Citrus sizer for optimal fruit sizing

Ensure precise fruit sizing and uniformity with an inline system that optimizes distribution and calibration, enhancing efficiency in citrus processing operations.

Sizes and Calibrates Citrus Fruits Efficiently

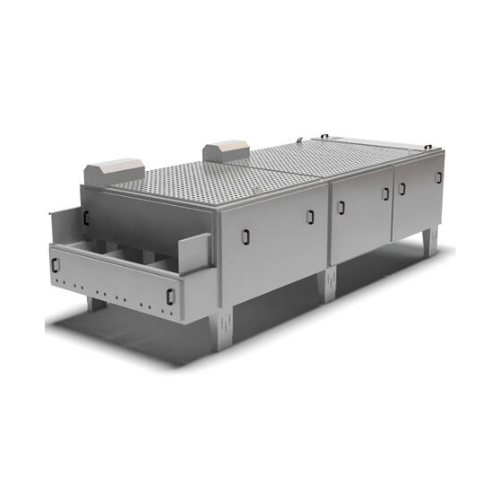

The Citrus Sizer from Bucher Unipektin is an innovative inline solution for precise citrus fruit sizing. Featuring independent inclined rails and electric motorized rollers, it ensures continuous fruit rotation for optimal calibration. Ideal for processing a variety of citrus fruits including oranges, lemons, and grapefruits, it effectively addresses the challenge of maintaining consistent fruit dimensions. The sizer operates at a high speed with configurations available in 6, 8, or 10 calibration tracks, powered by a 5 kW to 8 kW motor system. Constructed with stainless steel for enhanced durability and hygiene, it integrates seamlessly into food and beverage production lines requiring high throughput and continuous processing. The equipment’s structure supports easy integration into existing setups, making it suitable for citrus processing companies and fruit packaging operations. Electrical calibration adjustment and vulcanized belt drive drums ensure low maintenance, while its robust design minimizes operational downtime.

Benefits

- Enhances efficiency with continuous, high-speed fruit sizing.

- Minimizes manual labor with automated calibration adjustments.

- Ensures consistent product quality with precise roller calibration.

- Increases production line uptime with durable stainless-steel construction.

- Lowers maintenance needs with vulcanized belt drive drums.

- Applications

- Food processing, Citrus fruits, Fruit processing

- End products

- Tangelos, Grapefruits, Oranges, Tangerines, Lemons, Limes

- Steps before

- Harvesting, Sorting, Washing

- Steps after

- Packaging, Distribution, Quality Control

- Input ingredients

- citrus fruit, oranges, lemons, limes, grapefruits

- Output ingredients

- sized citrus fruit, calibrated citrus fruit

- Market info

- Bucher Unipektin is known for producing advanced equipment and systems for the food and beverage industry, specializing in juice processing and filtration technologies with a reputation for innovative solutions and reliable, high-quality products.

- Speed

- Fast inline operation

- Calibration setting

- 2" - 5"

- Configurations

- 6 / 8 / 10 calibration tracks

- Power

- 5 kW to 8 kW

- Material

- Stainless steel and thermoplastic

- Working Mechanism

- Inclined rails with motorised rollers

- Integrated Steps

- Continuous fruit rotation for sizing

- Inline vs Batch

- Inline

- Automation Level

- Electric calibration adjustment

- Changeover Time

- Independent calibration system

- Abrasion resistance

- Yes

- Biological compatibility

- Yes

- Cleanability

- Yes

- Corrosive resistance (e.g. acids)

- Yes

- Density/particle size

- N/A

- Machine footprint

- Compact

- Feed method

- Fruit receiving hopper with distributor

- Roller material

- Stainless steel

- Incline

- Inclined belt

- Discharge method

- Motorised rollers

- Calibration setting

- 2" - 5"

- Configuration options

- 6 / 8 / 10 calibration tracks

- Configurations

- 6 / 8 / 10 calibration tracks