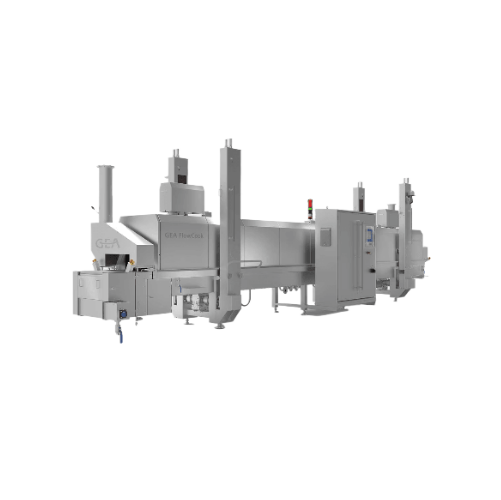

Dual-zone linear industrial oven for hot air cooking and roasting

Optimize your production with a dual-zone linear industrial oven that ensures precise control over cooking and roasting processes, effectively handling everything from dumplings to marinated chicken thighs. Experience minimal energy loss and consistent product quality with advanced airflow and humidity control techniques.

Cooks, Steams, and Roasts with Precision Control

The GEA FlowCook from GEA Group is a dual-zone, in-line industrial oven designed to streamline cooking processes across the food industry. It stands out for its dual independent temperature zones and a combination of vertical and horizontal booster airflow, providing unmatched precision in cooking, steaming, and roasting applications. Ideal for products ranging from breaded chicken nuggets to roast beef, it offers controlled conditions with spot-on dewpoint and temperature regulation. Capable of operating on lines 400mm to 600mm wide, it supports continuous operations with minimal downtime, featuring a continuous belt wash system. Energy efficiency is a priority, achieved through balanced airflow and superior insulation, reducing energy consumption. The FlowCook integrates seamlessly into production lines, enhancing productivity and consistent quality while ensuring environmental responsibility. Made from durable materials, it simplifies maintenance and supports extensive customization to meet varying processing demands.

Benefits

- Enhances production efficiency with independent dual-zone temperature control.

- Minimizes energy costs through optimized airflow and superior thermal insulation.

- Ensures consistent product quality with precise humidity and temperature management.

- Increases uptime with a continuous belt wash system for uninterrupted operations.

- Supports diverse product processing, reducing the need for multiple equipment types.

- Applications

- Steamed products, Marinated-enhanced browning, Formed products, Boneless products, Food processing, Coated products, Bone-in products, Natural roasting

- End products

- Hot dogs, Boneless chicken breasts, Bone-in pork chops, Marinated chicken thighs, Dumplings, Burger patties, Breaded chicken nuggets, Roast beef

- Steps before

- Preparation, Marination, Coating

- Steps after

- Packaging, Cooling, Quality Inspection

- Input ingredients

- steamed products, coated products, marinated-enhanced products, natural products, bone-in products, boneless products, formed products

- Output ingredients

- browned products, roasted products, steamed products, cooked products

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Cooking zones

- Dual-zone

- Temperature control

- Independent per zone

- Humidity control

- Dewpoint controlled

- Airflow type

- Vertical and horizontal

- Line width compatibility

- 400mm and 600mm

- Energy consumption

- Low, optimized airflow

- Process type

- Steaming, cooking, roasting

- Heat transfer

- Efficient

- Steam exhaust system

- Passive

- Insulation

- Superior thermal insulation

- Belt wash system

- Continuous

- Application range

- Steamed, coated, marinated, natural, roasted

- Uptime

- 99%

- Experience

- More than 35 years

- Installation

- Proven globally

- Working mechanism

- Dual-zone linear oven

- Integrated steps

- Steaming, Cooking, Roasting

- Airflow type

- Combined vertical and horizontal

- Automation level

- PLC for temperature and humidity control

- Batch vs. continuous operation

- Inline Continuous

- Energy efficiency

- Optimized airflow and thermal insulation

- Process control

- Dewpoint and temperature control in each zone

- Changeover time

- Not specified

- Cleaning method

- Continuous belt wash system

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Cooking application

- Steamed, coated, marinated, roasted

- Machine Width

- 400 mm / 600 mm

- Footprint

- Compact

- Oven Zones

- Dual-zone

- Airflow Direction

- Vertical, Horizontal

- Exhaust System

- Passive

- Chamber Construction

- Two Independent Chambers

- Temperature zones control

- Independently-controlled

- Airflow customization

- Vertical and horizontal

- Humidity control

- Spot-on dewpoint control

- Oven type

- Dual-zone

- Cooking Process Integration

- Steaming, Roasting, Cooking

- Line width compatibility

- 400mm and 600mm

- Exhaust system

- Passive

- Belt wash system

- Continuous