Continuous cooker for poultry and meat products

For processors seeking consistent cooking and browning of both coated and uncoated meats, this solution offers an efficient way to enhance flavor and achieve uniform results across a variety of poultry, meat, and seafood products.

Cooks and Browns Proteins Continuously

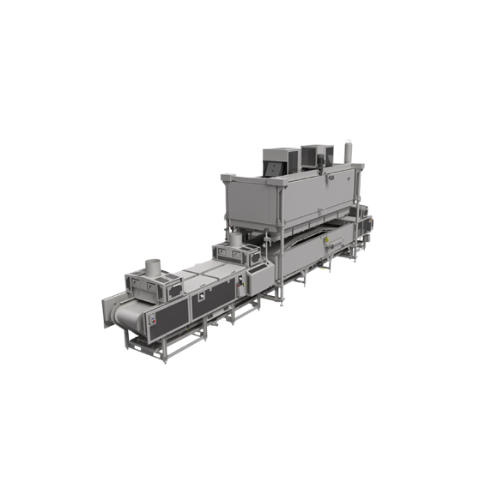

The Stein JSO-C Jet Stream® Oven by Stein offers a hygienically advanced solution for meat, poultry, and seafood processors seeking to optimize continuous cooking and browning. This mid-level capacity oven features a dual plenum air distribution system (DPD™), ensuring even heat application for both the top and bottom of the product. Ideal for processing a wide variety of coated and uncoated products, it excels in cooking chicken fillets, fish, and beef patties with precision. The JSO-C oven boasts a modular design with up to a 64-foot cook zone, allowing scalability for various production needs.

Automation is enhanced by its PLC control and Automatic Clean-in-Place (CIP) system, which streamlines maintenance and upholds hygiene standards. With energy-efficient indirect gas heating, it reduces utility requirements, and stainless steel construction provides durability and resistance to corrosion. Adjustable upper plenums and variable speed fans facilitate customized airflow, while the clamshell hood design simplifies inspection and cleaning operations. For processors aiming to transition from batch to continuous processing or seeking minimized utility consumption, this oven integrates seamlessly within existing production lines.

Benefits

- Streamlines operations with continuous cooking, enhancing productivity.

- Enhances product quality through even browning via dual plenum air distribution.

- Reduces energy usage with indirect gas heating.

- Simplifies maintenance with an Automatic Clean-in-Place system.

- Optimizes production space with a compact and modular design.

- Applications

- Seafood, Meatballs, Meat, Burgers, Uncoated foods, Poultry, Coated foods

- End products

- Chicken breast fillets, Fried chicken wings, Grilled beef patties, Turkey steaks, Breaded chicken nuggets, Battered fish sticks, Tempura shrimp, Pork sausages, Fish fillets, Shrimp skewers

- Steps before

- Grinding, Mixing, Injection, Portioning, Slicing

- Steps after

- Breading, Battering, Frying, Chilling, Freezing

- Input ingredients

- burgers, meatballs, poultry items, coated food substrates, uncoated food substrates

- Output ingredients

- fully cooked protein, browned protein, cooked burgers, cooked meatballs, cooked poultry items

- Market info

- JBT is known for manufacturing innovative industrial machinery and solutions, particularly in the food processing and air transportation sectors, renowned for their advanced technology, reliability, and customer-focused engineered-to-order solutions tailored to specific industry needs.

- Heating Type

- Indirect gas heating

- Cook Zone Length

- 16 to 64 ft

- Usable Belt Width

- 24 in. (600mm)

- Upper Plenums Adjustability

- Two to six inches above belt

- Circulation Fans

- Two variable speed, roof mounted VFD

- Cleaning System

- Automatic Clean-in-Place (CIP)

- Construction Material

- Stainless Steel

- Cooking method

- Continuous

- Automation level

- PLC

- Air distribution

- Dual plenum system (DPD™)

- Cleaning method

- Automatic Clean-in-Place (CIP)

- Heating type

- Indirect gas heating

- Adjustability

- Top and bottom damper from a single point

- Speed control

- Variable speed VFD circulation fans

- Cooking zones

- Single zone

- Changeover time

- Quick with clam shell hood design

- Machine footprint

- Compact design, 16 ft. long cook zone, with up to four modules (64 ft. cook zone)

- Discharge method

- Optional Infeed and discharge sections

- Usable belt width

- 24 in. (600mm)

- Hood design

- Clam shell hood with automatic lift

- Material

- Stainless Steel Construction

- Control panel type

- Single point damper control

- Integration possibilities

- Modular design with optional infeed and discharge sections

- Compact footprint

- Modular 16 to 64 ft. cook zone

- Airflow control

- Dual plenum air distribution (DPD™) system