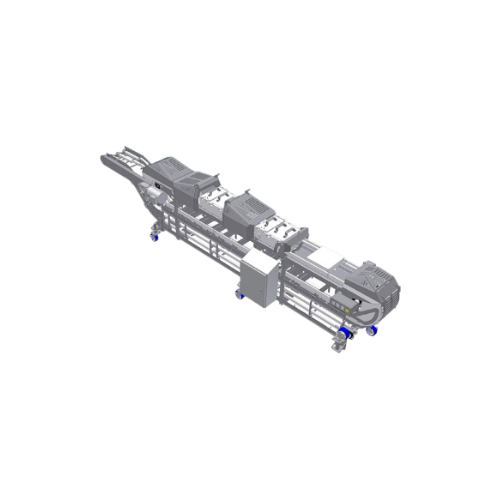

High-volume poultry portion cutter

Need precise weight and shape consistency for high-speed poultry processing? This versatile cutter handles diverse meat types, ensuring accuracy and reducing labor costs.

Portions and Slices Meat and Seafood

The PC-4 Portion Cutter from Prime Equipment Group revolutionizes volume portioning for poultry, meat, and seafood applications by offering a highly adaptable solution for achieving specific weight and shape requirements. This equipment employs customizable cavities and cut angles, allowing you to produce precise portions for products such as chicken breasts, salmon fillets, and pork chops. Designed for continuous high-speed operations, it can easily integrate into existing processing lines, diminishing manual labor while enhancing accuracy and consistency.

Its robust 1 hp drive motor and reliable construction ensure enduring performance and low maintenance needs. With a focus on efficiency, the PC-4 is equipped to handle various production rates and features a fast product changeover, minimizing downtime. Operating at 40 PSI with a 1 GPM water connection, the machine optimally balances production demands with resource utilization. Ideal for demanding food processing environments, it presents a versatile, dependable alternative to complex machinery, enhancing productivity and quality in your operations.

Benefits

- Reduces manual labor and enhances accuracy with machine-portioning technology.

- Supports diverse product specifications, offering versatility across multiple applications.

- Increases productivity with quick changeovers and continuous high-speed operation.

- Minimizes resource use with optimized water consumption and energy-efficient design.

- Integrates seamlessly into existing lines, improving overall production efficiency.

- Applications

- Seafood, Meat, Poultry, Red meat, Fish

- End products

- Salmon fillets, Chicken thighs, Pork chops, Beef steaks, Ground beef patties, Cod fillets, Tilapia portions, Chicken tenders, Turkey breast cuts, Chicken breast portions

- Steps before

- Deboning, Trimming, Fresh Cut Processing

- Steps after

- Packaging, Freezing, Chilling, Coating

- Input ingredients

- breast meat, tenders, dark meat, trim, red meat, fish

- Output ingredients

- portioned meat, portioned fish, specified weight portions, specified shape portions

- Market info

- JBT is known for manufacturing innovative industrial machinery and solutions, particularly in the food processing and air transportation sectors, renowned for their advanced technology, reliability, and customer-focused engineered-to-order solutions tailored to specific industry needs.

- Electrical Requirements

- 480v 3 ph, 60 Hz, 10 amps

- Motor Specifications

- 1 hp drive motor

- Water Requirements

- 1/4 connection

- 1.0 GPM

- 40 PSI min

- Net Weight

- 800 lbs

- Production Rate

- Variable depending on product

- Working mechanism

- Volumetric portioning

- Batch vs. continuous operation

- High-volume continuous operation

- Automation level

- Machine-portioning

- Changeover time

- Fast changeover

- Cleaning method

- Manual cleaning

- Product adaptability

- Custom cavities and cut angles

- Cleanability

- Easy to clean surfaces for food safety compliance

- Abrasion resistance

- Steel components resistant to wear during high-volume processing

- Biological compatibility

- Food-grade materials safe for direct contact with poultry, meat, and seafood

- Corrosive resistance

- Materials resistant to chemicals used in cleaning

- Portion type

- Breast meat, tenders, dark meat, trim, red meat, fish

- Net Weight

- 800 lbs

- Product configuration

- Custom cavities and cut angles

- Final product specifications

- Adaptable to various shapes and weights

- Machine design

- Reliable alternative to complex designs