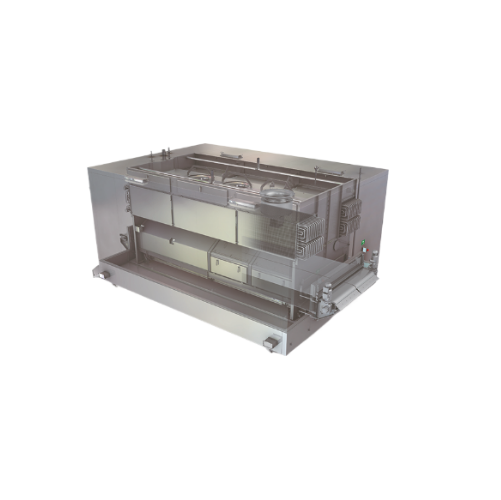

Impingement freezer for poultry and meat

Achieve rapid freezing and high product quality with high-velocity air impingement, reducing dehydration and operational costs in food processing lines.

Rapidly Freezes and Chills Food Products

The Frigoscandia ADVANTEC™ Impingement Freezer is a robust solution designed for rapid food freezing. Utilizing thousands of high-velocity air jets, it efficiently blasts away the boundary layer of air from products such as chicken nuggets, beef patties, and plant-based burgers, achieving fast freezing times and high product quality. With its modular design and pre-manufactured components, the freezer supports quick installation and integration into existing lines, whether in poultry, meat, or seafood processing. Models like the ADVANTEC 1250 and 1850 offer flexibility with single or dual stainless-steel belt configurations, reaching belt speeds of over 80 fpm to accommodate varying production demands. The stainless-steel construction ensures durability and corrosion resistance, while the optional frost management system extends run times and reduces maintenance interruptions. Additionally, its integrated wash-down system simplifies cleaning, facilitating adherence to food safety regulations, making the ADVANTEC Impingement Freezer an ideal choice for high-speed, continuous operations in diverse food processing sectors.

Benefits

- Enhances product quality by minimizing dehydration through rapid freezing.

- Increases operational flexibility with modular design and customizable belt configurations.

- Supports high-speed production with belt speeds over 80 fpm, maximizing throughput.

- Simplifies compliance and cleaning with an integrated wash-down system.

- Reduces energy consumption compared to cryogenic systems, lowering operational costs.

- Applications

- Seafood, Meat, Alternative meat, Poultry, Deli products

- End products

- Chicken nuggets, Beef patties, Shrimp, Plant-based burger patties, Deli ham slices, Turkey breast slices

- Steps before

- Grinding, Mixing, Forming, Portioning, Slicing

- Steps after

- Packing, Coating, Weighing, Packaging

- Input ingredients

- hamburger patties, thin products, meat products, poultry products, seafood products, alternative meat

- Output ingredients

- frozen hamburger patties, frozen thin products, frozen meat products, frozen poultry products, frozen seafood products, frozen alternative meat

- Market info

- JBT is known for manufacturing industrial ETO equipment, specializing in food processing and airport ground support systems. They are reputed for innovative solutions and reliable service in industries requiring sophisticated automated systems and machinery.

- Belt Material

- Stainless Steel Mesh

- Belt Speed

- Up to 80+ fpm

- Cooling Method

- Impingement freezing

- Freezing Time

- Extremely fast

- Module Lengths

- 15.5 ft. to 62 ft.

- Belt Configuration

- Single or double

- Evaporator Coil Material

- Galvanized Steel

- Heat Exchanger Material

- Stainless Steel Tube and Aluminum Fin

- Construction Material

- Stainless Steel

- Freezing method

- Impingement

- Airflow pattern

- High velocity jets

- Automation level

- Modular design

- Cleaning method

- Integrated wash down system

- Flexible configuration

- Single or double belt

- Belt speed range

- Variable up to 80+ fpm

- Energy efficiency

- High due to rapid freezing

- Corrosion resistance

- Stainless steel

- Cleanability

- Easy to clean design

- Biological compatibility

- Food-grade materials

- Abrasion resistance

- Stainless steel construction

- Footprint

- Modular lengths from 15.5 ft. up to 62 ft.

- Belt Configuration

- Single or double belt configurations

- Belt Speed

- Variable speeds up to 80+ fpm

- Construction Material

- Stainless steel construction

- Impingement Freezer Type

- ADVANTEC 1250, ADVANTEC 1850, ADVANTEC CC

- Evaporator Coils Material

- Galvanized steel

- Control Panel Type

- Integrated control panel

- Insulation Panel Material

- Insulated enclosure panels

- Control panel type

- PLC-based interface

- Belt configuration

- Single or double belt

- Belt speed

- Variable, up to 80+ fpm

- Model options

- ADVANTEC 1250, ADVANTEC 1850, ADVANTEC CC

- Evaporator coil material

- Galvanized steel

- Heat exchanger

- Stainless steel tube and aluminum fin

- Frost management

- Extended run time package

- Cleaning system

- Integrated wash down system