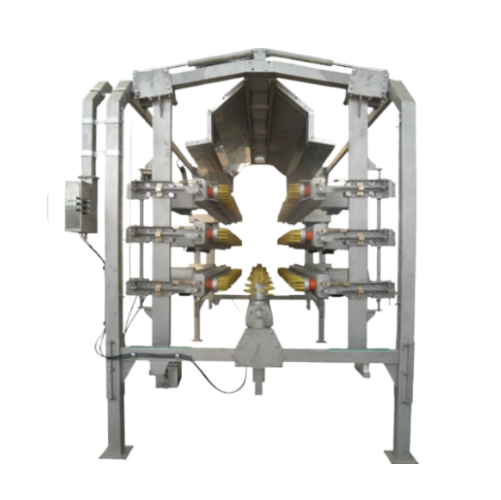

Disc finishing picker for poultry processing

Achieve precise defethering and picking with customizable adjustments for various bird sizes, enhancing efficiency and reducing maintenance costs in high-speed poultry processing environments.

Defeathers and Processes Poultry Efficiently

The B7-Series Disc Finishing Picker from Prime Equipment Group is an advanced solution tailored for poultry processing plants. This machine stands out with its versatile design, offering multiple models optimized for various line speeds and bird sizes. It operates on a unique picking mechanism, featuring independent lateral picking banks and adjustable side banks, allowing precise control to handle different poultry sizes such as chicken drumettes, turkey breasts, and whole turkeys. Ideal for continuous, high-speed operations, it uses twelve 3 hp motors and has specialized configurations to efficiently process up to 10 gallons per minute at 30 PSI. The construction includes high-grade plastic gears for quieter operation and reduced maintenance. Its integration into automated production lines is seamless, with optional hydraulic motors for enhanced picking efficiency, and it is especially effective in high-demand settings for producing chicken wings and turkey leg quarters. The machine supports easy, customizable throughput adjustments and features a feather deflector for streamlined processing, significantly reducing manual intervention.

Benefits

- Optimizes efficiency by accommodating various poultry sizes, reducing reprocessing needs.

- Lowers operational noise and maintenance costs with high-grade plastic gears.

- Enhances processing flexibility with adjustable picking banks for precise control.

- Integrates seamlessly into existing lines, supporting continuous, high-speed operations.

- Minimizes manual labor through automated feather and offal management.

- Applications

- Seafood, Meat, Poultry

- End products

- Turkey leg quarters, Chicken drumettes, Chicken thighs, Whole turkey, Turkey breasts, Chicken wings

- Steps before

- Scalding, Evisceration

- Steps after

- Portioning, Slicing, Freezing, Chilling, Proofing, Cooking

- Input ingredients

- live chicken, live turkey, poultry

- Output ingredients

- featherless chicken, featherless turkey, processed poultry

- Market info

- JBT is known for manufacturing innovative industrial machinery and solutions, particularly in the food processing and air transportation sectors, renowned for their advanced technology, reliability, and customer-focused engineered-to-order solutions tailored to specific industry needs.

- Motor Power

- (12) 3 hp motors

- Electrical Requirements

- 480V, 3 ph, 60 Hz, 100 amps

- Water Requirements

- (3) 3/4 connections

- 10.0 GPM (37.85 LPM)

- 30 PSI

- Bottom Bank Motor Power

- (5) 3hp motors

- Production Rates

- Variable and customizable

- Picking Mechanism

- Disc-Type

- Finger Hub Adjustability

- Wide Range

- Automation Level

- Variable Models

- Noise Levels

- Low Noise - High-grade Plastic Gears

- Versatility

- Adjustable for Bird Sizes

- Side Bank Adjustability

- Up/Down, In/Out, Tilt

- Production Rates

- Variable and Customizable

- Bird Focus areas

- Shoulders and Rear Neck Area

- Abrasion resistance

- High-grade plastic gears

- Cleanability

- Easy to clean

- Picking Coverage

- Maximum

- Discharge method

- Feather deflector directs to raceway

- Adjustable components

- Lateral and side banks adjustable

- Model availability

- Various models for different line speeds, bird sizes, stunning methods

- Picking bank adjustability

- Independent and adjustable up/down, in/out, with tilt

- Feather deflector

- Supplied to direct feathers to raceway

- Bottom bank

- Optional with hydraulic motors

- Plastic gears

- High-grade for noise reduction and maintenance ease