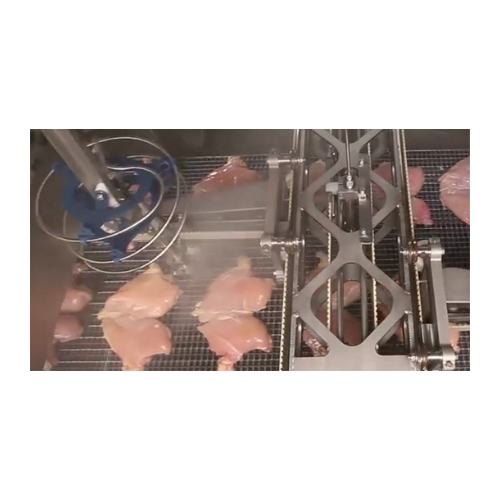

Waterjet portioning system for poultry and meat

Revolutionize your protein processing with high-speed waterjet technology that ensures precision portioning, maximizing yield and enhancing product consistency while reducing labor costs.

Scans, Optimizes, and Portions Meat Products

The DSI™ Waterjet Portioning System from JBT FoodTech revolutionizes poultry, meat, and seafood processing with advanced automation and precision. This system employs high-pressure waterjets guided by proprietary DSI Q-LINK™ software to accurately scan, optimize, and portion each product. Ideal for producing chicken breast fillets, turkey strips, beef portions, and more, it addresses critical needs in yield improvement and labor efficiency. Designed for continuous, high-speed operations, it reduces repetitive motion injuries and enhances food safety with automated control. The system is adaptable to varying production requirements, offering easy application changes at the touch of a button. Constructed for robustness and efficiency, it also supports seamless integration into existing production lines, making it an essential solution for processors aiming to maximize profit margins and product quality.

Benefits

- Increases yield by optimizing each cut to maximize product value.

- Reduces labor costs and minimizes injury risks through full automation.

- Achieves versatile production with rapid application changes.

- Enhances food safety with consistent portion accuracy and reduced human contact.

- Integrates seamlessly into existing production lines for streamlined operations.

- Applications

- Seafood, Meat, Poultry

- End products

- Chicken breast fillets, Salmon fillets, Beef portions, Fish nuggets, Pork chunks, Tilapia portions, Shrimp pieces, Turkey strips

- Steps before

- Inspection, Marination, Preparation, Grinding

- Steps after

- Packaging, Freezing, Chilling, Cooking

- Input ingredients

- raw products, fat-containing products, meat, poultry

- Output ingredients

- portions, nuggets, chunks, fat-free products, strips, trim fat

- Market info

- JBT is known for manufacturing industrial ETO equipment, specializing in food processing and airport ground support systems. They are reputed for innovative solutions and reliable service in industries requiring sophisticated automated systems and machinery.

- Portion Size Capability

- Portions, nuggets, chunks, strips

- Automation

- Automated processing

- Cutting Method

- High-pressure waterjets

- Software

- DSI Q-LINK™ Portioning Software

- Scan Features

- Locates fat, shape, thickness, weight

- Changeover Time

- Quick change at the push of a button

- Food Safety

- Enhanced through automation

- Automation level

- Computer-controlled high-pressure waterjets

- Changeover time

- Quickly change applications at the push of a button

- Batch vs. continuous operation

- Continuous

- Cleaning method

- Automated

- Energy efficiency

- Optimize cut strategy to maximize profits

- Automation

- Proprietary DSI Q-LINK™ Portioning Software

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Product Types

- Portions, nuggets, strips

- Compact footprint

- Yes

- Control panel type

- Touchscreen

- Discharge method

- Automated

- Machine footprint

- Customizable

- Size and dimensions

- Varies based on production needs

- Control panel type

- Touchscreen/PLC-controlled

- Integration possibilities

- Proprietary DSI Q-LINK™ Portioning Software

- Application Changeover

- Quickly change applications at the push of a button

- Sizing Options

- Sized to match production needs