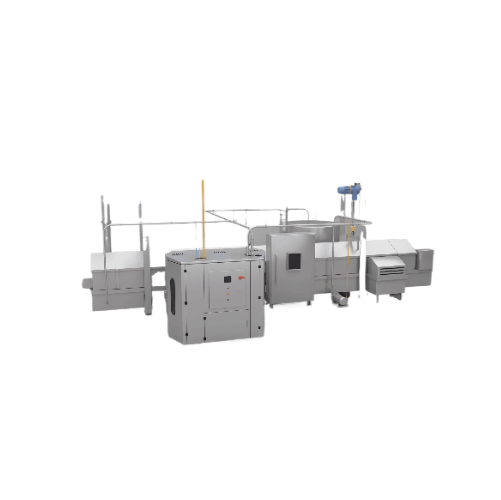

Industrial frying oil filtration system

Enhance your frying oil’s lifespan and maintain product quality by effectively managing sediment and particle removal, ensuring crisp, golden end products every time.

Filters and Manages Frying Oil for Quality Products

The GEA Oberlin OCL7, OCL2, and OPF4 are designed to revolutionize oil filtration for food processing. Specializing in sediment and particle removal, these filters extend the life of frying oil by up to five times. They operate automatically, filtering oil down to one micron and producing dry sediment cakes with minimal oil residue. Ideal for products like breaded fish fingers and vegetarian burgers, they ensure products meet desired quality and aesthetics while reducing oil consumption by up to 40%. Offering configurations to suit varying frying line sizes, these filters integrate seamlessly into your processing line, supported by GEA’s comprehensive engineering expertise. With optional stainless steel construction, they guarantee durability and resistance to corrosive environments, while also meeting stringent food safety standards. Enhance operational efficiency with potential oil savings and reduced environmental impact, making these filters indispensable for high-capacity industrial frying operations.

Benefits

- Extends frying oil life by up to five times, reducing operational costs.

- Ensures consistent product quality with efficient sediment removal.

- Reduces oil waste with dry sediment cake production.

- Enhances environmental sustainability with up to 40% oil savings.

- Seamlessly integrates into existing frying systems for streamlined operations.

- Applications

- Seafood, Snacks, Tempura-coated products, Meat, Vegetarian fried products, Food processing, Poultry, Non-coated fried products, Breaded products

- End products

- Fried chicken nuggets, Breaded fish fingers, Vegetarian spring rolls, Tempura shrimp, Golden french fries, Fried calamari, Breaded mozzarella sticks, Crispy onion rings, Fried plant-based burgers, Homestyle coated tenders

- Steps before

- Pre-frying preparation, Battering, Bread crumbing

- Steps after

- Cooling, Packaging, Labeling

- Input ingredients

- frying oil, tempura-coated products, breaded products, non-coated fried products, chicken nuggets, meatless snacks, fish fingers, fried pork, vegetarian fried products

- Output ingredients

- clear filtered oil, dry sediment, fried products, dry cake with little or no oil

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Automation

- Fully Automatic

- Filter capacity

- 11 m³/hr

- Filter capacity

- 3 m³/hr

- Filter capacity

- 8 m³/hr

- Particle removal size

- 1 micron

- Equipment dimensions

- 2540x1660x2200 mm

- Equipment dimensions

- 1700x1270x1850 mm

- Equipment dimensions

- 2430x1660x2580 mm

- Filter media width

- 32" wide

- Filter media width

- 20" wide

- Filter media width

- 26" wide

- Working mechanism

- Automatic filtration cycle

- Automation level

- Automatic / PLC

- Integrated steps

- Filtration and sediment drying

- Batch vs. continuous operation

- Continuous

- Cleaning method

- CIP compatible

- Energy efficiency

- High

- Changeover time

- Automatic filter cycle transition

- Filtration type

- Advanced sediment filtration

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Food oil filtration

- High performance

- Filtration system

- Automatic

- Machine footprint

- 2540x1660x2200mm, 1700x1270x1850mm, 2430x1660x2580mm

- Filter capacity

- 11 m3/hr, 3 m3/hr, 8 m3/hr

- Filter media width

- 32" wide, 20" wide, 26" wide

- Automatic operation

- Yes

- Sediment discharge method

- Automatic disposable filter material

- Filter capacity options

- 3 m³/hr, 8 m³/hr, 11 m³/hr

- Filter media width

- 20" wide, 26" wide, 32" wide

- Automatic operation

- Yes, including sediment drying and filter replacement

- Control system

- Automatic

- System configurations

- Multiple sizes to suit GEA Fryer