Multi-purpose batch cooker for meat, fish, and vegetables

Achieve consistent cooking and uniform results for diverse foods with a versatile rotary rack system, offering multiple cooking methods in one chamber for seamless integration into batch processing environments.

Processes and Cooks with Versatile Method Options

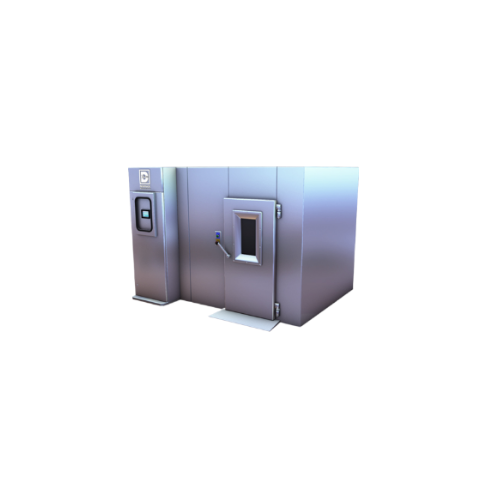

The Double D RevoRack™ Multi-Purpose Cooker from JBT is a versatile solution designed for diverse industrial kitchen applications. This rotary rack, batch-style cooking system offers the flexibility of steam, convection, and dry roasting methods within a single chamber, making it ideal for producing grilled chicken, steamed salmon, roasted turkey, baked vegetables, and cooked lasagna. The RevoRack™ features a rotating turntable and powered convection airflow distribution to maintain consistent cooking results and uniform color development, essential for high-quality end products.

Its fully programmable controls allow storage of up to 100 cooking programs, facilitating integration into existing production lines with ease. Capable of reaching up to 540°F (280°C), the RevoRack™ is suitable for both solid and liquid products. An optional Clean-in-Place (CIP) system minimizes downtime and eases maintenance by ensuring rapid and thorough cleaning. Customizable to suit varying production needs, this cooker supports sectors like meat, poultry, seafood, ready meals, and plant-based protein processing.

Benefits

- Ensures uniform cooking results with consistent airflow and rotation.

- Increases production flexibility with multi-method cooking in one chamber.

- Saves time and labor with programmable controls and recipe storage.

- Simplifies cleaning and maintenance with optional CIP system.

- Accommodates a wide range of products, supporting diverse market demands.

- Applications

- Ready meals, Meat, Vegetables, Poultry, Fish

- End products

- Grilled chicken breast, Cooked lasagna trays, Baked vegetables medley, Roasted turkey slices, Steamed salmon fillets

- Steps before

- Preparation, Marination, Injection

- Steps after

- Cooling, Freezing, Portioning, Slicing, Packing

- Input ingredients

- meat, fish, poultry, vegetables, ready meals

- Output ingredients

- cooked meat, cooked fish, cooked poultry, cooked vegetables, prepared ready meals

- Market info

- JBT is known for manufacturing innovative industrial machinery and solutions, particularly in the food processing and air transportation sectors, renowned for their advanced technology, reliability, and customer-focused engineered-to-order solutions tailored to specific industry needs.

- Cooking Method

- Steam, Steam and Elevated Temperature, Dry Roast and Bake

- Temperature Range

- Up to 540°F (280°C)

- Programmable Controls

- Yes, stores up to 100 programs

- Rotating Turntable

- Yes

- Air Distribution System

- Powered convection airflow

- Optional Cleaning

- Clean-in-Place (CIP)

- Working mechanism

- Rotary rack, batch style

- Integrated steps

- Steam, steam with elevated temperature, dry roast, bake

- CIP/SIP

- Optional Clean-in-Place (CIP)

- Automation level

- Fully programmable user friendly controls

- Batch vs. continuous operation

- Batch

- Cleaning method

- Optional CIP

- Heat resistance

- Up to 540°F (280°C)

- Steam compatibility

- Yes

- Corrosive resistance

- Stainless steel construction

- Cleanability

- Optional Clean-in-Place (CIP)

- Cooking chamber type

- Rotary rack, batch style

- Rotating turntable

- Yes

- Steam only option

- Available

- Steam and elevated temperature option

- Available