High-precision palletizing robot for industrial applications

Maximize efficiency and reduce floor space in your production line with a precision-driven solution designed for rapid, high-stacking palletizing tasks, even in extreme cold environments.

Handles and Palletizes Diverse Products Efficiently

The KR QUANTEC PA series from KUKA is a cutting-edge family of palletizing robots designed for precision and speed. These five-axis robots excel in high-speed operations, accommodating a range of applications from automotive parts and electronics to food and packaging materials. Their streamlined design includes a hollow wrist shaft, enabling compact installation and protected routing of energy supplies, translating to minimized interference and optimized floor space use.

The robots achieve minimal cycle times, maintaining constant throughput even at full payloads, and can manage stacking tasks reaching heights over 2,500 millimeters. The series supports a wide range of environments, including standard, Arctic conditions without needing a protective suit, and food-grade operations. With load capacities ranging from 120 to 240 kg and a maximum reach of 3195 mm, the KR QUANTEC PA efficiently serves industries from consumer goods to e-commerce logistics. Configurable with options such as the KR C4 or KR C5 controllers, these units are designed for seamless integration into any production line, contributing to enhanced productivity and reduced operational costs.

Benefits

- Enhances productivity by maintaining constant throughput at high speeds.

- Minimizes operational costs with space-saving, compact design.

- Ensures precision and reliability in extreme temperatures, including Arctic environments.

- Increases flexibility for diverse tasks across automotive, food, and electronics industries.

- Simplifies installation and maintenance with protected energy routing through a hollow wrist shaft.

- Applications

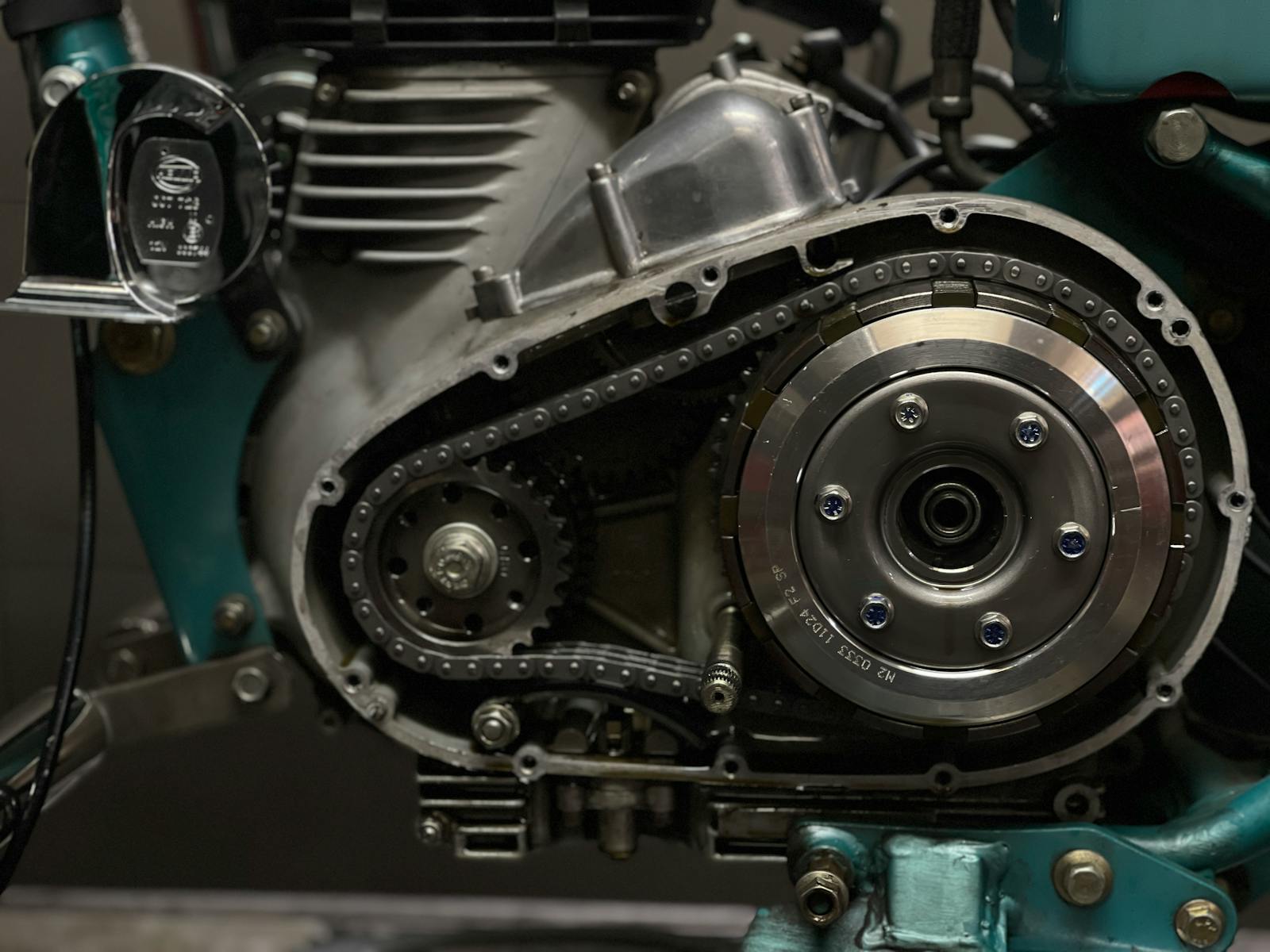

- Logistics and distribution, Frozen goods, Battery production, Automotive components, Consumer goods, Food and beverages, Packaging materials, Electronics, Metal products

- End products

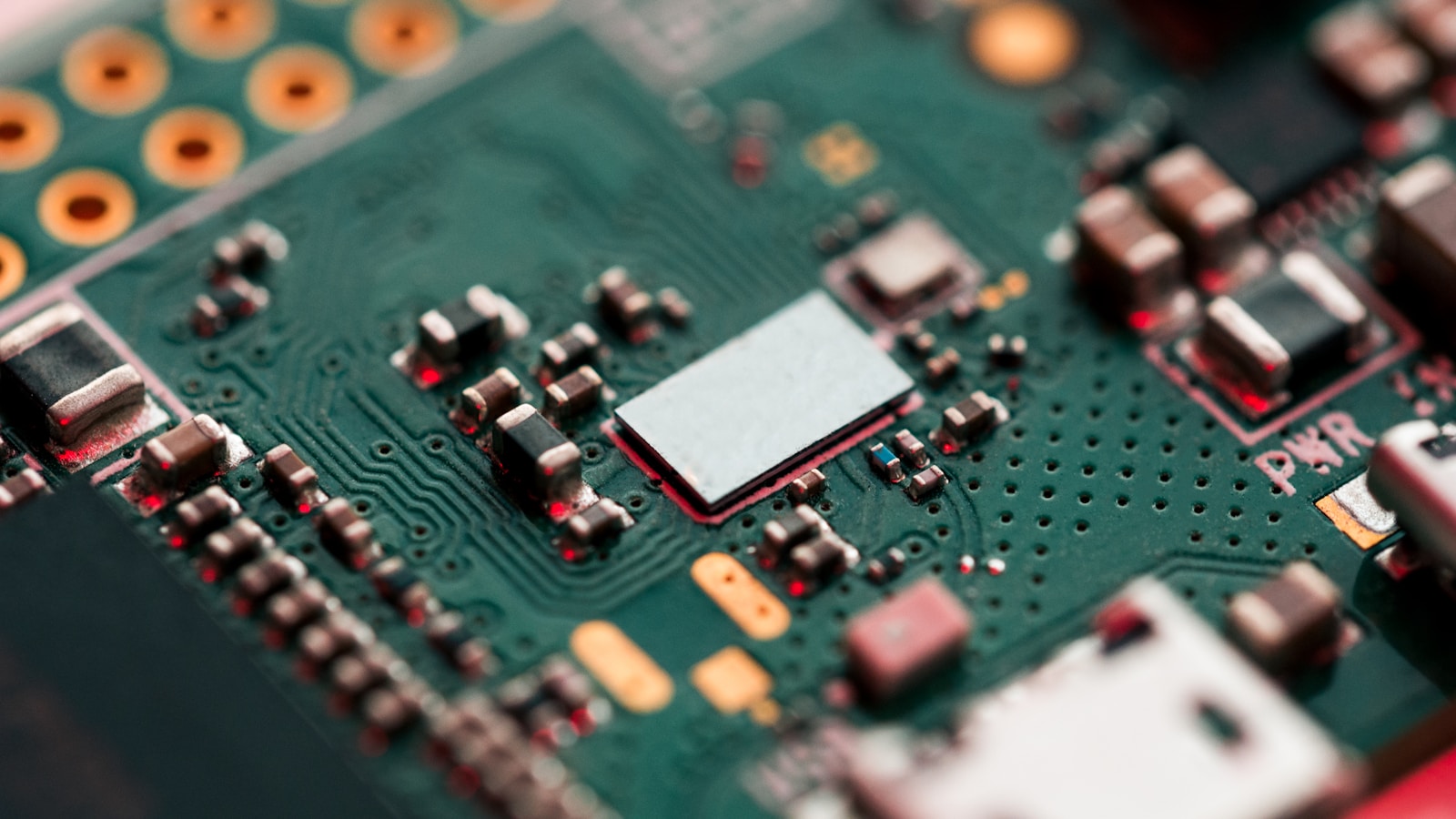

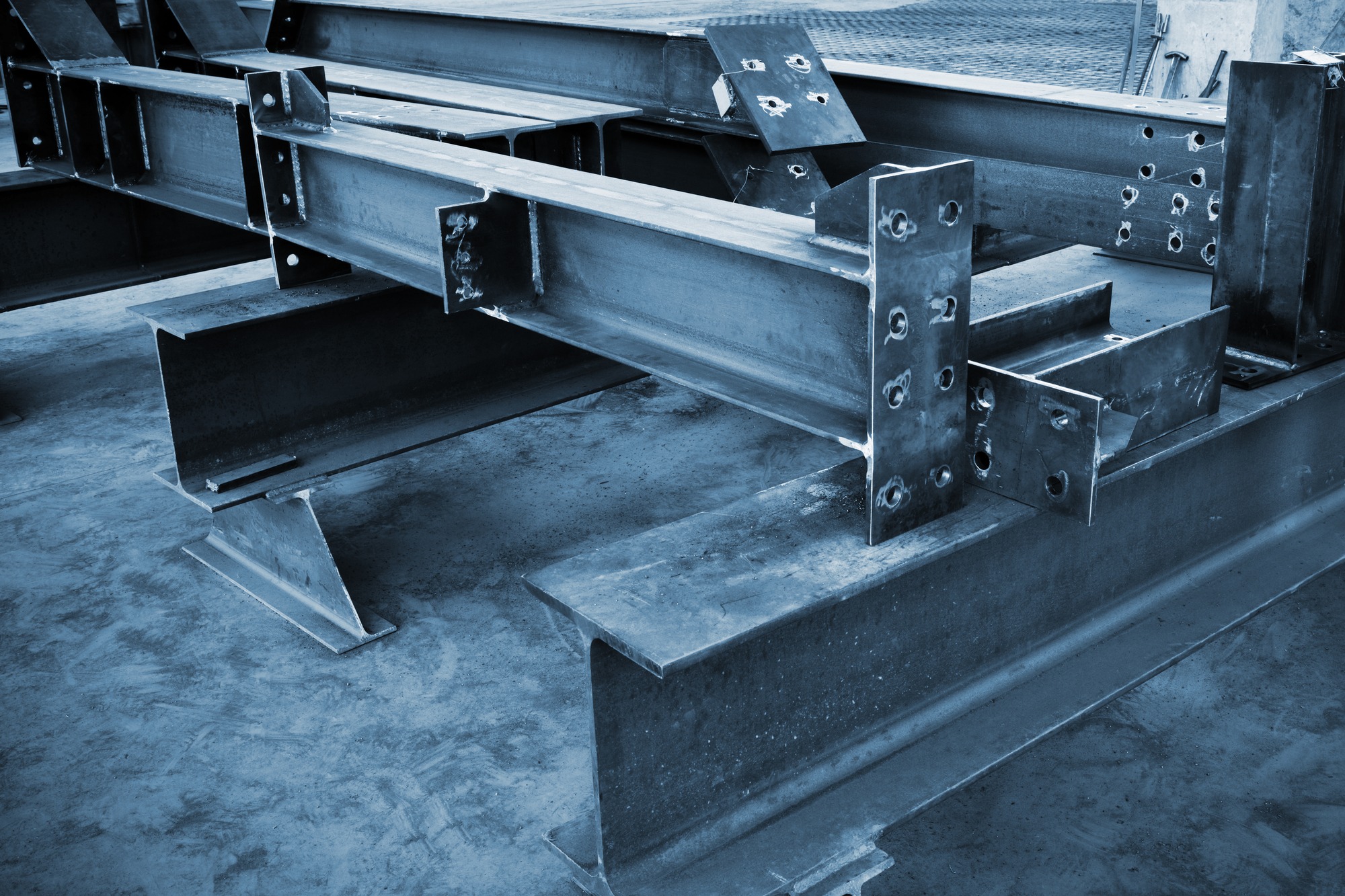

- Pallets, Circuit boards, Bottled beverages, Steel beams, Engine blocks, Frozen vegetables, Lithium-ion batteries, Home appliances, Cardboard boxes

- Steps before

- Material handling, Product preparation

- Steps after

- Pallet stacking, Packaging, Logistics, Distribution

- Input ingredients

- pallets, items for palletizing, materials for stacking, products for packaging

- Output ingredients

- palletized pallets, stacked items, packaged products

- Market info

- KUKA is renowned for its expertise in industrial robotics and automation solutions, specializing in providing advanced robotic systems for manufacturing, automotive, electronics, and logistics industries, with a reputation for innovation and quality in engineered-to-order equipment.

- Load Capacity

- 120–240 kg

- Maximum Reach

- 3195 mm

- Operating Environment

- Standard / Arctic / Food

- Mounting Positions

- Floor

- Precision

- High-precision palletizing

- Protection Class

- IP 65

- Cycle Time

- Short cycle times

- Temperature Range (Arctic)

- as low as -30°C

- Controller

- KR C5 / KR C4

- Cycle time efficiency

- Short cycle times

- Space requirement

- Minimized space

- Operating temperature

- Down to -30°C

- Palletizing height

- Up to 2500 mm

- Hollow-shaft wrist

- Yes

- Environment type

- Standard, Arctic, Food

- Stack height

- Over 2, 500 mm

- IP Protection Class

- IP 65

- Compact footprint

- Yes

- Stacking height

- Up to 2, 500 mm

- Hollow shaft diameter

- 60 mm

- Base frame size

- Narrow

- Mounting positions

- Floor