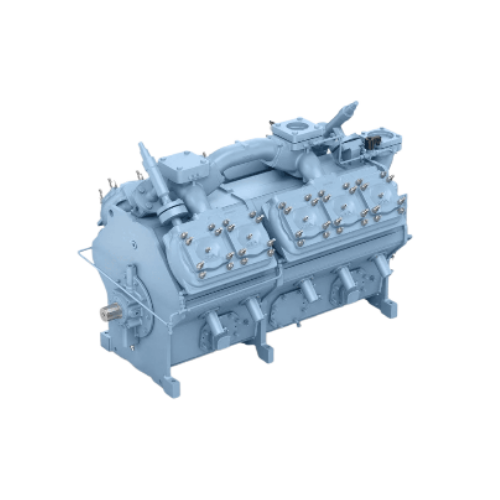

High-pressure ammonia reciprocating compressor for industrial refrigeration

Achieve higher efficiency with reduced energy consumption and robust reliability in your high-pressure ammonia applications, ensuring optimal performance for your heat pump and refrigeration systems.

Compresses Ammonia for High-Pressure Heat Applications

The GEA Grasso V XHP from GEA is a high-pressure ammonia reciprocating compressor that stands out for its ability to deliver efficient temperature control in demanding industrial applications. Designed for heat pump and refrigeration tasks, it compresses ammonia to deliver water temperatures up to +95 °C. This makes it ideal for hot water applications, industrial refrigeration, and a variety of food processing tasks, like producing packaged frozen foods and sterilized beverages. Equipped with a state-of-the-art GEA Omni control panel, it ensures seamless integration into high-speed, automated operations. Its design supports suction pressures from -15 °C to +60 °C, with a maximum discharge pressure suitable for water at +95 °C, optimizing for efficiency and low environmental impact. The unit is factory-tested for reliability and features multi-stage safety controls to prevent excess pressure. With a heating capacity ranging from 700 to 2300 kW, it meets the stringent demands of industries such as food, beverage, and pharmaceuticals, offering robust performance and long-term reliability.

Benefits

- Lowers energy costs with efficient ammonia compression.

- Ensures reliable operation with factory-tested components.

- Delivers precise temperature control for versatile applications.

- Minimizes environmental impact with zero global warming potential.

- Enhances safety with a multi-stage pressure protection system.

- Applications

- Hot water applications, Industrial refrigeration, Heat pump applications, Food industry, Processing applications, Cleaning processes

- End products

- Canned food items, Pasteurized dairy products, Sterilized bottled beverages, Heated cleaning solutions, Packaged frozen foods, Refined edible oils, Processed meats, Hot water for food processing

- Steps before

- Cooling, Refrigeration, Raw Material Storage

- Steps after

- Washing, Food Processing, Heat Treatment

- Input ingredients

- ammonia (NH3), refrigerant R717, suction pressure -15 °C to +60 °C

- Output ingredients

- water temperatures up to +95 °C, maximum heating capacity of approximately 2300 Kw

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Capacity

- Approx. 700 to 2300 kW

- Suction Pressure Range

- -15 °C to +60 °C

- Max Discharge Pressure

- 63 bar

- Speed Min / Max

- 500 / 1500 rpm

- Total Swept Volume at Full Load

- 376 to 941 m³/hr

- Design Suction Pressure

- 30 bar

- Design Discharge Pressure

- 63 bar

- Design Differential Pressure

- 50 bar

- Heating Capacity Conditions

- +35 °C and +95 °C

- Refrigerant

- R717

- Maximum Water Temperature

- +95 °C

- Automation level

- PLC / SCADA with GEA Omni control panel

- Batch vs. continuous operation

- Continuous for heat pump applications

- Energy efficiency

- Optimized for reduced total cost of ownership (TCO)

- Cleaning method

- CIP available on request

- Max operating temperature

- Up to +95 °C for water applications

- Pressure handling

- Design pressure up to 63 bar

- Performance range

- 700 to 2300 kW heating capacity

- Machine Footprint

- Compact design

- Control Panel Type

- GEA Omni control panel

- Cylinder Types

- 4

- 6

- 8

- 10 cylinders

- Total Swept Volume at Full Load

- 376 to 941 m³/hr

- External Connections

- Oil pump

- Control panel type

- GEA Omni control panel

- Cylinder options

- 4

- 6

- 8

- 10 cylinder configurations

- Application suitability

- Heat pump for cleaning and processing