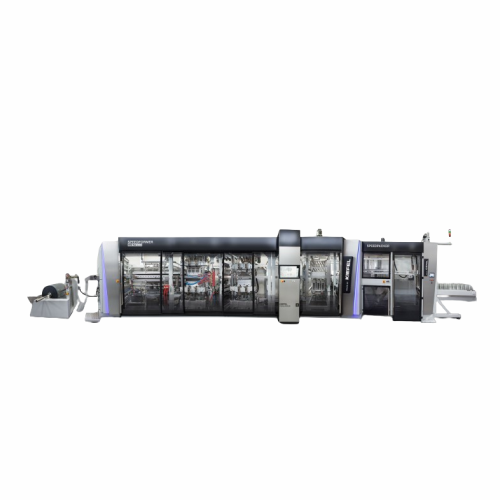

Steel rule cutting for thermoformed packaging

Optimize your thermoforming process with high-speed precision and flexible configuration, providing seamless integration for packaging solutions across various materials. Achieve efficient, consistent, and sustainable production results while reducing labor costs and ensuring superior product quality.

Thermoforms, Cuts, and Stacks Packaging Solutions

The SPEEDFORMER KMD series from Kiefel offers a highly efficient solution for packaging manufacturers, combining thermoforming and steel rule cutting into a seamless production line. Utilizing servo-driven operations, these machines ensure precision in every cut and form, catering to a wide array of end-products such as plastic food trays, clamshell packaging, and disposable cups. With models like the KMD 64.2 Speed and KMD 90.1 Premium, the series supports high-speed, continuous operation, facilitated by quick tool changes and robust automation. Each machine features energy-efficient heating systems that reduce consumption while maintaining product quality, offering sustainability without compromising throughput. The SPEEDFORMER KMD series is compatible with a variety of materials including PET, PP, PS, and PLA, making it suitable for both food and non-food packaging applications. Designed for easy integration into existing lines, these machines also provide extensive customization options to meet specific production needs.

Benefits

- Enhances production efficiency by integrating thermoforming, cutting, and stacking in one streamlined process.

- Reduces energy consumption through optimized servo motor drives and intelligent heating systems.

- Minimizes labor costs with advanced automation and quick tool change features.

- Accommodates diverse packaging materials, supporting sustainability initiatives with compostable options.

- Increases product quality with precision control systems and unique stacking solutions.

- Applications

- Pe packaging, Ps packaging, Non-food packaging, Pet packaging, Pp packaging, Food packaging, Thermoformed products, Pla packaging

- End products

- Pet bottles, Pp lids, Fruit punnets, Plastic food trays, Disposable cups, Disposable cutlery, Electronic device housing, Ps foam trays, Blister packs, Pe bags, Cosmetic packaging, Pla compostable cups, Yogurt containers, Clamshell packaging, Take-out food containers

- Steps before

- Film preparation, Tool selection, Material feeding

- Steps after

- Stacking, Packing, Quality control

- Input ingredients

- PET, PP, PS, PLA, PE, film

- Output ingredients

- thermoformed products, cut products, stacked products, packaging products

- Market info

- KIEFEL GmbH is renowned for engineering and manufacturing high-performance thermoforming and joining systems, specializing in solutions for the packaging, medical technology, and automotive industries, ensuring innovative and precise equipment to meet specific industrial demands.

- Forming Area

- 620 x 470 mm to 870 x 920 mm

- Tool Dimensions

- 640 x 490 mm to 890 x 940 mm

- Height Formed Part

- 120 mm to 160 mm

- Film Width

- 670 mm to 925 mm

- Film Thickness

- 0.2 - 1.8 mm

- Punching Force BFS

- 450 kN to 800 kN

- Punching Force Punching Station

- 500 kN to 850 kN

- Production Speed

- 30 to 50 cycles/min

- Automation

- Servo motor drives, fully automatic operation

- Energy Efficiency

- Drives with energy recovery system

- Temperature Control

- Film temperature measurement with closed-loop control

- Automation level

- Fully automated

- Changeover time

- Fast, ergonomic tool change

- Energy efficiency

- Drives with energy recovery system

- Batch vs. continuous operation

- Continuous

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine Footprint

- Varies by model, e.g., 760 x 580 mm forming area

- Tool Dimensions

- Max 780 x 600 mm to 890 x 940 mm

- Height Formed Part

- 120 mm to 160 mm

- Film Width

- 670 mm to 925 mm

- Film Thickness

- 0.2 - 1.8 mm

- Discharge Method

- Integrated stacking station

- Control Panel Type

- HMI with large touch screen

- Control panel type

- HMI with large touch screen, proven operation

- Integration possibilities

- Standard automation modules, e.g. SPEEDPACKER, SPEEDPADDER

- Tool compatibility

- Easy installation of existing tools, like RDK tools

- Plug and play

- Simple standard adapter for tools, such as Sencorp series