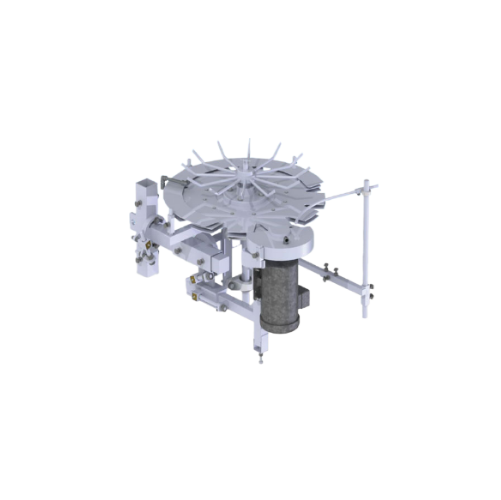

Wing lift neck skin cutter for poultry evisceration

Ensure optimal yield and quality in poultry processing by lifting wings to prevent damage during neck removal, seamlessly integrating into high-speed evisceration lines.

Cuts Necks and Lifts Wings in Poultry Processing

The WLNSC-1 Wing Lift Neck Skin Cutter from Prime Equipment Group is designed for seamless integration into poultry processing lines, focusing on efficient neck cutting and wing lifting. This machine is line-driven, utilizing an indexer to securely hold birds, ensuring precise cuts and preserving wing integrity while operating at speeds of up to 180 birds per minute. It is ideally suited for applications within poultry processing plants, enabling high throughput in neck and wing processing. The WLNSC-1 pairs effectively with the Prime Positive-Feed Neck Skinner for a cohesive, fully automated neck processing system. Featuring 230/460V electrical requirements, the cutter operates with a robust 2 hp blade motor, and is equipped to meet stringent production demands with minimized energy consumption. Durability is ensured with construction designed to handle the rigors of continuous operation, minimizing maintenance needs and maximizing uptime in high-speed processing environments.

Benefits

- Enhances product quality by preventing wing damage during neck processing.

- Increases yield with fewer nicks and cuts on wings, promoting higher-grade output.

- Operates efficiently at high speeds, processing up to 180 birds per minute.

- Integrates seamlessly into existing lines, supporting fully automated operation.

- Reduces operational costs with durable, low-maintenance design.

- Applications

- Seafood, Meat, Poultry

- End products

- Deboned poultry parts, Boneless chicken breast portions, Chicken necks, Whole chicken wings, Turkey necks

- Steps before

- Defeathering, Pre-scald and bird scrubbing, Giblet harvesting

- Steps after

- Portioning and slicing, Freezing and chilling, Whole bird chilling

- Input ingredients

- chicken, whole bird, poultry, raw poultry

- Output ingredients

- processed chicken, neck removed chicken, A-grade wing, necks, wing lift, neck skinless chicken

- Market info

- JBT is known for manufacturing innovative industrial machinery and solutions, particularly in the food processing and air transportation sectors, renowned for their advanced technology, reliability, and customer-focused engineered-to-order solutions tailored to specific industry needs.

- Production Rate

- 200 necks/min

- Voltage

- 230/460V

- Phase

- 3 ph

- Motor Power

- 2 hp blade motor

- Water Requirements

- 1.0 GPM

- Net Weight

- Approx. 400 lbs. (181 kg)

- Automation

- Fully automated

- Operational Speed

- up to 180 BPM

- Working mechanism

- Line-driven

- Integrated steps

- Wing diversion, Neck cutting

- Automation level

- Fully Automated

- Batch vs. continuous operation

- Continuous

- Cleaning method

- Manual

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Net Weight

- Approx. 400 lbs. (181 kg)

- Production Rate

- 200 necks/min

- Electrical Requirements

- 230/460V, 3 ph (others available)

- Water Requirements

- (2) 1/4

- 1.0 GPM

- Motor Specifications

- (1) 2 hp blade motor

- Integration possibility

- Compatible with Prime Positive Feed Neck Skinner

- Control panel type

- Line-driven automation

- Automation capability

- Fully automated, up to 180 BPM