Bread Manufacturing Equipment

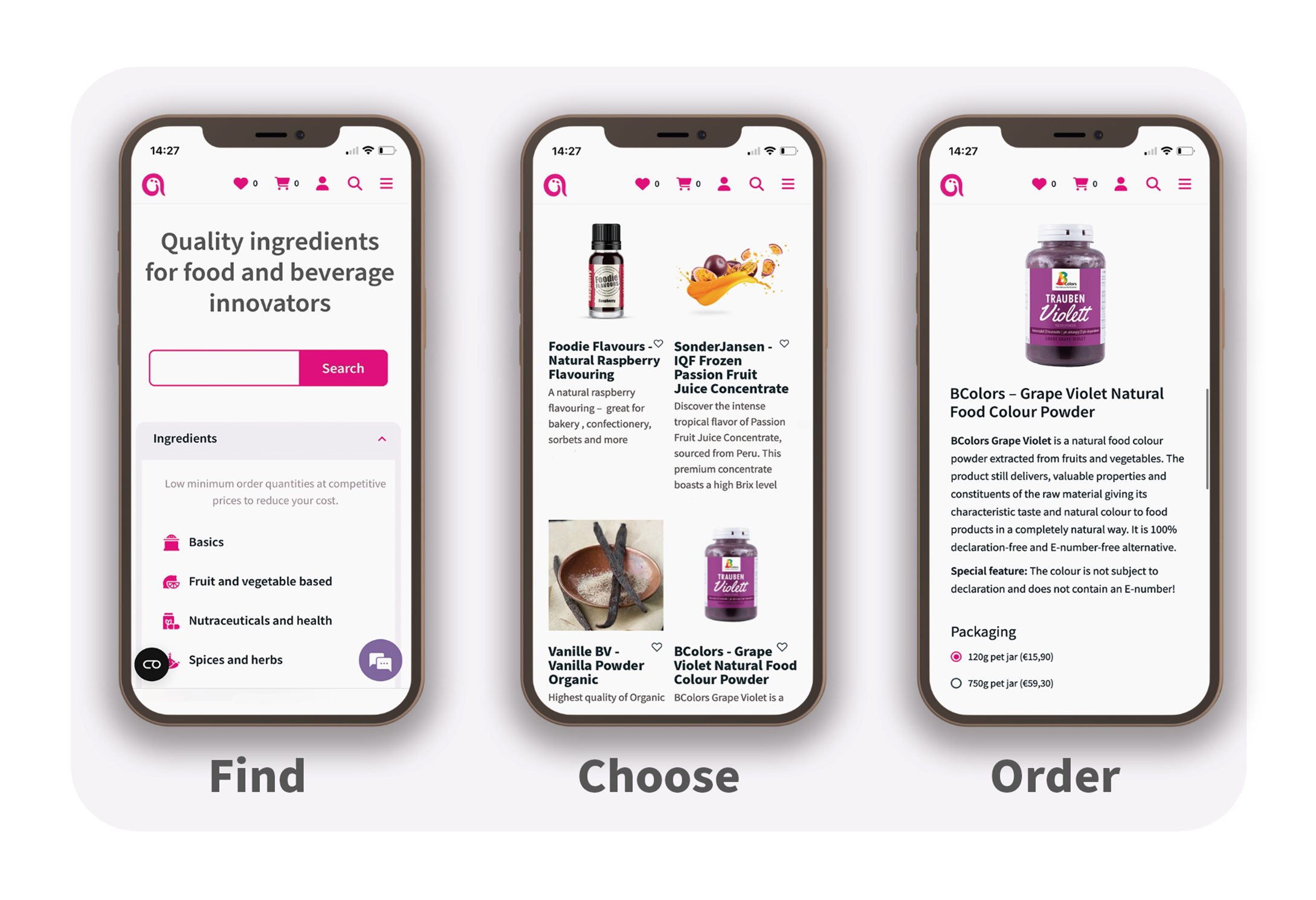

Find innovative production technology for making bread and connect directly with world-leading specialists

The Roman quip “bread and circuses” says everything about the ubiquity of loaves through the ages. But although flour, yeast, and water are still the main bread recipe ingredients today, the baking process as well as the bakery equipment available, takes this basic formula to new avenues. From sprouted wheat challah to beetroot ciabatta and protein rolls, breadmaking has changed considerably since the time of the Roman empire.

Technology picks for bread production

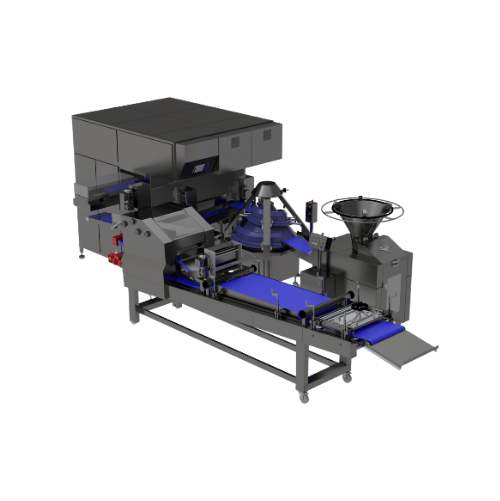

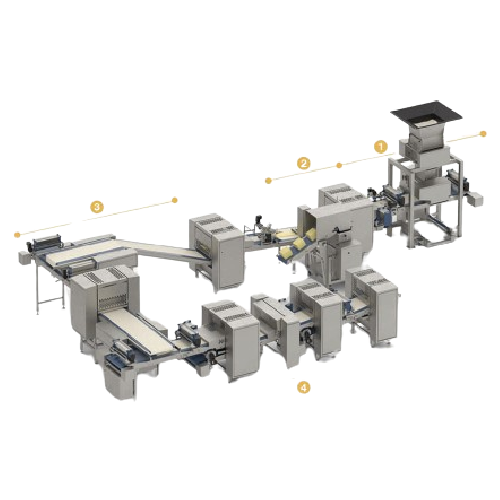

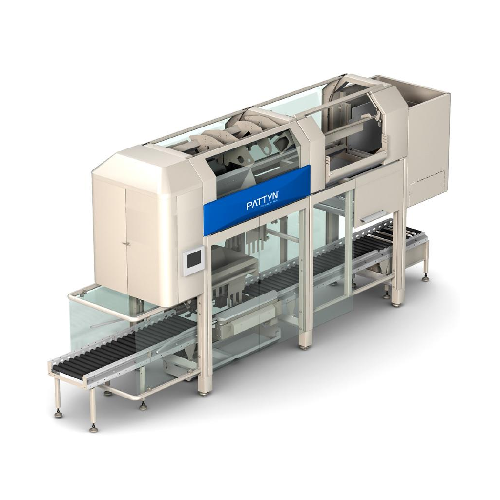

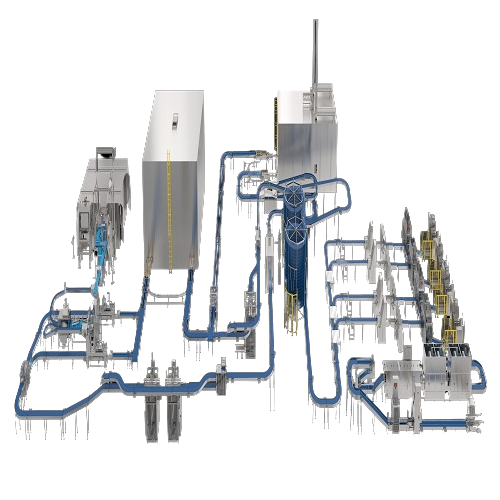

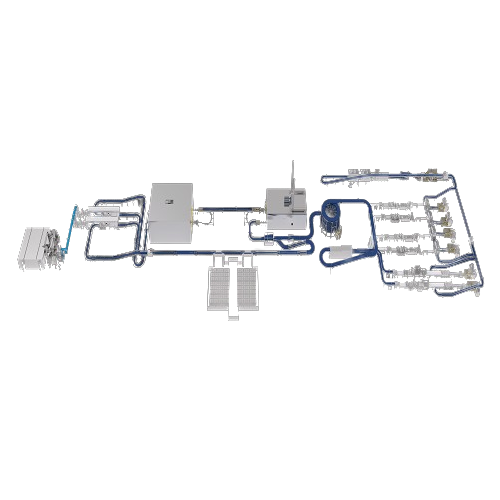

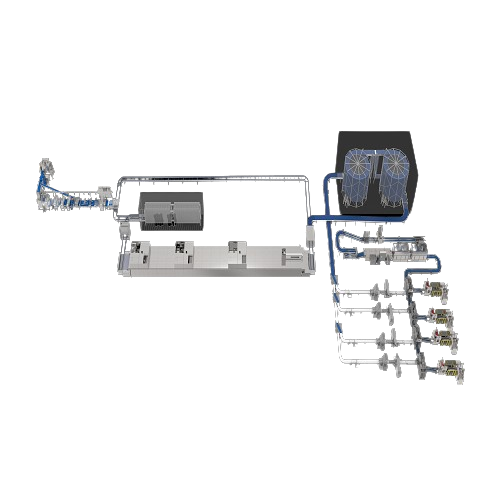

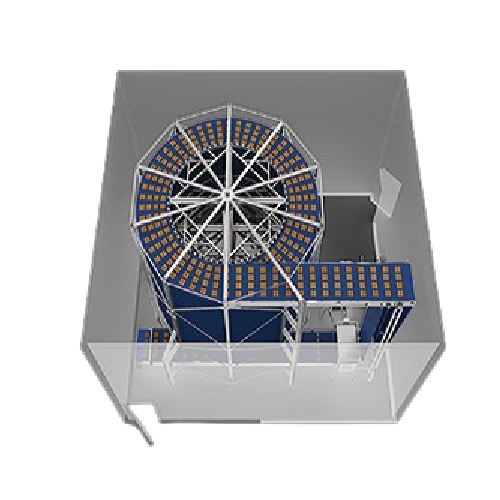

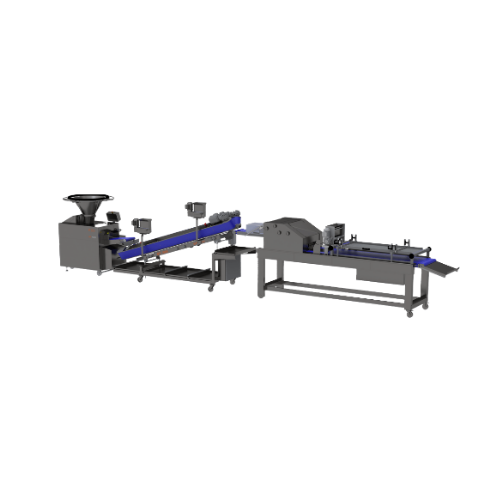

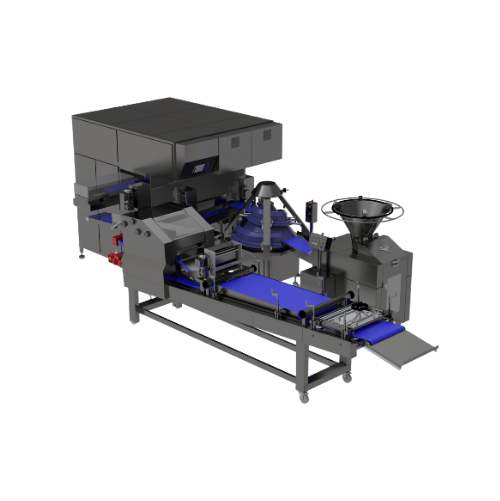

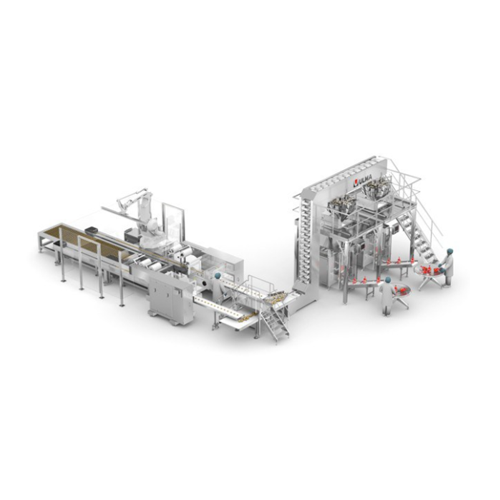

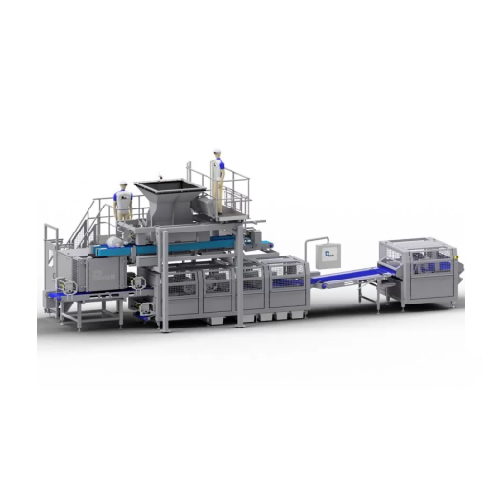

Automated artisan bread production line

Enhance your bakery’s efficiency with this versatile bread production line, d...

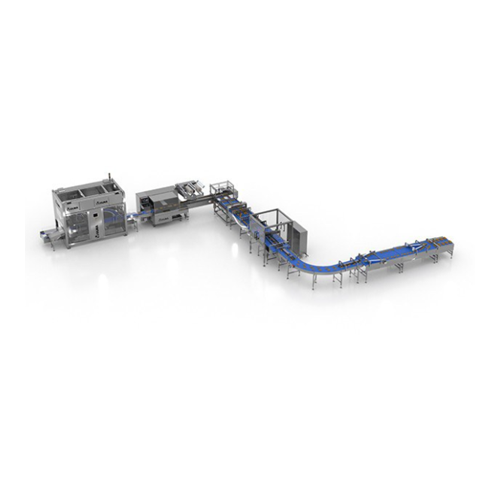

Automated dough make-up line for sweet bread production

Effortlessly handle diverse dough weights and consistencies to pr...

Bread fermentation for rye sourdough

Transform leftover bread into high-quality rye sourdough with a mobile, plug-in fermen...

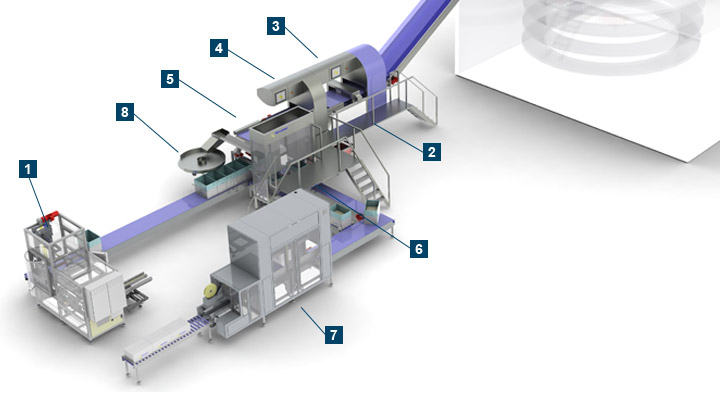

Automatic rework system for biscuit and bread scrap

Scraps are an inevitable byproduct of biscuit and bread production. W...

Select your bread process

Tell us about your production challenge

Use flour with 11% minimum protein composition

Fluffy pan loaves and crusty sourdoughs have contrasting textures, but they are essentially a flurry of gas bubbles inside a mass of protein. Form this bread dough by hydrating strong wheat flour (11% or more protein content) with water in a food-grade mixer, to produce gluten. The mixer should have dough hooks to make the kneading process more efficient.

The gluten gives the dough extendibility to grow and elasticity to keep intact. Mix the flour and water at high speeds for approximately 15 minutes. The dough’s temperature is between 25°C and 28°C.

Add brewer’s yeast to ferment the flour mix

Yeast is a vital ingredient in breadmaking, providing lift and lightness and giving the bread a doughy flavor. The Saccharomyces cerevisiae species is especially suited for modern bread processing because it is food-grade and relatively low-cost.

The yeast breaks down the carbohydrates in the flour and releases carbon dioxide, which remains trapped in the dough and expands it. Producing breads involve two stages of proving: the first one is after the dough is divided and then after it is molded.

Supplementary enzymes and oxidizing agents alter the protein complex

There are several methods for bread processing, but the Chorleywood technique developed in the latter half of the 20th century emerged as the manufacturing standard. The method modifies the protein structure of the flour using a closed high-speed mixer.

Meanwhile, adding oxidizing agents such as ascorbic acid to the mix shortens the fermentation process. Additional enzymes activate the yeast to enhance the rising of the dough.

Raise the baking temperature to 74°C to inactivate thermophilic yeasts

In the oven, the dough continues to expand while losing weight. A moderate heat transforms carbon dioxide in solution into a gas, occupying the microscopic cells. But as ethanol caused by fermentation evaporates, the mass becomes lighter.

The crumbs, however, need a higher temperature (around 60°C) to start stabilizing into a paste. The last yeast cells are killed when the heat reaches 74°C, but the loaf is not fully cooked until the crust forms at 160°C. The browning occurs as sugars contained in the flour caramelize.

Gluten-free formulas are worked with standard bread processing equipment

Gluten-free flours such as buckwheat or almond flour cannot replicate the level of viscosity that wheat flours do. This reduces the flexibility and extendibility of the dough. But these properties can be supported by functional ingredients in the mix.

Added protein provides the structure for the dough to form the network. Meanwhile, hydrocolloids such as HPMC perform a gelatinization function to ease expandability. You don’t require separate bread processing equipment to make gluten-free products.

Processing steps involved in bread making

Which bread technology do you need?

Baguette cutting and sauce filling system

Optimize your bakery production with an innovative system that seamlessly cuts a...

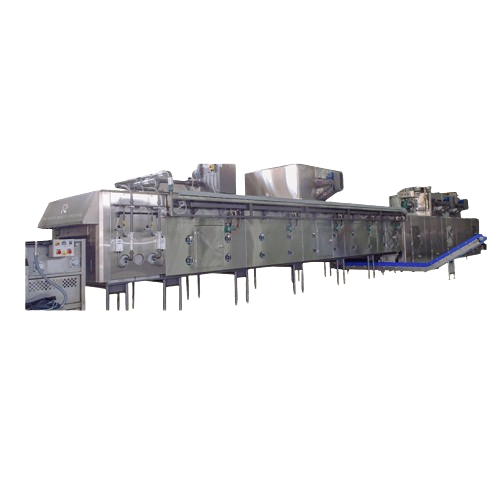

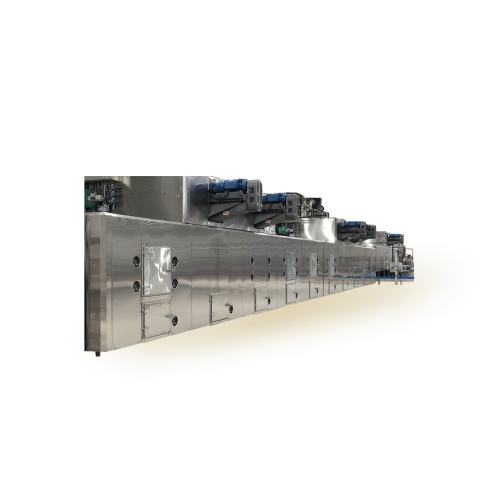

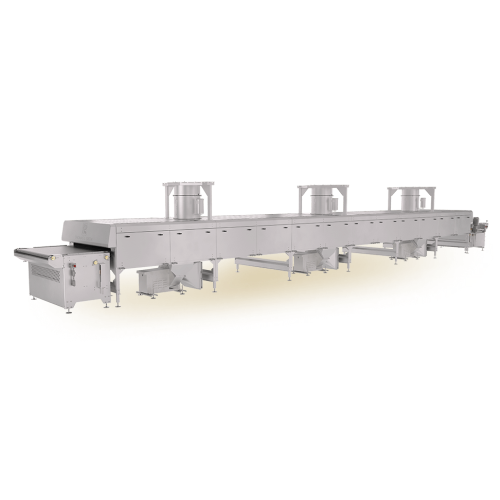

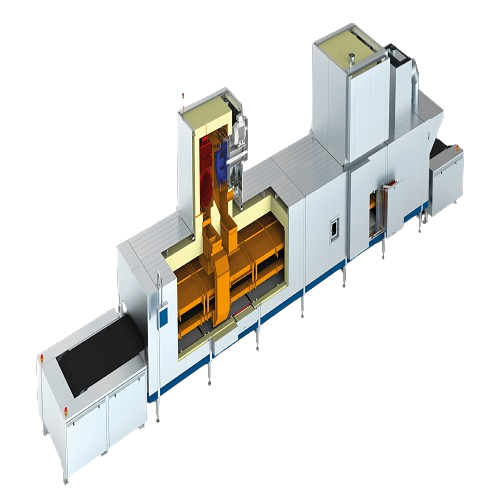

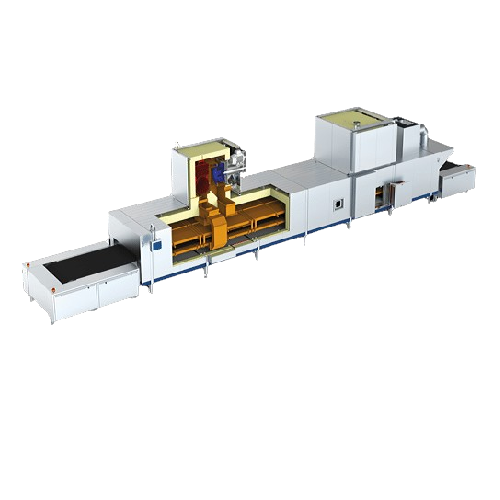

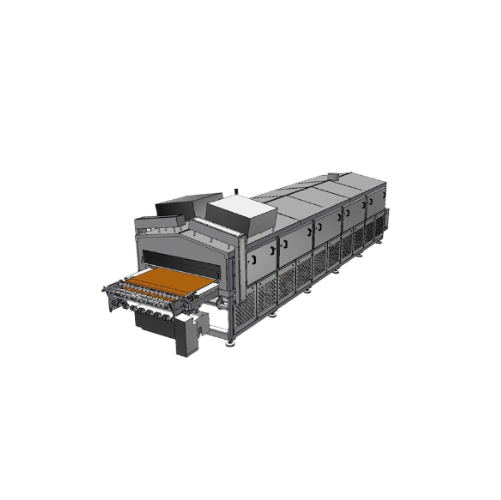

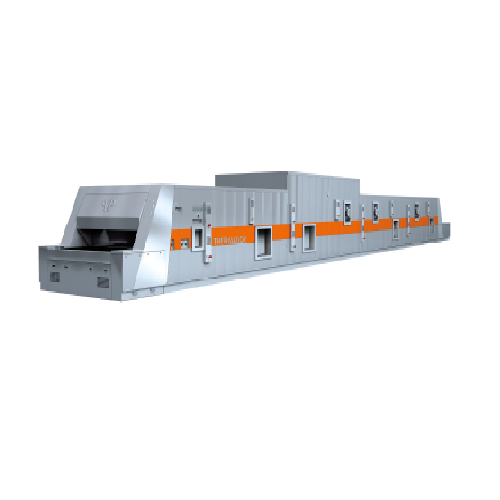

Industrial tunnel ovens for bakery products

Achieve precise control over baking processes with these industrial tunnel ove...

Cake and pastry depanner

Optimize your bakery’s output with this solution that seamlessly integrates into your production lin...

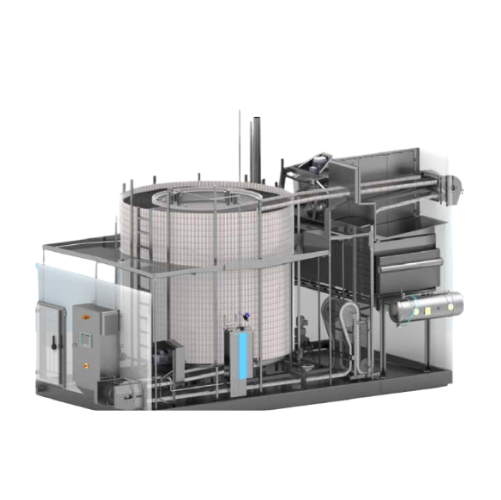

Freezing and cooling systems for bakery products

Enhance your bakery production line with advanced freezing and cooling sy...

Cakes and pastry fill injector

Achieve precise and efficient filling of a variety of bakery products, minimizing waste and d...

Smart bakery oven zone for flexible heating

Optimize your production with flexible heat transfer options that enhance cont...

Convection oven with integrated dryer for large scale baking

Optimize your baking process with a convection oven that ef...

Croissant production module for pastry make-up lines

Enhance your bakery’s product range with a versatile module de...

Donut production line for various shapes and sizes

Optimize your bakery’s output with precision-engineered dough pr...

Industrial dough laminator for croissants and pastries

Achieve consistently light and flaky products with precision lamin...

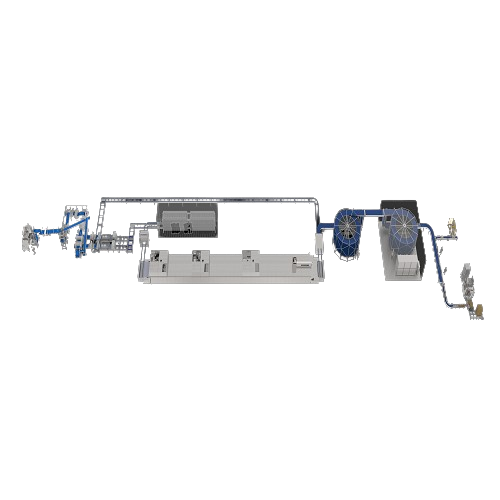

Pastry production line for large-scale bakeries

Streamline your bakery production with a versatile line designed to effici...

Dough laminating equipment for croissants and pastries

Optimize your bakery’s output with our advanced laminating e...

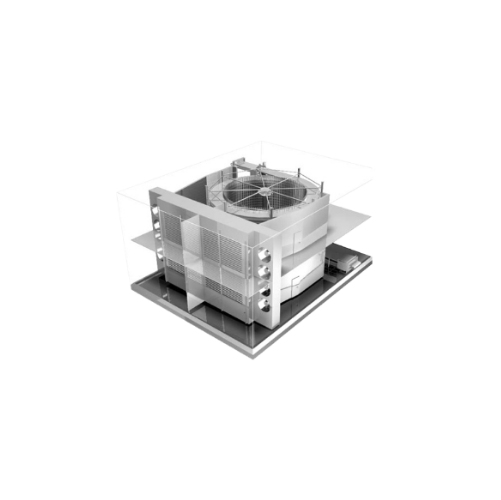

Ambient air cooler for bakery products

Efficiently cool fragile baked goods without causing distortion, using ambient air t...

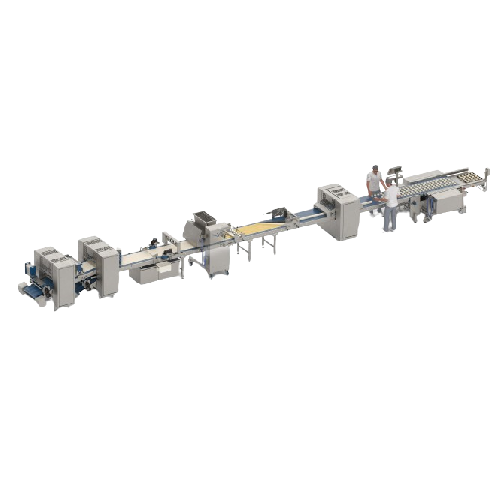

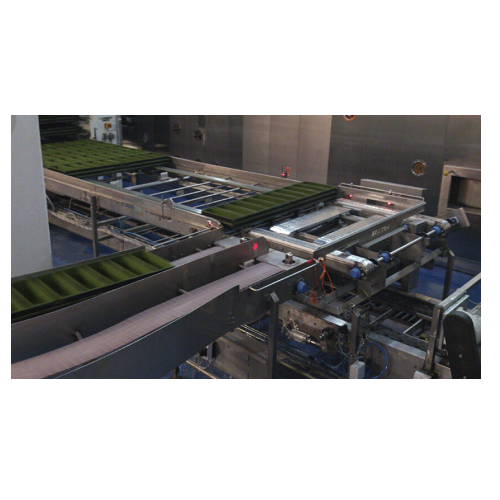

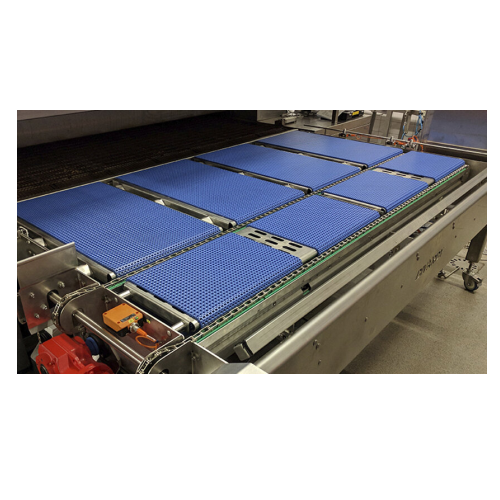

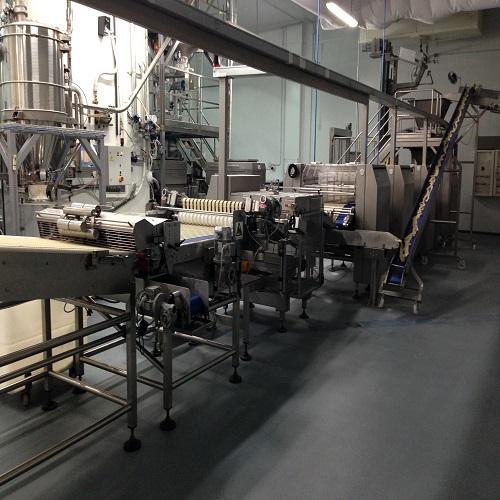

Industrial bread process line

Optimize your bakery operations with a versatile bread processing line, designed to handle a v...

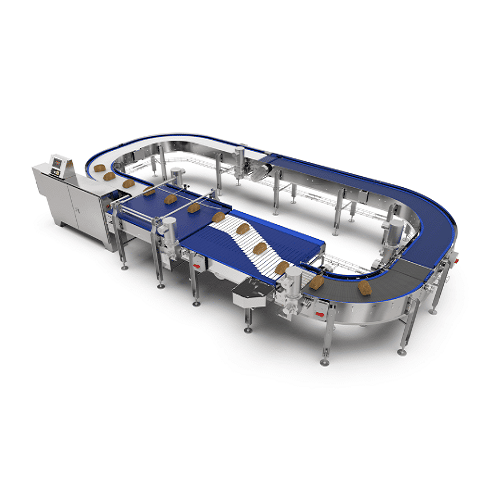

Industrial bakery conveying solutions

Ensure seamless, hygienic transport of bakery goods with precision-engineered conveyi...

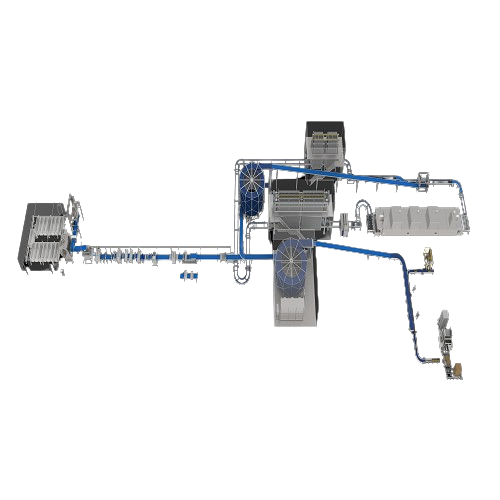

Industrial croissant production line

Streamline your bakery’s operations with a versatile solution capable of produci...

Advanced bakery depanning solutions

Streamline your bakery production with cutting-edge depanning technologies designed to ...

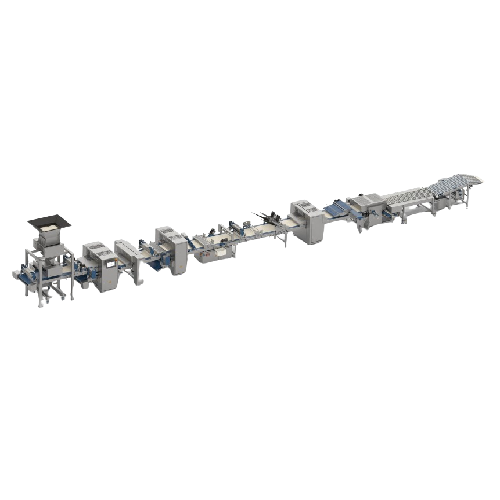

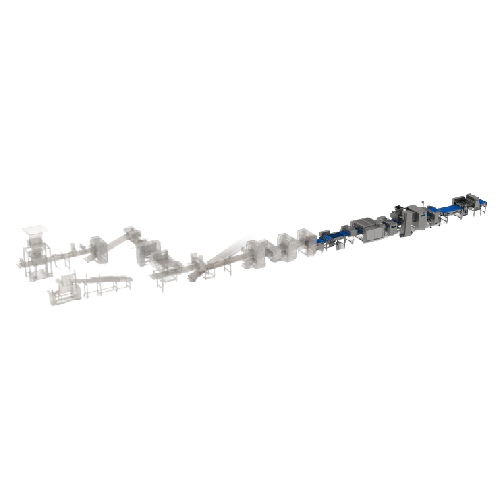

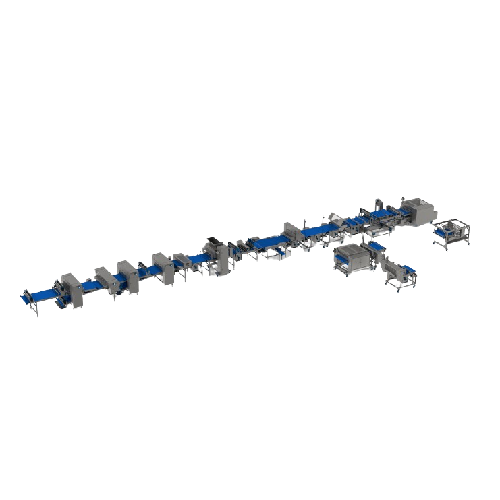

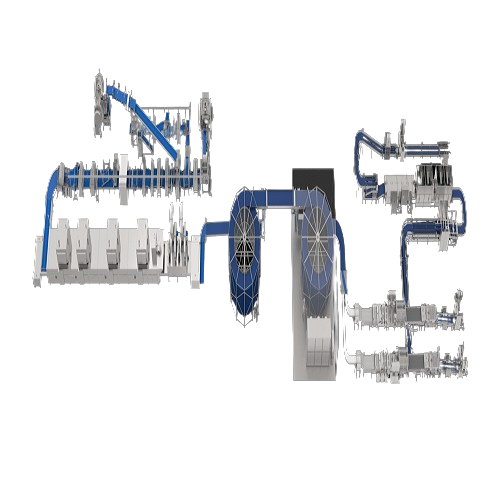

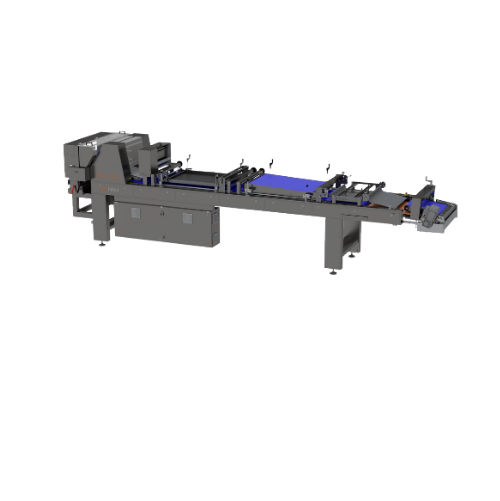

Automated bread production line

Optimize your bakery operations with precision-engineered systems that streamline every stag...

Automatic oven loading and unloading system

Streamline your bakery’s production efficiency with precise and synchron...

Universal pastry production line for industrial baking

Optimize your bakery operations with a versatile line capable of p...

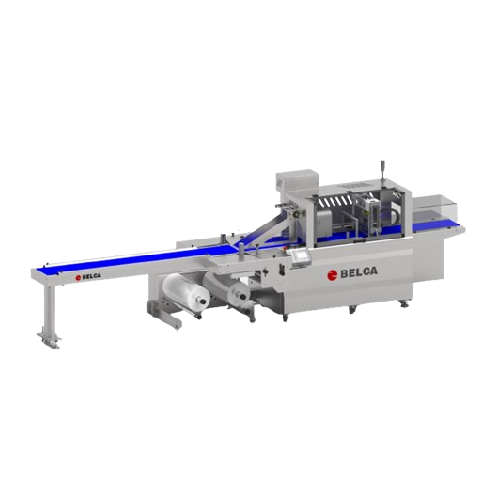

Intermittent motion end load cartoner for baked goods and home care products

Streamline your packaging line with high-...

Efficient cooling and cooking systems for food processing

Streamline your production with integrated cooling and cooking...

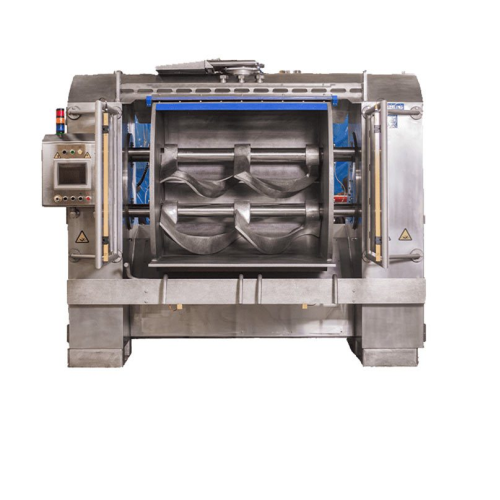

Open frame mixer for bread and pastry dough

Enhance your dough consistency and reduce production downtime with a robust, h...

Open frame mixer for bread and dough applications

Enhance baking productivity with a versatile mixer designed for efficie...

High-speed sandwiching for bakery production

Streamline your production of sandwich biscuits with a machine engineered to ...

High-speed sandwiching machine for bakery production

Streamline your baking operations with a machine designed to efficie...

Medium duty mixer for breads and pastries

Achieve consistent dough development and uniform mixing for a wide variety of ba...

Medium duty mixer for dough preparation

Achieve perfect dough consistency across various products with a versatile medium d...

Slurry mixer for cake batters and premix ingredients

Efficiently mix cake batters and premix ingredients with precision, ...

Traditional enclosed frame mixer for dough and batter preparation

Optimize your production with high-capacity mixing, e...

Industrial enclosed frame mixer for high-capacity dough mixing

Optimize your bakery’s output with a mixer designed...

Continuous mixer for batters and cremes

Achieve consistent texture and uniform cell structure in your cake batters and crèm...

Cream delivery solution for sandwiching lines

Achieve precise cream delivery with enhanced control and efficiency, optimiz...

Depositors for bakery fillings

Achieve precise and high-speed depositing of bakery and pastry fillings to optimize your prod...

Rotary dough feeder for bread and tortilla production

Optimize your dough processing by maintaining dough integrity and e...

Rotary dough feeder for uniform dough blocks

Efficiently feed consistent blocks of dough into your processing line without...

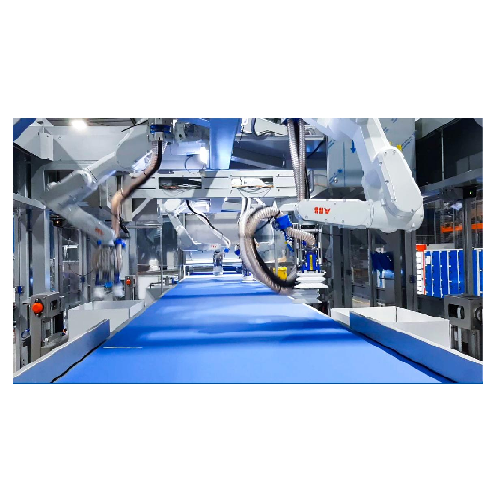

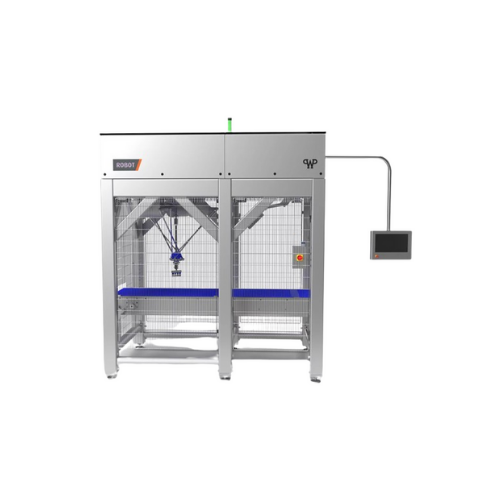

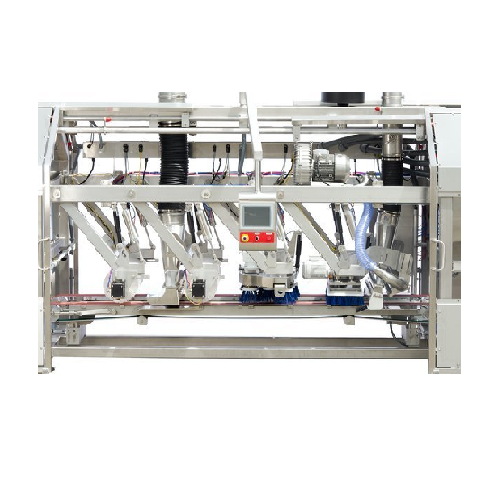

Robotic pick and place system for frozen products

Enhance efficiency in your packaging line with a solution designed for ...

Industrial vision robot for optimized packing

Optimize your bakery production line with a system designed to efficiently p...

Robotic solution for packing frozen bread products

Optimize your frozen bread packing process with high-speed, precise pi...

High-speed baguette case filling station

Effortlessly organize and pack bakery products into cases at high speed, ensuring ...

Industrial bakery bag dropper for boxes or trays

Enhance your bakery line with precision-based bag dropping solutions that...

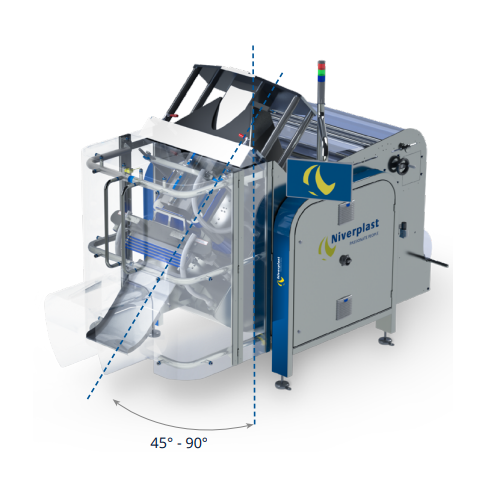

Vertical fill and seal bagging machine for bakery products

Streamline your bakery product packaging with this versatile ...

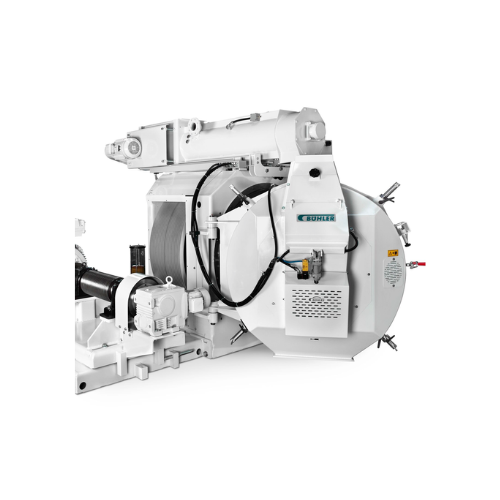

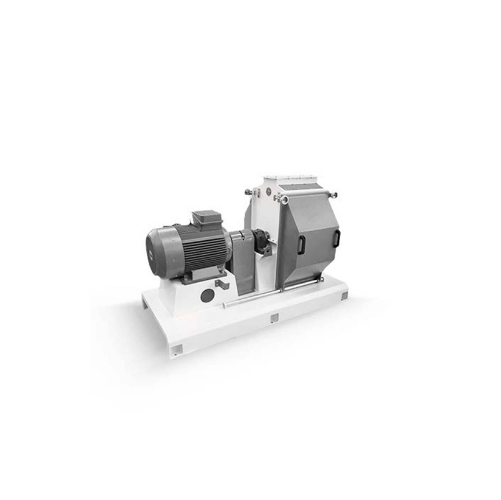

High efficiency roller mill for grain and oilseeds

Optimize your crushing and grinding processes with a versatile roller ...

High infeed palletizer for varied product types

Optimize your production line with high infeed palletizers, ensuring seaml...

Vertical form fill seal packaging system

Enhance your packaging line with precision sealing and efficient throughput, ideal...

High-precision batch counting solution

Achieve precise product alignment and counting with advanced vibration and photocell...

Case erecting and bag placing system

Streamline your packaging process with a compact system that integrates case erecting ...

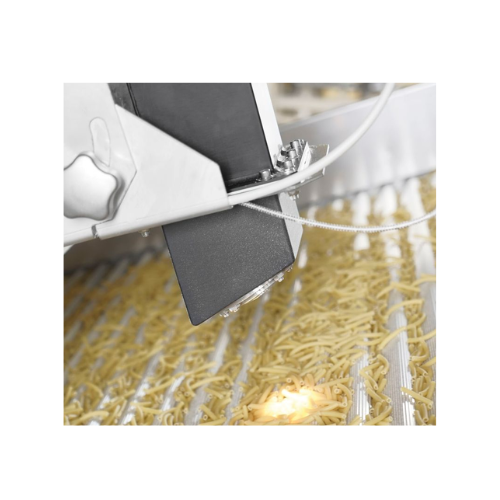

Professional grater for parmesan and hard cheeses

Enhance your processing line with a robust grater designed to efficient...

Gravity slicer for supermarkets and catering

Enhance your deli section with precision slicing, delivering uniform cuts for...

Convection oven for bakery production

Optimize your baking with precise temperature and humidity control, ensuring perfect ...

Steam pipe oven for industrial bakeries

Achieve consistent baking results with efficient heat distribution and steam genera...

Electrical deck oven for bakery applications

For bakery operations seeking precise control, our deck ovens deliver optimal...

Electrical deck oven for high-efficiency industrial baking

Achieve precise temperature control and energy efficiency in ...

Advanced convection oven for bakery applications

Enhance your bakery’s production efficiency and product quality with a ve...

Industrial long moulder for bakery production

Enhance your bakery’s efficiency with a high-speed long moulder ideal ...

Dough proofing solution for stress-free fermented dough

Ensure stress-free dough handling and optimal fermentation before...

Removable bowl system mixer for dough preparation

Optimize your bakery production with this advanced mixer featuring a re...

Fixed bowl spiral mixer for dough preparation

Ideal for perfecting dough consistency, this spiral mixer offers two-speed o...

Rotary rack oven for bakeries

Efficiently handle diverse baking needs with precise temperature and steam control, ensuring c...

Combinex for baking high-quality breads and pastries

Optimize your bakery or confectionery production with precise temper...

Industrial bakery oven with proofing cabinet

Optimize your bakery production with an all-in-one solution that seamlessly i...

Versatile bread slicer for bakeries and supermarkets

Effortlessly slice various bread types with precision and speed, ens...

Industrial bread cutter for loaves up to 500 mm

Optimize your bakery’s slicing precision with technology designed to...

Tabletop bread slicer for various bread types

Achieve precise slicing of breads and cakes with a compact solution that max...

High-volume breader for homestyle and standard coatings

Achieve seamless switchovers between homestyle and standard bread...

Flake ice weighing and batching system for dough processing

Optimize your dough’s freshness and consistency with p...

Automated flake ice storage solution

Streamline your ice management with a solution that eliminates manual handling, enhanc...

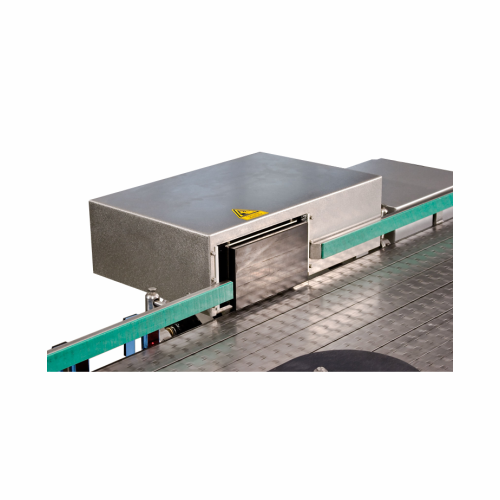

Conveyorized food metal detector for high-care environments

Ensure food safety with advanced metal detection tailored fo...

Gravity fed metal detector for dried foods

Ensure product purity and safety with metal detection between gravity feed hopp...

Cryogenic chilling for food processing

Optimize your food production line with cutting-edge cryogenic chilling solutions, d...

Vibrating sorting table for pre-dewatering

Efficiently streamline your production with a versatile vibrating sorting table...

Fruit processing and packaging line

Streamline your fruit and vegetable processing with this semi-automatic system designed...

Packaging solution for bulk vegetables and fruits

Ensure precise, high-speed packaging for diverse product sizes with a f...

Industrial thawing systems for meat products

Optimize your food production line with advanced thawing systems designed to ...

Large capacity horizontal motion conveyor for fragile products

Achieve gentle handling and minimize product damage with ...

Big bag unloading station for solid materials

Streamline your production line by efficiently handling and dosing bulk soli...

Horizontal element kieselgur filters

Enhance your production with a filtration system that ensures effective separation of ...

Industrial skids for liquid processing

Efficiently manage large-scale liquid and solid processing in your production line w...

Industrial case rejector for faulty packaging

Ensure product integrity by smoothly removing faulty cases from your product...

Advanced metal detection for food processing

Maximize your production line’s safety and efficiency with a cutting-ed...

Multi-lane checkweigher for mixed-application production lines

Achieve precise weight verification across multiple lanes...

Dough portioning system for bakery operations

Achieve precise dough portioning with minimal waste using our advanced syste...

Cutting unit for high-yield tin loaves

Experience precision and efficiency in dough portioning with our high-capacity cutti...

Continuous band blade decrusting slicer for bread

Achieve precise decrusting and slicing of various bread loaves with con...

Reciprocating blade slicer for high-speed cutting

Ensure precise, high-speed slicing of bakery products with an industria...

Reciprocating blades slicer for bread

Achieve precise, adjustable slicing for various bread types at medium speeds, enhanci...

High-speed industrial bread slicer

Optimize your bakery’s throughput with a continuous slicing solution designed to h...

Horizontal slicer with dual cutting disks

Achieve precise, high-speed slicing for a variety of baked goods with dual cutti...

Dough divider for industrial baking processes

Optimize your bakery production with precise dough dividing, delivering cons...

Bread moulder for consistent dough shaping

Ensure uniform dough shaping and enhance bread quality with precision moulding,...

Bread dough rounder for consistent shaping

Achieve uniform dough shaping and enhance product consistency for high-speed ba...

Continuous mechanical clipband closing system for bags

Streamline your bakery packaging process with a high-speed clipban...

Automatic packaging system for preformed bags

Enhance your bakery’s efficiency with advanced preformed bag packaging...

Horizontal partial cut slicer for bakery products

Achieve precision in your bakery with a horizontal partial cut slicer, ...

Industrial reciprocating blade slicer for high-speed slicing

Enhance your bakery production line with high-speed slicing...

Advanced dough mixing solution with removable bowl

Efficiently blending and kneading diverse doughs, this mixer enhances ...

Planetary mixer for industrial pastry production

Achieve precise dough consistency and enhance baked goods quality with th...

Double jacketed mixer for dough cooling

Achieve consistent dough quality and superior gluten development with precise tempe...

Spiral mixer with removable bowl for bakery production

Achieve consistent dough quality with advanced bowl locking and mo...

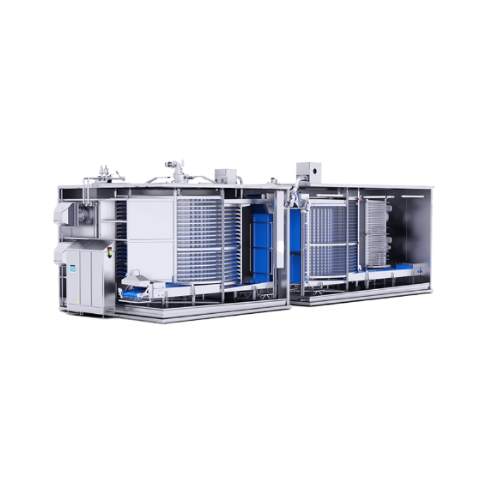

Large capacity cryogenic spiral freezer

Ensure consistent freezing quality and high yield in your continuous production lin...

Bread fermentation for rye sourdough

Transform leftover bread into high-quality rye sourdough with a mobile, plug-in fermen...

Rye sourdough production system

Achieve consistent, high-quality rye and wheat sourdough production with a versatile system ...

Sourdough fermentation unit for rye pre-doughs

Optimize your sourdough production with this compact unit, enabling precise...

Wheat and spelt predough production system

Optimize your bakery production with a flexible and mobile compact system desig...

Interchangeable tool stainless steel kneader

Streamline your batch processing with this flexible mixing technology that of...

Automated modified atmosphere packaging solution for pre-wrapped trays

Streamline your packaging process with high-spee...

Enrober for complete dry topping coverage on dough pieces

Ensure consistent, high-speed enrobing of dry toppings on doug...

Smart pattern splitter for bakery products

Achieve precise split patterns on various bread types with an innovative water ...

Advanced grain cleaning system

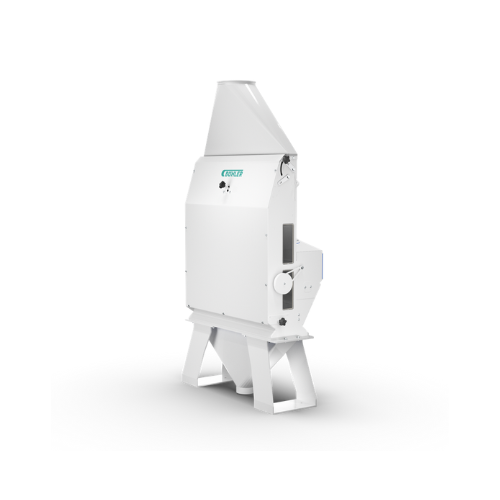

Optimize your grain processing with a cutting-edge cleaning solution that efficiently removes...

Efficient grain destoning and concentrating system

Optimize your grain processing with a solution that ensures precise se...

Chain conveyor for grain and floury products

Ensure seamless material handling with a versatile chain conveyor designed fo...

Industrial sieving solution for powders and granulates

Ensure top sanitation and food safety in your production line with...

Industrial grain plansifter

Streamline your milling process with high-capacity sifting and grading for grains, ensuring prec...

Pellet mill for biomass and sunflower hulls

Achieve high-speed, continuous production of durable pellets from varied mater...

Grain purifier for wheat and corn milling

Optimize grain processing with a high-throughput purifier designed to enhance pu...

Premixer for confectionery masses

Achieve consistent ingredient blending with precision-premixing for candy and baked goods...

Sieve tensioning device for milling applications

Achieve precise and consistent tensioning across various sieve frames wit...

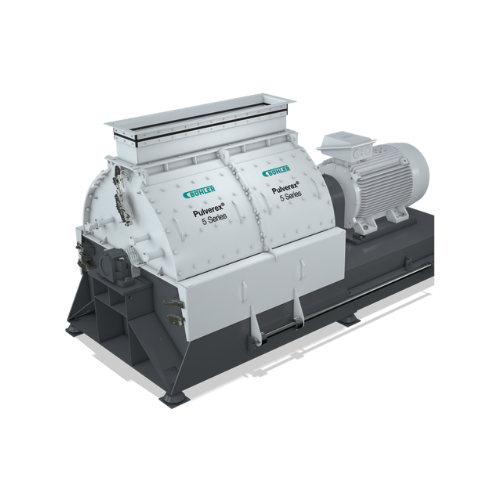

Pulverizer for fine grinding applications

Achieve optimal particle size distribution and enhance throughput with this adva...

Automatic silo scale for grain processing

Enhance your grain handling operations with precision weighing and dosing, ensur...

Hydrothermal kiln for oats and sorghum

Optimize your grain production with advanced enzyme inactivation and hydrothermal tr...

Oilseed flaking and milling system

Optimize your oilseed processing with a flaking system that enhances extraction efficien...

Control systems for wet grinding industry

Enhance precision and efficiency in your production line with advanced control s...

Digital process service for regulating water in dough preparation

Achieve consistent dough moisture levels with this di...

Weighing and receiving container for floury products

Achieve precise and consistent ingredient proportions with this syst...

Bran finisher for wheat and rye

Enhance your milling efficiency by separating finer flour from bran with ease. This compact ...

Optical sorter for wheat applications

Effortlessly enhance product purity by eliminating color defects and foreign material...

Integrated grinding system for wheat and grain

Optimize your grinding process with a system that delivers consistent parti...

Aspiration channel for grain cleaning

Achieve superior product quality by efficiently removing light impurities from granul...

Batch scale for high accuracy weighing of powdery products

Achieve unparalleled precision in powder dosing with our batc...

Fully automatic batch scale for powdery and granular products

Achieve precise and repeatable dosing for powdery and gran...

Air-recycling aspiration channel for grain cleaning

Optimize grain processing with an innovative air-recycling system tha...

Flour sifting and sorting solution for grain mills

Optimize your milling operations with efficient sifting and sorting te...

Purifier for semolina and middlings in grain mills

Upgrade your milling efficiency with a high-speed purifier that ensure...

Oilseed screening solution for soybean and canola

Optimize your grain and oilseed processing with a high-throughput scree...

Grain product plansifter

Optimize your grain processing with a magnetic drive plansifter that efficiently sifts and sorts a d...

Industrial plansifter for grain sifting and grading

Optimize your production line with precision grain separation, mainta...

Trough screw conveyor for transporting grains

Efficiently transport and handle bulk materials like grains and flour with r...

Bran finisher for efficient flour and bran separation

Optimize your grain processing efficiency with a solution designed ...

Grain screening for small to midsize operations

Streamline your grain processing with an economical screening solution tha...

Ultra-fine pulverizer for aqua feed and pet food

Achieve precise granulation with high efficiency for your feed and food p...

Industrial fine grinding pulverizer

Achieve consistent fine granulation at high capacity with reduced energy consumption, u...

Integrated grinder for wheat and grain

Achieve superior grinding performance and energy efficiency with this fully integrat...

Bran finisher for flour milling

Enhancing your milling process, this solution boosts flour yields by efficiently separating ...

Extensograph for assessing dough rheology

Optimize dough quality with precise rheological analysis, ensuring your baking p...

Measuring mixer for flour and dough analysis

Optimize your dough consistency and quality with precise mixing and kneading ...

Bran duster for flour yield and ash content optimization

Enhance your milling efficiency by optimizing flour yield and pr...

Standard flour viscometer

Ensure your baked goods meet the highest quality standards with precise starch and enzyme activity...

Retail ready packaging system for easy store stocking

Simplify shelf stocking with a sturdily designed packaging system t...

Industrial homogenizer for food and beverage applications

For manufacturers seeking consistent quality, this homogenizer...

Release agent sprayer for baking trays and moulds

Achieve perfect results in baking by ensuring efficient and uniform gre...

Rotating greaser for baking moulds and trays

Achieve precise greasing with minimal overspray for all your baking moulds an...

Inline ultrasonic slicer for bakeries

Achieve consistent precision in high-speed food portioning with this cutting-edge sli...

3-roll extruder for heavy dough products

Streamline dough processing for consistent, high-quality confections and baked goo...

All-in-one inspection system with leak detection, x-ray, and weighing

Optimize your production line with a compact syst...

Automatic tortilla production line

Streamline your tortilla production with a fully integrated line that handles pressing, ...

Automatic crumb breading machine for food production

Perfect for creating evenly breaded products like tempura shrimp and...

Industrial dough mixer for high capacity food production

Enhance dough consistency and texture with a high-speed industri...

Automatic bagel making system

Streamline your bakery production by transforming dough into perfect bagels efficiently, allow...

English muffin production system

Maximize your bakery’s output with our high-speed system designed to efficiently produce co...

Soft bread production system

Optimize your bakery operations by integrating a high-speed system for producing a wide variety...

High-speed bun and roll production system

Optimize your bakery’s output with this high-speed system designed to stre...

Energy-efficient oven monitoring system for bakeries

Optimize your baking operations with a smart oven system that enhanc...

Automated bread and soft roll production system

Streamline your bread and bun production with a system that ensures precis...

Artisan bread production line for high-volume bakeries

Optimize your artisan bakery operations with a production line tha...

High-speed baguette production system

Achieve seamless, high-speed production of artisan baguettes with minimal downtime an...

Swirl bread production system for commercial bakeries

Elevate your bakery’s output with high-speed, efficient produ...

Pie production line for sweet and savory pies

Optimize your pie production efficiency with this integrated system, designe...

Automated sheeting and laminating solution for filled snack bread production

Enhance your bakery line’s efficien...

Continuous proofer and oven systems for commercial bakeries

Enhance product consistency and throughput in your bakery op...

Bakery product conveying solution

Optimize your bakery’s production line by seamlessly transferring diverse products ...

Industrial tunnel oven for baking and step proofing

Optimize your production line with modular tunnel ovens and step proo...

Precision dough dividing equipment for bread production

Achieve unmatched precision and speed in your bakery operations w...

Open frame mixer for industrial dough mixing

Streamline your bakery’s mixing process with precision control and enha...

Industrial sheeting and laminating systems for baked goods

Elevate your bakery’s production line with cutting-edge...

Spiral cooler for industrial baking

Enhance your bakery’s efficiency and product quality with modular cooling solutio...

Gas steamer for food production

Achieve rapid and uniform steaming across diverse food applications with a robust solution t...

Industrial dough mixing system for bakeries

Enhance your bakery’s efficiency with a system that ensures precise doug...

Servo bakery tray depositor

Enhance production efficiency with precise dough placement, reducing manual labor and ensuring c...

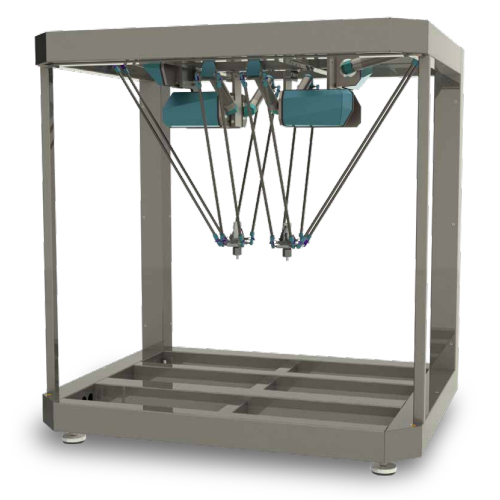

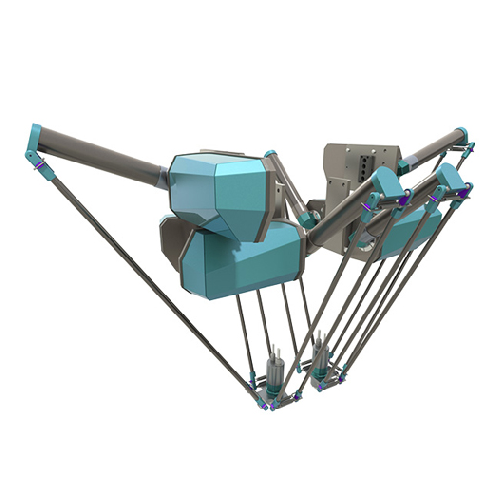

Direct drive delta robots for precision handling

Enhance operational speed and precision with innovative direct drive delt...

Dual-axis delta robot for high-capacity packaging lines

Enhance your production line’s efficiency with a dual-axis ...

Clean-in-place tanks for industrial sanitation

Optimize your sanitation processes with clean-in-place tanks, designed to r...

Spiral pasteurization system for packaged foods

Enhance product durability and quality with a compact spiral pasteurizatio...

Chargrill and bar marker for protein searing

Enhance product appearance and taste with precision searing and grill marking...

Open flame grill marking system

Enhance your food products’ visual appeal with precision grill marking, ensuring consi...

Continuous contact cooker for bottom crust treatment

Enhance dough product integrity with precise bottom heating, ensurin...

On-food traceability technology for produce

Enhance your product authenticity with a revolutionary traceability technology...

Self-stacking belt for industrial freezers

Enhance your production line with advanced self-stacking belt technology, desig...

Compact spiral freezer for food processing

Enhance your production efficiency and hygiene standards with a compact, self-s...

Spiral freezer for high-capacity food freezing

Enhance your production line by efficiently freezing up to 3,500 kg/hour, o...

Spiral freezer for frozen food production

Optimize your product’s shelf life and quality with advanced freezing tech...

Industrial spiral freezer for high-volume food processing

Optimize your production line with a modular spiral freezer th...

Industrial spiral freezer for high-volume processing

Optimize your high-volume food production with a robust spiral freez...

Spiral freezer for bakery and confectionery

Maximize space and efficiency while preserving the quality and freshness of di...

Storage silos for granular products

Enhance storage efficiency and flexibility with modular silos, ensuring precise monitor...

Authentic homestyle bread solution

Achieve authentic homestyle breading on an industrial scale with a drum breader that ens...

Flexible battering system for food production

Optimize your coated product output with a flexible battering solution that ...

Robotic pick and place system for bakery products

Enhance your bakery production line with advanced robotic systems that ...

Laned product distribution for high-capacity wrappers

Efficiently distribute high-capacity product flow across multiple w...

Process control for baked goods production

Enhance your production line with precise process control designed to optimize ...

Robotic tray handling for baking production lines

Enhance production efficiency by seamlessly integrating advanced roboti...

Automated dough loading system for bakeries

Streamline your bakery operations with an automated system that efficiently lo...

Automated scoring system for dough pieces

Eliminate the tedium of manual bread scoring while ensuring precision and consis...

Tray cleaning system for bakery applications

Ensure the highest hygiene standards with a system that efficiently cleans an...

Mixing system for long dough resting times

Achieve consistent dough quality with extended resting times, optimizing water ...

Linear mixing system for high-capacity dough production

Achieve perfect dough consistency with precise mixing, rapid cycl...

Modular roll line for high-capacity bakery production

Streamline your bakery’s production process with high-speed, ...

Bread dough divider for high-precision weight control

Achieve unparalleled dough weight precision and gentle handling wit...

Industrial dough divider and rounder for rolls and buns

Achieve precise, high-speed dough dividing and rounding for consi...

Dough strip line for producing artisan rolls and breads

Optimize your bakery’s production with a modular dough stri...

Dough strip and roll line for artisan and classic rolls

Eliminate the need for separate machines by seamlessly integratin...

Industrial spiral mixer for dough production

Achieve precise control in dough consistency and quality with this spiral mix...

Industrial spiral mixer for dough processing

Achieve optimal dough consistency and quality effortlessly with a cutting-edg...

Ryena bread production line for soft dough and ancient grains

Efficiently process soft dough and ancient grains into var...

Continuous tunnel oven for panettone baking

Optimize your bakery production with a modular tunnel oven that integrates sea...

Vacuum cooling system for baked goods

Rapidly cool bakery products to extend shelf life and maintain crispness by using adv...

Compact bread production line for varied dough types

Optimize your bakery’s space with a compact line that produces...

Industrial bread dough divider for accurate weight control

Achieve precise weight accuracy and gentle handling for a var...

Round- and long-moulder for bakery dough production

Achieve precise and consistent bread shaping with a compact solution ...

High-speed moulder for baguettes and oblong bread

Streamline your bakery’s production line with a high-speed mouldi...

Dough divider for various dough types

Achieve precise portioning in your dough production with a solution designed to handl...

Three-pocket dough divider for high-output bakery production

Achieve precise dough division effortlessly with this robus...

Weight accurate dough divider for various dough types

Achieve high-speed, precise dough portioning with adjustable pressu...

Dough divider for varied dough types

Achieve precise and consistent dough portioning with a single pocket divider designed ...

Industrial dough divider for versatile baking applications

Optimize your bakery production with a high-capacity, precise...

Automatic baguette production system

Efficiently shape and perfect long, oblong bread varieties with high consistency and m...

Bread production line for classic bread types

Unlock versatile bread production with a modular line that adapts to any bak...

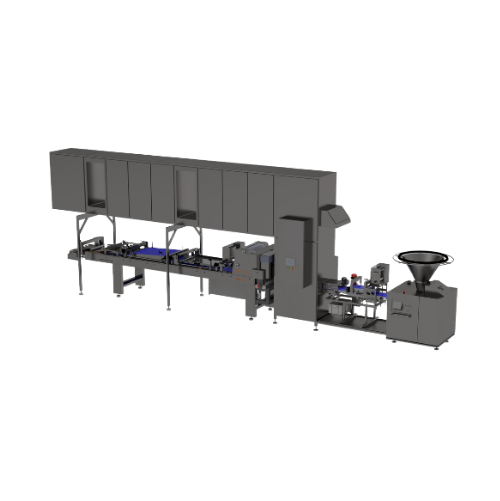

Automated artisan bread production line

Enhance your bakery’s efficiency with this versatile bread production line, d...

Automated bread production line for toast bread and rolls

Streamline your bakery operations with a high-speed line desig...

Long moulder for wheat and wheat/rye dough

Achieve perfect uniformity and precision in every loaf with adjustable folding ...

Conical dough rounder for multiple dough types

Achieve consistent rounding for a variety of dough types with our equipment...

Industrial dough rounder for high-capacity production lines

Optimize your bakery’s efficiency by integrating a hig...

High-precision checkweigher for dough processing

Ensure consistent dough quality and reduce waste with precise weight corr...

Long moulder for toast and tin breads

Achieve perfect dough consistency with precise sheeting and moulding, ensuring your b...

Long dough moulder for rustic bread

Optimize your bakery’s production line by effortlessly handling various dough typ...

Adjustable conical dough rounder

Optimize your dough processing with a conical rounder that effortlessly handles high water ...

Conical rounder for common dough types

Enhance efficiency and precision in dough processing with this conical rounder, idea...

Seeding unit for bread dough

Enhance your bread production by achieving consistent seed distribution and decoration on your ...

Single pocket dough divider for baking applications

Achieve precise, dough-friendly portioning for various bread types wi...

High-speed dough divider for baguettes and petit pains

Optimize your production efficiency with a high-speed dough divide...

Industrial dough divider for high-capacity production

Optimize your bakery’s throughput with a versatile dough divi...

Industrial long moulder for pan and hearth bread

Enhance your bread production with precise sheeting and curling that impr...

Industrial long moulder for pan bread

Seamlessly mold diverse dough types into uniform loaves with high-speed precision, op...

Intermediate proofer for mediterranean bread

Efficiently handle oblong dough shapes like baguettes and ciabatta by streaml...

Intermediate dough proofer for industrial baking

Achieve precise dough fermentation and enhanced product consistency with ...

High-speed checkweigher for dynamic weighing

Achieve precision and consistency in high-speed production environments with ...

Semi-automatic loading system for production ovens

Enhance your bakery’s efficiency with a system that streamlines ...

Multi-deck oven for uniform bakery results

Achieve consistent baking with precision-engineered multi-deck ovens that maste...

Energy-efficient rack oven for bakeries

Achieve superior baking efficiency and quality with a rack oven that reduces energy...

Double rack oven for high-capacity baking

For large-scale bakeries facing high production demands, this double rack oven e...

Pellet-fired oven for wood-flavored bakery bread

Achieve consistent, flavorful bread with precise temperature control and ...

Industrial vacuum cooling system for bakeries

Achieve rapid cooling of oven-hot baked goods with minimal moisture loss, en...

Vacuum cooler for artisan baked goods

Rapidly cool artisanal baked goods with precision to maintain their freshness and vol...

Automatic tray loading robot for bakery systems

Streamline your bakery’s tray handling by integrating a robotic solu...

Compact roll baking system for high capacity

In tight bakery spaces, achieving high volume production without sacrificing ...

Modular roll baking system for small bakery items

Optimize your bakery production with a modular roll baking system that ...

Bakery refrigeration systems for controlled dough tempering

Achieve consistent bakery quality by precisely controlling y...

Dough dividing and round moulding solution for bread rolls

Achieve precision and consistency in your bakery line with a ...

Industrial dough divider and round moulder

Optimize your bakery’s operations with a machine that ensures precise dough div...

Automatic loading system for production ovens

Enhance your bakery’s efficiency with this system designed for precise...

Manual loading system for deck ovens

Streamline your bakery’s workflow by simplifying the manual loading and unloading proc...

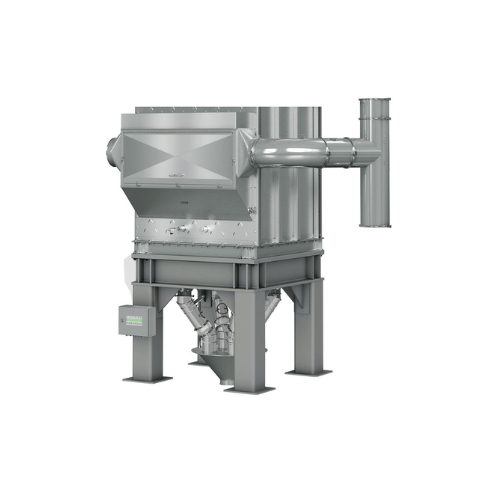

Atex-certified flanged polygonal dust collectors

Ensure dust control and compliance in explosive environments with our com...

Industrial dust collection system for air filtration

Optimize air quality in your production line with this compact dust ...

Membrane pressure relief valve for silos and bins

Ensure silo safety with our valve that instantly balances internal pres...

Silo overfill protection valves

When abnormal pressure threatens your silo’s integrity, reliable pressure relief becom...

Drop-through rotary valve for powder and granular material feeding

Achieve precise control in discharging and feeding p...

Live bin bottom for difficult material discharge

Efficiently manage the discharge of challenging materials like biological...

Trough screw conveyor for flour mills

Optimize your flour processing with efficient material handling, precisely designed f...

Fork mixers for bakery industry

Achieve consistent, high-quality dough mixing with fork mixers designed to enhance tradition...

Laboratory mixers for recipe testing in bread-making

Guarantee consistent quality in your dough production with advanced ...

Sourdough fermenter for artisanal bakeries

Streamline sourdough production with a solution that automates key processes li...

Fixed bowl vertical mixer for bakery and pastry

Optimize dough quality and consistency with a versatile vertical mixer tha...

Vertical mixing solution for bakery and snacking industry

Streamline your dough processing with robust and reliable spir...

Top load cartoner for various carton shapes

Optimize your production line with a versatile cartoning solution, perfect for...

Industrial spiral cooling and freezing system

Optimize your bakery operations with adaptable cooling and freezing systems ...

Bread and dough decorating equipment

Enhance the visual appeal and quality of your baked goods with specialized equipment d...

Industrial depanning solutions for baked goods

Streamline your bakery’s efficiency by integrating versatile depannin...

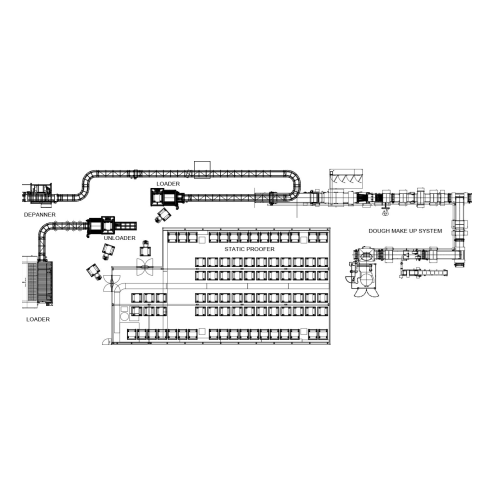

Industrial dough proofing systems

Optimize your bakery’s efficiency with customizable proofing systems designed to fi...

Baking form storage system

Optimize your production line with efficient and flexible baking form storage and buffering, ensu...

Bias slicer for elongated produce

Achieve consistent crinkle or flat bias slices for elongated products, ensuring uniformit...

Industrial food processor for diverse applications

Optimize your production line with a versatile processor capable of ch...

Cheesecake production system for automated baking

Enhance your dessert production line with a versatile system that autom...

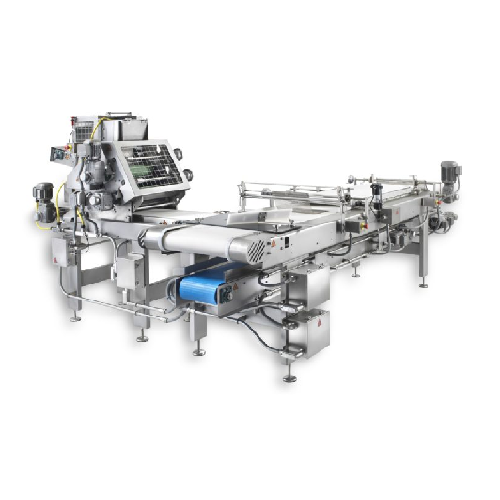

Horizontal flow pack wrapper for medium-high performance packaging

Optimize packaging efficiency with a horizontal flow...

Horizontal flow wrapper for vacuum packaging

Enhance your food packaging line with a solution designed for precision vacuu...

Complete solution for packaging of bakery products

Streamline your bakery’s packaging process with a fully automate...

Automated packaging and case packing for soft bread & buns

Ensure consistent and high-speed packaging for your bakery go...

Automated line for baked goods packaging

Enhance your packaging efficiency with a seamless integration of precise loading a...

Turbo sifter for milling processes

Optimize your milling efficiency with a high-speed turbo sifter designed to precisely se...

Industrial extraction scale for accurate material weighing

Ensure precise ingredient proportions in your milling operati...

Silo discharger for freely flowing materials

Optimize your material flow and prevent bottlenecks with a highly efficient s...

Automated grain blending system

Achieve precise blending ratios for grains and seeds, streamlining your production line by a...

Blending machine for pre-grinding or tempering processes

Optimize your grain processing with precise blending and mixing ...

Horizontal wheat transport conveyor

Efficiently transport grains horizontally without breakage while maintaining product in...

Industrial heavy particle separator for wheat cleaning

Optimize the performance of your filtration systems by interceptin...

Ecluse for pneumatic conveying systems

Ensure seamless and leak-free material flow in continuous and high-speed operations ...

Flour insect control system

Eliminate pest contamination and preserve flour quality with high-speed larva destruction, ensur...

Square plansifter for flour production

Optimize your flour milling process with enhanced sifting and classification, ensuri...

Horizontal scourer for flour and semolina mills

Achieve efficient grain cleaning by removing hulls and contaminants seamle...

Hammer mill for grinding dry or low-moisture grains

Efficiently transform dry grains into high-quality feed and flour wit...

Flow meter for wheat dampening process

Ensure precise water control in grain processing with advanced flow measurement, ess...

High-efficiency bran finishing solution

Optimize your grain processing with this advanced bran finisher, designed to enhanc...

Intensive dampening system for flour mills

Enhance grain quality and moisture control with a high-speed solution that mini...

Professional slicer for cold cuts, meat, cheese, and bread

Achieve precise and consistent slicing of cold cuts, cheese, ...

Professional meat and cheese slicer

Achieve precision in slicing cold cuts, cheese, and bread with consistent thickness and...

Industrial hard cheese grater

Optimize your food preparation process with high-speed grating, perfect for transforming hard ...

High sensitivity metal detectors for food products

Ensure food safety and product quality by effectively detecting and re...

Food production metal detector for packaged products

Ensure product safety and compliance by detecting metal contaminants...

Industrial metal detector for packaged food products

Ensure the safety and compliance of your packaged food products by d...

Commercial food mixers for versatile culinary applications

Streamline your food production with mixers and kneaders desi...

Commercial bakery equipment for improved baking efficiency

Streamline your baking processes with commercial bakery equip...

Automated cleaning in place system for bakery production lines

Ensure unmatched hygiene and operational efficiency in fo...

Small rotating pita bread oven

Optimize your bakery operations with a compact oven designed for precision baking of pita and...

Automatic pita bread making solution

Efficiently produce high-quality pita, Arabic bread, and tortillas with a seamless sol...

French bread rolling machine

Efficiently shape and roll dough for a variety of bread styles with precision, enhancing consis...

Industrial egg breaking and separating solution

Streamline your egg processing with precision egg breaking and liquid sepa...

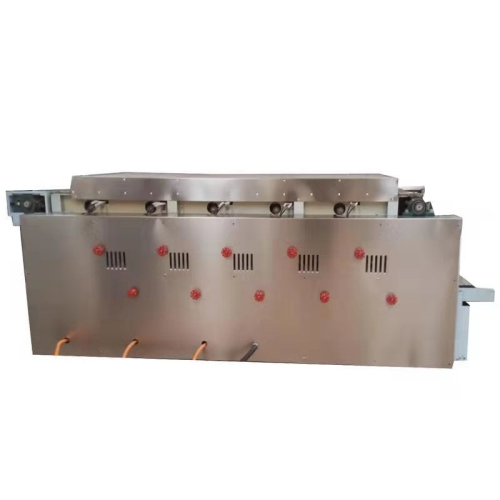

Industrial biscuit baking tunnel oven

Achieve consistent, high-quality baked goods with our tunnel oven, designed for effic...

Fully automatic chapati making machine

Streamline your flatbread production with this intelligent system that mimics handcr...

Pneumatic inline sifter for dry flowing material

Ensure precise particle segregation and foreign matter removal with this ...

Industrial conical dough rounder

Streamline your dough production with a high-capacity rounder designed to optimize dough sh...

Intermediate proofing cabinet for dough resting

Optimize your dough resting with a versatile proofer that adapts to variab...

Flexible continuous dough processing line for bakeries

For bakeries aiming to streamline operations, this highly adaptabl...

Industrial bread production line

Optimize your dough processing workflow with this robust system designed to streamline high...

Automated dough divider for high accuracy dough handling

Ensure precision in dough portioning with this solution, designe...

Conical dough rounder for perfectly round dough balls

Achieve impeccable dough rounding with precision-engineered technol...

Grain dryer with air circulation system

Enhance efficiency and product quality with our versatile grain dryer, designed to ...

Laser-based volume measurement for bakery and solid products

For precision in product quality control, this laser-based ...

Self-priming centrifugal pump for entrained air handling

Effortlessly manage entrained air and foam in fluid processing w...

Flowpacker for packaging products

Achieve seamless packaging with high-speed, automated flowpacking that enhances product p...

Dough mixer for high-volume bakery production

Effortlessly handle diverse dough varieties with precision using this mixer,...

Refrigeration jacket for triple roller bar mixers

Enhance dough mixing performance by efficiently managing temperature co...

Continuous pan cleaner for bakery pans

Efficiently clean and prepare baking pans with precision by leveraging continuous, h...

Bread moulders for bakery production

Efficiently shape various bread types like baguettes and ciabatta, ensuring consistent...

Dough chunkers for bakery production

Optimize dough processing by efficiently feeding and dividing dough portions, ensuring...

Conveyor belt metal detection system

Ensure seamless product safety with a system that detects and separates metallic conta...

Efficient jam and marmalade production line

Optimize your fruit and bakery product lines with equipment designed for high-...

Grain cleaning reel scalper

Maximize throughput by efficiently removing oversized particles from your feed inputs with a rob...

Flowpacker for packaging products in flowpacks

Optimize your flowpack packaging line with a preconfigured solution that ac...

Industrial breadchips cutting solution

Achieve precise, high-speed slicing of bread-based strands into thin, uniform chips ...

Bread topping system for consistent seed and flour application

Achieve precise topping consistency with our system, desi...

Industrial baking ovens for consistent and high-quality bread production

Achieve precise baking results with ovens engi...

Pre-dough preparation for bakery products

Streamline your bakery operations with pre-dough preparation, enhancing both dou...

Final proofers for industrial baking

Streamline your baking operations with advanced proofing solutions that optimize clima...

First proofer for industrial bakeries

Optimize dough development with flexible proofing solutions that enhance product qual...

Industrial freezing solutions for baked goods

For bakeries requiring precise temperature control, these systems ensure con...

Industrial dough moulders for consistent bread quality

Achieve precision and uniformity in your bakery operations with ad...

Reliable oven loaders for industrial baking

Maximize efficiency in your baking line with custom-engineered oven loaders, e...

Dough rounders for consistent bakery production

Achieve uniform dough pieces effortlessly with versatile dough rounders, e...

Automated dough scoring system

Ensure precision and consistency in your bakery with an advanced scoring system that adapts t...

Dough sheeting solution for high-quality bread production

For bakeries aiming to perfect dough consistency, this solutio...

Industrial storage silos for food ingredients

Optimize your food processing operation with robust storage solutions that s...

Industrial bread cooling systems

Extend the shelf life of bakery products by efficiently regulating temperature and humidity...

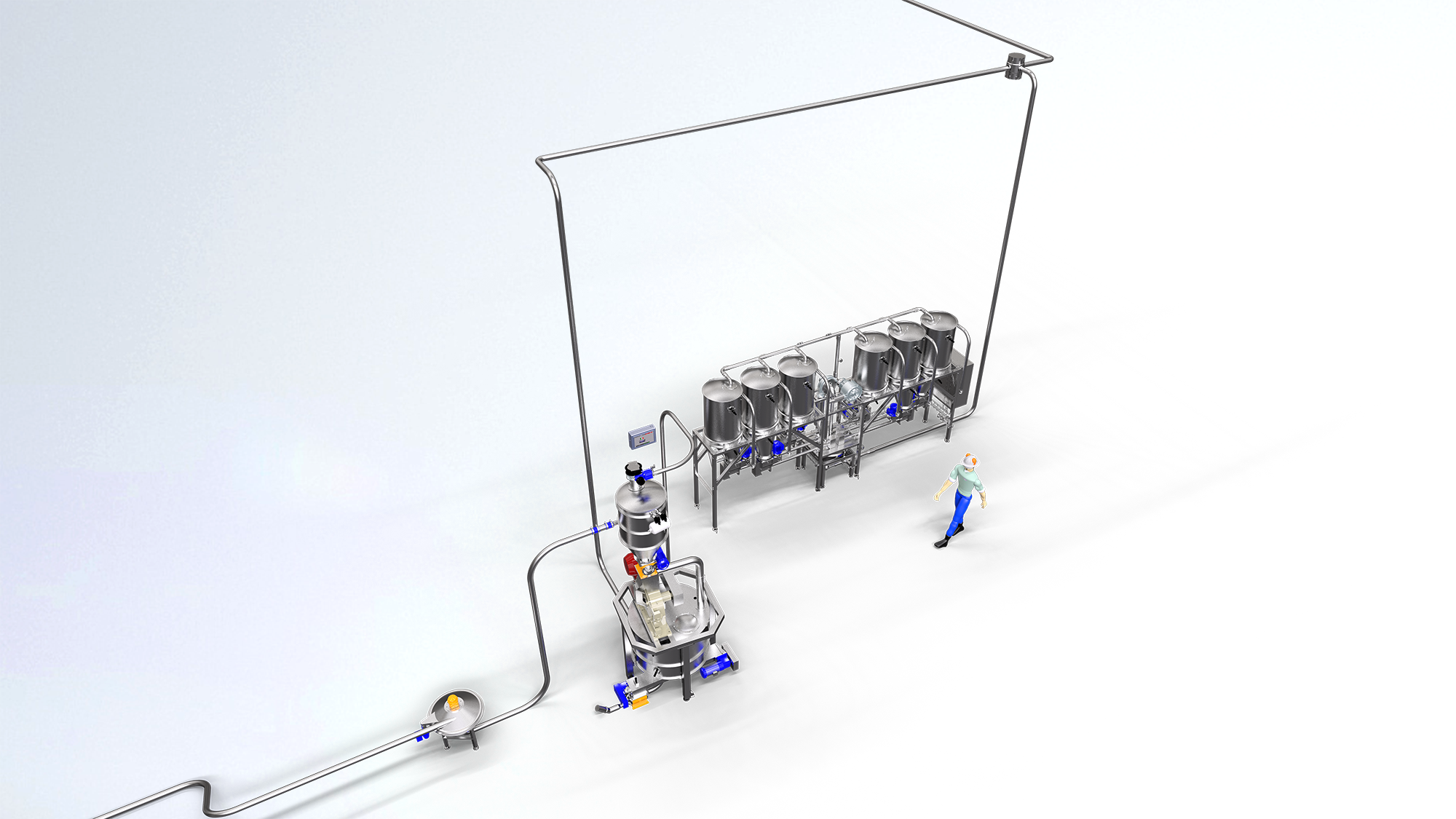

Pneumatic vacuum conveying system for dry raw materials

Optimize efficiency and precision in your bakery operations with ...

Dough divider for accurate bakery processing

Enhance dough consistency and product uniformity with advanced measurement te...

Moulding machine for croissant

Croissants are a popular line in commercial bakeries and are sold in high volumes. An automat...

Moulding machine for rolled bread

As great snacks and accompaniments to meals rolled bread is a staple product in commercia...

High capacity freezer for food

Freezing is one of the most important industrial methods for the long-term preservation of fo...

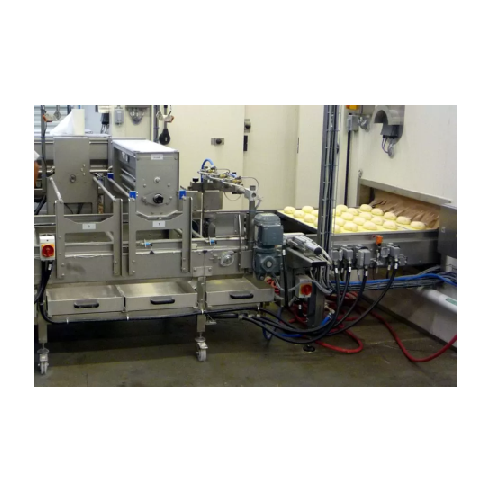

Automated packaging line for bread

If you want a fully automated packing line to efficiently handle buns, burger buns, hot-...

Industrial washer for plastic crates

In the food production sector, hygiene regulations are getting stringent by the day. E...

Planetary mixer for confectionery and bakery production

For the best quality confectionary and bakery products, controlla...

Horizontal dough mixer

The mixing of hard doughs or highly viscous product like chewing gum requires specialist equipment to ...

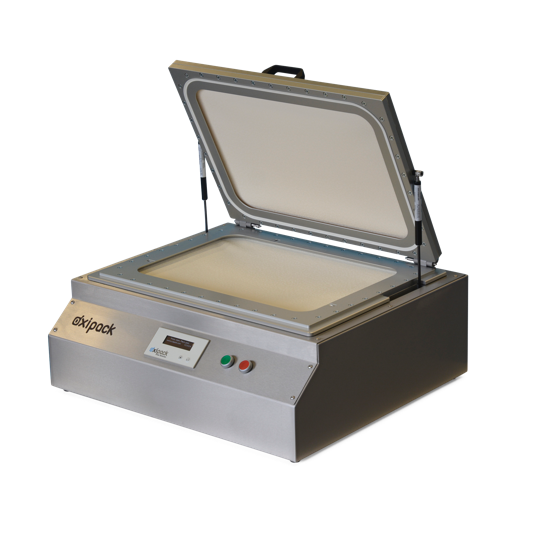

Leak tester for pouches and MAP packaging

Nuts are packed with unsaturated fatty acids, which means they are prone to oxid...

High capacity spiral proofer for pastry

Proofing is a phase in the baking production line that can’t be rushed. It’s an ess...

Hygienic and fully-welded spiral freezer for food

Food freezers are often the last step in the food production chain. The...

High capacity spiral cooler for food

Cooling baked goods and food products can be problematic for sliced baked goods. A cru...

Inline ultrasonic big scale food cutting machine

In the food industry, where accuracy in the cutting process is desired, u...

Washing cabinet for trolleys

Food manufacturing facilities, bakeries, or restaurants are ridden with efficiency-related issu...

Hygiene washer for food utensils

Thorough and quick cleaning of kitchen utensils, such as baskets, knives, trays, and other ...

Washing cabinet for food bulk containers

With an ever-increasing demand for output and stricter hygiene regulations for foo...

Food crates washer

With the increasing demand of food production sectors for cutting costs, while increasing quality of produ...

Tunnel washer for food containers

With an increase in demand for production across food service and manufacturing companies...

High-speed depositor of garlic butter

Across the globe, slices of bread are typically buttered by hand which often results ...

Mobile depositor of tiger wash

Manufacturers of tiger bread and other similar consumables often find that achieving perfect ...

Milk protein decorator for bread

It is time to leave behind old and saturated decoration methods that look neither natural n...

Industrial crate washing machine

In order to meet the increasing demand of the beverage industry, it’s essential to find a c...

Moulding machine for bread sticks

Breadsticks are popular as an appetizer in restaurants or as a starter served with prosci...

Semi-automatic dough sheeter

There is a wide range of commercial dough sheeters available, many of which are purpose-built f...

Automatic bread dough sheeter

Dough for speciality breads must first be rolled into sheets of varying thickness, to facilita...

Square or rectangular moulding machine for bread

Automated bread molders should form various types of dough into a range o...

Stand-alone ultrasonic food cutting machine

For some foods such as cake, pizza, sandwiches or ice cream, the end product i...

Conveyor belt metal detector for food products

Inspecting and rejecting finished food products for metal contamination is ...

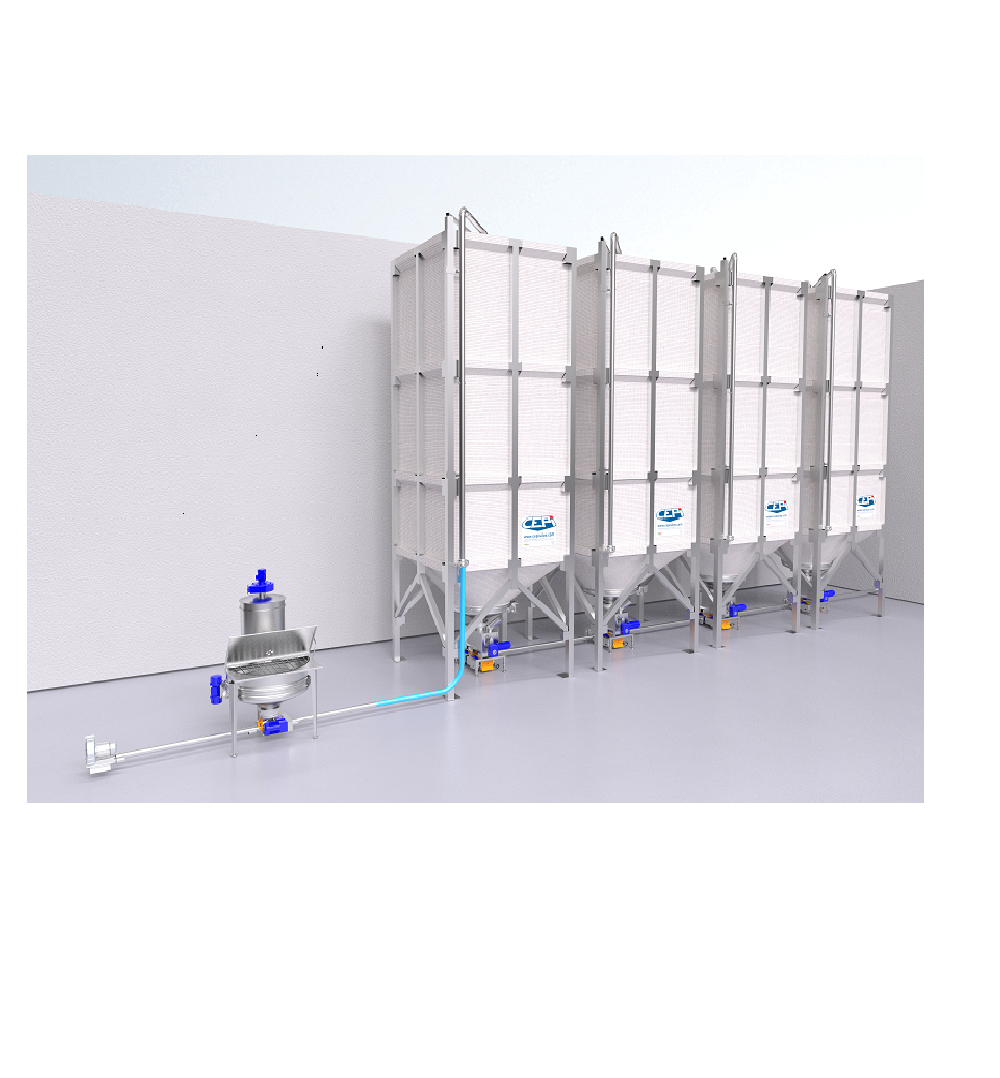

ATEX confirmed outdoor silo for flour

Bulk outdoor storage of flour, dry milk and other powder ingredients for the bakery i...

Automatic rework system for biscuit and bread scrap

Scraps are an inevitable byproduct of biscuit and bread production. W...

Manual bag discharger for bakery industry

Many minor and intermediate ingredients for bakery products are delivered in bag...

Microdosing system for bakery industry

Storage and dosing of powdered minor ingredients such as flavourings, colours and si...

ATEX Indoor silo for sugar and flour

Storing granulated or powdered materials such as sugar and flour prior to processing r...