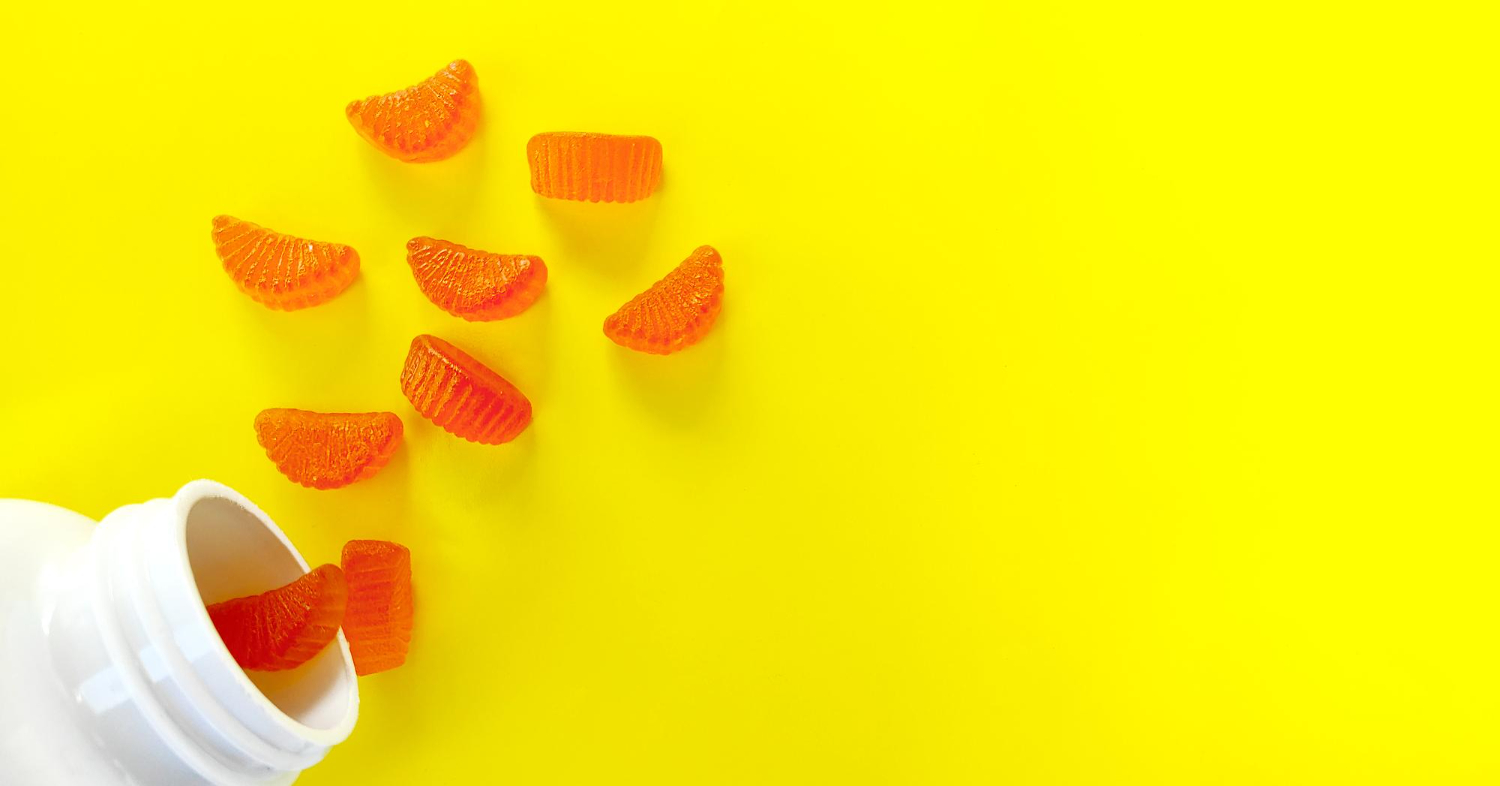

Find Vitamin Gummy Equipment

Find innovative production technology for making vitamin gummies and connect directly with world-leading specialists

Chewy, sweet, and nutritious. Vitamin gummies were a couple’s attempt to get their child to take their essential micronutrients. The idea quickly caught on, and manufacturing vitamin gummies soon grew into a whole new industry.

Stories about vitamin gummies

Starting up your OTC non-starch gummy production

Making healthier gummy formulations

Delving into the fungal fun of gummy goodness

Activate your candy game: from a nutraceutical idea to an active candy

How to turn a bag of sugar into a bag of scrumptious gummies

Find the perfect balance between sweets and wellness with vitamin candies

Preserving gummy texture in low or no sugar confectionery

How to craft gummy bears in 8 simple steps

Exploring the artistry of candy-making

Tech is [was] keeping vitamin gummy manufacturers from cutting starch

Select your vitamin gummies process

Tell us about your production challenge

A menu of 13 micronutrients for vitamin gummies manufacturing

Vitamins are only one of the raw materials that make these unique gummies. There are 13 essential vitamins ranging from Folic Acid to Vitamin C. The nutrients you choose are extracted from biological sources and purified.

Mix the powdered vitamins with gelatin and cook the blend in a preheated kettle. The additives in the recipe, such as sweeteners, colorants, and flavorings, are now ready to be blended in. Once the ingredients combine, cool the mixture down.

Build the candy around a frame of gelatin

Gelatin plays the leading role in vitamin gummy manufacturing. As it heats up in the industrial cooker, the cells of the substance bind together into a matrix. This structure forms the flexible scaffold that gives gummies their chewy consistency.

Gelatin has neither taste nor odor, providing a blank canvas for producers to manipulate the flavor and sweetness level. The substance is naturally off-white, so colorants are added to alter its appearance. The most popular dyes include Red #40, Blue #1, Yellow #5, and Yellow #6.

Opt for plant-based alternatives

If you prefer to use plant-based gelling agents as a alternative to gelatin in your functional gummies, there are luckily many options. Pectin is a plant-based substance derived from fruits, such as apples or citrus.

Agar-agar is a vegetarian gelling agent derived from seaweed. Carrageenan is another seaweed-derived ingredient that you can use in your gummy manufacturing process. Using the alternative options you don’t need entirely different gummy making machines, but you have to keep an eye out to the specific properties of the gelling agents while gummy formulation.

Reduce water content from the gummies with a bed of starch

After cooling down the base mixture, transfer it to the starch molding machine. The technology gives turns the compounded slurry into individual gummy drops.

A layer of starch separates the viscous blend and keeps it from sticking to the mold trays. It also contains the candies during the setting phase while still fluid. Finally, the carbohydrate absorbs moisture from the mixture to give the gummies their texture.

Add springiness to the gummies with calcium carbonate

Calcium carbonate is an alternative additive in the formulation of vitamin gummies. Because of its low rate of water solubility, the mineral does not dissolve and remains suspended in the gelatin mixture.

The additive reduces firmness in the recipe and considerably increases the final product’s springiness. However, calcium carbonate also masks the overall smell and taste of the gummies.

Which vitamin gummies technology do you need?

Adjustable weighing system for raw materials

Optimize your confectionery and nutraceutical production with precise weighin...

Cooker for jelly and gummies production

Experience efficient gummy and jelly production with precise heating and mixing, en...

Laboratory unit for small quantity production and r&d

For product developers needing precise control and flexibility, thi...

Hard candy forming line for manufacturing

Experience seamless candy production with advanced forming technology, ensuring ...

Integrated process system for hard caramel production

Optimize your candy production with a fully integrated system desig...

Automatic gummy production system

Achieve precise control in gummy production with systems that cater to diverse formulatio...

Powder and oil coating system for gummies

Enhance your gummy production with precise powder and oil coating, achieving con...

Oil coater for gummies

Optimize your gummy production with high-speed oil coating for consistent, flavorful finishes, ensurin...

Packaging system for gummy products

Optimize your gummy production with a flexible packaging system that safeguards product...

Rapid gummy channel counter

Ensure accurate gummy counts and streamline your production process with a solution designed to ...

Sugar coating system for gummies

Achieve a flawless sugar coat on up to 240,000 gummies per hour, seamlessly integrating int...

Portable water activity meter for gummy production

Ensure consistent gummy quality and extended shelf life by precisely m...

Automatic gummy manufacturing system

Efficiently streamline your candy production with a system capable of producing up to ...

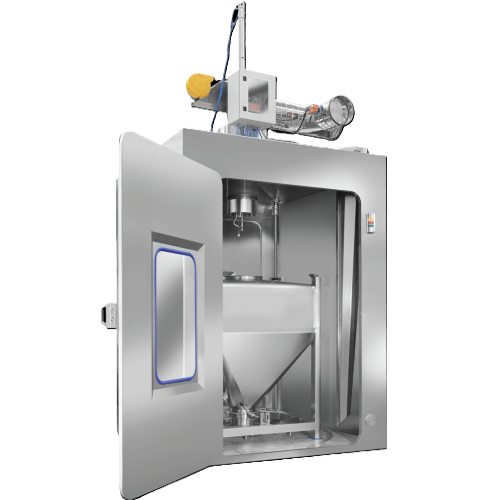

Internal and external bin washing cabinet

Streamline your sanitation process with automated bin cleaning that ensures thor...

Automatic gummy production system for Cbd and vitamin gummies

Achieve high-speed, continuous gummy production with preci...

High-capacity automatic gummy production line

Achieve high-speed gummy production with precision depositing and cooling, i...

Automatic gummy candy production system

Maximize your confectionery output with a high-speed system capable of producing up...

4-side seal horizontal form-fill-seal packaging system

Streamline your confectionery and snack packaging with high-speed,...

Servo multi food portioner

Achieve precise portion control and high-speed depositing for diverse applications with this adva...

Mini extruder for early development phase testing

In early development, tackling limited material availability is crucial...

Roller compactors for dry granulation

Optimize your powder processing with advanced roller compaction, ensuring consistent ...

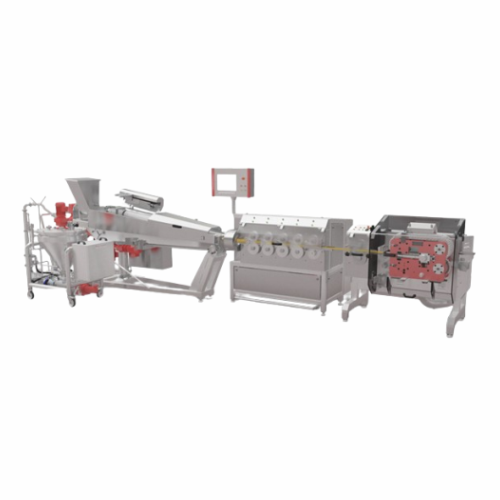

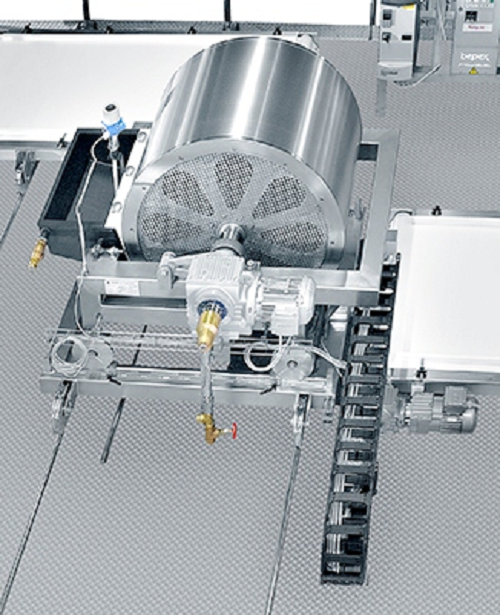

Industrial gummy and jelly production line

Optimize your gummy and jelly production with a system that streamlines operati...

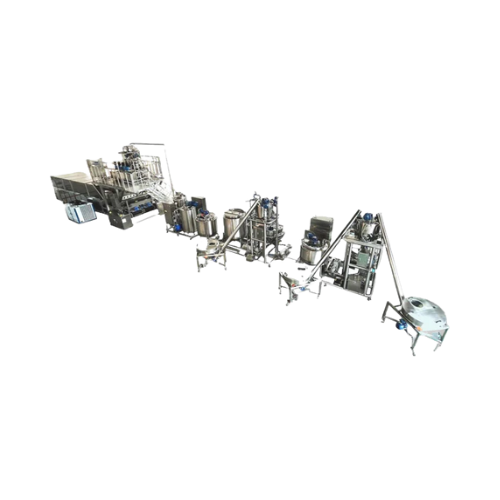

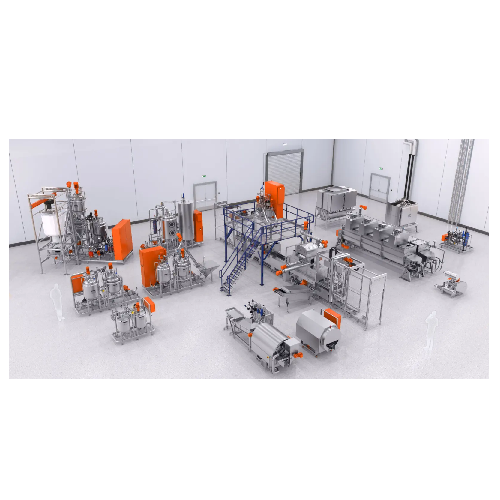

Automatic production line for gummies and nutraceuticals

Maximize the versatility and efficiency of your production space...

Mid-capacity gummy and jelly production system

Ideal for manufacturers aiming to integrate functional ingredients into gum...

Automatic production line for gummies, jellies, and nutraceuticals

Optimize your production space with a compact line t...

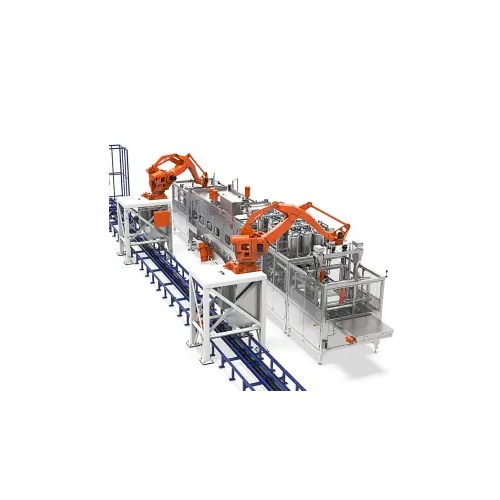

Robotic production line for gummies and nutraceuticals

Streamline your gummy and nutraceutical production with a versatil...

Industrial bag sealing solution for medical and food applications

Enhance your packaging line with reliable and versati...

Agitator bead mill for functional foods and flavors

Fine-grinding solid flavors to improve taste properties and integrati...

Start-up production line for CBD gummy production

High-value products like CBD gummies demand precision equipment such as...

Lab scale production line for nutraceutical gummy production

By gradually investing in the individual parts, a productio...

Small-scale demoulder for starchless functional gummy production

Removing vitamin or CBD gummies from the moulds by hand...

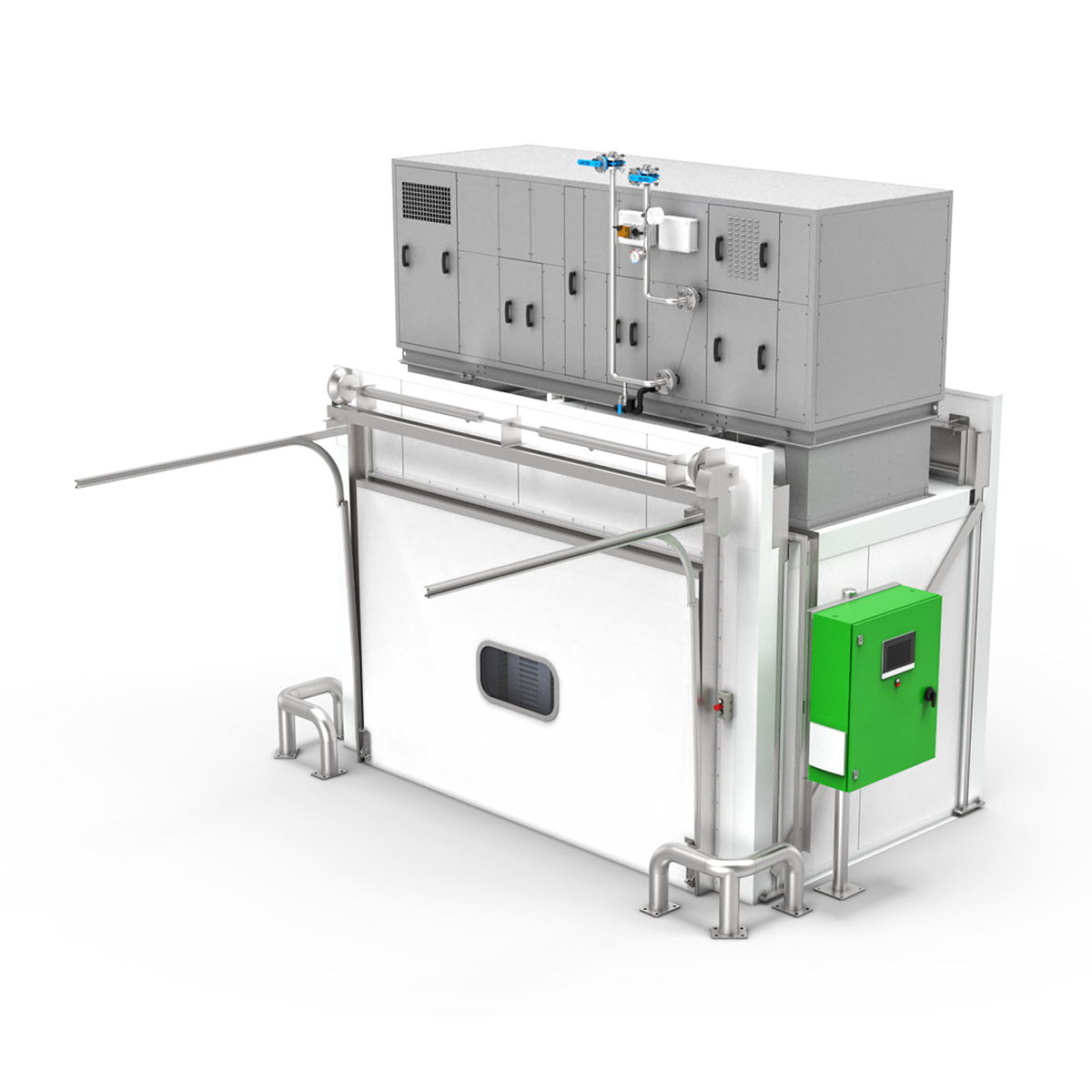

Entry-level conditioning system for drying nutraceutical gummies

The drying process demands specific environmental condi...

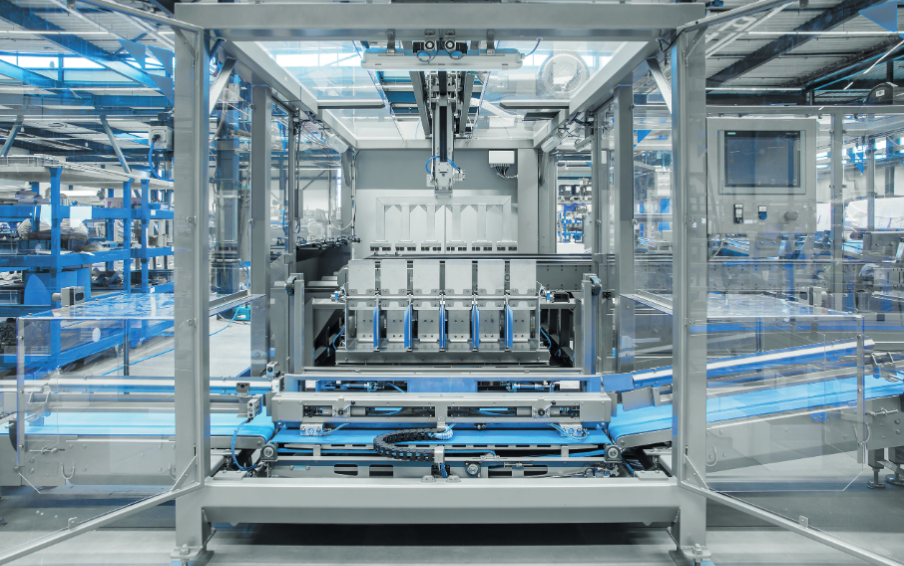

Entry-level starchless depositor for nutraceutical gummies

Manufacturing nutraceutical products such as vitamin, CBD ,or...

Entry-level cooking system for vitamin and CBD gummies

Producing functional gummies or jellies with functional ingredient...

Low Output Production Line for Gummies and Jellies

The original technique for making gums and jellies exploited the non-s...

Flexible Output Line For Gummies and Jellies

The traditional method for gummy and jelly production uses starch to keep the...

High Output Industrial Production Line for Gummies and Jellies

Mainstream technology for the preparation of gummies and ...

Confectionery bags case packer for large scale

Mass production lines need faster and more efficient package processing to ...

Emulsifier and mixer for gelling agent

When making jams and marmalades, gelling agents, such as pectin, are used to thicken...

Temperature-treatment mixer for bakery & gastronomy

The production of creams, sauces, ragouts, ready-to-bake, and sim...

High speed carton closing machine

Choosing a carton closing machine becomes a significant consideration when the closing of...

Endload cartoning machine

As demand for food production increases, so does that of packaging and sealing the product and mak...

Bagger with mechanical driven jaw actuation

If you want to pack into unique bag styles like Quad-seal and Doypack, but you...

Mini sugar coating machine

The coating of grains or nuts with sugar is a popular process in the manufacture of many bakery p...

High-speed flow pack wrapping machine for hard candy and jellies

For some high-quality candy which require individual wr...

Packaging machine for preformed paper bags from 500 g to 5 kg.

Paper bag filling and closing for larger quantities of ma...

Continuous vertical bagger

Want a machine to pack unique bag styles such as quad-seal and Doy-pack bags at incredible speeds...

Cooling drum for soft and caramel mixtures

Cool your product to the temperature required for further processing. This is a...

Whipping machine for soft candy

Prepare your ingredients for any whipped or aerated product component. This is a pressurized...

Pressure cooker for caramel and soft candy

Prepare your ingredients for soft candy production. This is a highly flexible c...