Industrial Food Drying Equipment

Find drying equipment for the food industry and connect directly with leading machine and equipment manufacturers world wide.

Why do you have to dry your food products? This is simply because the product contains too much moisture after processing. Food products go through a drying process so their quality can be enhanced and the shelf life of the product can be extended. So, how can we choose the right food drying equipment for your drying process? The answer lies in the nature of the materials to be handled.

Do you know which properties you want for your product? - selecting the correct drying equipment

Have you thought about the product’s moisture content, consistency, particle size and distribution, temperature resistivity, and porosity? Phew, these are a lot to consider. Yes, but these are necessary factors you should think about to determine which food drying technology you need. You may consider direct or indirect heating of your product, freeze or vacuum drying solutions, continuous fluid beds, belt dryers, or air dehumidifiers.

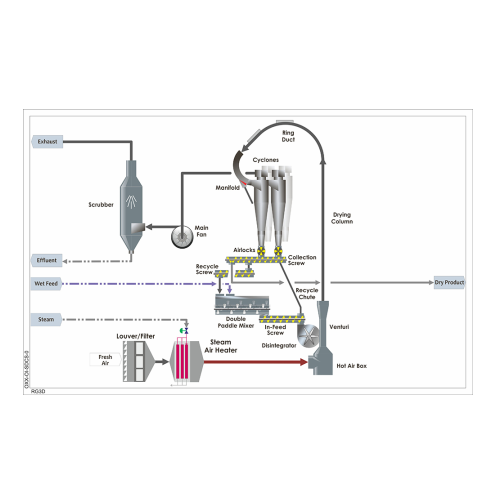

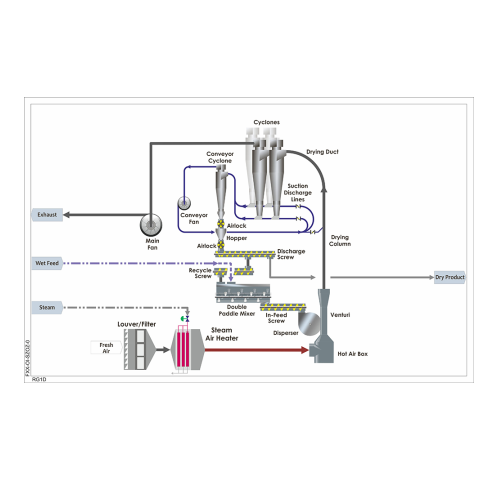

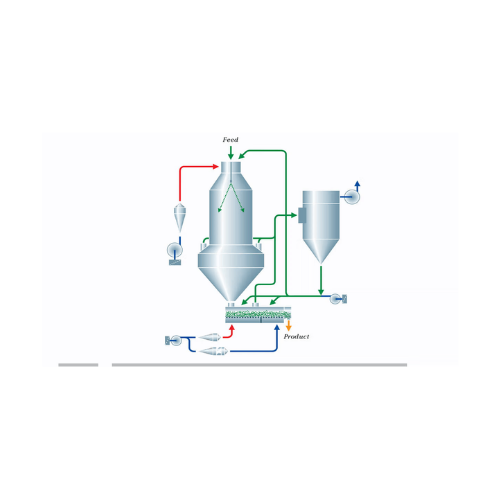

Continuous flash drying is often employed for drying fish and fish feed. Ingredients like garlic, algae, plankton, and milk products (like colostrum and breast milk) are often freeze-dried. Vacuum drying is a more efficient and faster method appropriate for thermal and oxygen-sensitive materials – such as gelatin powder or protein powder. Belt drying technology can be applied to fruits and vegetables, like carrot chips. And fluid bed drying equipment often involves a fluidization and granulation process, and it usually involves pharma products and some food products in powder form, like cocoa powder.

Pay attention to these when you are drying your food products - explosion risks, airflow, and hygiene

Remember that handling temperature-sensitive products, as well as living cell structures, requires a high degree of care and attention. There are a few factors to pay attention to during the industrial food drying process. First, you need to keep the constant air circulation during the process since this will bring more efficient and faster results. Secondly, you need to make sure the equipment is safe. This includes considering the explosion risks to guarantee operator safety. Lastly, do not undermine hygiene. Pay attention to the hygienic aspect of the equipment to prevent health risks and manufacture high-quality end products.

Which industrial food drying technology do you need?

Industrial shrink and drying units for food products

Ensure optimal product integrity and extended shelf life by seamless...

Film coater for Otc and food supplements

Achieve optimal film coating for tablets and capsules with precision-engineered so...

Industrial food dehydrator for fruit and vegetables

Optimize your drying process with a high-temperature food dehydrator ...

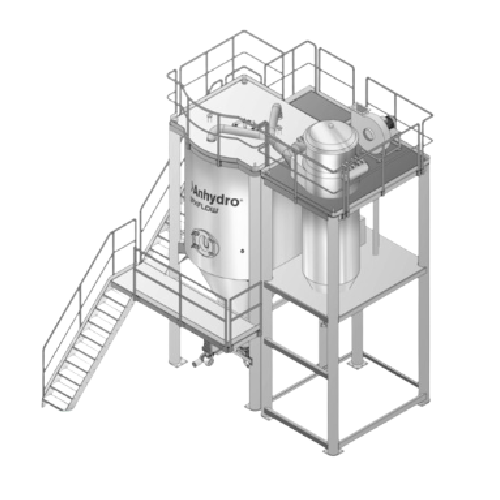

Tall form bustle dryer for dairy and food products

Experience efficient drying and precise moisture control with this inn...

Wide body dryer for dairy and food products

Achieve precise moisture control and optimal powder agglomeration for dairy an...

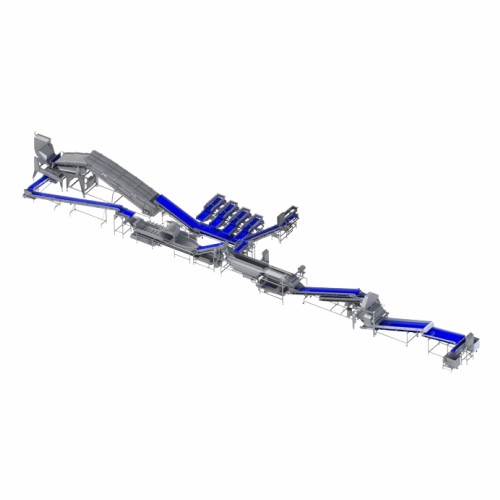

Collection conveyors for food processing

Optimize your production line by efficiently collecting and conveying solid produc...

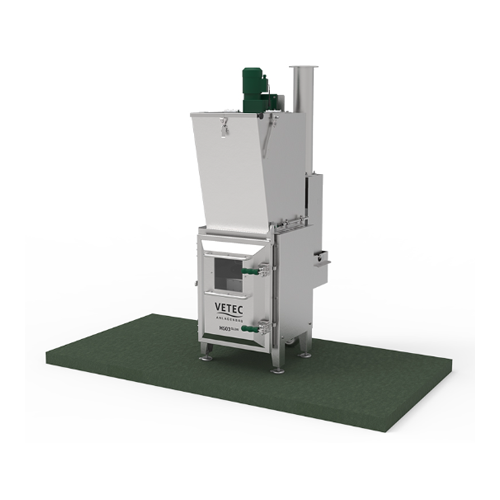

Industrial water removal system for food preparation

Enhance your production line with advanced surface water and starch ...

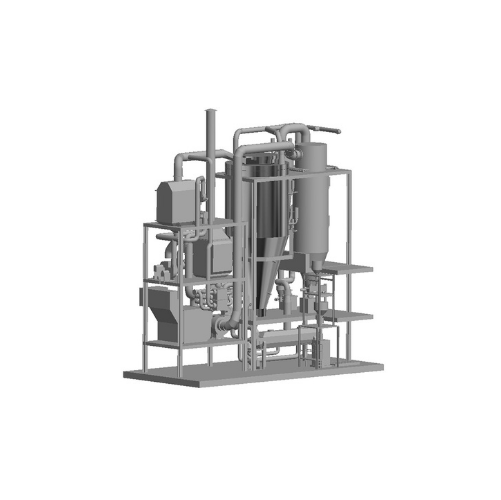

Compact food drying system

Achieve precise moisture control for product development and testing with this versatile compact ...

Food drying system for diverse products

Achieve precise moisture control and versatile drying for your diverse product line...

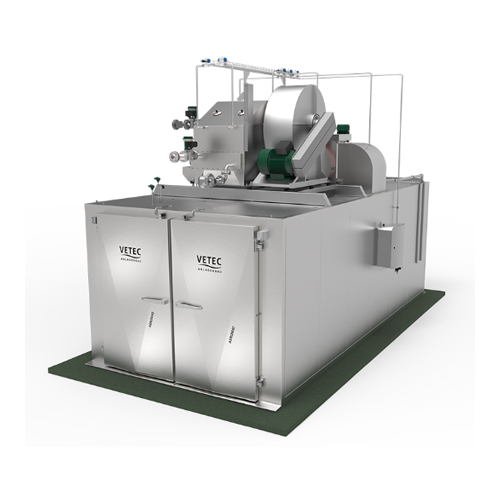

Batch drying system for food, pet feed, pharmaceuticals, and more

Optimize your drying needs with precision control for...

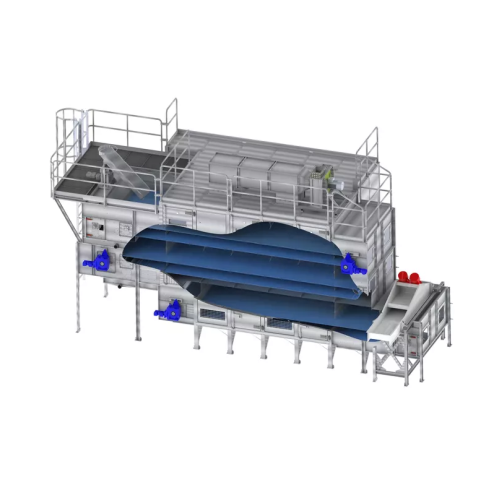

Rotary drum dryer for robust food products

Achieve uniform and gentle drying for sensitive and robust products alike with ...

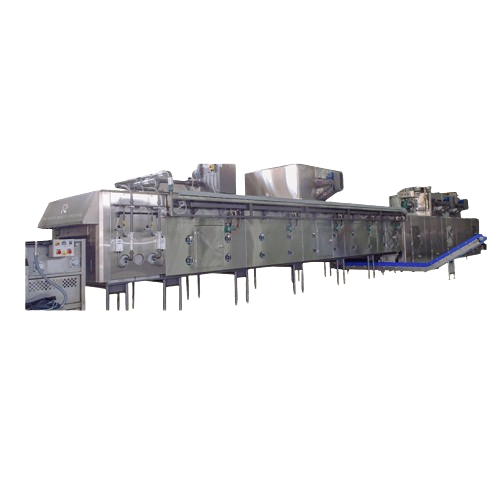

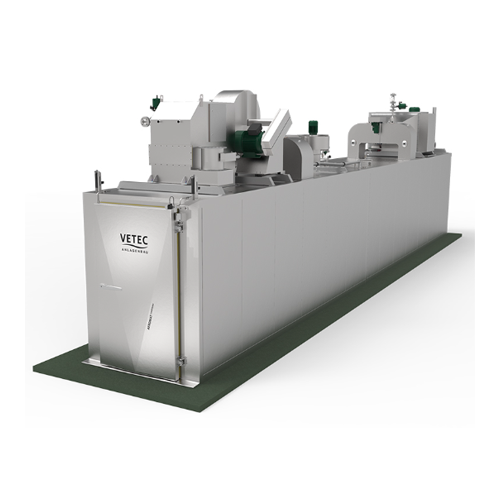

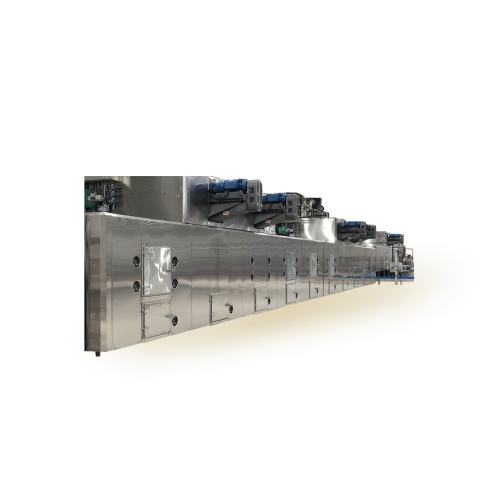

Continuous tunnel dryer for food products

Achieve precise moisture removal with adaptable drying technology, ensuring your...

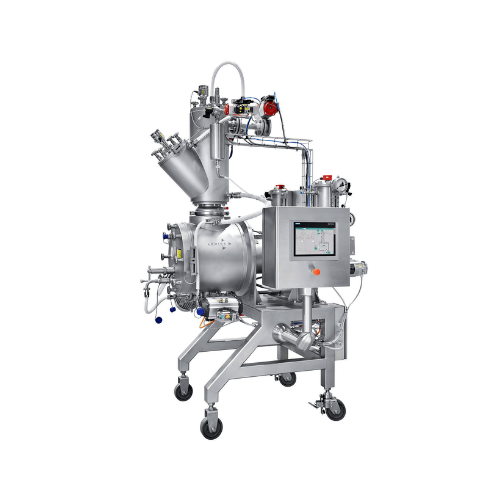

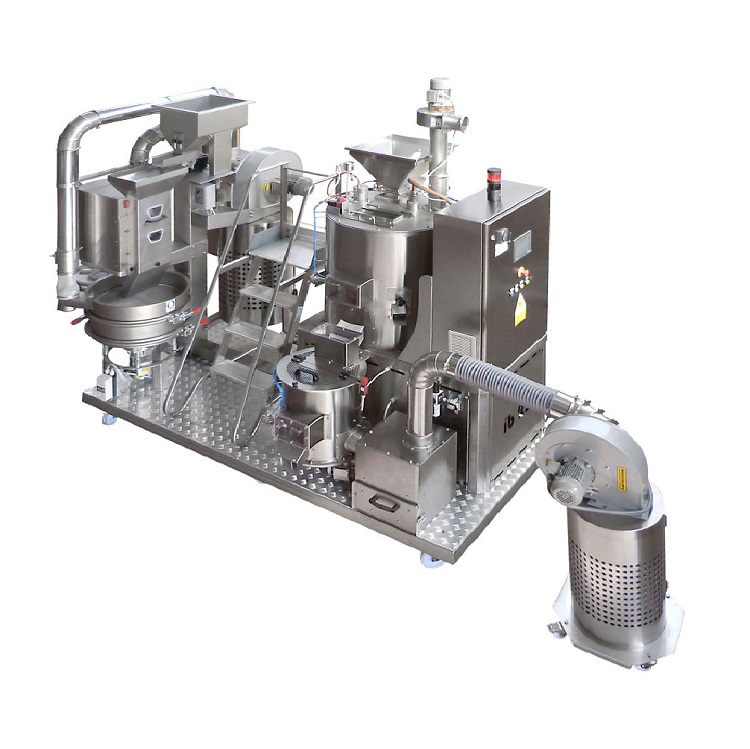

Fluid bed granulation system for food and chemical industries

Achieve efficient granulation and drying of liquids with c...

Fluid bed granulator for food and chemical industries

Ensure consistent particle size and moisture control in your produc...

Spouted bed processing for food, feed, and fine chemicals

Tackle the challenge of processing temperature-sensitive and s...

Industrial steam washer for pharmaceutical and food industry

For production lines requiring efficient and eco-friendly c...

Efficient drying solution for food packaging pouches

Optimize your packaging line with precise moisture control, ensuring...

Advanced vacuum coating system for pet food and feed

Achieve uniform saturation in pellets and granules with precise liqu...

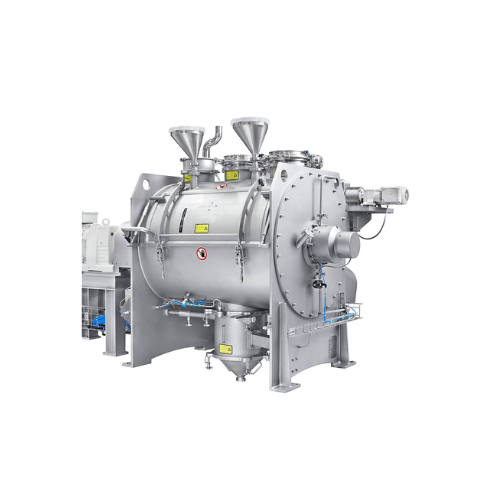

5-in-1 industrial mixer for food and chemical industries

Streamline your production with a multifunctional system that ef...

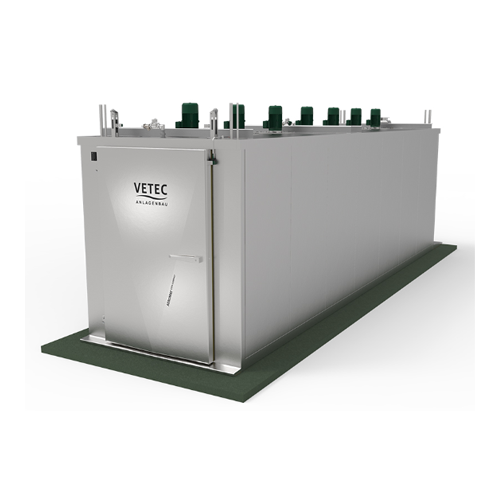

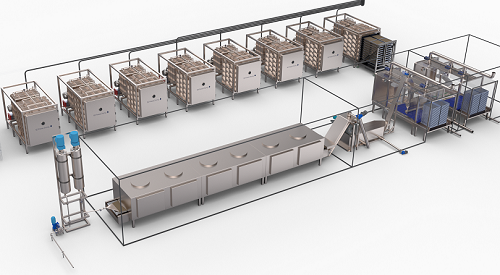

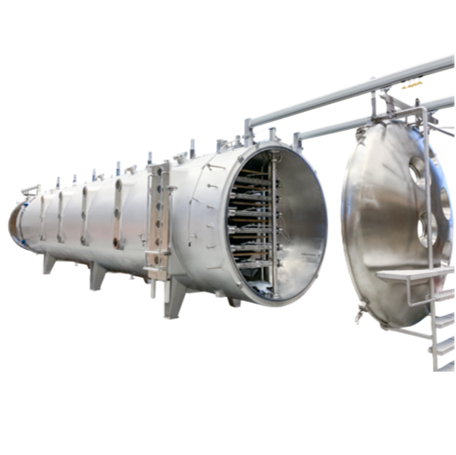

Vacuum and freeze drying plants for food and pharmaceuticals

Ensure high-quality, extended shelf-life products with inno...

Pea fiber drying solutions for food or feed applications

Ensure top-tier product quality with precise drying of pea fiber...

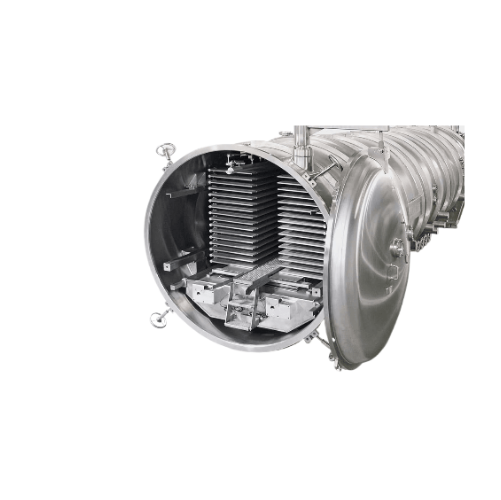

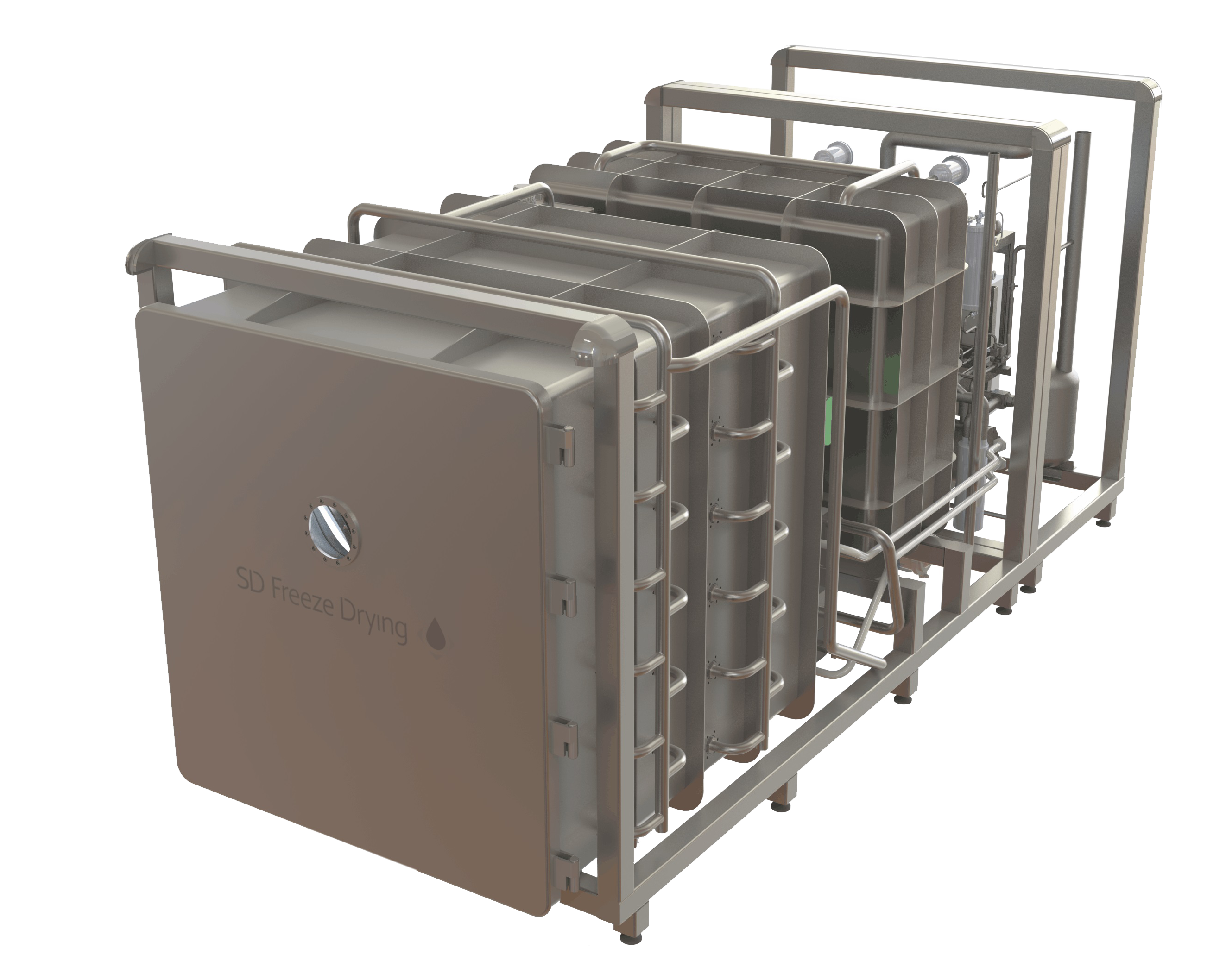

Industrial freeze dryer for large scale food processing

Optimize moisture removal for high-quality food preservation and ...

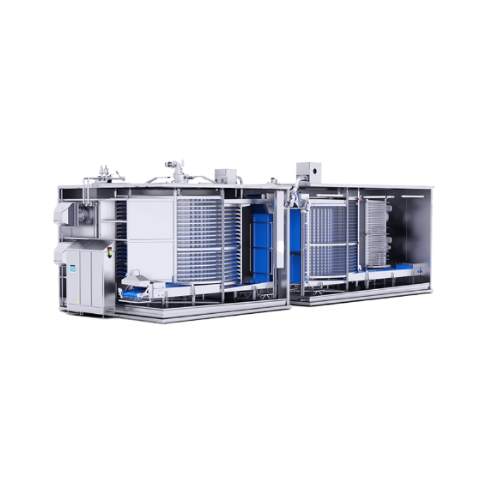

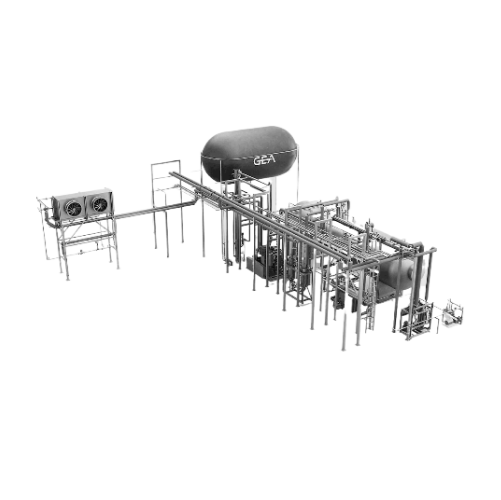

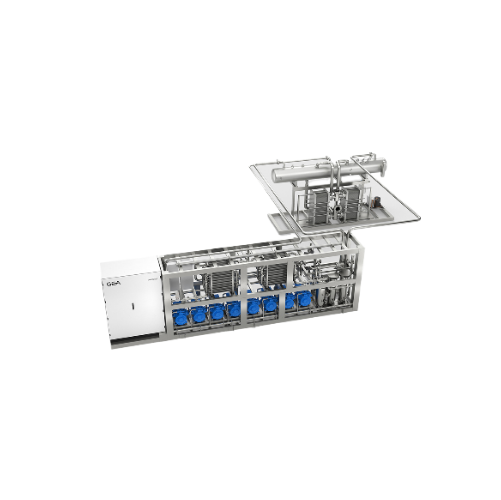

Continuous freeze drying solution for coffee and food pieces

Achieve optimal moisture removal in heat-sensitive products...

Industrial stir fryer for food production

Maximize cooking efficiency with a multi-function stir fryer that excels in cont...

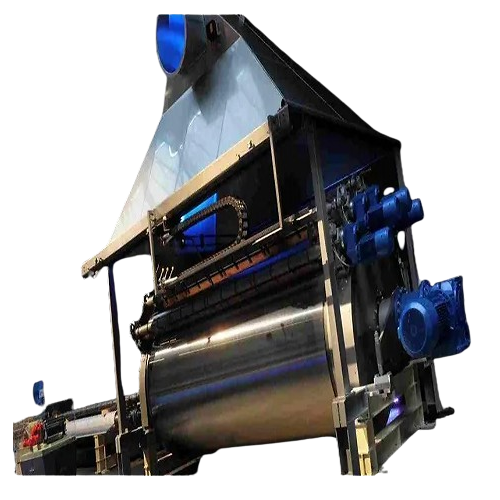

Contact drum dryer for industrial food and chemical processing

Optimize your drying process with a contact drum dryer th...

Spiral pasteurization system for packaged foods

Enhance product durability and quality with a compact spiral pasteurizatio...

Dry condensing vacuum system for food industry

Optimize energy consumption and wastewater disposal in your production line...

Industrial predryer for humidity reduction in food processing

Ensure optimal shelf life and prevent product sticking wit...

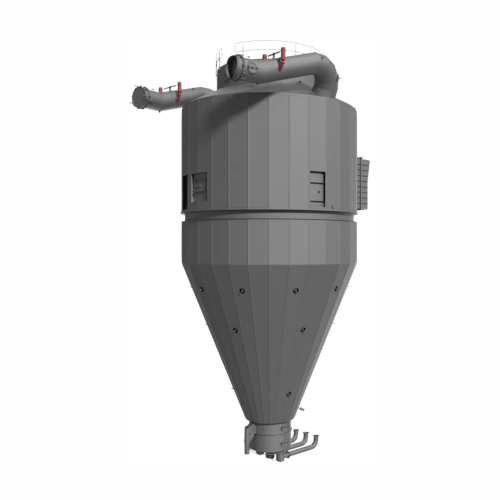

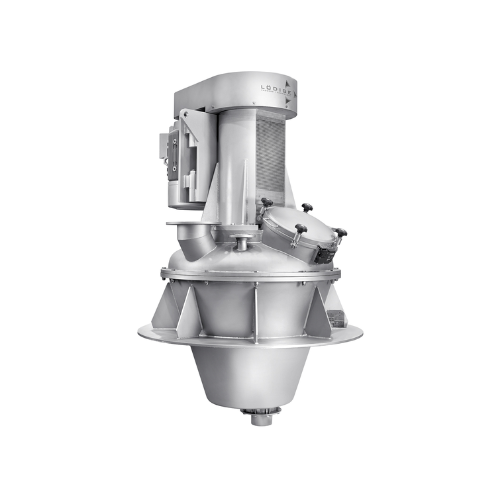

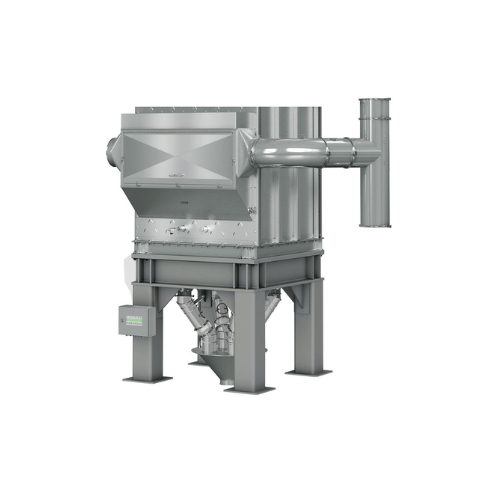

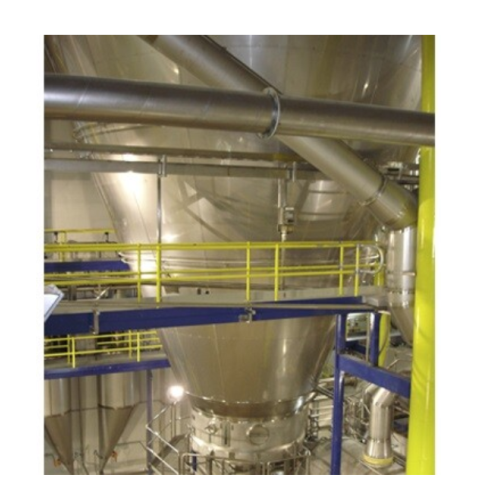

Powder separation cyclone for food and chemical industries

Optimize your powder production with advanced cyclone technol...

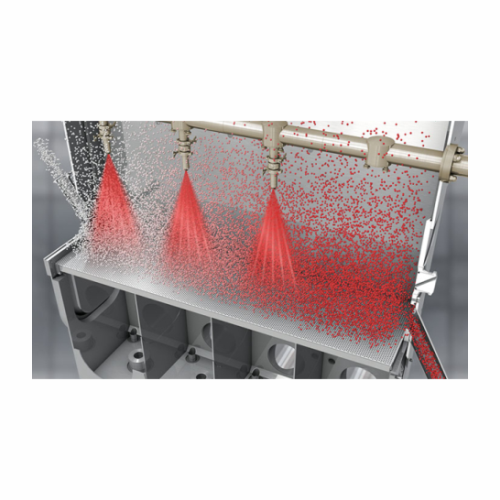

Automated fines return system for food and dairy spray dryers

Enhance your spray drying process by eliminating manual in...

Industrial freeze drying system for high-volume food products

Achieve precise moisture removal and preserve product qual...

Batch freeze drying system for food and beverage preservation

Achieve precise and efficient preservation of your food an...

Spray dryer for food and dairy products

Achieve consistent drying for diverse powders and granulates with precision technol...

Food freeze dryer for bulk materials

Achieve efficient and uniform drying of fruits, herbs, and other materials with advanc...

Convection roaster for pet food and delicate food products

Achieve optimal texture and moisture control in delicate food...

Liquid smoke system for meat and seafood processing

Achieve uniform smoking results across diverse products by employing ...

Industrial food cooling system

Achieve precise core temperatures and optimized shelf life with rapid cooling for diverse foo...

Compact food dehydrator with Bpa-free trays

Achieve precise dehydration with compact, kitchen-friendly equipment, perfect ...

Compact food dehydrator for fruits and meats

Achieve precise dehydration of fruits, vegetables, and meats with a compact s...

Large-capacity commercial food dehydrator

Achieve precise dehydration for a wide range of food items with unmatched consis...

Food dehydrator with Bpa-free trays

Effortlessly retain nutrients while creating a variety of dehydrated snacks using dual ...

Cabinet Food dehydrator

Achieve precise drying control with dual fan technology, ensuring even airflow and optimal nutrient p...

Food dehydrator with Bpa-free plastic trays

Achieve precise dehydration for fruits, vegetables, and snacks with advanced t...

Food dehydrator with stainless steel trays

Achieve optimal dehydration with precise temperature control and efficient dual...

Low temperature food dehydration system for fruit and vegetables

Optimize your food processing with advanced low-tempera...

Professional food dehydrator for fruits and vegetables

Enhance your culinary creations with precise dehydration technolog...

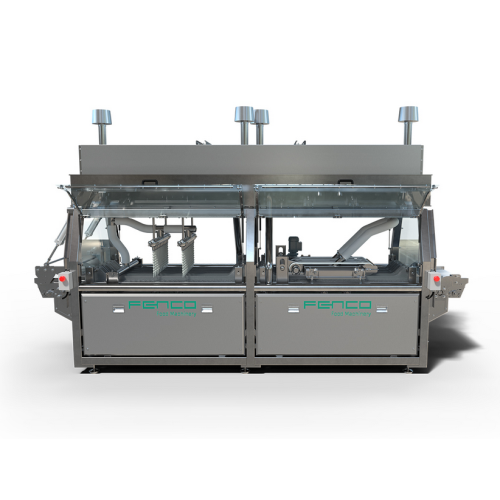

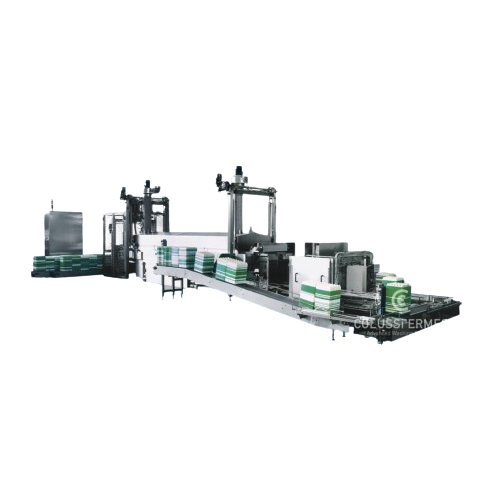

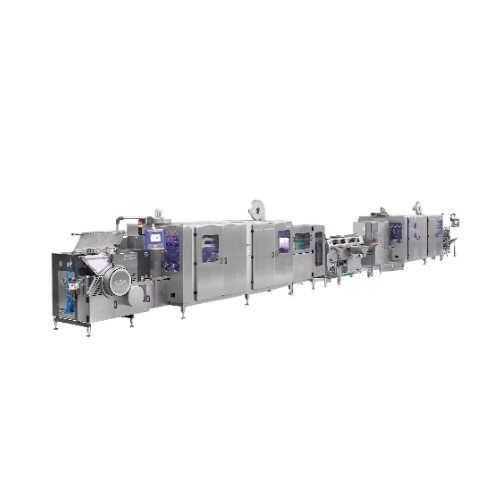

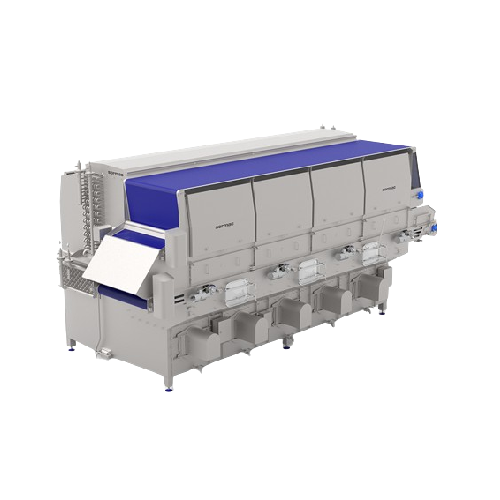

Continuous food washing and drying line for vacuum-packed products

Achieve optimal cleanliness and efficient moisture r...

Small vegetable food dehydrator

Efficiently remove moisture from your fruits and vegetables with this centrifugal dehydrator...

Mesh belt food dryer

Achieve uniform and efficient drying of diverse materials with the mesh belt food dryer, designed to max...

Industrial food drying oven

Achieve efficient dehydration and heat curing with precision control, ensuring uniform drying ac...

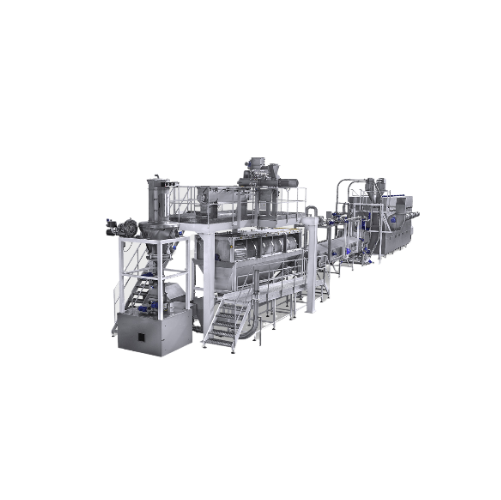

Fried food production line

Achieve consistent quality in fried snacks with this integrated production line, streamlining pro...

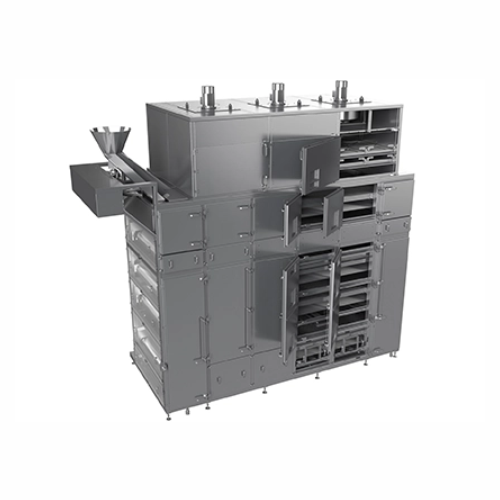

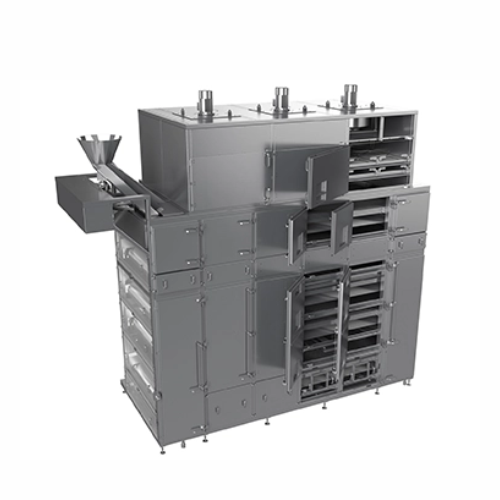

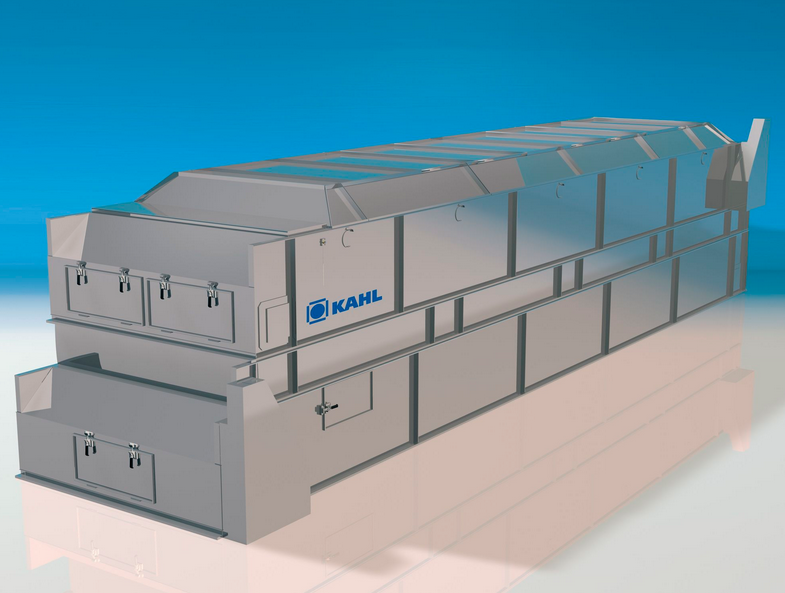

Layer dryer for food and pet food applications

Optimize drying efficiency with multi-layer technology that minimizes space...

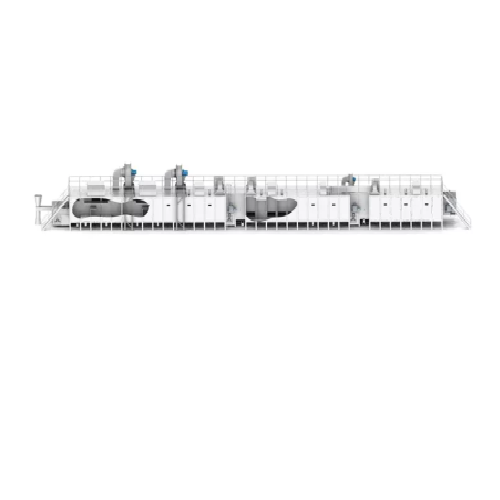

Belt dryer for food and pet food products

Optimize drying processes with customizable belt dryers, engineered to handle ro...

Mid-size belt-chamber vacuum packaging for smallgoods and seafoods

Optimize your packaging line with efficient mid-spee...

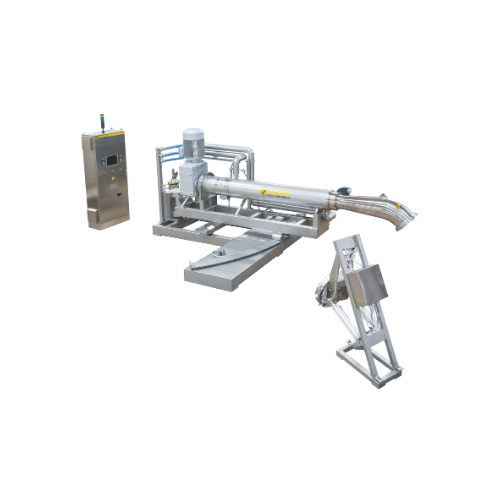

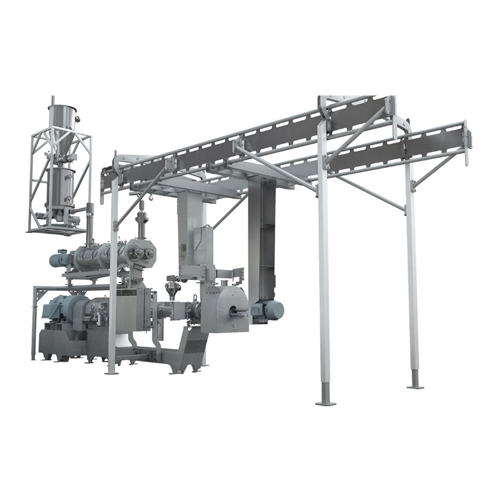

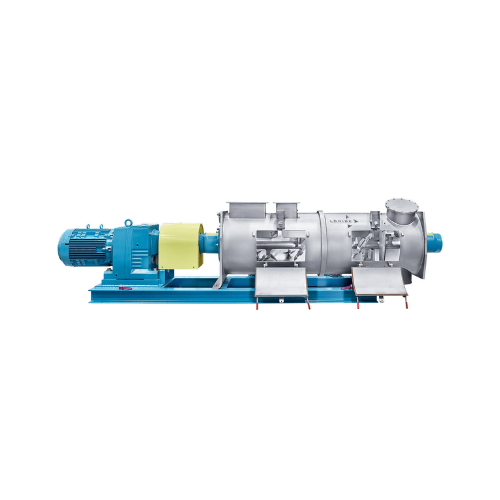

Food product extruder for low to high capacity production

Optimize your snack production with versatile extruders that e...

Energy saving cabinet dryer for food

Traditional drying systems use a lot of energy and take a long time to dry the product...

Vacuum cabinet dryer for plant extracts and functional foods

Plant extracts are vital to functional food preparations. B...

Industrial food freeze dryer

Nutraceuticals and dietary supplements can be highly sensitive and need to be protected against...

Co2 recovery system for breweries

Unlock the full potential of fermentation by capturing and purifying CO2 for immediate re...

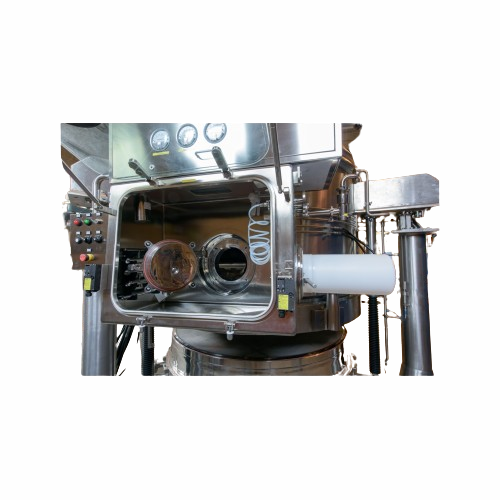

Dual camera system for spray dryer monitoring

Enhance safety and operational efficiency in your drying process by combinin...

Spray dryer performance optimization system

Achieve unparalleled spray drying efficiency with real-time monitoring and con...

Fluid bed dryer for bulk material laboratory drying

Efficiently dry and mix organic and inorganic materials with precise ...

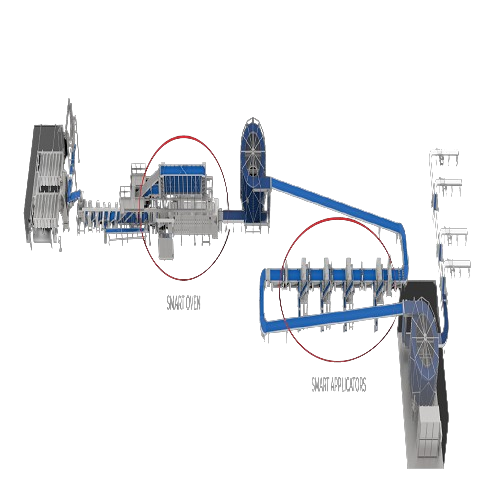

Smart bakery oven zone for flexible heating

Optimize your production with flexible heat transfer options that enhance cont...

Emithermic zone for baking biscuits and cookies

Enhance your baking efficiency and precision with a flexible heat transfer...

Industrial continuous heat treatment for dry ingredients

Optimize your production line with a continuous system that ensu...

Indoor microalgae cultivation technology

Enhance sustainability and productivity in microalgae cultivation with a vertical ...

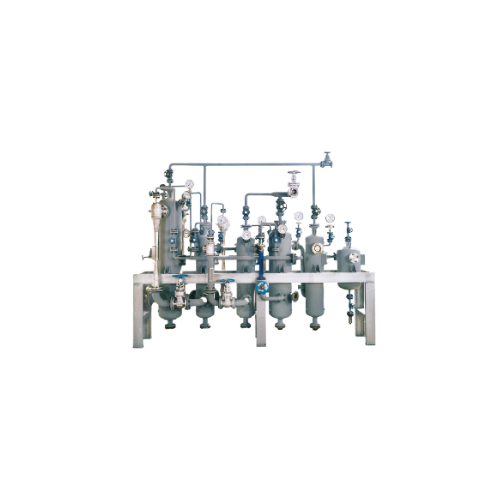

Ped tested filtration system for sparkling wines

Ensure consistent carbonation and clarity in your sparkling beverages wit...

Sesame seed dryer

Optimize your sesame processing with efficient moisture removal, ensuring desired quality and consistency f...

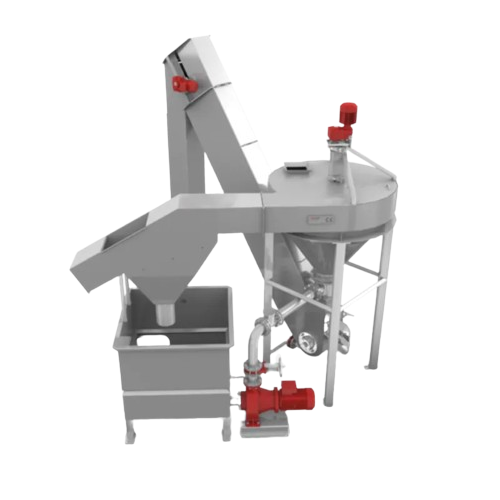

Sesame seed washing system

Eliminate the bitterness and impurities from sesame seeds efficiently, setting the stage for high...

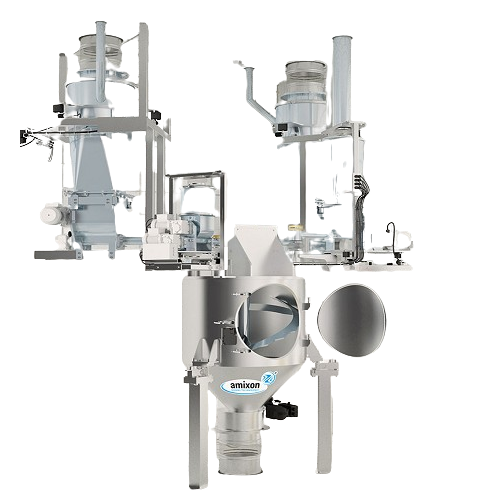

Ibc cleaning equipment for hygienic powder handling

Optimize cleaning efficiency and maintain hygiene standards with a ve...

Horizontal tray dryer for moisture removal

Ensure consistent product quality in nut and olive processing by efficiently re...

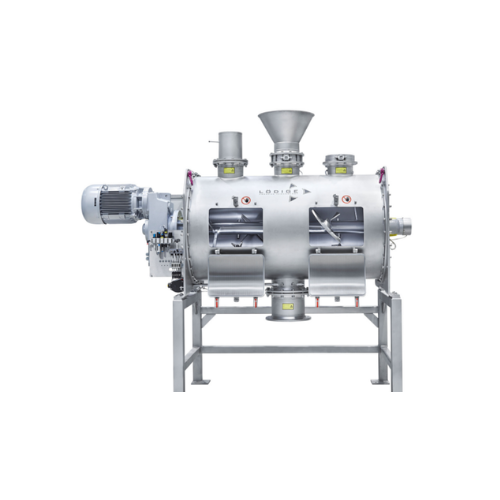

Laboratory ploughshare mixer for small-scale production

Achieve precise mixing and granulation for R&D and small-bat...

Hygienic mixer for batch operation

Achieve consistent and precise mix quality across diverse powders and granules with this...

Wet mixer for viscous and paste-like products

Achieve high-quality mixing of medium to highly viscous products with precis...

Continuous granulation dryer for chemical and polysaccharide applications

Enhance your production with precise drying ...

Laboratory mixer granulator

Achieve high-quality mixtures in R&D and small-batch production with versatile laboratory m...

Vegetable and salad spin dryer

Optimize your vegetable and fruit processing with precision dehydration that maintains textur...

Industrial vegetable and lettuce spinner

Effortlessly achieve optimal drying and dewatering for salads, vegetables, and mor...

Industrial vegetable and lettuce spin-dryer

Achieve consistent, gentle drying for a wide range of food products with seven...

Lettuce processing and packaging line

Maximize throughput with seamless integration of trimming, cutting, washing, and pack...

Processing line for lettuce, vegetables, and fruit

Enhance efficiency and product quality in your production line with a ...

Potato processing line for tubers

For food processors seeking efficiency, this semi-automatic line streamlines peeling, cut...

Automated processing line for lettuce and leafy vegetables

Optimize your salad and leafy greens processing with this ful...

Centrifugal drying system for lettuce and vegetables

Enhance your production line’s efficiency with this high-capac...

Industrial fruit drying cabinet

Efficiently transform fresh produce into long-lasting, nutrient-dense snacks with precise dr...

Compact drying solution for regular skim and Wpc powders

Streamline your drying process with a compact solution that effi...

Milk product evaporator for high solids concentration

Efficiently concentrate milk products to high solids, optimizing pr...

Industrial thawing systems for meat products

Optimize your food production line with advanced thawing systems designed to ...

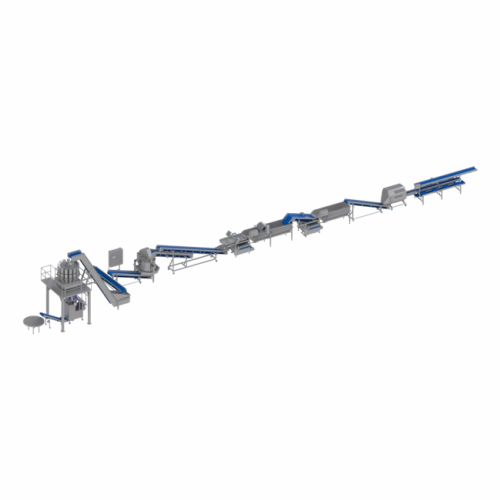

French fry and coated french fry processing line

Optimize every potato’s potential from pre-cleaning to frying with ...

Hash brown production line for formed potato products

Optimize potato processing with this advanced production line, tran...

High shear plough mixer for powders, granules, and pastes

Achieve rapid and efficient blending with high shear mixers de...

Homogenous blending solution for powders and granules

Achieve precise, homogenous blending of challenging materials like ...

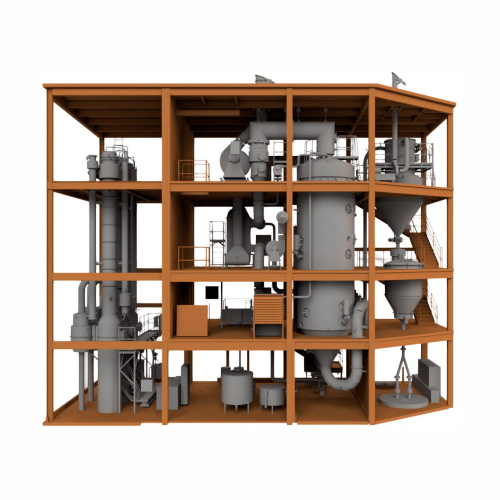

Industrial water tube steam boilers

Optimize energy efficiency and reduce fossil fuel reliance with high-performance steam ...

High shear impact mixer for agglomeration and dispersion

Achieve precise homogeneity and efficient agglomeration with a h...

Batch mixer for segregative, free-flowing powders and pastes

Achieve precise and gentle batch mixing for delicate produc...

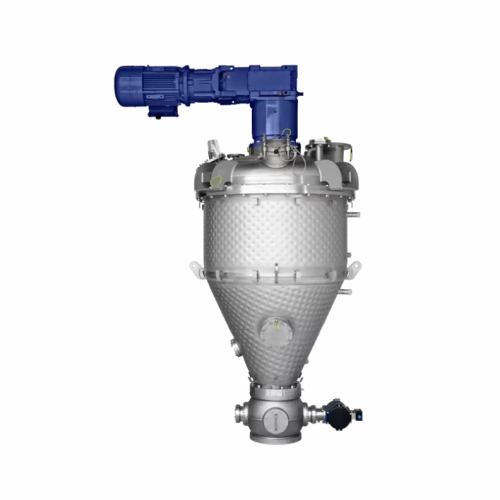

Vacuum dryer for powders and granules

Achieve precise moisture control for sensitive materials with a versatile vacuum dryi...

Laboratory vacuum dryer for heat-sensitive materials

Optimize moisture control in heat-sensitive materials with precise a...

Table roller mills for mineral raw material comminution

Achieve precise mineral raw material comminution and energy-effic...

Continuous powder agglomeration system

Enhance product solubility and flowability while minimizing energy consumption with ...

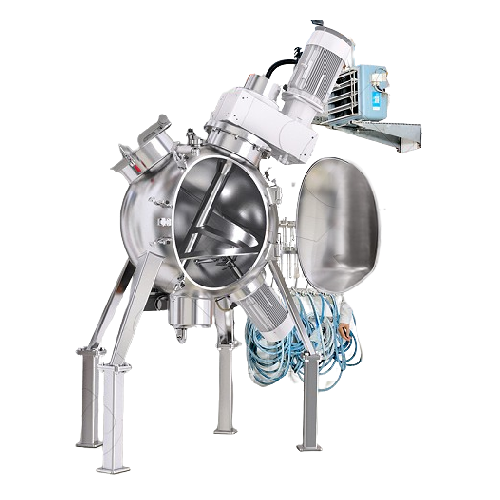

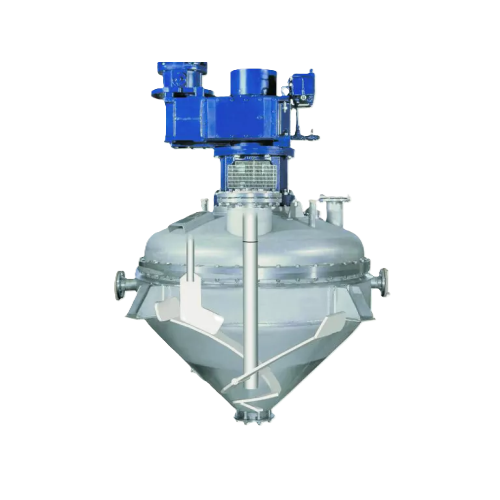

Conical paddle vacuum dryer for powders and granules

Achieve efficient drying of sensitive materials with this versatile ...

Mid-capacity film coating solution

Enhance your seed coating and biofuel pellet production with a customizable turn-key sol...

Vacuum marinating and tumbling for laboratories and small enterprises

Streamline your meat processing operations with v...

Vacuum pan dryer for heat-sensitive pasty products

When dealing with highly viscous, heat-sensitive products, efficient m...

Chemical filter dryer for fine chemical production

When processing chemical intermediates, precise filtration and drying ...

Horizontal vacuum paddle dryer for bulk production facilities

Achieve precise moisture control in powders with a versati...

Pilot plant filter dryer for small scale production

Optimize filtration and drying processes in your pilot plant with a v...

Pilot unit filter dryer for laboratory applications

Efficiently manage filtration and drying processes with precise tempe...

Sterilizable filter dryer for pharmaceutical applications

Ensure full sterility and efficient moisture removal in critic...

Conical screw vacuum dryer for hazardous and temperature-sensitive products

When you need precise moisture control for...

Vacuum drying solution for filter cake or viscous materials

When faced with the challenge of drying filter cake or trans...

Pilot plant conical screw dryer

Optimize drying efficiency with this versatile pilot plant solution, ideal for simulating an...

Wafer sandwich cooling systems

Efficiently setting cream fillings for clean cuts, this cooling system ensures your wafer san...

Horizontal peeler centrifuge for chemical applications

Achieve high-throughput product separation and purification with p...

Continuous extruded snack dyeing system

Enhance the aesthetics of your extruded snacks with precise and continuous dyeing, ...

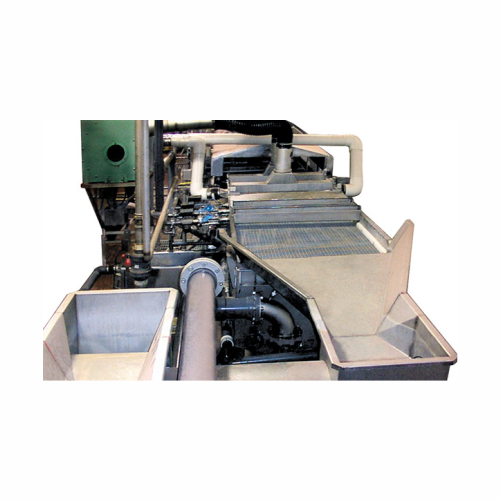

Potato slice washer for surface starch and fines removal

Ensure optimal cleaning and dewatering of potato slices while si...

Industrial tunnel dryer

Optimize drying efficiency and maintain product quality with continuous tunnel drying, ideal for prec...

Large continuous tunnel dryer

Optimize your production with advanced drying and dehumidification technologies, ensuring prec...

Continuous drying system for viscous substances

When handling viscous substances, ensure precise moisture control with con...

Pharmaceutical and laboratory product drying solution

Ensure precise moisture control for diverse products, from pharmace...

Pharmaceutical and med-tech drying solution

Achieve precise moisture control and adaptability across diverse products with...

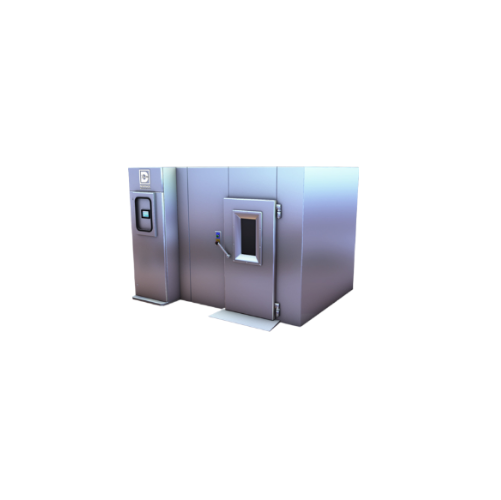

Batch-operated chamber dryer for surface drying

Enhance production efficiency with precise, low-temperature drying and coo...

Continuous tunneling drying system for industrial applications

Streamline your drying process with precision-controlled ...

Industrial sludge drying solution

For facilities needing precise moisture removal, this compact solution ensures efficient ...

Continuous belt dryer for large-scale drying applications

Optimize your production with a continuous belt dryer, enginee...

Compact dryer for product and process development

Optimize your testing and product development with a compact drying sol...

Flexible drying system for various industrial applications

Achieve precise moisture control across diverse materials wit...

Batch drying solution for industrial applications

Achieve precise and gentle moisture control in diverse production proce...

Drum dryer for animal feed

Achieve efficient and uniform drying for a variety of products, from nuts to medicinal cannabis, ...

Continuous tunnel dryer for tray carts

Efficiently dry diverse products with precision temperature control, ensuring gentle...

Continuous dryer for large production volumes

Achieve high-speed moisture removal with precision and minimal thermal impac...

Continuous conveyor belt dryer for endless products

Optimize your continuous production line with a high-speed drying sol...

Batch drying solutions for industrial applications

Ensure precise moisture control across diverse materials with our vers...

Continuous belt dryer for industrial production

For operations requiring precise moisture control, this continuous belt dr...

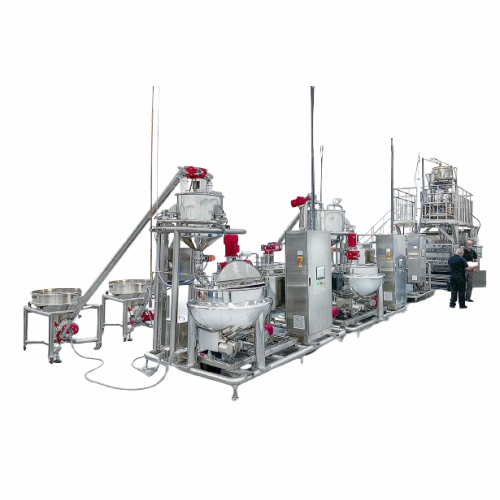

Integrated process system for hard caramel production

Optimize your candy production with a fully integrated system desig...

Automatic tray washer for gummy production cleanup

Eliminate gummy residue efficiently with high-pressure tray washing, e...

High-capacity gummy production system

Optimize your gummy production with a starchless system that deposits up to 240,000 g...

Din standard glass-lined reactors

Streamline your chemical reactions with these DIN standard glass-lined reactors, designed...

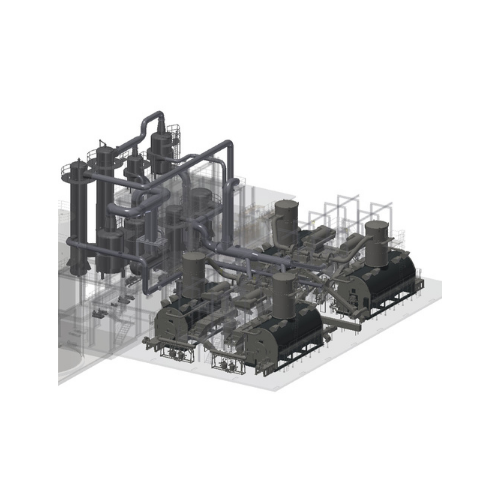

Industrial continuous distillation system

Enhance product purity and efficiency with a robust continuous distillation syst...

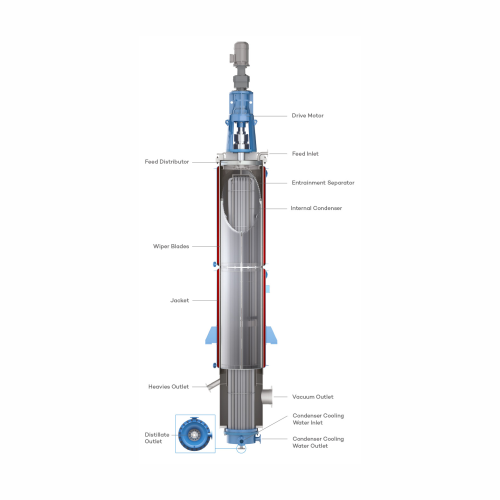

Wiped film evaporator for high boiling point materials

For challenging separations of high boiling, viscous, or heat-sens...

Vacuum paddle dryer for active pharmaceutical ingredients

For precise moisture control and contamination-free conditions...

Fluid bed and spouted bed systems for granulation and coating

Optimize your production line with cutting-edge fluid bed ...

Mini batch blender for pharmaceutical solids

Achieve precise mixing homogeneity with the mini batch blender, perfect for l...

Complete bottling lines for beverage industries

Optimize your bottling process with high-speed, precision-engineered lines...

Downdraft conveyor dryer for industrial drying applications

Achieve consistent drying with reduced energy consumption us...

Superheated water sterilizer for large volume parenterals

When sterilizing large volumes of liquid products, achieving p...

Laboratory sterilizer for microbiology and analytical labs

Designed for laboratories requiring versatile sterilization s...

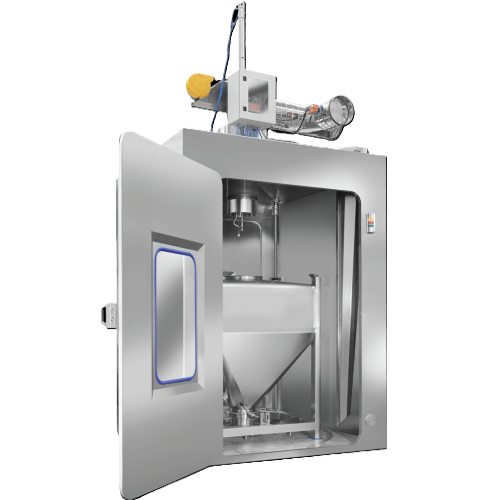

Internal and external bin washing cabinet

Streamline your sanitation process with automated bin cleaning that ensures thor...

Fluid bed processor for granulation and coating

Fluid bed processors offer efficient granulation and coating, streamlining...

Screw heat exchanger for efficient thermal processing

Optimize your heating and cooling processes with this robust double...

Sludge dryer for humid and pasty materials

Effortlessly manage pasty and sticky materials with a sludge dryer that ensures...

Conical powder mixer for uniform powder blending

Achieve consistent powder blending while preserving the integrity of deli...

Pulsed electric field treatment for roots, tubers, and fruits

Enhance your production line with advanced pulsed electric...

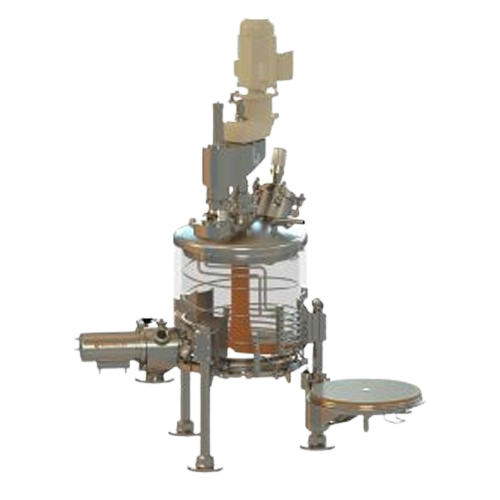

Pilot single-pot processor for granulation and drying

For efficient pilot production, streamline your mixing, granulating...

Granulation line for pharmaceutical manufacturing

Enhance your batch production with integrated mixer and fluid-bed techn...

Pharmaceutical granulation line

Streamline your production with an integrated system that combines mixing, granulation, and ...

Laboratory unit for mixing, granulating, and vacuum drying

Achieve precise mixing, granulating, and drying in laboratory...

Fluid bed processor for large batch spray granulation

Optimize your production with precision granulation, drying, and co...

Industrial mixer for batch granules or grains

Achieve precise mixing with seamless integration of heating, sterilization, ...

Extraction plant for natural essences and active ingredients

Optimize your extraction processes with a versatile system ...

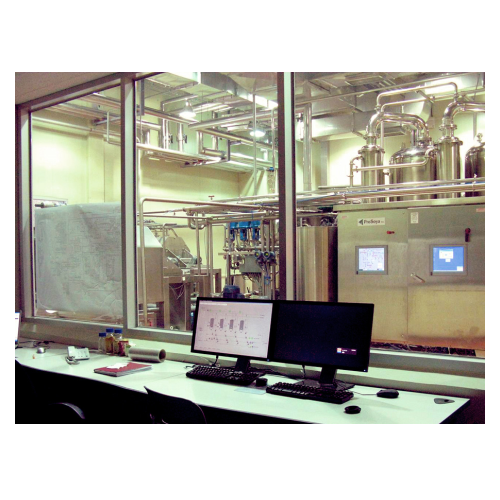

Thermal process plants for liquid treatment

Achieve precision thermal processing with systems designed to optimize the hea...

Roll linear labelling machines for bottling and packaging

Achieve precise and efficient labeling with roll linear labell...

Corn starch drying solutions

Ensure precise moisture control and maintain product integrity in your corn starch processing w...

Freeze dryer for high sugar or acid content products

Achieve precise moisture control for challenging high sugar or acid ...

Industrial low temperature freeze dryer for high sugar or acid content products

For processing challenging high sugar ...

Large-scale industrial freeze dryer

Achieve precise moisture control and preserve product integrity with a large-scale free...

Low temperature freeze dryer for high sugar or acid content products

Perfect for producing freeze-dried goods from food...

Continuous deodorizing for oils and fats

Achieve optimal purity and flavor in oils and fats with advanced continuous deodor...

General purpose freeze dryer for small commercial batches

Maximize your production line’s flexibility with this ve...

Continuous vacuum dryer for protein products

Achieve precise moisture control and maintain product functionality with low-...

Zero effluent discharge system for solvent extraction plants

Eliminate wastewater in your solvent extraction process whi...

Industrial egg tray washer

Ensure immaculate cleanliness and hygiene of egg trays while boosting efficiency with an advanced...

Oscillating heat exchanger for gelatin production

Ensure hygienic transfer in gelatin production with an innovative oscil...

Industrial spiral freezing system

Optimize your food processing line with a reliable spiral system, designed to efficiently...

Flexible spheronization kit for wet granulation pellets

Achieve precise pellet and granule formation with a versatile ben...

Advanced superheated steam drying solution

Harness the power of consistent drying technology to achieve optimal moisture c...

Four-roller and eight-roller mill for wheat and grain grinding

Optimize your grinding operations with this versatile rol...

Hydrothermal kiln for oats and sorghum

Optimize your grain production with advanced enzyme inactivation and hydrothermal tr...

Fully automatic batch scale for powdery and granular products

Achieve precise and repeatable dosing for powdery and gran...

Fluid-bed toaster for cereal processing

Achieve precise control over texture and taste while reducing operating costs with ...

Rice sifter for optimal rice processing

Achieve precise rice classification and quality enhancement with this compact sifti...

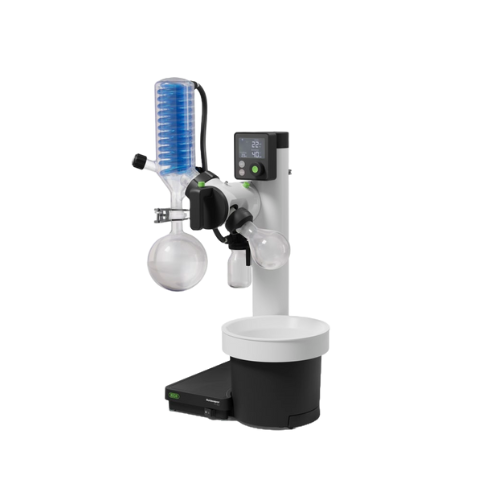

Compact rotary evaporator for laboratory distillation

Achieve efficient solvent removal and sample concentration with thi...

Parallel evaporation system for laboratory sample preparation

Achieve precise sample concentration and drying with autom...

Multitasking extraction system

Effortlessly manage complex extractions with high-speed, reliable results, ensuring sample in...

Parallel sample evaporator

Process multiple samples efficiently with precise control, ensuring quick evaporation and consist...

Nano spray drying system for pharmaceuticals and nanotechnology

Transform minuscule samples into submicron particles eff...

Industrial dehumidifier for continuous spray drying

Ensure stable spray drying conditions with precise humidity control, ...

Inert loop for safe organic solvent spray drying

Ensure safe handling and efficient recovery of organic solvents in spray ...

Vacuum dryer cabinet for heat-sensitive products

For manufacturers handling heat-sensitive products, achieving precise moi...

Vertical chestnuts dryer

Achieve optimal moisture removal for chestnuts with precise hot air cycling, perfect for converting ...

Chestnut sterilisation system for parasite control

Ensure pest-free chestnuts with precision-controlled hot water sterili...

Release agent sprayer for baking trays and moulds

Achieve perfect results in baking by ensuring efficient and uniform gre...

Vertical ribbon vacuum dryer for thermosensitive products

Achieve optimal drying of thermo-sensitive materials like powd...

Sanitary horizontal paddle vacuum dryer

For sensitive product drying, ensuring short cycles and high thermal efficiency is ...

Horizontal vacuum paddle dryer for thermosensitive products

For high-viscosity products like active pharmaceuticals or p...

Horizontal vacuum paddle dryer for thermosensitive products

Achieve precise drying and mixing of high-viscosity, thermos...

Vertical conical screw vacuum dryer

Achieve precise moisture control with ultra-vacuum batch drying, ideal for thermo-sensi...

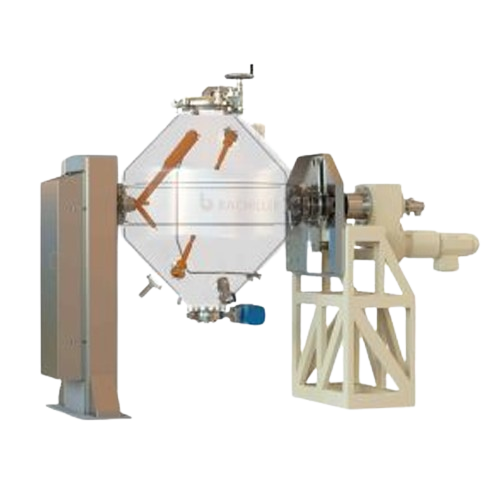

Double cone vacuum dryer for thermosensitive products

For precise drying of heat-sensitive powders, this double cone vacu...

Nutsche filter-dryer for solid-liquid separation

Ensure precise moisture control and efficient solid-liquid separation for...

Vacuum drum filter for solid/liquid separation

Optimize your solid/liquid separation process with a versatile vacuum drum ...

Vertical vacuum dryer and mixing reactor

Achieve precise control over drying and mixing processes with a versatile unit des...

Spherical mixer for industrial mixing applications

Experience precise and efficient mixing with this hollow spherical mix...

Vertical single-shaft mixer for dry, moist, and viscous materials

In industries requiring precise and thorough mixing o...

Conical mixer for dry, moist, and viscous materials

Achieve optimal mixing consistency and precision for diverse material...

Conical vacuum dryer for viscous materials

Achieve precise drying and mixing of moist and viscous materials, ensuring cons...

Continuous powder mixer for dry, moist and suspended goods

Achieve precise homogenization and deagglomeration with a con...

Ai solutions for pizza production in bakeries

Bring unparalleled precision and efficiency to your bakery with intelligent ...

Indirect drying drums for solvent-based products

Optimize energy use and safety with our indirect drying drums, ideal for ...

Vibration batch dryer for difficult solids

Ensure efficient drying of complex solids prone to sticking and shape irregular...

Flash dryer for high-moisture bulk materials

Tackle high-moisture challenges head-on with rapid drying solutions that effi...

Fluidized bed dryer for industrial materials

Enhance product quality and energy efficiency with fluidized bed dryers, opti...

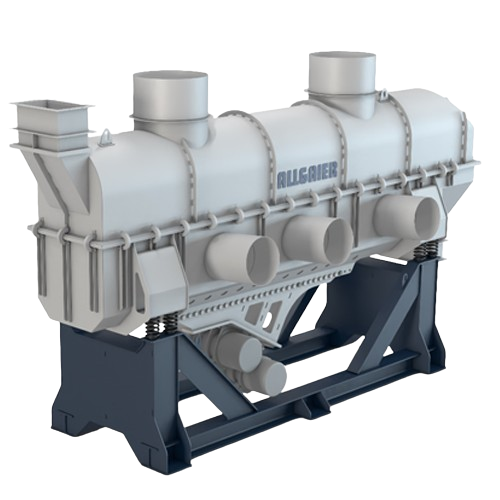

Fluidized bed dryers/coolers for bulk material processing

Achieve high-efficiency drying and cooling of bulk materials i...

Fluidized bed spray granulators for liquid to solid conversion

Transform liquid suspensions into stable, dust-free granu...

Decanter centrifuge for olive oil processing

Optimize olive oil production by achieving higher oil clarity and reduced wat...

Scraped surface evaporator for high-viscosity materials

Efficiently concentrate high-viscosity and hard-to-handle materia...

Moist granulation system for pharmaceutical and chemical industries

Transform powdered materials into uniform granules ...

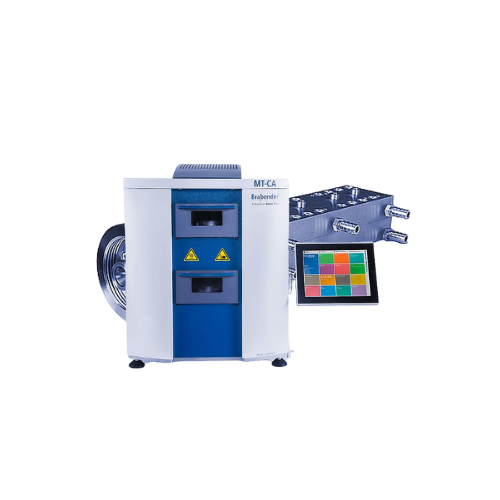

Moisture analyzer for laboratory samples

Accurate moisture analysis is crucial for ensuring product quality in pharmaceutic...

High capacity continuous puffer for popcorn

Optimize your snack production with advanced airflow and speed controls design...

Batch roaster for nut processing

Achieve precise roasting and flavor development with batch roasters that offer customizable...

Continuous nut roaster for large-scale nut processing

Streamline your nut processing capabilities with a machine designed...

Air and suction dryers for fresh salads and vegetables

Ensure longer shelf life and optimal quality for your fresh produc...

Centrifuge for drying fragile salads

Achieve consistent drying of delicate leafy greens with minimal damage, enhancing prod...

Salad processing line for fresh cut vegetables

Efficiently transform raw produce into market-ready salad mixes with stream...

Multi-purpose batch cooker for meat, fish, and vegetables

Achieve consistent cooking and uniform results for diverse foo...

Single pass dryer for fresh produce

Optimize your fresh produce processing with a continuous drying solution that enhances ...

Smart dryer system for fresh produce

Optimize your fresh produce drying process while ensuring consistent quality and effic...

Fruit and vegetable shelf life extender

Extend the freshness and appeal of your produce with our innovative dipping solutio...

Multi-stage steam jet vacuum pumps for industrial applications

Achieve precise vacuum conditions for evaporation, distil...

High pressure pumps for viscous fluid transfer

Optimize fluid transfer with high pressure pumps designed to handle viscous...

Vibrating conveyor for powder and granule handling

Effortlessly convey and process fragile products with precision, minim...

Short-cut pasta production line

Optimize your pasta production with a line engineered for efficient short-cut pasta shaping,...

Couscous production line

Enhance your couscous production with a seamlessly integrated line that ensures precise granule sizi...

Explosion protection vents for spray dryers

Optimize safety and hygiene in your spray drying operations with advanced expl...

Spray dryer for agglomerated powders

Achieve uniform, coarse, and free-flowing agglomerated powders with precise drying and...

Heat pump solution for spray dryers

Enhance your spray drying efficiency and sustainability with an innovative heat pump sy...

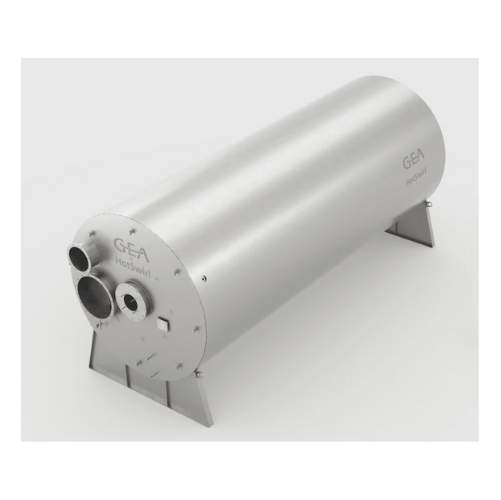

Industrial hot air system for spray dryers

Ensure consistent hot air delivery for critical drying processes, enhancing ene...

Spray dryer for nutritional and dairy powders

Achieve precise particle size and optimal drying of nutritional and dairy po...

Spray drying solution for uniform powder production

Achieve seamless transformation of liquid feeds into uniform, free-fl...

R&d spray drying solution for small batch production

Efficiently convert liquid solutions into precise, uniform powders f...

Spray dryers for ceramics and pharma products

Achieve consistent powder quality for heat-sensitive and sticky products wit...

P-type ring dryer for thermally sensitive products

Optimize moisture control and prevent thermal degradation in your prod...

Industrial ring dryer for efficient particle processing

Control particle size and drying efficiency with precise recircul...

Industrial rotary dryer for high moisture content materials

Achieve consistent drying performance with industrial rotary...

Spray dryer for whey and milk powders

Optimize your drying process for dense, agglomerated whey and milk powders with a spa...

Conventional spray drying for chemical industry

Achieve optimal particle size uniformity in food powders with precision at...

Wet grinding system for coffee flavor preservation

Achieve unparalleled coffee flavor and aroma by integrating a low-temp...

Flash dryer for industrial moisture removal

Optimize your production with rapid moisture removal, efficiently transforming...

Swirl fluidizer for drying pastes and slurries

Optimize your production line with an efficient drying solution for homogen...

Static fluid bed dryer for powder and granular materials

Achieve optimal moisture control in powder and granular products...

Vibrating fluid bed for final stage powder drying

Enhance powder processing precision with a vibrating fluid bed that ens...

Pilot plant freeze dryer for sensitive products

Achieve precise moisture control and nutrient preservation in food and pha...

Coated lollipop production line

Transform your confectionery line with a solution that forms, cools, and coats 3D lollipops ...

Decanter centrifuge for chemical and mineral processing

Optimize dewatering and clarification efficiencies in your proces...

Chemical and mineral processing centrifuge

Optimize your chemical and mineral extraction processes with this high-performa...

Industrial citrus fruit selection, washing, drying, and calibration line

Enhance your fruit processing efficiency with ...

Laboratory freeze dryer for small batch processing

Ensure precise moisture control and stability in sensitive samples wit...

Autoclaves for laboratory and production with square chamber

Optimize your laboratory space with compact autoclaves that...

Single-chamber freeze dryer for liquid products

When precision drying of sensitive liquids is crucial, this single-chamber...

Plastic processing systems for high plant availability

Achieve unparalleled throughput and efficiency in your production ...

Pneumatic mixer for fluidizable bulk materials

Achieve uniform and gentle mixing of powdered ingredients with minimal effo...

Advanced degassing and temperature control solution for process silos

Optimize your production line with precise contro...

Efficient ribbon mixers for precise powder blending

Achieve consistent and uniform blending with this advanced U-Trough m...

Double cone mixer for free-flowing material blending

Optimize your production with precision blending and gentle drying o...

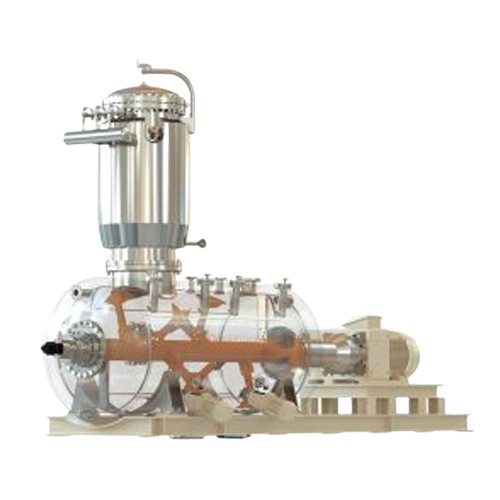

High capacity horizontal dryers and coolers for industrial applications

Achieve consistent moisture levels and uniformi...

Sanitary dryers for textured vegetable proteins

Optimize drying and sanitation for textured vegetable proteins and pet foo...

High-sme extruder for structured meat analogs

Enhance production versatility with precise extrusion control, accommodating...

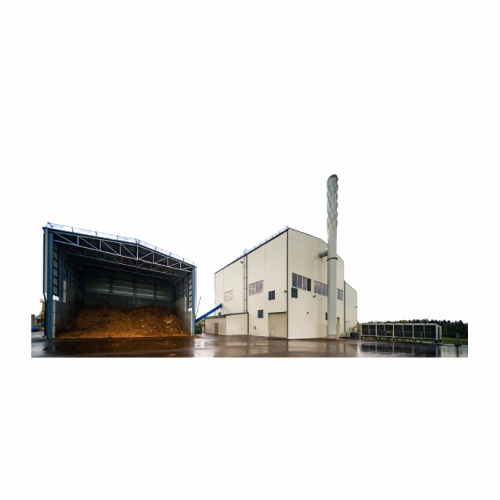

Drying systems for bioethanol production

Optimize your bioethanol production with advanced evaporation and drying equipment...

Spray drying system for heat sensitive products

For heat-sensitive products requiring precision drying, this spray drying ...

Wet spent grains pre-dewatering system

Optimize your brewery operations with a dewatering system that efficiently reduces m...

Wheat processing systems for industrial applications

Maximize efficiency in wheat processing with a system designed for p...

Drying and smoking solution for meat, fish, and cheese

Optimize your production with precise climate control, ensuring co...

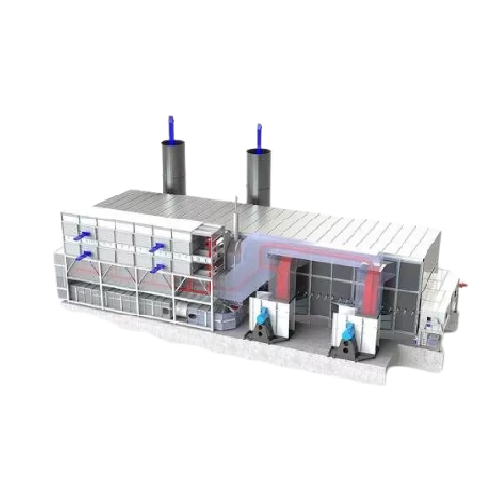

High-capacity industrial smoking and drying system

Maximize your production volume without expanding your facility footpr...

Friction smoke generator for hot smoking and climatic maturing

Optimize your production with a friction smoke generator ...

Closed glow smoke generator for hot smoking installations

Enhance your smoking process with efficient energy use and sea...

Glowing smoke generator for hot smoking installations

Enhance your production line with dense, aromatic smoke that ensure...

Thermal processing system for various meat products

Optimize your thermal processing with a versatile system that ensures...

Advanced processing unit for meat and fish products

Transition seamlessly from hot to cold processing with a system that ...

Horizontal air flow drying and smoking system for meat products

Achieve superior drying and smoking efficiency with hori...

Air-conditioned storage chambers for post-curing

Ensure consistent product quality with precise humidity control, essentia...

Brushing systems for agricultural produce

Enhance the precision and efficiency of fruit and vegetable processing with vers...

Water polisher for rice refinement

Enhance rice quality and shelf life by efficiently removing bran residues, minimizing ox...

Turnkey potato flake processing line

Effortlessly transform raw potatoes into high-quality flakes with this integrated line...

Industrial potato washing line

Optimize your potato processing with a versatile washing line that ensures thorough cleaning,...

French fry production line

Optimize your French fry production with a seamless line that ensures precise cutting, consistent...

Ultra-pure water preparation system for pharmaceutical industry

Ensure your pharmaceutical production line meets stringe...

Sanitary vessels for pharmaceutical applications

Ensuring the highest standards of aseptic processing, these sanitary vess...

Automatic case packer for pharmaceutical industry

Optimize your packaging process with a versatile case packer designed t...

Multifruit processing line for wholemeal pulps and juices

Optimize your fruit processing capabilities with a skid-based ...

Centrifugal vegetable dryer for leafy and heavy vegetables

Efficiently remove excess water from leafy and heavy vegetabl...

Lab scale roller compactor for dry granulation

Achieve seamless scale-up from lab development to full-scale production wit...

Bag tipping unit for Cip processes in powder handling

Ensure seamless powder handling and high hygiene standards in your ...

Versatile spray dryer for dairy and plant-based powders

Achieve precise moisture control and optimal powder functionality...

Permeate powder spray dryer

Optimize permeate powder production with continuous spray drying, ensuring premium, non-caking o...

Air jet cleaning system for powder production

Eliminate water and chemical use while maximizing production efficiency with...

Spray dryer for dairy, whey, and plant-based powders

Achieve precise control over powder attributes with our versatile sp...

Continuous spray dryer for permeate powder

Efficiently transform liquid whey and milk into high-quality, non-caking, and n...

Belt dryers for gelatin processing

Efficiently transform liquid gelatin into high-quality solids with precise moisture cont...

Continuous fluid bed dryers for various industrial applications

Achieve precise moisture control with fluid bed dryers, ...

Continuous fluid bed dryer for powder and granules

Enhance your production line with precise moisture control and energy ...

Vibrating fluid bed dryer for bulk materials

Ensure efficient moisture removal and thermal processing with this fluid bed ...

Ventilation and dehumidification for meat processing plants

Achieve precise humidity and condensation control in meat pr...

Freeze dryer for small batch scale-up in biotech and pharma

Optimize freeze-drying processes for small batches or high-v...

Research and scale-up freeze dryer for biological and pharmaceutical applications

Allows efficient scale-up of lyophi...

Basic research freeze dryer for biomedical applications

For laboratories seeking precise sample preservation, this bencht...

Automated cleaning in place system for bakery production lines

Ensure unmatched hygiene and operational efficiency in fo...

Vegetable salad production line for lettuce processing

Streamline your vegetable processing with an all-in-one solution d...

Integrated vegetable washing drying grading line

Effortlessly transform large volumes of freshly harvested produce into ma...

Industrial strawberry and blueberry washer

Ensure your soft fruits remain intact and impurity-free with this specialized w...

Industrial sausage smoking oven with easy operation

Streamline your meat processing with an advanced sausage smoking oven...

Peanut roaster for various nuts

Elevate your nut processing with efficient roasting solutions that enhance flavor, texture, ...

Automatic noodle maker for diverse noodle shapes

Streamline your noodle production with a machine that crafts a variety of...

Industrial onion peeling solution

Optimize your onion processing with precision peeling and cutting, reducing waste and enh...

Jujube pitting and nut removing solution

Streamline your fruit processing with this efficient solution designed to remove p...

Commercial mango dehydrator

Optimize your fruit processing with a commercial mango dehydrator that ensures precise moisture ...

Garlic splitting and peeling line

Streamline garlic processing with this high-speed line designed to efficiently split, pee...

Ginger powder processing line

Optimize your spice production with comprehensive ginger powder processing, transforming fresh...

Bubble type fruit and vegetable washer

Ensure your produce is impeccably clean and damage-free with our bubble-type washing...

Complete fruit and vegetable washing plant

Optimize your production line with efficient fruit and vegetable washing, ensur...

Automatic egg washing machine for chicken and duck eggs

Ensure hygiene and extend shelf life with this advanced egg washi...

Fruit and vegetable drying equipment

Achieve optimal moisture control for your fruits, vegetables, and herbs with versatile...

Date palm processing line for jujube cleaning and drying

Optimize your date and fruit production with our line that ensur...

Chili pepper washing line for industrial processing

Efficiently streamline your pepper processing with a continuous washi...

Boba tapioca pearl maker for bubble tea

Optimize your bubble tea production with precise control over tapioca pearl formati...

Small scale cashew nut processing plant

Optimize your nut processing with our comprehensive cashew line, designed to stream...

Air dryer for vegetables and fruits processing

Enhance your processing line with efficient moisture removal—perfect for ma...

Vegetable and fruit air drying production line

Efficiently dry fruits, vegetables, and vacuum-packed goods while maintaini...

Stationary drying system for agricultural products

Optimize moisture control and energy efficiency in your drying process...

Industrial-scale vacuum packing for fresh meat and cheese

Optimize packaging operations with this machine designed for h...

Industrial air heater for agriculture and industry

Optimize energy efficiency and maintain high air quality in your produ...

Belt dryer for timber industry

Optimize moisture removal and ensure consistent drying in your production line with advanced ...

Belt dryer for sawdust

Optimize your drying process with advanced technology engineered for precise moisture reduction in div...

Low-emission belt dryer for timber industry

Achieve maximum drying efficiency and significant energy savings in your proce...

Hybrid dryer for agriculture and industrial applications

Achieve efficient moisture reduction in varied materials, from f...

Automatic belt chamber vacuum packing for meat and cheese

Achieve seamless integration into your packaging line with a m...

Stainless steel drying tunnel for packaging lines

Optimize your packaging line efficiency by ensuring products are thorou...

Wet granulation system for pharmaceutical tablets

Optimize your tablet production with precise particle size reduction an...

Fluid bed dryer for wet granulation in pharmaceutical industry

Streamline your production with fast, uniform drying and ...

Wet granulation co mill for pharmaceutical formulations

Optimize your manufacturing process with precise particle size re...

Small scale spray dryer for r&d and production

For precise moisture removal in small batches, this flexible spray drying s...

Small scale spin flash dryers for high-viscosity liquids

Optimize moisture control with cutting-edge spin flash dryers de...

Spray bed dryer for agglomerated powder production

Efficiently transform liquid feedstock into consistent, dust-free powd...

Centrifugal atomizer for precise spray drying

Achieve precise control over particle size and moisture content with centrif...

Industrial fluid bed dryers for powder processing

Enhance moisture control and uniformity in powder products with dynamic...

Dewatering screens for industrial applications

Efficiently transforming wet material into dry, manageable outputs, these d...

Industrial smoking chamber for meat processing

Achieve consistent, high-quality smoking for diverse foods with this chambe...

Smoking chamber for meat processing

Enhance your food products’ flavor profile with precise smoking, coloring, and dr...

Combination chamber for meat processing

Optimize your food production with a multi-process chamber designed to seamlessly i...

Combination chamber for smoking, cooking, and baking

Optimize your food processing with a versatile chamber that efficien...

Benchtop evaporator for parallel chemistry and environmental testing

Enhance lab efficiency with a compact evaporator t...

Centrifuge for drying leafy vegetables

Efficiently dry delicate leafy vegetables without product damage, ensuring optimal m...

Centrifuge for drying delicate salad leaves and vegetables

Achieve precise moisture control for fresh salad leaves and d...

Drying conveyor for hard vegetables

Ensure optimal drying of hard vegetables with a seamless integration of air blowing sta...

Centrifuge for removing water from leafy vegetables

Eliminate excess water from leafy vegetables efficiently, ensuring op...

Air drying solution for leafy vegetables

Achieve optimal moisture reduction with precision air drying, ideal for maintainin...

Efficient grinding and drying mill

Transform your production line with a versatile mill that simultaneously grinds, dries, ...

Industrial plow mixer for efficient solid and liquid mixing

Experience unparalleled mixing precision with high-speed plo...

Infrared moisture analyzer for lab and production use

Achieve precise and reliable moisture analysis with minimal time an...

High-speed moisture analyzer for liquid and pasty samples

Ensure precise moisture analysis with rapid microwave drying, ...

High-accuracy moisture analyzer for lab weighing

Achieve precise and reproducible moisture content determination for diver...

Continuous hot air conveying dryer for chemical and pharmaceutical industries

Ensure rapid moisture removal with high-...

Continuous spray dryer for thermosensitive products

Ideal for processing thermosensitive slurries, this spray dryer ensur...

Semi-continuous freeze dryer with easy-loading

Freeze-drying is both a time- and energy-consuming process. In addition to ...

Energy efficient steam dryer for feed products

Traditional drying technologies with low investment cost, such as hot air d...

Vacuum belt dryer for fruit, vegetable and herbal extracts

Organic volatile compounds from fruits, vegetables and herbs ...

Industrial heat pump dryer

The drying of extruded products is highly energy-demanding in traditional belt dryers that use ga...

Washing cabinet for trolleys

Food manufacturing facilities, bakeries, or restaurants are ridden with efficiency-related issu...

Milling and drying machine for fine powders

When you need to produce ultra-fine powders, the milling and drying process em...

Flash drying grinder for powders

Drying and grinding can be an important feature when trying to process products such as raw...

Industrial freeze-dryer for fruits

Freeze-drying is a complex and delicate process. If you are searching the market for a f...

Pilot scale freeze dryer

Freeze drying is a complex and time-consuming drying process which requires maintaining the quality ...

Automatic freeze drying system

Freeze drying can be an expensive and cumbersome process. When dealing with nutraceuticals it...

Air knife system for bottling lines

Wet containers are unacceptable and can be problematic in the food and beverage industr...

Recirculating batch dryer

Drying can be the most energy and time-consuming process in the food industry. This can have an ef...

Continuous dryer machine

Traditional drying methods in the pet food, aquafeed, and extruded food industry can be the most ene...

Industrial dehydration machine

Dried fruits are popular both as food in themselves and as ingredients. Traditional drying te...

Laboratory scale active freeze dryer

The laboratory-scale active freeze-drying is used for dehydrating high-value products ...

Air knife drying system for containers

In food or beverage production where a product is filled into jars, there is often r...

Air knife dryer for pouches

Flexible pouch packaging is a popular choice for many consumer food products. Before final print...

Mobile air knife dryer for tanks

Sanitizing and cleaning of large vessels such as storage tanks or blenders is a vital stage...

Air rinsing system for containers

Traditional water rinsing solutions for containers used in the food and pharmaceutical se...

Shell and tube heat exchanger

Heating, cooling and tempering are important processes in the production of many products acro...

Continuous vacuum belt dryer

For gently drying liquid concentrates into granulates or powders, a vacuum drying solution is t...

Continuous belt freeze dryer

Freeze drying is the most gentle and aroma protective method of drying, widely used in the coff...

Horizontal paddle vacuum dryer

Agitated vacuum dryers can be difficult to clean which makes them unsuitable for multi-produc...

Dehumidifier for difficult wet airflows

Sealed rooms can be challenging to dehumidify with ordinary dehumidifiers. The wet ...

Large scale desiccant dehumidifier

Moisture sensitive processing and storage facilities need low humidity environments to s...

Customizable dehumidifier

Dehumidification needs can vary significantly from one project to another. Dehumidifiers with a fi...

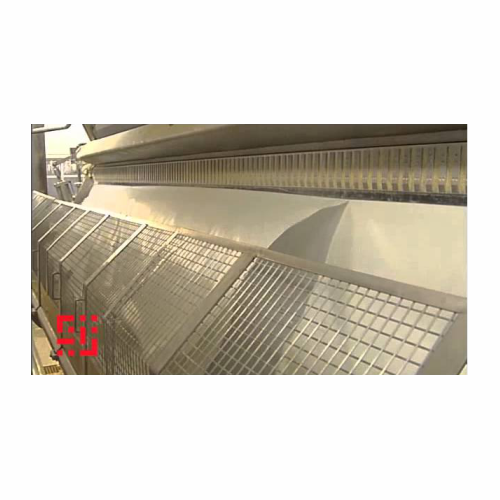

Hygienic belt dryer

A belt dryer typically applies the product through an infeed chamber onto a perforated horizontal belt, w...

Drum mills for fine grinding of large volumes

Achieve consistent and precise pulverization of large sample volumes with dr...

Ultrafine grinding solution for nanoparticles

Achieve ultrafine particle sizes with high-speed precision, ideal for labora...

Convection oven with integrated dryer for large scale baking

Optimize your baking process with a convection oven that ef...

Agitated nutsche filter dryers for chemical synthesis

Enhance your production efficiency by integrating a system that com...

Soya protein isolate production line

Ensure the highest protein purity with this comprehensive production line designed to ...

Pilot scale spray dryer for product development

Achieve precise moisture levels and product consistency in development env...

Small-scale scraped surface heat exchanger for high-viscosity products

For R&D teams tackling complex formulations...

Uht/htst aseptic processor for pilot plants

Achieve precise heat treatment and aseptic processing with flexible pilot syst...

Ploughshare mixer for batch operation

Achieve superior mixing quality with a system designed for rapid batch operations. Ex...

Continuous ploughshare mixer for diverse industrial applications

Enhance mixing efficiency and achieve precise particle ...

Vacuum paddle dryer for chemical and pharmaceutical applications

Achieve precise moisture control and efficient drying i...

Vacuum paddle dryer for laboratory use

Achieve precise temperature and moisture control in your batches with this vacuum sh...

Batch mixer for powdery, granular, and fibrous materials

Achieve precise consistency and high batch reproducibility in yo...

Lactose drying system for high-quality edible powder

Achieve precise and cost-effective lactose transformation into high-...

Industrial potato flake production line

Maximize yield and quality in potato processing by integrating advanced pre-cleanin...

Containment solutions for hazardous material processing

Ensure safe and efficient processing of hazardous materials with ...

Conical screw mixer for powder blending

Achieve precise and homogeneous blending with the conical screw mixer, ensuring uni...

Ultra-fine powder flash drying system

Achieve rapid moisture removal and particle refinement with this integrated system, d...

Vertical vacuum dryer for heat sensitive products

Achieve optimal drying and mixing for your heat-sensitive and shear-sen...

Filter dryer with containment system for hazardous materials

Ensure operator safety and product integrity during hazardo...

Pharmaceutical filter dryer

Achieve precise moisture control and efficient drying of sensitive materials with this advanced ...

Horizontal vacuum paddle dryer for sensitive pharmaceutical ingredients

Achieve precise drying and mixing of sensitive ...

Vertical pilot plant centrifuge for pharmaceutical applications

Ensure precise separation and optimal scaling in your la...

Laboratory system for drying and mixing processes

Enhance your R&D capabilities with precise drying and mixing contr...

Inverting filter centrifuge for high-potent Api products

Achieve optimal separation and reduce residual moisture with pre...

Pharmaceutical horizontal peeler centrifuge

Optimize product consistency and purity with precise separation and filtration...

Cocoa sterilizing and alkalizing plant

Optimize cocoa product quality with a system engineered for precise sterilizing, alk...

Wurster coating system for fine powders and pellets

Achieve precision coating for multiparticulate cores and mini-tablets...

Tablet coater for precision pan coating

Achieve precise coating control for pharmaceuticals and nutraceuticals, accommodati...

Pilot High shear granulator for wet granulation

Achieve consistent particle sizing and superior homogeneity in your powder...

Fluid bed granulator for industrial granulation

Optimize your production efficiency with versatile fluid bed granulation, ...

Precision feedstocks for biomass energy production

Optimize your biomass conversion with precision-sized feedstocks desig...

Laboratory mixer and dryer for solids

Enhance your laboratory capabilities with precision mixing and drying for small batch...

Vacuum dryer for free-flowing and pasty solids

Achieve precise drying and mixing with this vacuum dryer, optimizing heat t...

Roll support dryers for web transportation

Eliminate web curl issues and enhance drying precision for diverse materials wi...

Laboratory granulator and coating system

Optimize your research with a versatile benchtop unit that combines fluid-bed proc...

Single-pot processor for wet granulation and vacuum drying

Achieve efficient mixing, granulation, and swift vacuum dryin...

Processing plants for instant coffee production

Achieve optimal flavor retention and cost efficiency in instant coffee pro...

Chemical-physical treatment plants for water treatment

Optimize your water and wastewater treatment processes with system...

Grape sorting and washing lines

Optimize grape processing with efficient sorting and washing lines that streamline the prepa...

Industrial ring dryers for high-capacity drying applications

Maximize drying efficiency for diverse materials with ring ...

Flash dryer for surface moisture removal in powders

Optimize moisture removal in heat-sensitive materials with rapid, uni...

Oil and fat refining system

Ensure high-quality oil and fat production by efficiently removing contaminants such as phosphat...

Industrial oil bleaching process

Optimize your oil purification process with advanced bleaching technology, significantly en...

Percolation extractor for high-volume vegetable protein extraction

Optimize extraction efficiency across diverse materi...

Efficient dryer-cooler for solvent-extracted meals

Optimize moisture control and energy efficiency in your production lin...

Renewable diesel pretreatment system

Extend hydrotreater catalyst life and boost plant uptime by optimizing feedstock purit...

Dryer-cooler for solvent-extracted meal

Achieve optimal moisture and temperature control for solvent-extracted vegetable-oi...

Flash desolventization system for oilseed processing

Achieve rapid desolventization with minimal heat exposure, preservin...

Heavy-duty horizontal dryer/cooler for pellets and meal

Optimize your production line with continuous high-speed drying a...

Chocolate mould washer

Ensure immaculate cleanliness and precise drying of chocolate moulds, enhancing production efficiency ...

Scraped surface heat exchangers for gelatine processing

Effortlessly manage the cooling, gelling, and extrusion of gelati...

Leaf vegetable sorting and cooling system

Ensure optimal freshness and extended shelf life for leaf vegetables with precis...

Granola drying solution

Optimize your granola production with modular drying technology that ensures precise moisture control...

High temperature industrial oven for advanced heating processes

Achieve precise heat treatment for critical components, ...

Continuous-flow dryer for grain and oilseeds

Streamline your grain and oilseed processes with efficient moisture eliminati...

Rotary evaporation for laboratory applications

Achieve precise evaporation and concentration with modular, high-speed rota...

Laboratory freeze dryer for continuous sublimation

Achieve seamless continuous freeze drying with stable, reproducible pa...

Moisture analyzer for flour and tobacco

Optimize your moisture measurement process with precision and speed, ensuring quali...

Pressure drum filter for fine-grained products

Achieve exceptional precision in fine particles processing with this pressu...

Agitated nutsche filter for solid-liquid separation

Ensure high-purity solid-liquid separation with minimized contaminati...

Agitated nutsche filter dryer for solid-liquid separation

Achieve high-purity solid-liquid separation with optimized thr...

Automatable benchtop agitated nutsche filter-dryer

Effortlessly integrate seamless solid-liquid separation into your labo...

Soft gel encapsulation system

Efficiently produce high-quality soft gel capsules with precision encapsulation, rapid drying,...

Benchtop freeze dryer for laboratory and small production use

Optimize your lab’s efficiency by adding precise, space-sa...

Centrifugal evaporator for medicinal chemistry

Achieve precise evaporation and crystallization with innovative anti-bumpin...

Paddle dryer for industrial sludge

Achieve consistent drying and pasteurization of complex materials with this advanced pad...

Soft bread production system

Optimize your bakery operations by integrating a high-speed system for producing a wide variety...

Industrial drum dryer for bulk solids

Optimize your production line with high-throughput drying for varied particle sizes, ...

Hot air dryers for non-hygroscopic material

Ensure reliable material quality by effectively reducing moisture in non-hygro...

Centrifuge for drying fresh-cut vegetables

Enhance your production line with reliable surface water removal from fresh pro...

Bird tumbler for water removal in poultry processing

Optimize your poultry processing line with advanced water removal te...

Heavy metal removal system for industrial flue gas

Effectively remove harmful heavy metals from industrial emissions whil...

Spray drying solution for heat-sensitive products

Optimize the drying of heat-sensitive and challenging materials into hi...

Lab-scale spray dryer for small volume powder samples

When developing new formulations, achieving consistent powder quali...

Industrial fruit washing and loading hopper system

Streamline your juice production by ensuring optimal fruit preparation...

Freeze drying systems for pharmaceutical production

Optimize your production line with advanced freeze drying systems des...

Laboratory vacuum drying system

Achieve precise moisture removal and maintain product integrity with advanced vacuum drying,...

Industrial long moulder for high-capacity dough processing

Optimize your bakery production with a high-speed moulder tha...

Industrial sigma mixer extruder for homogeneous mixing and extrusion

Achieve precise mixing and seamless extrusion of d...

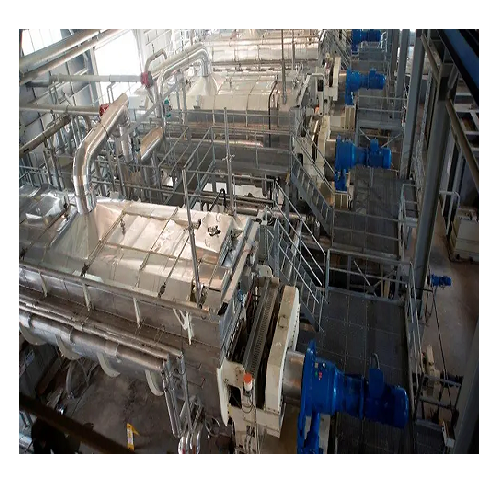

Corn wet milling plant drying systems

Optimize corn processing efficiency with integrated drying and dewatering systems des...

Flash dryer for corn starch

Reduce energy consumption and maintain product quality with efficient drying solutions designed ...

Steam heated tube bundle dryer

Efficiently achieve precise moisture control and gentle drying for diverse feedstocks with th...

Advanced drying system for salami sticks

Achieve rapid drying and smoking of small-caliber products with up to 80% moisture...

Air-conditioning curing for raw sausage production

Enhance your meat processing line with precise climate management for ...

Cross-flow smoking and fermentation system for raw sausage

Enhance yield and ensure consistent quality in sausage and fi...

Avocado sorting and processing systems

Ensure consistent quality and maximize yield in your avocado production with precisi...

Mandarin and clementine processing sorting and grading system

Optimize your citrus operations with advanced processing s...

Pharmaceutical ultra pure water distribution system

Ensure stringent purity standards with a modular water distribution s...

Roller compaction for dry granulation in pharmaceuticals

Ensure consistent granule size and density in your product line ...

Spray dryer for heat-sensitive powders

Ensure high-quality drying of heat-sensitive powders, producing non-caking and non-h...

Spray drying system for nutritional powders

Enhance production efficiency and product quality with a versatile spray dryin...

Belt dryer for large-scale continuous drying

Achieve precise moisture control and energy-efficient processing with this be...

Continuous bulk fluid bed dryer

Achieve rapid and energy-efficient moisture removal across diverse materials with our advanc...

Basic research laboratory freeze dryer

Achieve unparalleled precision in lyophilization with a compact solution tailored fo...

Industrial smoking chamber for smoked meat and fish products

Achieve consistent smoky flavors and enhanced textures in y...

Drying and cooling classifier for plastic pellets

This solution enhances efficiency by combining drying, cooling, and cla...

Slat conveyor dryer for industrial drying processes

Optimize your drying process with a robust slat conveyor system that ...

Stationary grain dryer with exhaust air system

Optimize your drying process with a system designed to handle diverse mater...

Continuous drying for cohesive and non-cohesive pastes

Transform high-viscosity liquids and pastes into fine, flowable po...

Tall form dryer for producing large non-agglomerated particles

Achieve precise particle size control and optimal moistur...

Spray dryers for producing free-flowing dustless powders

Achieve consistent product quality with customizable spray dryer...

Centrifugal evaporators for medicinal chemistry

Streamline your solvent evaporation and drying processes with this solutio...

Pneumatic drying system for industrial slurries

Efficiently transform high-moisture slurries into dry solids in a single p...

Industrial vacuum batch dryer for reducing moisture content

Achieve precise moisture control with a solution that handle...

Mechanical air separator for uniform fineness

Achieve precise material separation and de-dusting with our air separator, e...

Start-up production line for CBD gummy production

High-value products like CBD gummies demand precision equipment such as...

Lab scale production line for nutraceutical gummy production

By gradually investing in the individual parts, a productio...

Entry-level conditioning system for drying nutraceutical gummies

The drying process demands specific environmental condi...

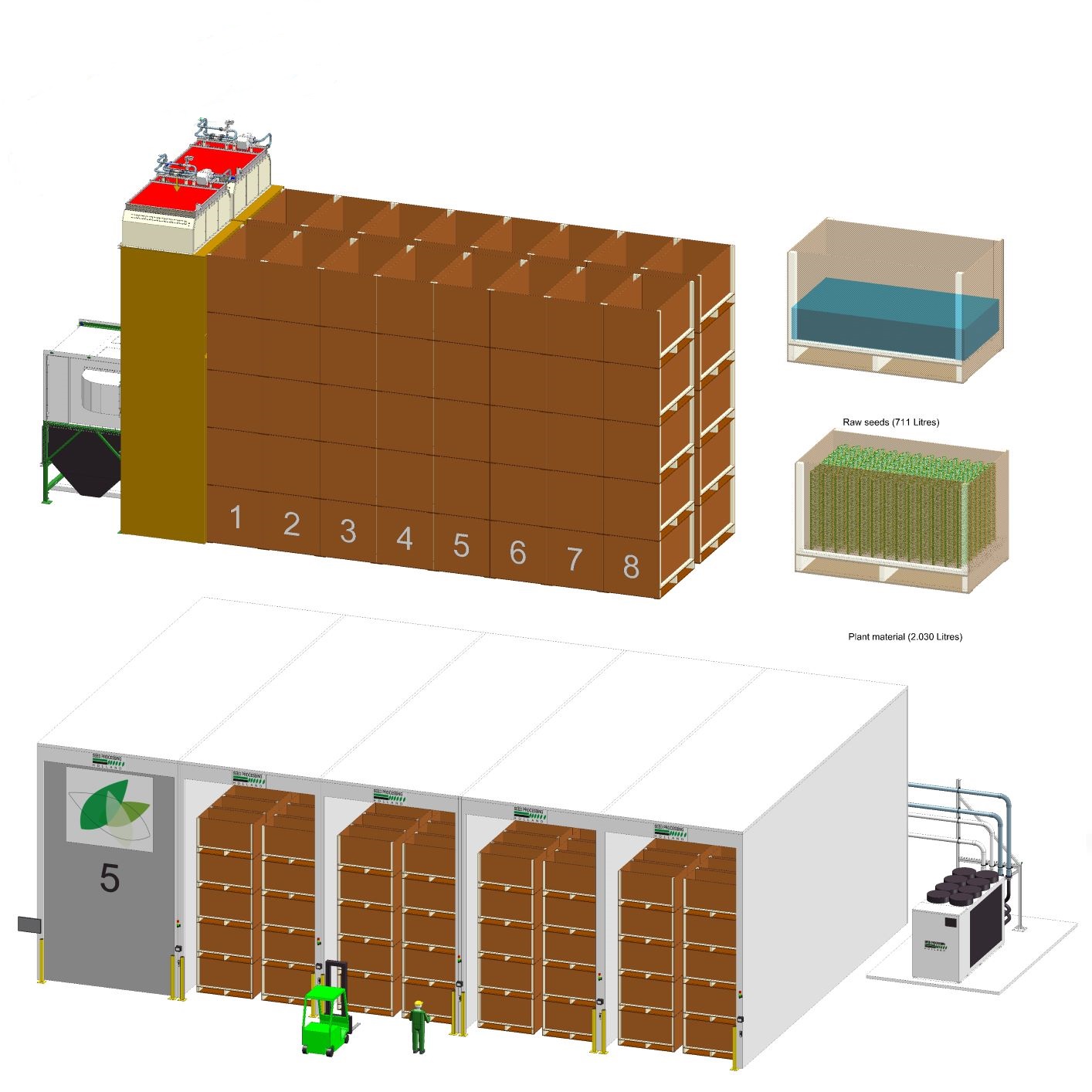

Rotary Seed Dryer Coater

Large-volume vegetable and field crop seeds manufacturers may prefer a fully automated coating and d...

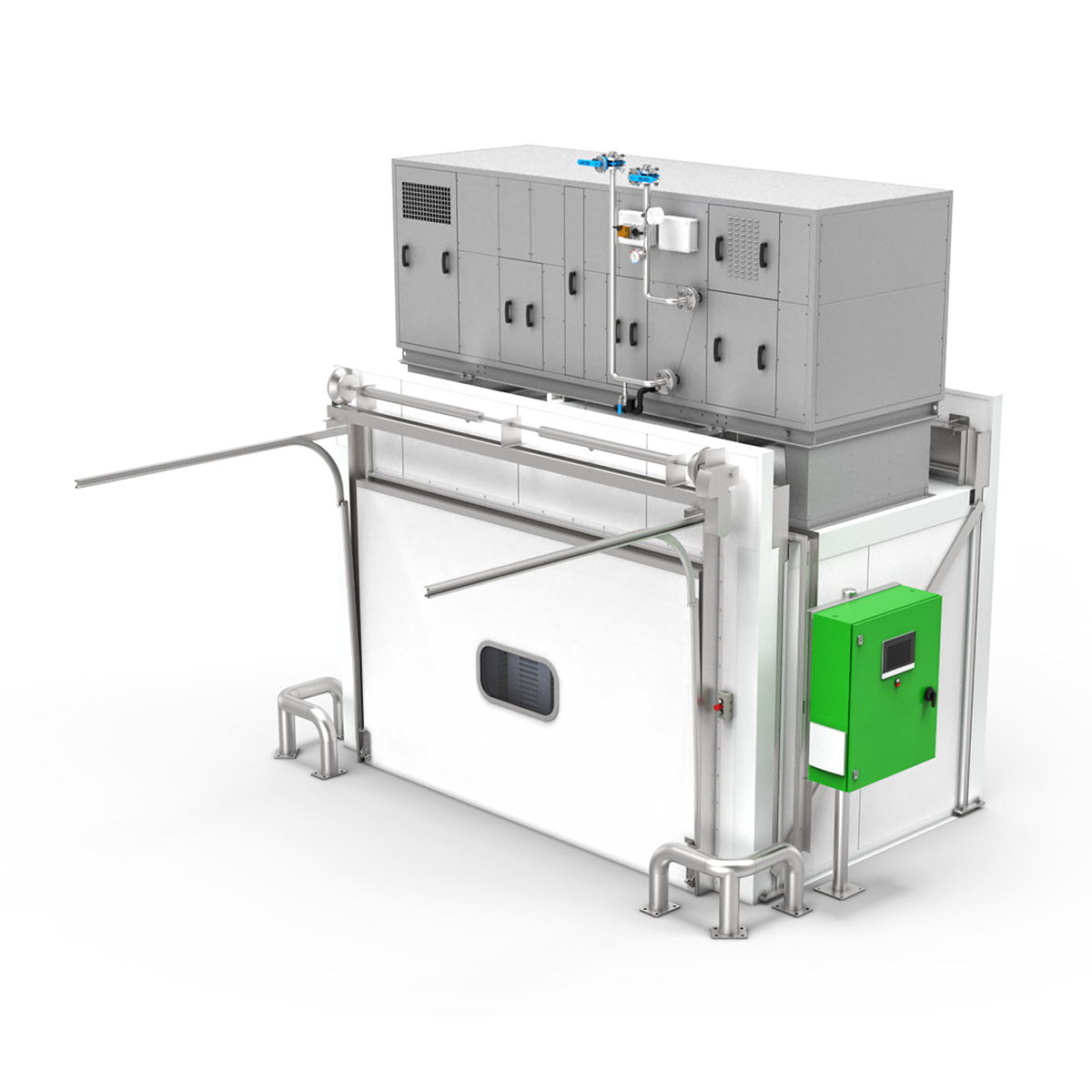

Conditioned Box Dryer

Seeds that are harvested are dried as part of their initial process of cleaning. Having huge quantities...

Freeze drying system for berries and fruit powders

Delicate fruits with high moisture levels, such as berries, risk losin...

Mass flow air knife drying system for cans

For large-scale production of canned beverages, line throughput and efficiency ...

Conditioned seed drying machine

It’s essential to dry moist seeds before you process and store them. Seeds with too high or ...

Cabinet dryer for cannabis

If you need careful drying for products like pharmaceutical-grade cannabis buds then traditional ...

Industrial Nut Roaster

Moisture considerably depletes the shelf life of nut products. At the same time, however, manufacturer...

Seed Coating Machine With Integrated Dryer

Seed coating, also known as seed dressing, refers to the covering of seeds with...

Continuous cocoa bean roasting line

When you are processing chocolate, after the conditioning and fermenting of cocoa, the ...

Vacuum belt dryer for instant drink powders

Extracting the essential acids and compounds from fruits and plants is a compl...

Industrial drying cabinet

The production of high-quality biltong and similar dried meat products can pose problems with main...

Industrial belt dryer for fruits and vegetables

The industrial belt dryer by Pigo is a simple yet super effective fruit an...

Infrared rotating drum dryer

Traditional drying methods are often slow and can actively damage ingredients, reducing the fin...

Code printer for cans with integrated drying system

Printing date and batch code information on canned consumer items req...

Air knife dryer for bottles

When filling glass bottles during beverage production, the cleaning and filling processes often ...

Blow off system for containers

Packaging powders into plastic or glass containers often leaves a residue that needs to be re...

Rinsing and drying system for containers

The filling of containers used in a range of consumer-packaged goods often leads t...

Small scale cocoa beans processing machine

For the highest quality chocolate production, complete control of the entire pr...

R&D roaster for cocoa beans

When designing a new chocolate line or experimenting with new ingredients for existing processes...

Entry-level infrared nut drying machine

For small scale production of cocoa beans and nuts, the use of traditional toasters...

Cocoa powder processing line

Cocoa beans are first fermented, dried, roasted, and separated from their skins to obtain a coc...

Continuous fluid bed dryer

In a Fluid Bed, a product or solid is made fluid by an upward moving flow of gas. The mechanical ...

Sorption dehumidifier with air-chilled condenser

It is not always possible to duct out the wet air from a dehumidifier ser...

Small portable dehumidifier

Water damaged areas require dehumidification to limit the damage and prepare the area for restor...

Sorption dehumidifier for large temperature differences

Small, humid areas can be difficult to dehumidify in humid ambien...

Sorption dehumidifier for deep drying

Humid ambient conditions such as those in tropical climates make dehumidification mor...

Heat recycling sorption dehumidifier

Facilities that handle large amounts of water can become very humid. High humidity may...

Industrial desiccant dehumidifier

Dehumidification of medium sized manufacturing and processing facilities can be a dauntin...

Air dehumidifier for bulk products

When your product or process is sensitive to humidity, using an air dehumidifier may res...

Thin film dryers

Dry dissolved or slurried crystallizing or amorphous products to a pourable powder.

Gypsum centrifuge

Especially designed for flue gas desulphurization, applications in coal fired power plants and waste incine...

Belt dryer/cooler for pellets and granules

Many industries that process materials in pellet, powder, or crumble form need ...