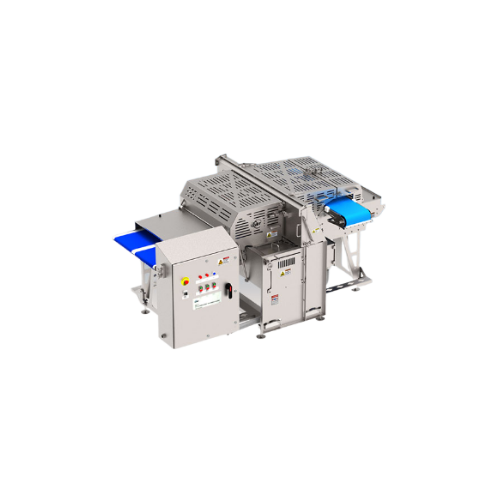

Poultry breast slicer for consistent thickness

Achieve superior slice consistency and maximize yields with dual-lane high-speed slicing, designed to handle jumbo fillets and reduce product variability.

Slices and Portions Meat, Poultry, and Seafood

The DSI CT 32 Consistent Thickness Slicer from DSI is engineered for precise slicing and portioning of poultry, meat, and seafood. Its continuously moving blade system ensures smooth, uniform cuts, reducing product variation by up to 30% compared to standard slicers. The unique dual-lane configuration enables processing of up to 320 fillets per minute, with adjustable thickness settings allowing quick changes without halting production. Ideal for chicken breast fillets, turkey slices, and beefsteak, this slicer seamlessly integrates into automated lines. Operating at high belt speeds, it minimizes energy and water usage, featuring a patented compliant hold-down system for superior cut consistency. The slicer is constructed with robust materials suitable for food processing environments, and it supports easy maintenance with its simple mechanical adjustments.

Benefits

- Enhances portioning accuracy by up to 30%, minimizing waste.

- Increases processing capacity to up to 320 fillets per minute.

- Facilitates quick thickness adjustments without stopping production.

- Decreases water usage with efficient operation.

- Seamlessly integrates into automated processing lines, reducing labor requirements.

- Applications

- Seafood, Meat, Poultry

- End products

- Chicken breast fillets, Pork chops, Bacon strips, Tuna steaks, Salmon portions, Beefsteak, Turkey breast slices, Fish fillets

- Steps before

- Injection, Marination

- Steps after

- Packaging, Freezing, Refrigeration

- Input ingredients

- whole breast meat, half breasts, poultry fillets, jumbo-sized breast, side-by-side fillets

- Output ingredients

- consistently thick slices, butterflies, fillets, smooth cuts, superior cut quality

- Market info

- JBT is known for manufacturing industrial ETO equipment, specializing in food processing and airport ground support systems. They are reputed for innovative solutions and reliable service in industries requiring sophisticated automated systems and machinery.

- Blade Speed

- 80 feet per minute (24.4 meters per minute)

- Slicer Capacity

- Up to 160 butterflies or 320 fillets per minute (dual lane)

- Slice Thickness

- Up to 3.5 inches (88.9 mm)

- Usable Belt Width

- 12.5” (320 mm) per lane

- Electrical Voltage

- 380/480 VAC (50/60 HZ)

- Phase

- 3

- Amperage

- 30 Amps

- Water Supply (Low Pressure)

- 0.9 gal/min (3.3 L/min)

- Drain

- 1.0-2.0 gal/min (3.7-7.5 L/min)

- Automation

- Automatic compression adjustment

- Product Weight Capacity

- Up to 1, 400 grams (whole breast meat)

- Working mechanism

- Continuous blade movement

- Integrated steps

- Automatic compression application

- Batch vs. continuous operation

- Continuous

- Automation level

- Fully automated

- Changeover time

- Seconds

- Production speed

- Up to 320 fillets/min (dual lane)

- Energy efficiency

- Low maintenance effort

- Cleaning method

- Manual

- Utility requirements

- 380/480 VAC, 50/60 HZ

- Water usage

- 0.9 gal/min (3.3 L/min)

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Dual lane configuration with 12.5” (320 mm) usable belt width per lane

- Belt speed

- 80 feet per minute (24.4 meters per minute)

- Slicing thickness

- Adjustable up to 3.5 inches (88.9 mm)

- Discharge method

- Continuously moving blade for smooth cuts

- Feed method

- Dual lane for processing high volumes

- Lane Configuration

- Single / Dual Lane

- Blade Movement Speed

- High-speed, continuously moving

- Slice Thickness Adjustment

- Mechanical adjustment

- Top Slice Removal

- Switchable

- Integration capability

- Automated line integration