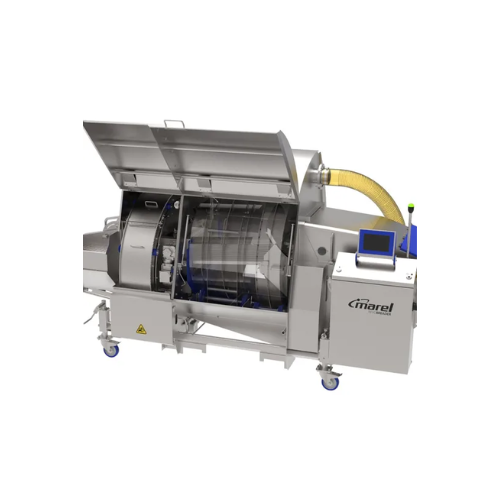

High-volume breader for homestyle and standard coatings

Achieve seamless switchovers between homestyle and standard breaded products, minimizing production downtime to under two minutes and optimizing coating retention for a higher quality output in high-speed food processing environments.

Applies Consistent Coating and Pre-Dusting

The RevoBreader from Marel is a versatile machine designed for seamless integration into food processing lines, offering both drum and flatbed coating capabilities in a single enclosure. This equipment excels in producing high-quality coatings, providing uniform breading and pre-dusting with minimal changeover time, making it ideal for a wide range of products, including chicken nuggets, plant-based tenders, and tempura-coated items. Its large drum design ensures high crumb retention and excellent coverage, while the flatbed mode offers quick transitions for different coating types without reconfiguration.

Built for high-speed, continuous operations, the RevoBreader supports various coating materials, from powders to granules, ensuring reliable performance in food, poultry, meat, and fish industries. Marel’s integration extends into digital solutions; the Innova Food Processing Software offers real-time production control, traceability, and monitoring, enhancing food safety and quality. The optional Cyclone accessory maintains operational hygiene, while the CrumbFeeder streamlines material handling, reducing labor requirements. Available with multiple belt widths, this equipment offers flexibility for diverse production needs, backed by Marel’s global service network for reliable maintenance and support.

Benefits

- Minimizes downtime with changeover times under two minutes.

- Enhances product quality with consistent, high-coverage coating.

- Reduces labor requirements through automated material handling.

- Improves operational hygiene with optional dust-free environment.

- Provides real-time production insights for optimal process control.

- Applications

- Convenience products, Nuggets, Schnitzels, Plant-based products, Popcorn, Retail food, Coating materials, Strips, Sausages, Quick service restaurant (qsr) food, Potato specialties, Prepared foods

- End products

- Chicken nuggets, Popcorn chicken, Breaded vegetable patties, Tempura-coated products, Retail-ready breaded snacks, Qsr homestyle chicken tenders, Battered fish fillets, Crispy chicken strips, Plant-based chicken tenders, Savory sausages, Breaded schnitzels, Pre-dusted potato croquettes

- Steps before

- Pre-dusting, Meat preparation

- Steps after

- Frying, Packing, Labeling

- Input ingredients

- raw poultry, raw meat, chicken strips, nuggets, schnitzels, coating materials, crumbs, flakes, flour, breading ingredients

- Output ingredients

- homestyle coated products, standard coated products, coated strips, coated nuggets, coated schnitzels, breaded poultry, breaded meat, crumbed products

- Market info

- Marel is known for its advanced food processing equipment, specializing in systems and services for poultry, meat, and fish industries. It is recognized for innovation, quality, and improving processing efficiency and sustainability.

- Drum size

- Large

- Belt width

- 600, 700, 1000 mm

- Changeover Time

- Less than two minutes

- Automation

- Manual/Auto

- Coating type

- Homestyle / Standard / Pre-dusting

- Working mechanism

- Flatbed and drum breader modes

- Integrated steps

- Pre-dusting, breading, coating

- Changeover time

- Less than two minutes

- Batch vs. continuous operation

- Continuous inline operation

- Cleaning method

- Manual / Tool Cart for cleaning

- Automation level

- PLC-controlled

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Coating Type

- Homestyle / Standard

- Drum size

- 600, 700, 1000 mm

- Discharge method

- Flatbed and drum modes

- Control panel type

- Touchscreen / PLC

- Integration possibilities

- Innova Software Integration

- Drum size

- Adjustable

- Belt width options

- 600, 700, 1000 mm

- Functionality modes

- Flatbed / Drum Breader / Pre-dusting