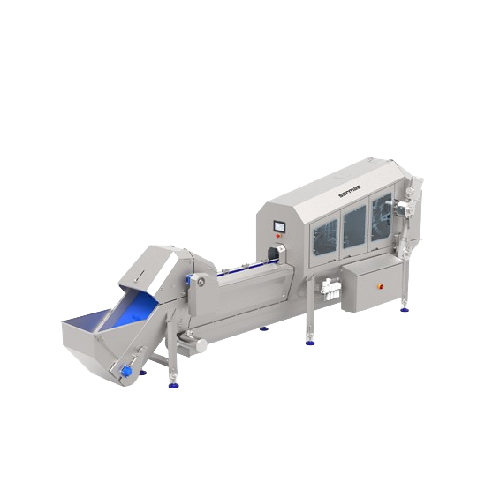

Industrial onion peeler for efficient processing

Efficiently peel, cut, and prepare onions with precision, ensuring high-speed processing that minimizes waste and optimizes quality, perfect for facilities aiming to enhance their vegetable production capabilities.

Peels and Processes Onions Efficiently

The Onion Peeler USM-H100 from Sormac is an efficient solution tailored for food processing companies and vegetable processing plants. This machine combines peeling, cutting, blowing, and topping into one continuous process, significantly enhancing throughput. Capable of processing up to 6,000 onions per hour, the USM-H100 is suited for creating peeled onions, diced onions, and onion rings, ensuring a high-quality end product.

Constructed entirely from stainless steel, it ensures maximum hygiene and durability, making it ideal for high-demand environments. The integrated Sormac air-saving technology optimizes energy efficiency by reducing air consumption during operation, while the unit’s small footprint facilitates seamless integration into existing production lines.

Operators benefit from a user-friendly digital control panel, which provides real-time data on efficiency and operational status, ensuring complete process transparency. Maintenance is simplified with a hygienic design that includes easily accessible components and replaceable stainless steel cutting discs, minimizing downtime and ensuring a microbiological clean end product.

For enhanced operational versatility, the USM-H100 can be configured with various options such as a directly mounted inspection table and waste transporter, adapting to diverse processing requirements.

Benefits

- Enhances productivity by processing up to 6,000 onions per hour, minimizing bottlenecks in high-demand operations.

- Reduces energy costs with air-saving technology while maintaining high-quality peeling.

- Ensures product hygiene with a stainless steel construction, essential for strict food safety standards.

- Minimizes maintenance downtime through a hygienic design and easily replaceable components.

- Facilitates seamless integration into existing lines with a compact design and versatile configuration options.

- Applications

- Food processing, Vegetables, Onions

- End products

- Onion ingredients for ready meals, Onion ingredients for sauces, Diced onions, Peeled onions, Onion rings

- Steps before

- Sorting, Loading, Positioning

- Steps after

- Inspection, Quality Control, Packaging, Waste Disposal

- Input ingredients

- onions

- Output ingredients

- peeled onions, onion skins, topped onions

- Market info

- Sormac is known for its expertise in manufacturing high-quality vegetable processing equipment, particularly peeling, washing, and slicing machines, with a strong reputation for innovation, reliability, and customer-focused solutions in the food processing industry.

- Capacity

- 6, 000 onions per hour

- Diameter Range

- 60–120 mm

- Automation

- Digital control panel

- Construction Material

- Stainless steel

- Energy Consumption

- Low (air-saving technology)

- Footprint

- Small

- Peeling Quality

- Enhanced by air-saving technology

- Automation level

- Manual / PLC

- Batch vs. continuous operation

- Continuous

- Cleaning method

- Manual

- Energy efficiency

- Low energy consumption due to air-saving technology

- Control panel

- Digital control panel with useful functions

- Peeling throughput

- 6, 000 onions per hour

- Abrasion resistance

- Stainless steel components

- Biological compatibility

- Microbiological clean end product

- Cleanability

- Hygienic design, easy to clean

- Corrosive resistance (e.g. acids)

- Stainless steel construction

- Compact footprint

- Small

- Material

- Stainless steel

- Feed/discharge method

- Separator conveyor with holders

- Control panel type

- Digital control panel

- Control panel type

- Digital control panel

- Integration possibilities

- Pockets for deviating onion diameters

- Customization for different onion sizes

- 60–120 mm

- Option for 140 mm

- Options for waste management

- Waste transporter

- Mounting options

- Inspection table, Side platform