventing underweight or overweight pro...

Compact grader for poultry and meat processing

Streamline your production line with this precise grading solution, designe...

Metal detector for conveyorized applications

Enhance your production line by ensuring product safety with advanced metal d...

Industrial metal detector for food production lines

Ensure product safety and compliance by seamlessly detecting metal co...

Conveyorized food metal detector for high-care environments

Ensure food safety with advanced metal detection tailored fo...

High-capacity checkweigher for heavy products

Ensure compliance and precision in weighing large and heavy packaged product...

Flexible industrial robot for medium payloads

Optimize your production line with a versatile robotic solution that adapts ...

High payload industrial robot

Optimize your production with high payload robots designed to enhance flexibility and reduce o...

Caustic residue detection for bottle washing

Ensure product purity by detecting and eliminating residual caustic in return...

Cheese blockformer for dairy industry

Achieve consistent cheese block quality and seamless curd fusion through precision en...

Optical measuring and weighing instrument for peeled potatoes

Enhance your potato processing efficiency by precisely det...

Fiber thermoforming system for sustainable packaging

Achieve fast, efficient production of biodegradable fiber packaging ...

Rejection system for standing bottles and cans

Ensure seamless quality control by precisely rejecting defective bottles an...

Container ejection system for Pet bottles and beverage cans

Ensure product quality by seamlessly ejecting defective cont...

Optical sorter for blueberries

Enhance product quality and yield by precisely sorting blueberries, ensuring only optimal fru...

High-capacity optical sorter for food processing

Optimize your production line with precise sorting and separation, enhanc...

Rotary capper for round and irregular shaped containers

Efficiently cap round and irregular containers with precision and...

High-speed pouch filling and sealing system for food and dairy

Achieve precise spouted pouch filling with minimal waste ...

Industrial case rejector for faulty packaging

Ensure product integrity by smoothly removing faulty cases from your product...

Industrial container rejector for faulty product removal

Ensure seamless removal and sorting of defective containers in h...

Full case check for beverage production lines

Ensure complete packaging integrity by detecting and removing cases with mis...

Empty bottle sorting system

Efficiently remove unstable, misshapen, and contaminated empty bottles before they disrupt your ...

Horizontal vacuum paddle dryer for sensitive pharmaceutical ingredients

Achieve precise drying and mixing of sensitive ...

Industrial metal detector for gravity feed applications

Ensure the purity of your products by detecting and removing both...

Pipeline metal detection for pumpable products

Ensure safety and quality by detecting and rejecting metal contaminants in ...

Advanced metal detection for food processing

Maximize your production line’s safety and efficiency with a cutting-ed...

Multi-spectrum metal detector for food industry

Achieve unmatched detection accuracy in your food processing line with thi...

Corn masa preparation system

Efficiently transform dry corn into fresh masa in minutes using a continuous process, eliminati...

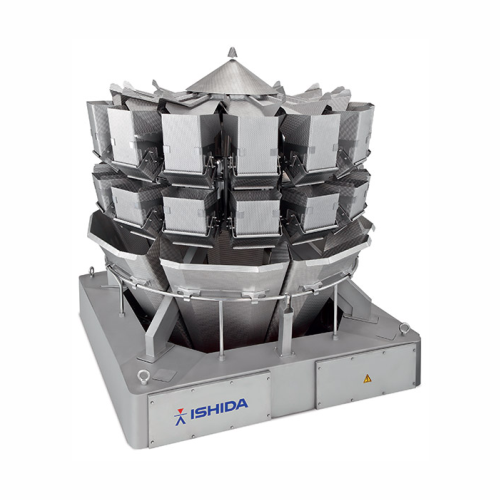

Fresh produce weighing system

Achieve precise weighing and seamless integration in fresh produce packaging with multihead we...

Scara robots for high-precision assembly and handling

Optimize your high-speed assembly and precision handling applicatio...

Vibration transport system for hygienic conveying of bulk goods

Optimize your production line with efficient and hygieni...

Hygienic industrial grinder for food and pharma applications

Achieve optimal hygiene and efficiency in your grinding pro...

Custom-designed work platform for safe operator access

Enhance operator safety and productivity by providing secure and h...

Basic checkweigher for weight control in low to medium performance

Ensure accurate weight control with a versatile chec...

Precision weigh filler for food and pharma industries

Optimize precision in multi-component dosing with seamless integrat...

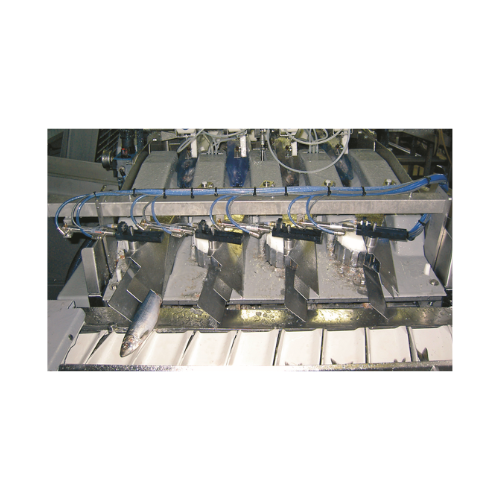

Camera-operated fish sorting system for filleting machines

Streamline your fish processing line with a system that optim...

Weighing optimization with sensorfeed

Optimize your production by enhancing weighing accuracy and reducing material waste t...

Optical sorter for coffee, grains, nuts, and plastic flakes

Ensure precise defect detection and foreign material removal...

Optical sorter for rice

Enhance your product quality by efficiently sorting and removing color defects and foreign materials ...

Wafer block cutter

Optimize your confectionery production with precision cutting technology that transforms wafer blocks into...

Optical rice sorter

Achieve impeccable quality in rice processing with an advanced optical sorter that ensures unparalleled a...

High-precision diameter measurement for round profiles

Achieve continuous, non-contact diameter measurement of round prof...

Pressure equipment directive (ped) compliant tanks

Achieve precise pressure regulation and safety with tanks designed to ...

Industrial under vacuum homogenizer

Optimize the consistency and texture of creams and lotions with precision-controlled mi...

Vacuum homogenizer for high-quality mixing and emulsification

Achieve optimal consistency and enhanced product stability...

In-line aggregation module for serialized item management

Optimize your serialization process by seamlessly managing and...

Rejector and diverter system for beverage production lines

Ensure precision and reliability in high-speed production lin...

Metal detector and checkweigher for cosmetics production

Ensure seamless quality control by combining metal detection and...

Vibration batch dryer for difficult solids

Ensure efficient drying of complex solids prone to sticking and shape irregular...

Rotary jet head for hygienic tank cleaning

Ensure efficient, hygienic cleaning with a rotary jet head designed to optimize...

X-ray detection for bones in poultry and fish

Ensure precise removal of calcified bones in poultry and fish products with ...

Industrial weight tracking system for injected products

Optimize your production line by accurately tracking product weig...

Salad processing line for fresh cut vegetables

Efficiently transform raw produce into market-ready salad mixes with stream...

Weighing conveyor for consistent product flow in food processing

Ensure uniform product distribution and precise weight ...

Automated scoop insertion system for powder containers

Streamline your container filling operations by ensuring precise s...

Meat portioning and slicing system for precision cuts

Streamline your production process with precise portioning and slic...

Can seamer for high-speed liquid applications

Ensure consistent seal integrity and maximize throughput with this advanced ...

Powder sampling solution for dairy and food processors

Ensure precise quality control with a versatile sampling system de...

Powder spool sampler for dairy and food processors

Efficiently manage powder quality with a robust spool sampler designed...

Lane converger and package rejector for thermoforming packaging systems

Streamline your packaging line with a system de...

Oxygen and leakage detection in Map packaging

Ensure enhanced food safety and reduce waste with precise oxygen and leak de...

Thermoforming packaging system for meat products

Enhance your packaging capabilities with a modular thermoforming system d...

Thermoforming packaging for food products

Enhance your packaging operations with advanced thermoforming technology, perfec...

Product manipulation and stacking systems

Efficiently transition products from flat to stacked on a conveyor while minimiz...

Pre-cut hot-melt label applicator for bottles

Optimize efficiency and precision in your labeling process with this advance...

Dosing and conveying screw for dry bulk materials

Efficiently manage the precise dosing and conveying of dry, powder, and...

Checkweigher with integrated metal detection system

Ensure the quality and safety of your packaged foods with precise wei...

Leak testing system for aerosol cans

Ensure the integrity of your aerosol and metal packaging with a high-speed leak testin...

Food-grade round dust collectors

Maintain a clean production environment with this food-grade dust collector, designed to ma...

Rubin cherry tomato sorting and grading system

Efficiently sorting and grading Rubin cherry tomatoes, this system ensures ...

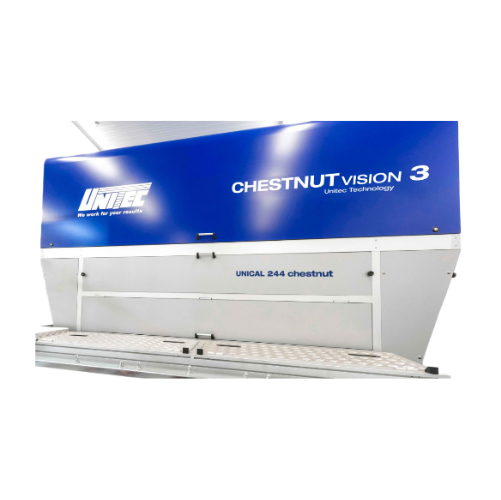

Chestnut sorting and grading system

Optimize chestnut processing with advanced sorting technology that ensures precise size...

Storage tank integrity testing

Prevent costly contamination and streamline your operations with advanced tank integrity test...

Chicken breast packaging system

Streamline your poultry packaging line with a solution that ensures precise loading, wrappin...

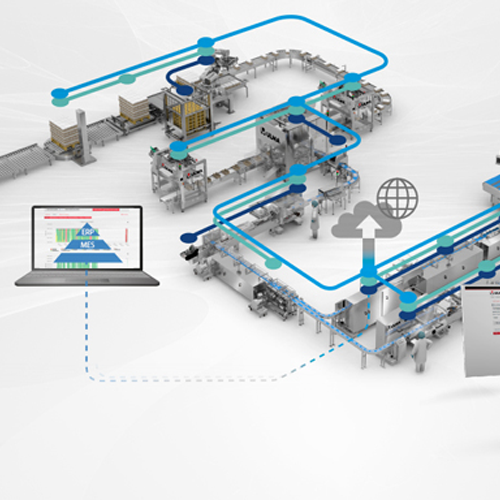

Real-time packaging process tracking solution

Achieve seamless connectivity and control across your packaging processes wi...

Pharmaceutical ultra pure water distribution system

Ensure stringent purity standards with a modular water distribution s...

Automatic case packer for pharmaceutical industry

Optimize your packaging process with a versatile case packer designed t...

High-precision sorter for nuts, coffee, seeds, and grains

Achieve unrivaled accuracy in sorting nuts, seeds, and grains ...

Food sorting system for nuts and dried fruit

Streamline sorting processes by removing visual irregularities, defects, and ...

Heavy duty checkweigher for large packages

Achieve precise in-motion weighing for large packages without halting your prod...

High sensitivity metal detectors for food products

Ensure food safety and product quality by effectively detecting and re...

Entry-level metal detector for food production

Ensure your food and beverage products remain contaminant-free with a cost-...

Versatile filling system for aseptic packaging

Achieve seamless integration in high-speed aseptic packaging with this flex...

Automatic egg washing machine for chicken and duck eggs

Ensure hygiene and extend shelf life with this advanced egg washi...

Capsule filling for nutrition and health products

Optimize your production line with advanced capsule filling capabilitie...

Automated cup filling solutions for liquid and viscous products

Ensure precise and hygienic filling of dairy, baby food,...

Portable texture analysis for low force applications

Easily perform precision texture measurements on low-force applicati...

Weigh-belt feeder for industrial processes

Efficiently manage material flow and precision with a dependable weigh-belt fee...

Semi-automatic tablet hardness tester

Optimize your tablet production with precise and reliable testing of hardness, dimens...

Motorized cap torque tester for bottle closures

Ensure precise seal integrity and compliance with bottle cap torque measur...

High-precision biscuit sandwiching system

Efficiently align, fill, and sandwich high-speed biscuit rows while ensuring pre...

Metal detection system for powders & granules

Ensure product integrity and protect your machinery from metallic contaminan...

In-line metal detector for liquids & pastes

Ensure product safety by seamlessly integrating a metal detection system into ...

Conveyor belt metal detection system

Ensure seamless product safety with a system that detects and separates metallic conta...

Metal detector systems for conveyor belts and chutes

Ensure the integrity of your production line by efficiently detectin...

Pet bottle production for small and medium outputs

Optimize your production line by manufacturing PET bottles in-house, r...

Pick & place robots for industrial packaging

Elevate your production line with advanced automation that ensures precise pa...

Flowpacker for packaging products in flowpacks

Optimize your flowpack packaging line with a preconfigured solution that ac...

Small-scale egg breaking and separation

Efficiently transform eggs into high-quality liquid products with advanced breaking...

Metal detection system for twisted sausages production

Ensure the safety of your twisted sausage production line by detec...

Sensor for Modified Atmosphere FIBCs

Every year, more than 200 million FIBCs are filled with food for storage and transport...

Pipeline metal detector for sauces

Ensuring liquid and viscous products such as sauces, soups, juices and meat are contamin...

Metal detector for granulated products

Free-fall applications, such us flour, sugar, spices and other granulated or powdere...

Standalone metal detector for food

Adding advanced metal detection to existing lines can be difficult and expensive, often ...