Biscuit Manufacturing Equipment

Find innovative production technology for making biscuits and connect directly with world-leading specialists

Biscuits are confectionery products that contain mostly flour, which you mix and bake with other ingredients as sweet or savory snacks. Biscuit production involves four primary processes: mixing, forming, baking, and cooling. For you to perform these processes, you need basic biscuit processing equipment, including mixers, molders/cutters, and ovens.

Technology picks for biscuit production

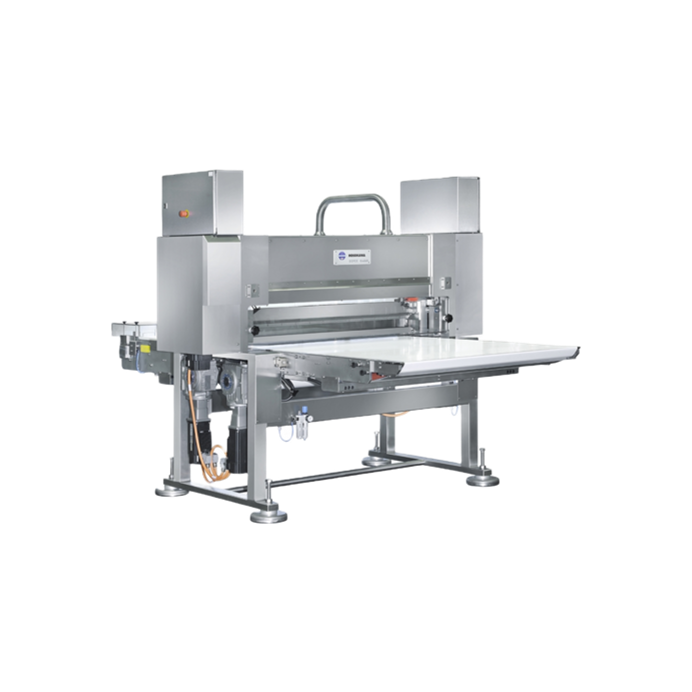

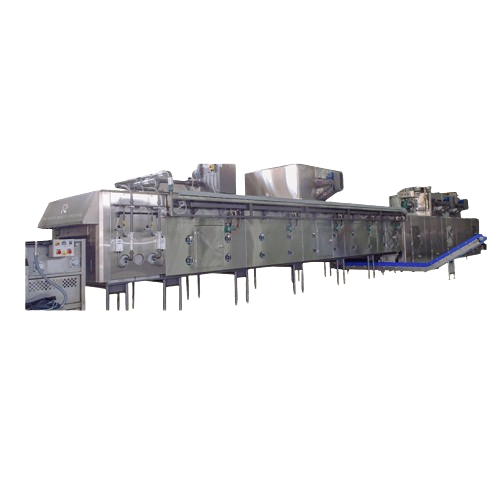

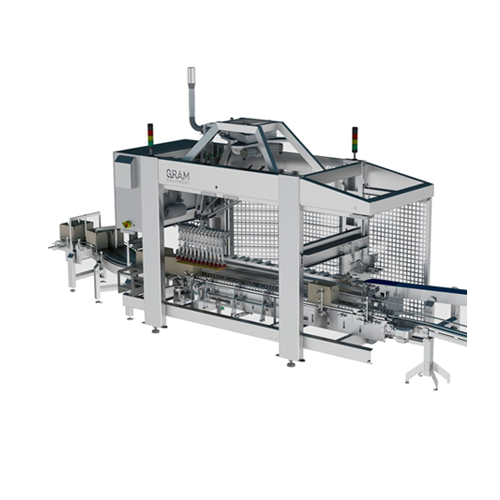

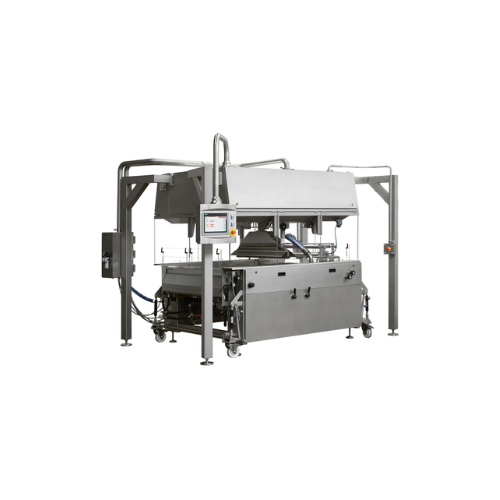

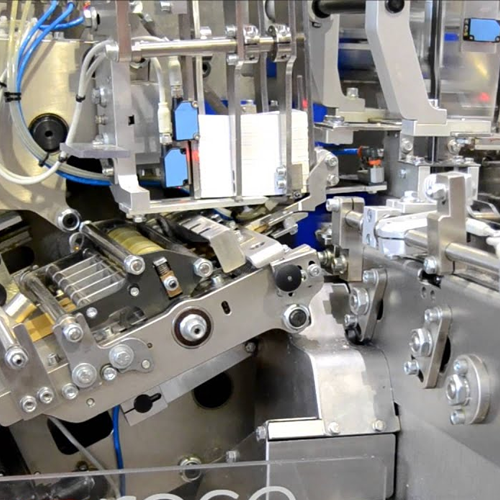

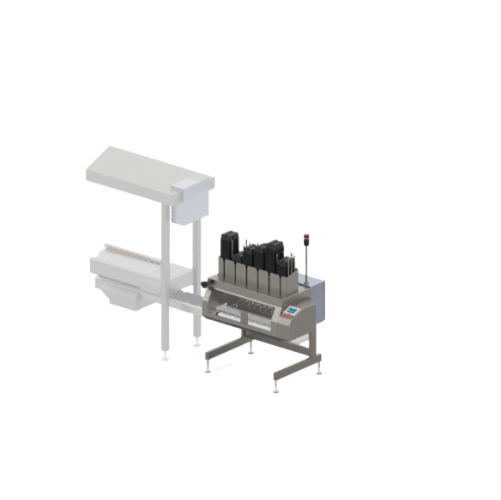

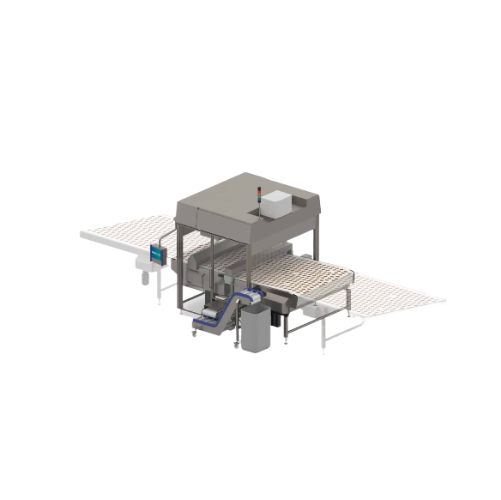

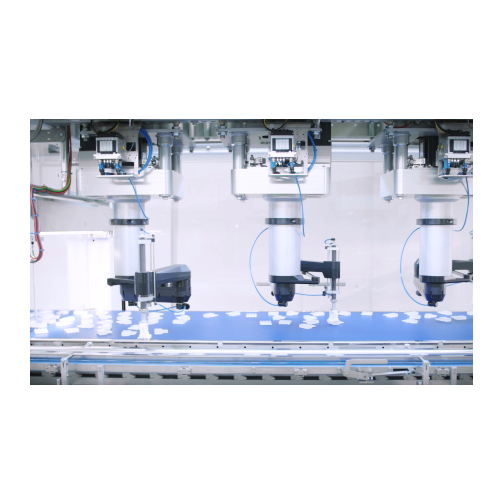

Biscuit sandwiching system

Optimize your biscuit production by seamlessly aligning, overturning, and capping for uniform, hi...

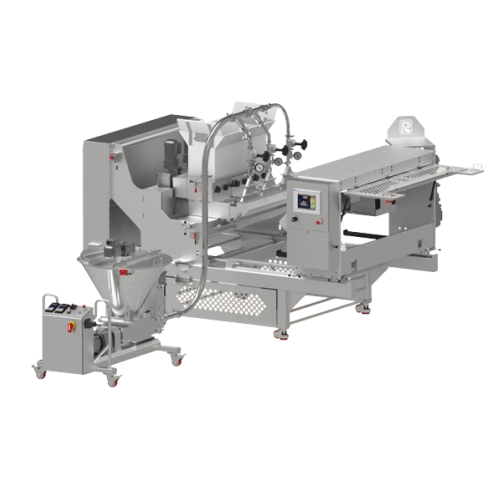

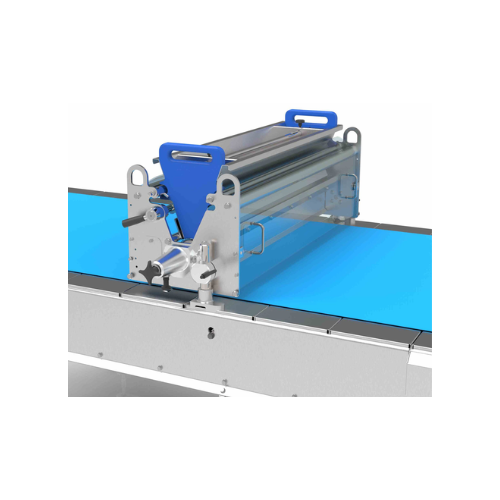

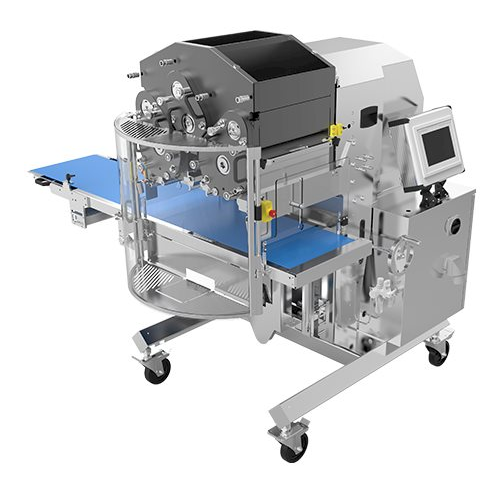

Biscuit wire cutter and depositor for confectionery production

Streamline your production of intricately designed cookie...

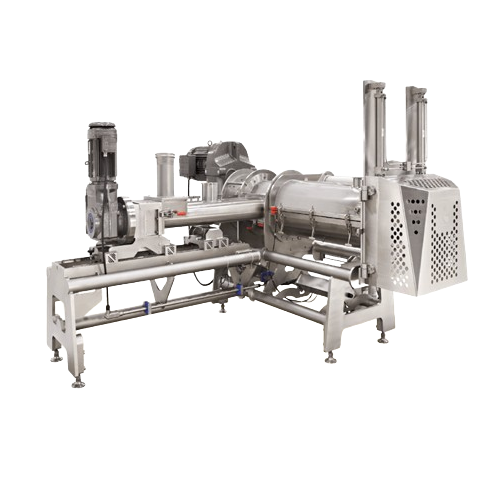

Caramel enrobing system for biscuits and wafers

Achieve consistent caramel coverage with precise temperature control, ensu...

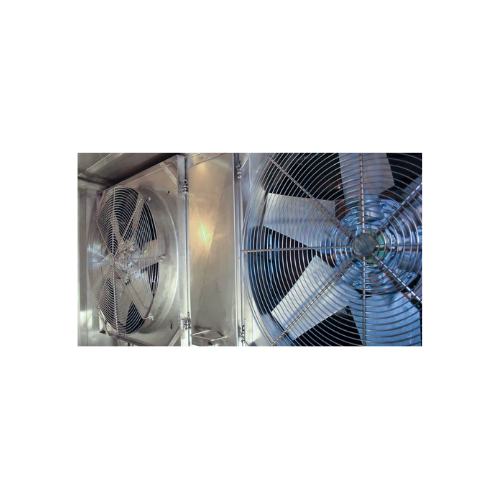

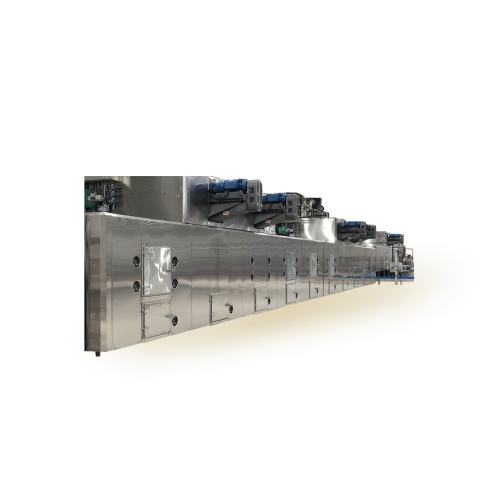

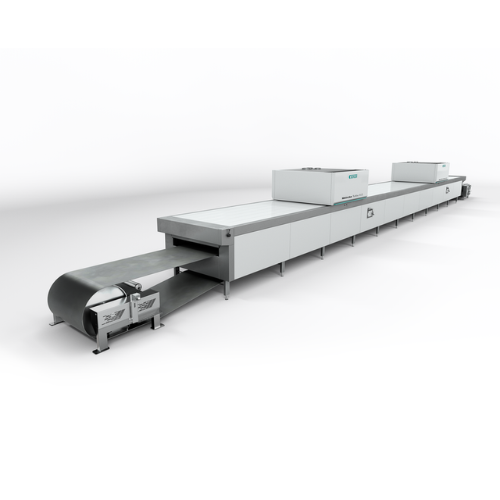

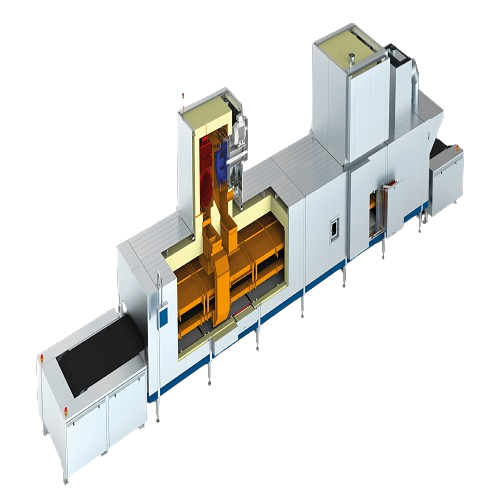

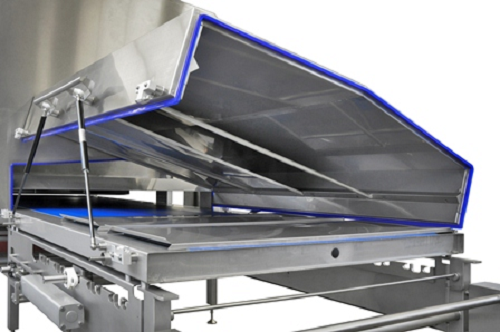

Cooling tunnel for artisanal biscuits and chocolates

Streamline your confectionery production with a cooling solution des...

Stories about biscuits

Tell us about your production challenge

Blooming biscuits with the right ‘flour’

Wheat flour comprises most of the biscuits’ dough and provides its base structure. Its proteins, specifically glutenin and gliadin, and their denaturation during mixing and baking, contribute to the final biscuit texture. As an alternative, gluten-free substitutes include chickpea flour, which boasts a high protein and fiber content.

Another choice can be corn flour, which contains more protein, fiber, starch, vitamins, and minerals than cornstarch. However, using these may also negatively affect your biscuits, such as making the biscuits seem heavier (from chickpea flour) or adding a more yellow hue (from corn flour), while also requiring you to meticulously adjust your recipes.

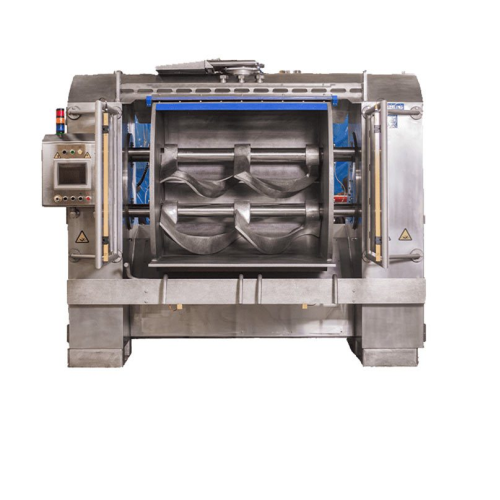

Proper mixing is a must to better develop the soft doughs. When choosing your biscuit production line, three types of industrial mixers suit dough development. Horizontal mixers, for large batches that you mix in short periods of time; spiral mixers, like horizontal mixers but use less electrical power; or planetary mixers, for home kitchens. Before deciding on a biscuit mixer machine, it is recommended to have an idea of your production capacity. This helps determine which machinery will be most suitable for your production.

Cracking bad (biscuits)

Hard and cracked biscuits are products of overworked dough and/or low oven temperature during baking. Excessive mixing destroys the protein bonds formed during dough formation, while a low oven temperature prevents the caramelization and overall proper baking of the biscuits.

Aside from using the proper processing parameters and biscuit making equipment, simple techniques can prevent the undesirable cracking of biscuits. One method is to keep the ingredients cold, especially the fats, while making the oven hot to ensure quick rising before the top hardens. Another technique to avoid biscuit cracking is mixing in short bursts to enable proper dough development.

Ruling gluten out of your biscuits

Gluten is an allergen commonly present in wheat flour. As an inherent ingredient, you cannot process it out nor remove it through any mechanical means during processing. Regulations dictate that to get a gluten-free product, it must contain less than 20 parts per million of gluten, the lowest limit used in laboratory testing.

For compliance, it is best to substitute gluten-containing ingredients, specifically wheat flour, in biscuits. Aside from chickpea and corn flour, other substitutes include coconut, almond, and rice flour. However, as these don’t contain gluten necessary for dough development, you need to adjust the biscuit formulation carefully to maintain the desired flavor and texture. You may tweak the formulation by playing with the ingredient content as increasing your sugars for better biscuit structure or adding more butter for additional flavor.

Processing steps involved in biscuits making

Which biscuits technology do you need?

Rotary molder for softdough biscuits and shortbreads

For high output bakeries, achieve precise dough piece formation and ...

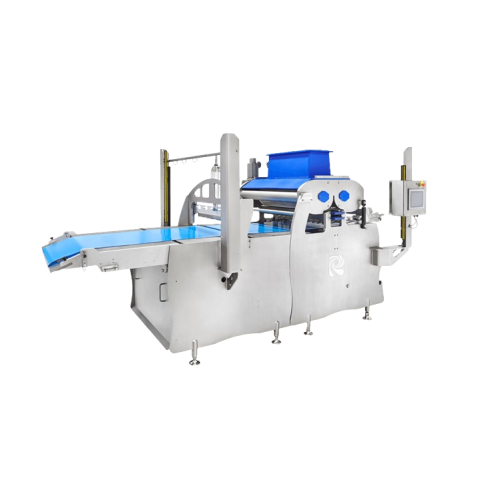

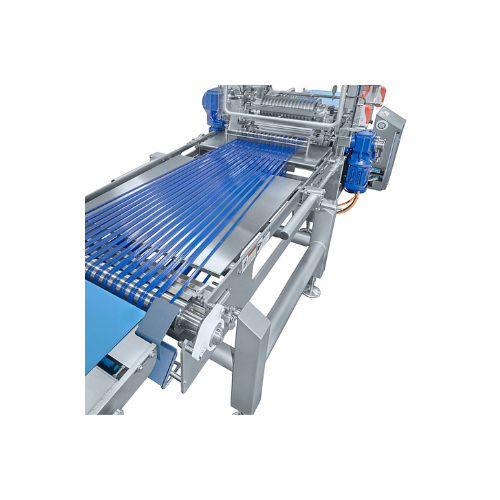

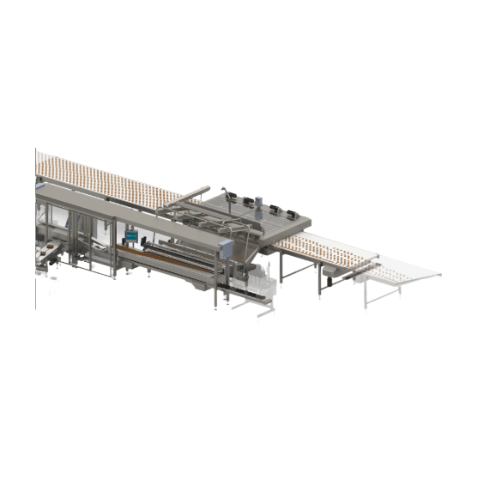

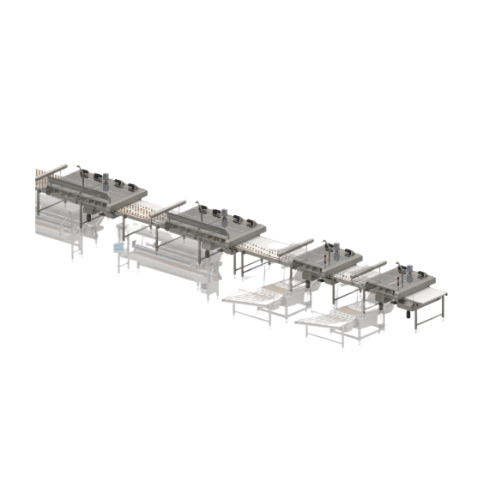

Sheeting lines for biscuit and cracker production

Enhance your bakery production efficiency with advanced sheeting techno...

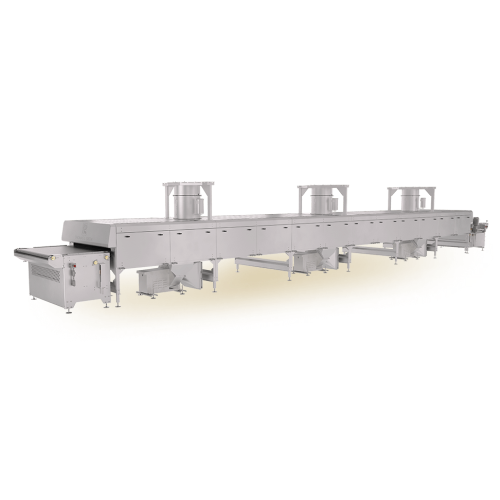

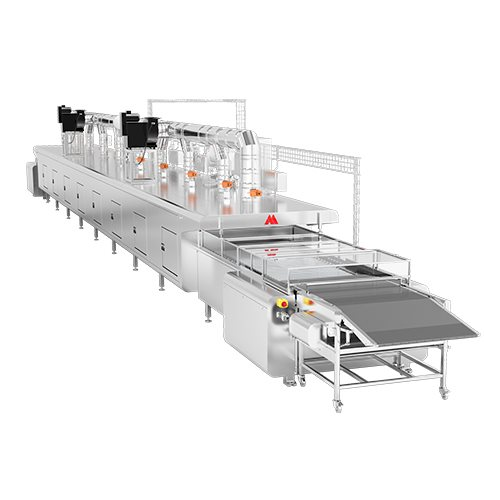

Industrial tunnel ovens for bakery products

Achieve precise control over baking processes with these industrial tunnel ove...

Lobe depositors and extruders for filled and decorated cookies

Optimize your bakery production with precision depositing...

Biscuit sandwiching system

Optimize your biscuit production by seamlessly aligning, overturning, and capping for uniform, hi...

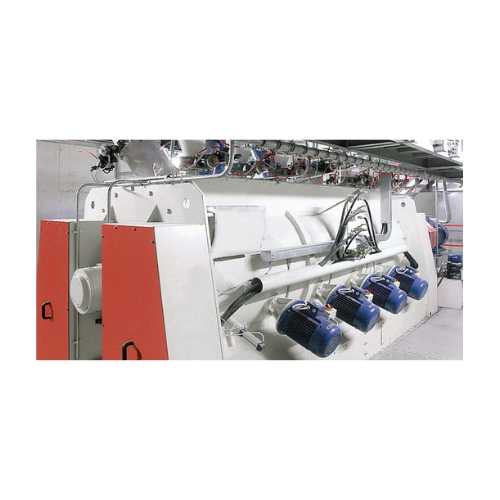

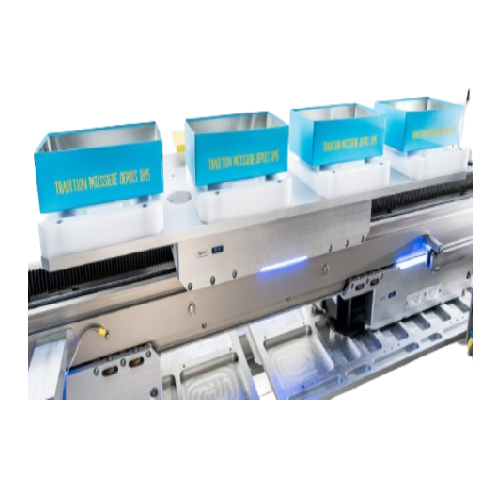

Dough feeding system for biscuits and cookies

Streamline your bakery production with a dough feeding system that efficient...

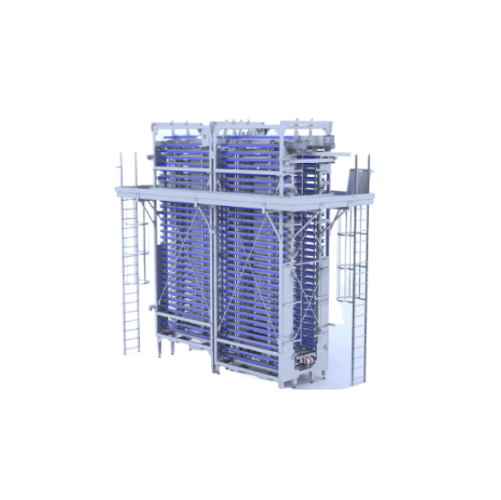

Freezing and cooling systems for bakery products

Enhance your bakery production line with advanced freezing and cooling sy...

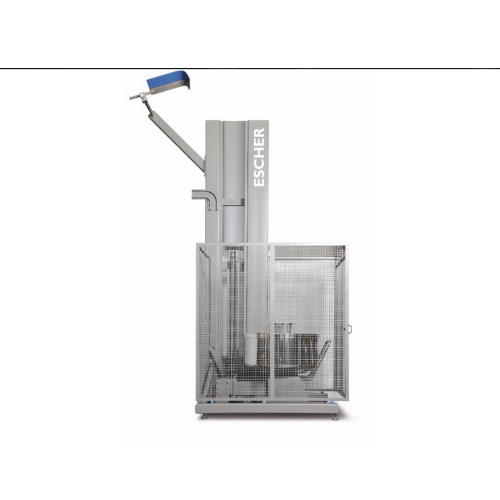

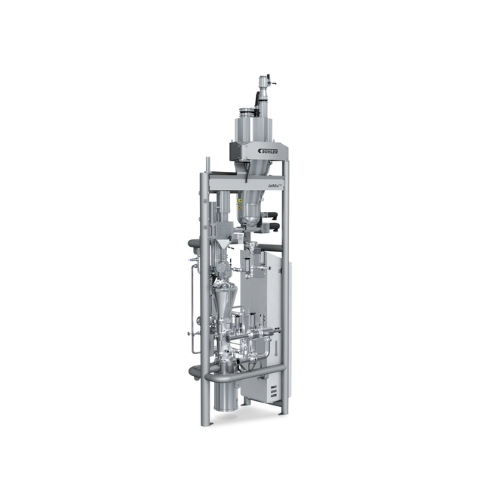

Vertical spindle mixer for dough processing

Optimize your dough consistency and quality with this vertical spindle mixer, ...

Rotary moulder for high-definition cookie dough shapes

Efficiently shape intricate dough designs with precision, ensuring...

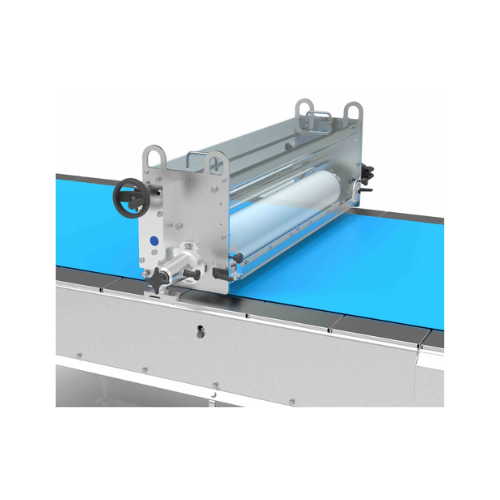

Precise dough sheet cutting station for bakeries

Efficiently shape and cut dough sheets for diverse snack and bakery produ...

Industrial tumble dryer for moisture control in snack production

Ensure precise moisture reduction and optimal air circu...

Instant dough hydration system

Efficiently hydrate dry ingredients instantly with minimal heat increase, streamlining your m...

Servo in-line dough laminator for industrial bakeries

Optimize your snack production with precise dough sheet cutting, st...

Continuous mixer for cookie dough

Achieve consistent dough quality and streamline your production with a continuous mixing ...

Low pressure extruder for pretzel and snack production

Achieve versatile snack production with a low pressure extruder th...

Industrial multi-pass dryer for bakery products

Ensure consistent moisture reduction and quality enhancement in your baker...

Filled stick extruder for bakery products

Streamline your snack production line with a versatile extruder capable of creat...

Fried snack extruder for potato rings

Efficiently produce a variety of fried snacks, from potato rings to ethnic noodles, w...

Automated frozen dough production solution

Maximize your frozen dough production with precision control and streamlined ma...

Dough thickness reduction system

Achieve precise dough sheet reduction with controlled thickness to enhance consistency and ...

High pressure extruder for expanded snacks

Enhance your snack production with precise control over texture and shape throu...

Smart bakery oven zone for flexible heating

Optimize your production with flexible heat transfer options that enhance cont...

Electric oven zones for snack and cookie baking

Optimize your baking line with electric oven zones designed to eliminate e...

Emithermic zone for baking biscuits and cookies

Enhance your baking efficiency and precision with a flexible heat transfer...

Emithermic Xe zone for baking biscuits and crackers

Achieve precise baking and drying for your bakery products with a sys...

Continuous mixer for wheat-based products

Achieve consistent dough quality with minimal variation using a continuous mixer...

Convection oven with integrated dryer for large scale baking

Optimize your baking process with a convection oven that ef...

Industrial direct drive mixer for dough preparation

Optimize your production line with a robust mixer designed for seamle...

Automated dough handling system for pretzel production

Streamline your dough processing with a system that precisely port...

Efficient dough dump station for bakery systems

Streamline your dough handling process with this advanced dumping station,...

Vertically feeding system for cookie dough

Optimize your dough handling with a system that ensures seamless and efficient ...

3-roll sheeter for dough forming

Achieve smooth and consistent dough sheeting crucial for high-quality biscuits, cookies, an...

Ambient air cooler for bakery products

Efficiently cool fragile baked goods without causing distortion, using ambient air t...

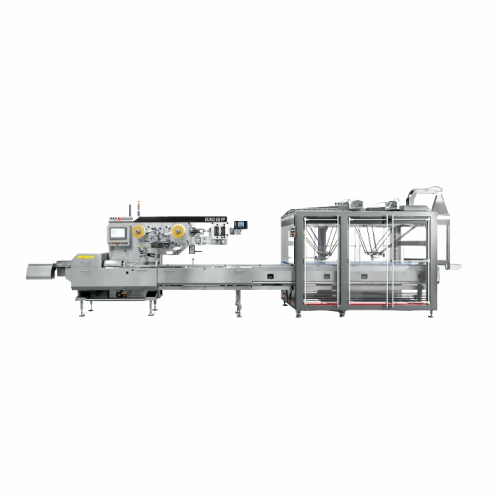

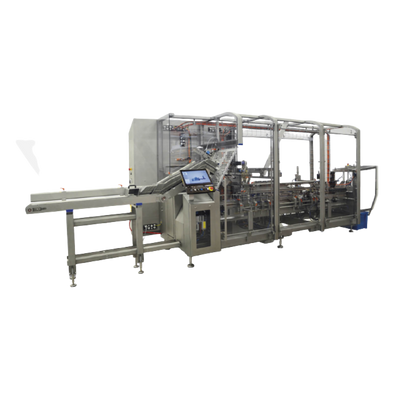

Intermittent motion end load cartoner for baked goods and home care products

Streamline your packaging line with high-...

Intermittent end load cartoner for baked goods and snacks

Optimize your packaging line with an efficient, space-saving c...

Rotary indexing sealer for cup filling

Streamline your production line with precise cup filling and sealing, ideal for a wi...

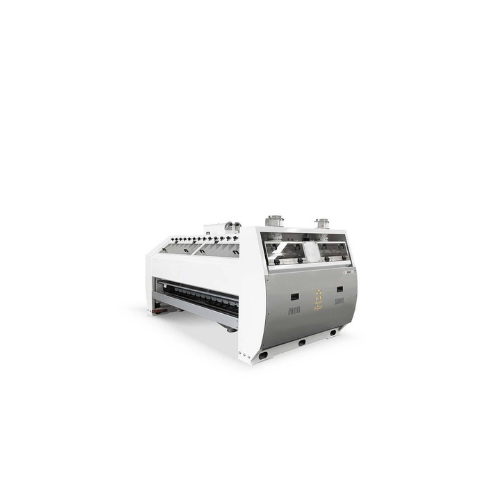

High efficiency milling solution for pharma and food industries

Achieve precise particle size control and enhance produc...

Cone mill for size reduction

Achieve precise particle size reduction and deagglomeration with minimal heat generation, ensur...

Industrial cooker for sauces and stews

When producing diverse culinary delights such as sauces and stews, achieving even he...

Precise dosing technology for praline and chocolate production

Streamline the production of pralines, chocolate bars, an...

Chocolate moulding system for small-scale production

Optimize your chocolate production by efficiently melting, tempering...

Chocolate tempering system for mould filling and vibrating

Ensure a flawless finish for chocolates and confections with ...

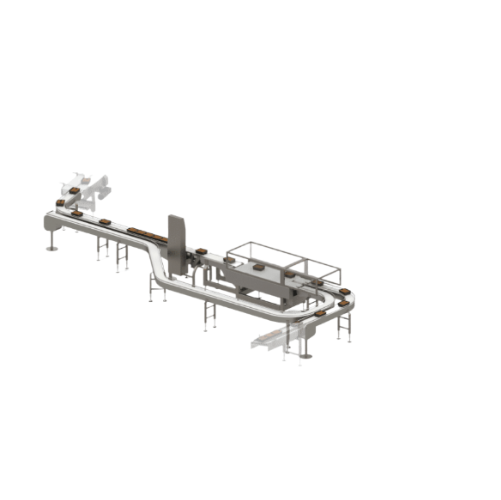

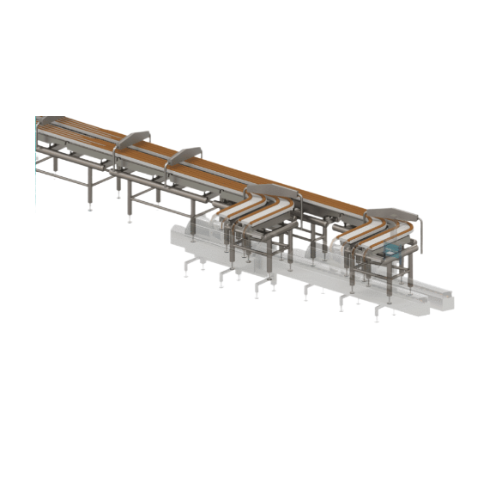

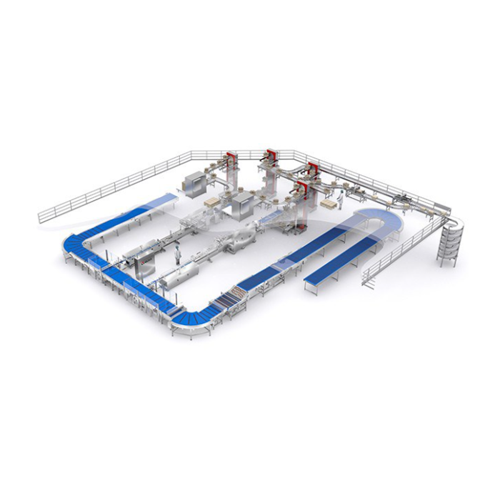

Tailor-made transport systems for confectionery production

Optimize your confectionery production line with customizable...

Cooling tunnel for biscuits and chocolates

Ensure product quality and consistency with precision-controlled cooling tunnel...

Chocolate decoration system for pralines and biscuits

Achieve intricate chocolate patterns and uniform coatings on confec...

Chocolate enrobing system for industrial production

Effortlessly transition between chocolate types in your high-speed pr...

Modular system for chocolate drops production

Enhance your chocolate production with a versatile machine that forms and co...

Coating solution for nuts and dried fruits

Easily apply multiple layers of chocolate to nuts, coffee beans, and more, achi...

Cooling tunnel for biscuit and chocolate production

Ensure consistent quality control in your confectionery production wi...

Continuous cooler for biscuits and chocolates

Enhance cooling efficiency for your confectionery and bakery production with...

Chocolate moulding system for small batch production

Streamline your chocolate product line with precision moulding and t...

Cooling tunnel for industrial pre-cooling

Efficiently reduce product temperatures with this custom-designed air cooling tu...

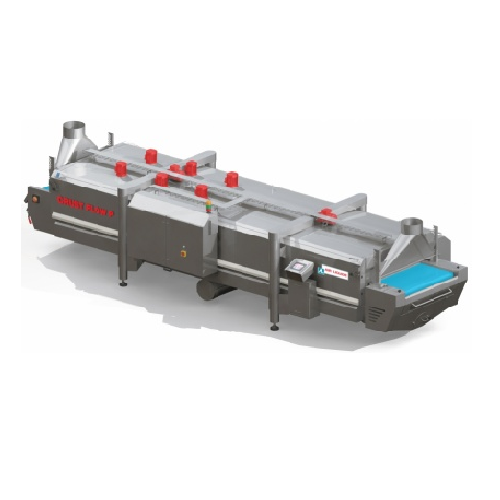

Cooling tunnel for artisanal biscuits and chocolates

Streamline your confectionery production with a cooling solution des...

Industrial chocolate enrobing system for biscuits and fillings

Enhance your production line with this innovative enrobin...

Chocolate filling application system for manons

Efficiently apply a variety of fillings, from delicate buttercream to rich...

Chocolate coating system for nuts and small biscuits

Effortlessly achieve consistent chocolate coatings on nuts, fruits, ...

Enrobers for bakery goods coating

Ensure complete and uniform coating of baked goods, snacks, and pastries, enhancing produ...

Open frame mixer for bread and pastry dough

Enhance your dough consistency and reduce production downtime with a robust, h...

Open frame mixer for bread and dough applications

Enhance baking productivity with a versatile mixer designed for efficie...

High-speed sandwiching for bakery production

Streamline your production of sandwich biscuits with a machine engineered to ...

High-speed sandwiching machine for bakery production

Streamline your baking operations with a machine designed to efficie...

Medium duty mixer for breads and pastries

Achieve consistent dough development and uniform mixing for a wide variety of ba...

Medium duty mixer for dough preparation

Achieve perfect dough consistency across various products with a versatile medium d...

Slurry mixer for cake batters and premix ingredients

Efficiently mix cake batters and premix ingredients with precision, ...

Traditional enclosed frame mixer for dough and batter preparation

Optimize your production with high-capacity mixing, e...

Industrial enclosed frame mixer for high-capacity dough mixing

Optimize your bakery’s output with a mixer designed...

Continuous mixer for batters and cremes

Achieve consistent texture and uniform cell structure in your cake batters and crèm...

Cream delivery solution for sandwiching lines

Achieve precise cream delivery with enhanced control and efficiency, optimiz...

Depositors for bakery fillings

Achieve precise and high-speed depositing of bakery and pastry fillings to optimize your prod...

Rotary dough feeder for bread and tortilla production

Optimize your dough processing by maintaining dough integrity and e...

Rotary dough feeder for uniform dough blocks

Efficiently feed consistent blocks of dough into your processing line without...

Automatic patty former

Optimize portion control and maintain hygiene with this refrigerated patty former, ensuring consistent...

Compact dough depositor for artisan confectioneries

Ideal for crafting intricate and uniform pastries, this machine enhan...

Dual dosing and topping system for bakery products

Enhance your bakery’s production efficiency with advanced dosing...

Pastry depositor for versatile product shapes

Enhance your bakery’s production with a versatile depositor that effor...

Rotating nozzle depositor for pastry production

Optimize your pastry production with precise dosing and shaping capabiliti...

Depositing system for fixed deposited biscuits

Optimize your bakery production with a versatile depositing system designed...

Rotary moulder for shortbread and pie crust production

Achieve precise molding of diverse baked goods with high-speed eff...

Co-extruder for filled sweet and savoury products

Effortlessly create a variety of filled sweet and savoury products, fro...

Intermittent pick and place solution for stackable items

Optimize your production line with high-speed, intermittent oper...

Enrobing system for high-quality chocolate applications

Enhance your confectionery line with precise chocolate coating ca...

Advanced convection oven for bakery applications

Enhance your bakery’s production efficiency and product quality with a ve...

Conical rounder for bakery products

Optimize your dough handling process with efficient shaping solutions, ensuring consist...

Fixed bowl spiral mixer for dough preparation

Ideal for perfecting dough consistency, this spiral mixer offers two-speed o...

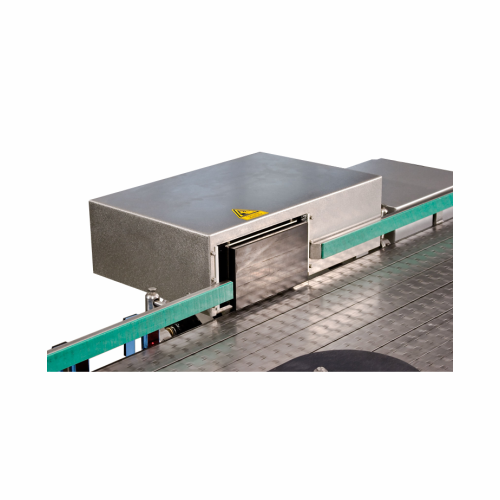

Curtainless x-ray inspection for small lightweight packaged food products

Eliminate product damage and false rejects w...

High speed rolling line for confectionery production

Enhance your confectionery production with a versatile rolling line ...

Packaging solution for bulk vegetables and fruits

Ensure precise, high-speed packaging for diverse product sizes with a f...

Versatile cone mill for uniform size reduction

Achieve precise particle size consistency and gentle deagglomeration across...

Heavy duty lump breaker for coarse and pre-grinding

Achieve consistent particle size reduction with this heavy-duty solut...

High-speed side loading case packer for small dimensions

Optimize your packaging line with a high-speed solution designed...

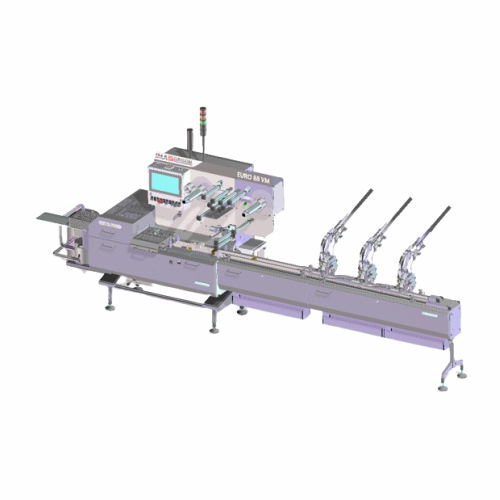

Automatic biscuit sandwiching equipment for high-volume production

Optimize your biscuit production line with high-spee...

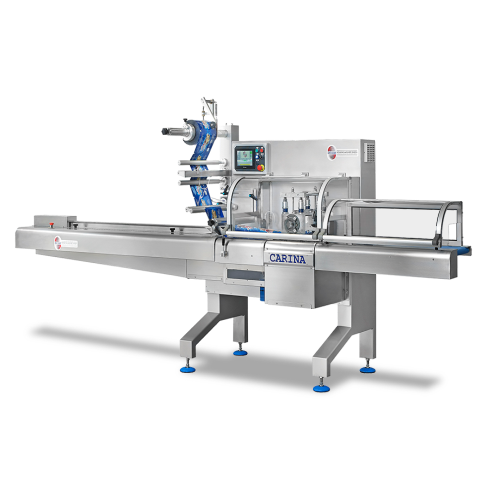

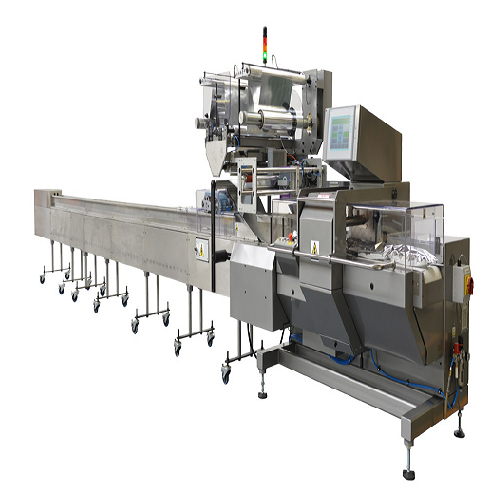

Entry-level flow wrapping machine for small and medium products

Optimize your packaging line with a high-speed flow wrap...

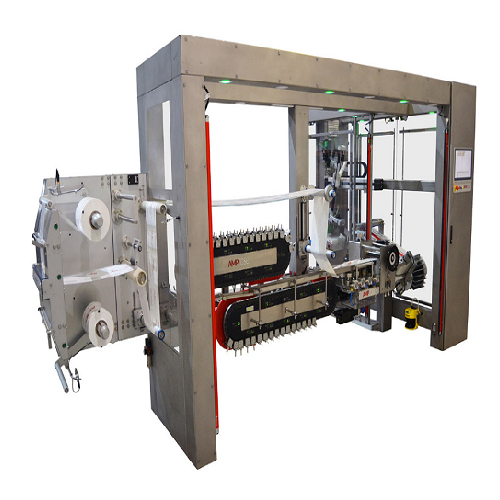

Horizontal form fill and seal for biscuits on edge

Optimize your packaging line with a machine that streamlines wrapping ...

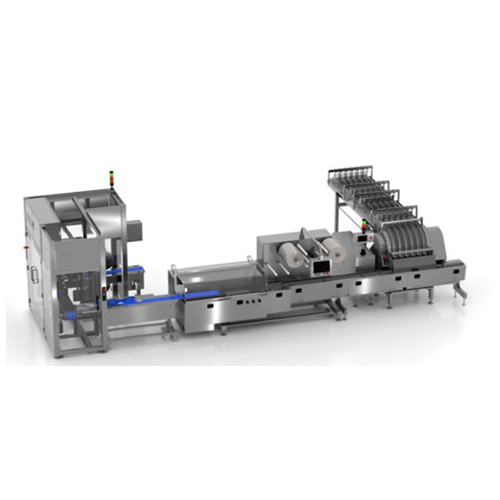

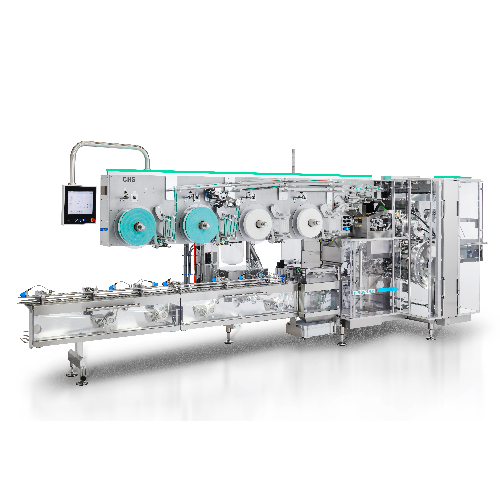

Automatic sandwich biscuit production system

Elevate your biscuit production line with high-speed sandwiching capabilities...

Flow wrapper for high-speed confectionery packaging

Achieve gentle, high-speed packaging for delicate confectionery items...

Flow wrapping with pick and place robots

Streamline your confectionery and bakery packaging with precision flow wrapping, u...

Flow wrapper for biscuits in stacks

Optimize your biscuit packaging with a flow wrapper designed to efficiently portion and...

Automatic portion volumetric feeder for biscuits and crackers

Streamline your biscuit and cracker packaging process with...

Intermittent cartoner for flexible packaging solutions

Enhance your production line’s efficiency with a versatile c...

Industrial case rejector for faulty packaging

Ensure product integrity by smoothly removing faulty cases from your product...

Large continuous tunnel dryer

Optimize your production with advanced drying and dehumidification technologies, ensuring prec...

Continuous multi-lane wrapping solution

Achieve precision and speed in packaging with an advanced solution designed for con...

Continuous flow-wrapping system for high productivity

Optimize your packing line with a high-speed flow-wrapping system d...

Advanced dough mixing solution with removable bowl

Efficiently blending and kneading diverse doughs, this mixer enhances ...

Planetary mixer for industrial pastry production

Achieve precise dough consistency and enhance baked goods quality with th...

Planetary mixer with double tool for pastry dough

Optimize your pastry production with precise mixing capabilities that e...

Industrial bowl lifter-tipper

Streamline your bakery production with a solution that simplifies dough handling by seamlessly...

Feeding hoppers for dough production lines

Optimize your dough production with precision feeding and portioning, ensuring ...

Medium to large-size box making line

Streamline your packaging process with a versatile box making line that efficiently ha...

Industrial elevator tipper for efficient material handling

Optimize your material handling process with a high-performan...

Biscuit depositing system for two-color biscuits

Enhance your bakery line’s efficiency with a high-speed depositing ...

Biscuit storage and depositing system

Ideal for small labs, this compact machine efficiently deposits and stores diverse bi...

Horizontal flow pack packaging machine for multi-format packaging

Streamline your packaging process with a versatile ho...

Biscuit depositing system

Optimize your biscuit production with a high-speed depositing system designed for continuous opera...

Flow pack packaging for flexible wrapping material

Achieve precise and secure packaging with three-sided sealed packages ...

Dual-purpose biscuit and jam depositing system

Enhance your production line with a versatile solution that seamlessly depo...

Horizontal packaging system for high-speed operations

Achieve unmatched sealing precision and packaging speed with this h...

Compact biscuit depositor for small bakeries

For artisanal producers seeking precision and versatility, this compact equip...

Three-side sealing flow pack machine

Optimize packaging efficiency with a high-speed flow pack machine that ensures precise...

Three-side sealing packaging machine

Achieve precise, three-side sealed packaging for both food and non-food products, enha...

Product unscramblers for industrial automation

Efficiently organize and orient jumbled products for seamless integration w...

High-speed packaging system for flow-wrapping

Streamline your packaging operations with a high-speed flow-wrapping solutio...

Double sigma kneader for viscous product mixing

Optimize the mixing and kneading of high-viscosity products with our doubl...

Multilane wrapping solution for food and confectionery products

Enhance your packaging line efficiency with high-speed m...

Biscuit overwrapper for x-fold or hermetic sealing

Ensure each biscuit, cookie, and sweet treat is securely wrapped and s...

Grain separator for impurity removal in milling

Optimize grain cleaning with a high-performance separator designed to effi...

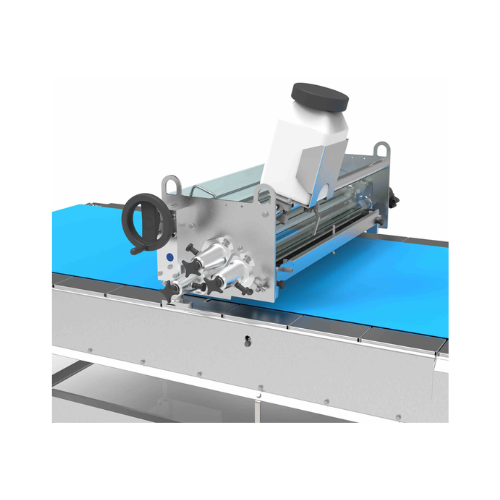

Washover unit for baked goods

Maximize production efficiency with quick-changeover washover units designed for seamless liqu...

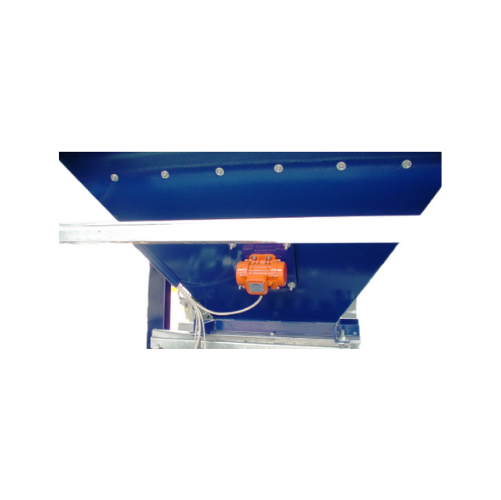

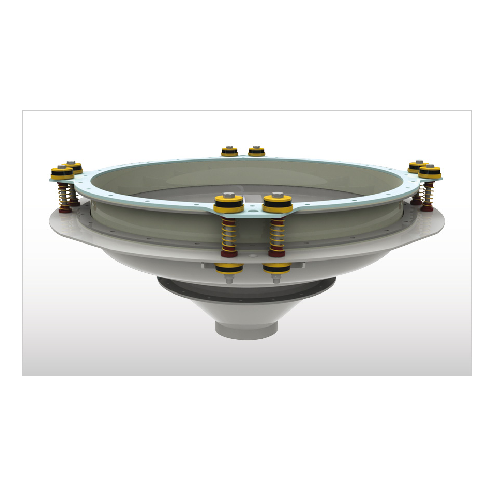

Vibro discharger for silo emptying

Achieve complete and even discharging of bulk materials from various silo types, ensurin...

Automatic rice whitening solution

Need consistent rice whiteness and bran removal without manual intervention? This high-sp...

Sprinkling unit for confectionery and baked goods

Achieve precise and uniform toppings on baked goods with versatile and ...

Pressing roller for cookie thickness adjustment

Ensure consistent cookie thickness and unique product patterning with a hi...

Premixer for confectionery masses

Achieve consistent ingredient blending with precision-premixing for candy and baked goods...

Hammer mill for fine grinding in food and feed industries

Achieve exceptionally fine particle-size distribution with a h...

Dough sheeter for rotary-cut biscuits

Achieve consistently smooth dough bands essential for high-quality biscuits and confe...

Oil sprayer for biscuits and crackers

Enhance the flavor of your baked goods with precise oil and liquid flavor application...

Industrial tunnel oven for biscuits and cakes

Achieve uniform baking results with optimized heat transfer and precise mois...

Biscuit wire cutter and depositor for confectionery production

Streamline your production of intricately designed cookie...

Vibration sprinkler for uniform dough decoration

Elevate your baked goods with precise, uniform decoration using a vibrati...

Hydration solutions for baked goods

Achieve consistent dough quality faster with a system that precisely hydrates and mixes...

Batter roller sheeter for biscuits and cakes

Achieve consistent batter deposition for your baked goods with this high-spee...

Cooling conveyor for baked goods

Efficiently adapt your baked and confectionery goods to ambient conditions, ensuring optima...

Hybrid tunnel oven for biscuits and cakes

Enhance production efficiency and product consistency with a versatile oven syst...

Cut-sheet laminator for cracker and biscuit production

Achieve precise dough lamination for consistent quality in cracker...

High-efficiency cooling tunnel for confectionery production

Optimize your product cooling process with high-efficiency t...

High-speed mixer for dough production

Achieve consistent dough quality and streamline your production process with this ver...

Wafer acceleration belt for chocolate enrobing

Optimize your confectionery production with precise wafer separation and al...

Chocolate enrober for bars, cookies, and wafers

Ensure consistent and high-quality enrobing for confections with advanced ...

Advanced enrobing line for confectionery

For confectionery producers seeking seamless chocolate coating versatility, our en...

Industrial fanning belt for strand separation

Enhance your production line efficiency with precise strand separation, ensu...

Oilseed flaking and milling system

Optimize your oilseed processing with a flaking system that enhances extraction efficien...

Dough feeder for biscuit and cookie production

Achieve precise dough feeding with seamless integration into high-speed pro...

Continuous dough extruder for baked goods

Achieve optimal dough consistency and reduce production time by integrating cont...

Weighing and receiving container for floury products

Achieve precise and consistent ingredient proportions with this syst...

Industrial plansifter for grain sifting and grading

Optimize your production line with precision grain separation, mainta...

Twin-screw extruder for breakfast cereal

Optimize your production with a robust twin-screw extruder that accommodates high ...

Laboratory plansifter for grain milling and brewing

Achieve precise particle-size distribution and quality control across...

Integrated grinder for wheat and grain

Achieve superior grinding performance and energy efficiency with this fully integrat...

Bran finisher for flour milling

Enhancing your milling process, this solution boosts flour yields by efficiently separating ...

Coffee roasting system

Optimize your coffee production from green beans to finely ground espresso with this versatile system,...

Material handling system for confectionery production

Optimize your production line with a system designed for efficient ...

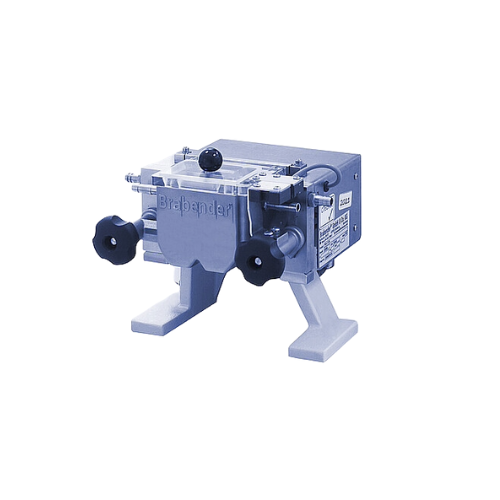

Measuring mixer for flour and dough analysis

Optimize your dough consistency and quality with precise mixing and kneading ...

Measuring mixer for flour farinograph tests

Achieve precise dough consistency with ease—this mixer ensures reliable testin...

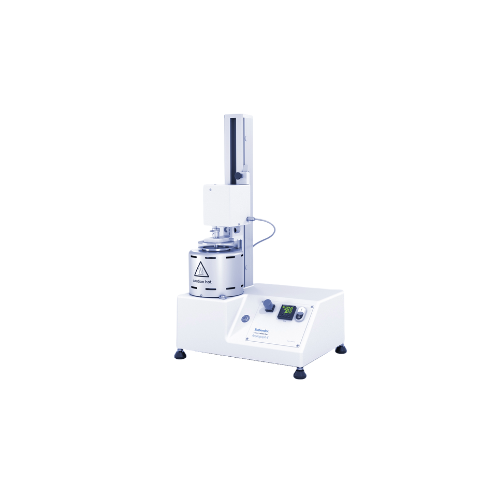

Standard flour viscometer

Ensure your baked goods meet the highest quality standards with precise starch and enzyme activity...

High-speed vertical and horizontal case packer

Enhance your packaging line efficiency with a versatile case packing soluti...

Table top depositor for semi-liquid and solid products

Streamline your bakery operations with a compact solution engineer...

Icebox cookies extrusion solution

Streamline your cookie production with a solution that efficiently extrudes, shapes, refr...

Multipack flowrapping system

Streamline your packaging process with a multipack flowrapping system that effortlessly handles...

Wrapper for flat bottomed chocolate articles

Optimize your confectionery packaging with a machine designed for swift, secu...

Neapolitan chocolate wrapping solution

Efficiently wrap and label square chocolates with this fold wrap solution, ideal for...

Multipack wrapping system for snacks

Streamline your snack packaging process with a machine engineered for high-speed, effi...

4-side seal horizontal form-fill-seal packaging system

Streamline your confectionery and snack packaging with high-speed,...

Double twist wrapping machine for sweets

Optimize your confectionery packaging line with high-speed double twist wrapping, ...

Chocolate moulding line for filled and inclusions bars

Achieve seamless chocolate production with modular flexibility, al...

Energy-efficient oven monitoring system for bakeries

Optimize your baking operations with a smart oven system that enhanc...

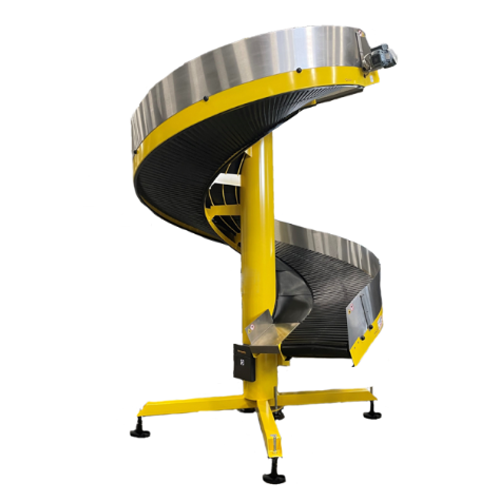

Spiral conveyor for logistics and packaging

Ensure seamless elevation and transportation of diverse products with this ver...

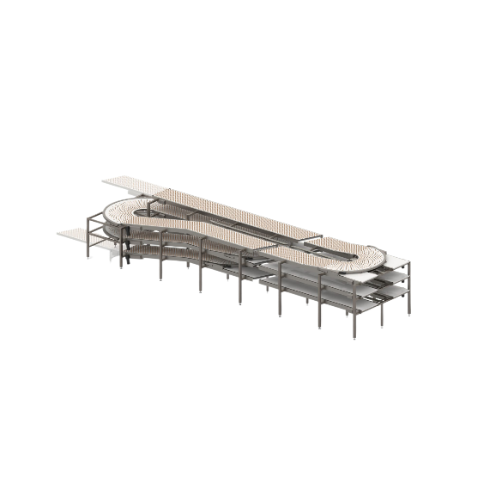

Non-contact accumulator for packaging lines

Experience seamless integration and reduced product interference with this inn...

Modular conveyor system for internal unit load transport

Optimize your production line with a versatile conveyor system t...

Curved conveyor for logistics and packaging

Efficiently tackle space constraints in your production line with a flexible c...

Controlled spiral conveyor for logistic centers

Efficiently manage parcel flow and minimize product damage with this spira...

Spiral conveyor for repeating size cases

Optimize your line’s efficiency by elevating rigid items at higher inclines,...

Automatic wrapping for small products

Achieve precise and efficient packaging of diverse small products with seamless verti...

High speed horizontal flow wrapper for food products

Achieve precise, high-speed packaging for snacks with this versatile...

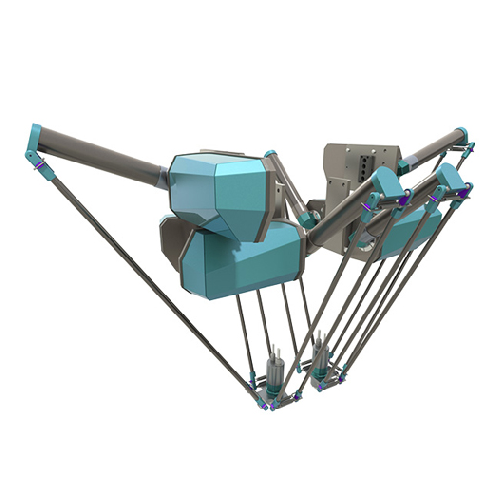

Modular delta robot for high-speed precision handling

Optimize your production line with high-speed precision handling, t...

Dual-axis delta robot for high-capacity packaging lines

Enhance your production line’s efficiency with a dual-axis ...

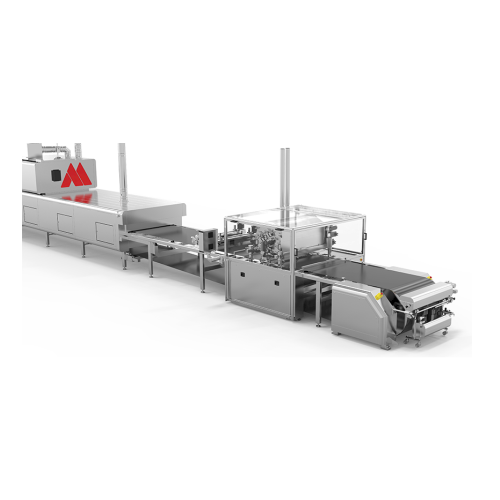

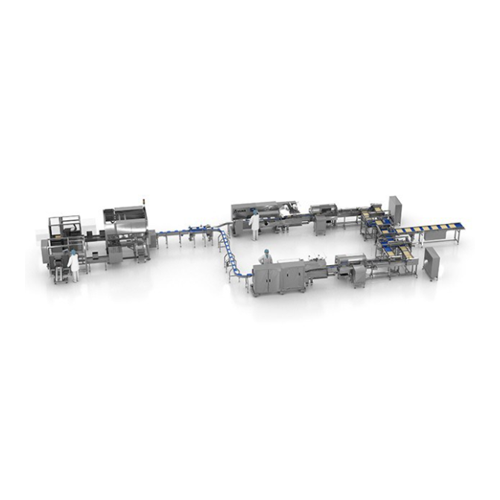

Versatile bakery production line

Enhance your bakery’s versatility with a production line that enables dynamic customi...

Chocolate enrober for large scale production

Efficiently enrobe a wide range of products, from chocolate bars to delicate ...

Bottom enrober for chocolate and confectionery products

Optimize your production line with precise bottom enrobing, ensur...

Compact extruder and depositor for confectionery and bakery production

Streamline your confectionery and bakery product...

Convection oven for uniform baking

Achieve precise, energy-efficient baking with this convection oven, offering fast heatin...

Direct gas fired oven for biscuit and cracker production

Achieve consistent, energy-efficient baking for a wide range of ...

Flexible depositor and extruder for small-scale production

Achieve precise multi-mass creations with a compact, versatil...

Industrial guillotine for precision cutting

Achieve precise portioning with a high-capacity guillotine, designed for seaml...

Industrial melting tank for chocolate and confectionery production

Maximize your production efficiency by seamlessly in...

Chocolate pump for consistent mass transport

Efficiently transport chocolate mass with precision, ensuring gentle handling...

Cooling tunnel for chocolate and bakery products

Achieve precise cooling and crystallization for chocolate and confectione...

Dough feeder for flexible and gentle dough handling

Ensure precise, gentle handling and optimal integration with your pro...

Wafer and biscuit feeder for chocolate moulding

Efficiently integrate wafers and biscuits into your chocolate production l...

Clean-in-place tanks for industrial sanitation

Optimize your sanitation processes with clean-in-place tanks, designed to r...

Spiral freezer for bakery and confectionery

Maximize space and efficiency while preserving the quality and freshness of di...

Storage silos for granular products

Enhance storage efficiency and flexibility with modular silos, ensuring precise monitor...

Mixer kneader sheeter for fresh pasta processing

Streamline your pasta and dough production with a single machine that eff...

Volumetric loading system for biscuits and crackers

Streamline your snack production with efficient volumetric loading, d...

Automatic tray denesting and erecting system

Streamline your packaging line with precise and efficient tray handling—ensur...

Tray weight inspection system

Ensure accurate and efficient quality control by seamlessly integrating a high-speed tray weig...

Product distribution system for multiple stencil creamers

Facilitate seamless product flow distribution across multiple ...

Product distribution system for large capacity wrappers

Optimize your high-speed production lines by efficiently distribu...

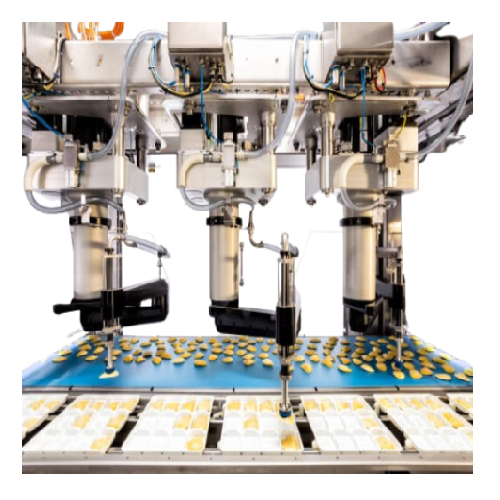

Vision guided robotic pick and place system for bakery settings

For manufacturers tackling high-volume, diverse-sized ba...

Robot for picking and placing cookies in wrappers

Boost efficiency and flexibility in your bakery production line with vi...

Robotic pick and place system for bakery products

Enhance your bakery production line with advanced robotic systems that ...

Robotic pick and place system for cookies

Streamline your bakery production with a flexible robotic system that seamlessly...

Cookie arrangement system for packaging

Enhance your packaging efficiency by seamlessly arranging and loading diverse confe...

Biscuit slug loading system

Enhance your confectionery line with high-speed, precise slug loading that integrates seamlessly...

Automatic loader for irregular shaped cookies

Optimize your bakery line operation by efficiently loading non-uniform cooki...

Chicane system for portion pack flowrapper

Streamline your packaging process with a system that ensures precise portioning...

Cooling system for post-baking stabilization

Optimize your production line by integrating a cooling system that ensures po...

Vision-based product inspection system for rejecting defective items

Enhance your production line efficiency by ensurin...

Product manipulation and stacking systems

Efficiently transition products from flat to stacked on a conveyor while minimiz...

Vibratory buffer system for line efficiency

Enhance your production line by efficiently managing downstream stoppages and ...

Fifo inflow buffer for efficient production lines

Optimize your production flow with a solution that seamlessly absorbs d...

Tray buffering system for downstream absorption

Handle production line disruptions effortlessly by temporarily absorbing t...

Sandwich and biscuit depositing system

Achieve high-capacity sandwich and biscuit production while maintaining precision wi...

Product spreader for cooling conveyor

Optimize the cooling process of cream-filled products by gently spreading sandwiches ...

High-volume product distribution system

Efficiently manage high-volume snack and confectionery production flows with a syst...

Laned product distribution for high-capacity wrappers

Efficiently distribute high-capacity product flow across multiple w...

Conveyor system for ambient product cooling

Ensure precise cooling of baked and confectionery products while maintaining l...

Battery production facilities with precision weighing

Achieve maximum product purity and precision in your production pro...

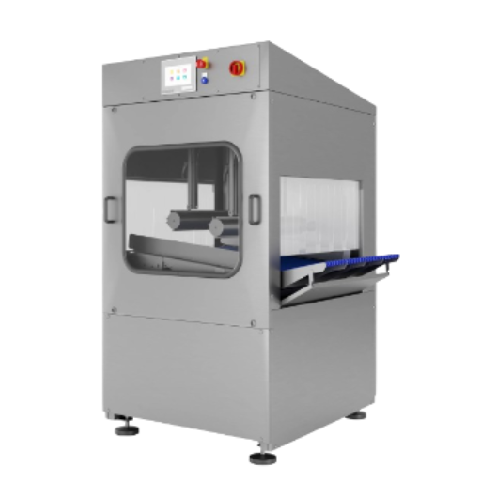

Industrial baking sheet cleaning system

Enhance hygiene and streamline operations with a system designed to clean, dry, and...

Tray cleaning system for bakery applications

Ensure the highest hygiene standards with a system that efficiently cleans an...

Stick press for pretzel and biscuit production

Transform your snack production with a versatile solution that presses, fil...

Pv processing vessels for liquid and cream mixing

Optimize your mixing operations with versatile processing vessels desig...

Industrial sigma mixer extruder for homogeneous mixing and extrusion

Achieve precise mixing and seamless extrusion of d...

Industrial mixers for hire

Optimize your production line with versatile mixers designed for precision blending, heating, and...

Tanker loading bellow for dust-free bulk solids loading

Optimize tanker loading while minimizing dust emissions with this...

Batch-type single shaft mixer for industrial mixing

Achieve precise and uniform mixing with high-speed, single-shaft mixe...

Batch-type single shaft mixers with bomb-bay discharge

When you need rapid, residue-free discharge in your batch mixing p...

Food-grade round dust collectors

Maintain a clean production environment with this food-grade dust collector, designed to ma...

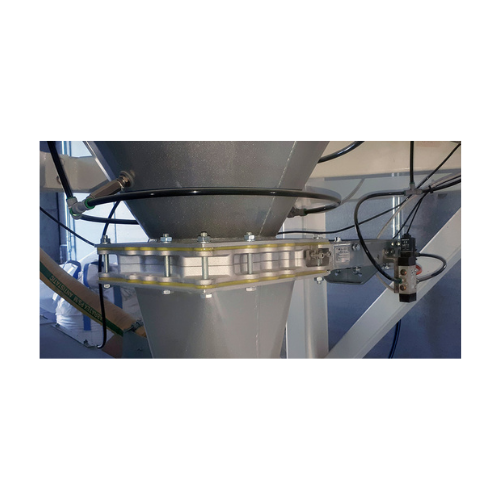

Fit-frame butterfly valves for dry bulk solids

Achieve precise control and minimize contamination in your dry bulk materia...

Butterfly valves for powders and granules

Ensure precise flow control and reliable sealing for gravity-fed or pneumatic sy...

Butterfly valves for powder and granular material handling

Experience seamless material control with advanced butterfly ...

Membrane pressure relief valve for silos and bins

Ensure silo safety with our valve that instantly balances internal pres...

Low profile slide valve for controlling powder flow

Optimize your powder and granule flow management with precision-engin...

Slide valves for flow interception in powder and granular materials

Effectively manage the flow of powdery and granular...

Flap diverter valves for pneumatic conveying

Streamline material flow in your pneumatic conveying system by effortlessly r...

Diverter valves for pneumatic conveying lines

Experience precise flow control in pneumatic conveying with diverter valves ...

Drum-type diverter valves for pneumatic conveying

Optimize your pneumatic conveying system by effortlessly controlling th...

Vibro-aerators for bulk solids discharging

Optimize your powder flow and ensure consistent discharge with this advanced ae...

Spring-loaded pressure relief valves for silo overfill protection

Ensure safety and prevent costly overfills with press...

Food-grade tubular screw conveyors

Ensure complete hygiene in your production line with these stainless steel tubular screw...

Food-grade stainless steel tubular screw conveyors

Ensure contamination-free material handling with our tubular screw con...

Drop-through rotary valve for powder and granular material feeding

Achieve precise control in discharging and feeding p...

Drop-through rotary valve for precise powder and granule feeding

Ensure precise material handling with this drop-through...

Blow-through rotary valves for pneumatic conveying

Optimize your pneumatic conveying systems with high-efficiency blow-th...

Rotary ball vibrators for aggregate reclaiming

Enhance efficiency in your production line with a solution that optimizes t...

Rotary ball vibrators for bulk solids discharging

Ideal for enhancing material flow, this equipment efficiently handles f...

Manual bag opener for bulk solids discharging

Effortlessly open and empty bags while containing dust emissions, ensuring a...

Single impact pneumatic hammers for flow aids

Combat material clogs and ensure smooth flow in your production line with pn...

Pneumatic hammers for bulk solids discharging

Optimize your production efficiency and solve material flow challenges with ...

Pneumatic hammers for aiding material flow

Optimize material flow and eliminate blockages in your processing line with pne...

Industrial vibrator for high-frequency vibration

Achieve efficient material flow and compaction across various production ...

Rotary turbine vibrators for bulk solids discharging

Enhance the efficiency of material handling with high-speed, low-noi...

Rotary turbine vibrators for material flow aid

Optimize your production efficiency with high-speed, silent operation vibra...

Continuous impact vibrators for bulk material removal

Combat material flow issues like bridging and rat-holing with our i...

Continuous impact vibrator for aggregate reclaiming

Tackle material flow challenges head-on by preventing common issues l...

Rotary roller vibrators for concrete compacting and hopper emptying

Achieve higher compaction and efficient emptying wi...

Rotary roller vibrators for material flow assistance

Enhance material flow efficiency in your production line with high-f...

External electric motovibrators for industrial applications

Optimize material movement and improve discharge efficiency ...

External electric motovibrators for bulk solids conveying

Enhance material flow efficiency and solve challenging dischar...

Silo overfill protection system

Prevent silo overfilling and excess pressurization with a system designed to safeguard silos...

Silo overfilling safety system

Ensure safe silo filling with our system that prevents overfilling and excess pressurization,...

Micro-batch feeders for powder and granular material

Struggling with clog-prone powders? Gain precise control and consist...

Laboratory batch mixer for small scale production

Achieve rapid and reproducible mixing results with this laboratory batc...

Bin level indicator for bulk solids

Ensure precise material level detection across your production processes, minimizing th...

Bin level indicators for wastewater treatment

Ensure reliable material level monitoring in your silos and hoppers with ILT...

Electronic pressure meter for silo safety

Ensure the safety of your silos by efficiently monitoring internal pressure chan...

Electronic pressure meters for silo safety monitoring

Ensure precise pressure management in your systems with this advanc...

Pneumatic linear vibrators for bulk material flow

Prevent bridging and rat-holing in your production process with silent,...

Cushioned pneumatic linear vibrators for bulk solids

Combat material bridging and rat-holing with silent vibratory techno...

Hopper venting filter for efficient dust filtration

Achieve superior dust control and efficient material handling with a ...

Anti-wear elbows for pneumatic conveying systems

Reduce wear and extend the lifespan of your pneumatic conveying systems w...

Cushioned pneumatic vibrators for coarse particle materials compaction

Enhance your material flow and compaction proces...

Stainless steel trough screw conveyor

Ideal for precise handling of powdery and granular materials, this solution ensures m...

Loss-in-weight screw feeder for precise powder dosing

Achieve high precision in continuous dosing with this advanced scre...

High capacity vertical conveying for flour

For consistent, high-speed handling of delicate and powdery materials, this eng...

Waste bag compactor for bulk solids

Efficiently compact waste bags to a fraction of their volume, streamlining disposal whi...

Vibratory outlet hopper for bulk material discharge

Struggling with material bridging and inconsistent discharge? Enhance...

Food-grade bin activator for optimized material flow

Ensure hygienic and efficient discharge from hoppers with our food-g...

Food-grade bin activator for hygienic bulk solids discharge

Achieve consistent material flow and avoid contamination wit...

Industrial bin activator for smooth material flow

Enhance your material handling process with a solution that ensures con...

Rotary bin discharger for bulk solids

Efficiently manage bulk solids with a rotary bin discharger that minimizes residue an...

Horizontal flat pouching solution for foods and chemicals

Achieve precision in pouching liquids and powders with high-sp...

Stand-up pouch packaging for various industries

Elevate your packaging capabilities with a high-speed horizontal pouching ...

Bin activator for silo and hopper discharge

Ensure optimal material flow and prevent blockages in your storage systems wit...

Vibratory outlet hopper for bulk solids discharge

Reduce material handling challenges with highly efficient vibration tec...

Continuous stand-up pouching solution for up to 1000ml

Maximize efficiency in high-speed production lines with precise st...

Spiral mixers for bakery dough

Transform your bakery production with precise and consistent dough mixing, ensuring every bat...

Automated infeed and outfeed systems for packaging lines

Streamline your production line by integrating reliable infeed a...

Industrial dough proofing systems

Optimize your bakery’s efficiency with customizable proofing systems designed to fi...

Vertical form fill seal packaging for medium-speed production

Achieve efficient and reliable packaging for diverse food ...

Vertical packaging system for medium-high speed applications

Optimize your packaging line with a system that delivers pr...

Side seal shrink packaging machine

Achieve seamless and efficient packaging for varied product sizes with continuous side s...

Shrink film sleeve wrapper for packaging

Achieve efficient packaging for diverse products with a versatile sleeve wrapper d...

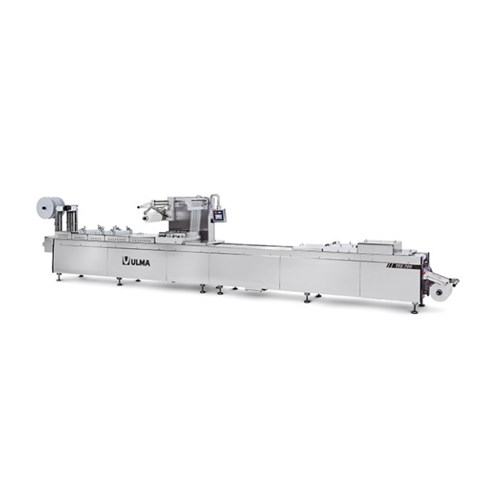

Thermoforming solution for flexible or rigid packaging

Optimize your packaging efficiency with a high-performance thermof...

Hygienic thermoformer for flexible film packaging

Streamline your packaging process with a hygienic thermoformer, offerin...

Traysealer for modified atmosphere packaging

Enhance your food packaging line with precise traysealing and modified atmosp...

Automatic tray sealer for preformed trays

Enhance packaging efficiency with a high-speed tray sealer designed for precisio...

Industrial tray sealer for food packaging

Optimize your packaging operations with precise tray handling and versatile seal...

Automatic tray sealer for cut & seal and Map applications

Optimize tray packaging efficiency with a versatile solution f...

Advanced horizontal flow wrapper for food packaging

Achieve seamless high-speed packaging for diverse food products with ...

Horizontal flow pack wrapper for medium-high performance packaging

Optimize packaging efficiency with a horizontal flow...

Flow pack wrapper for shrink and film wrapping

Optimize your packaging operations with a versatile solution capable of hig...

Horizontal flow wrapper for vacuum packaging

Enhance your food packaging line with a solution designed for precision vacuu...

Automatic hamburger packaging solution

Streamline your hamburger production with a fully automated packaging system that en...

Complete packaging solution for meat products

Achieve seamless packaging integration with a solution designed to streamlin...

Horizontal flow wrapper for medium to high production

Optimize your packaging line with a versatile horizontal flow wrapp...

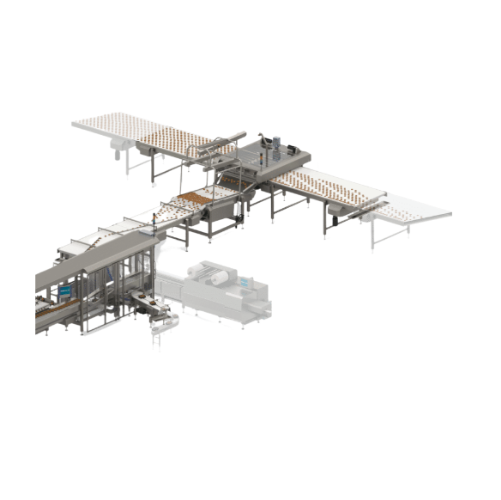

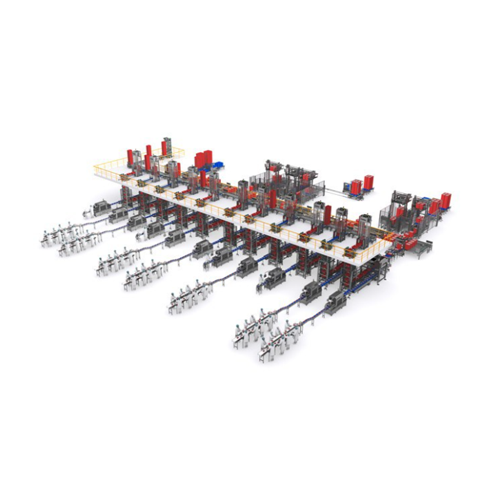

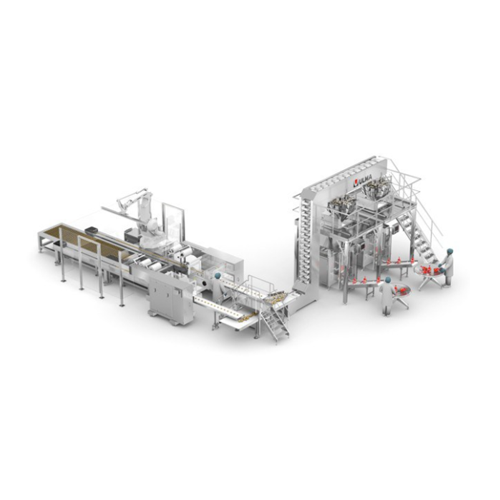

Automated feeding and packaging line for crackers

Optimize your cracker production with seamless integration of high-spee...

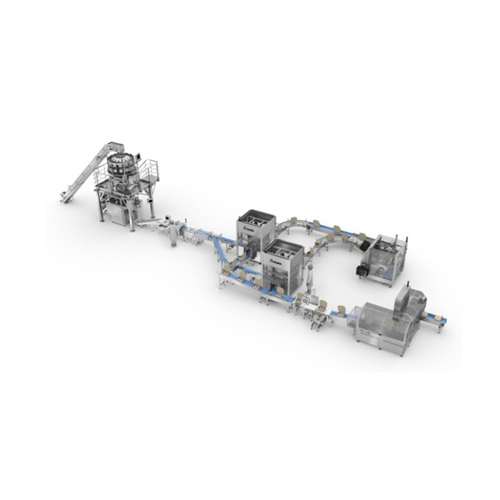

Automated bagging system for confectionery products

Achieve seamless integration in your confectionery packaging line wit...

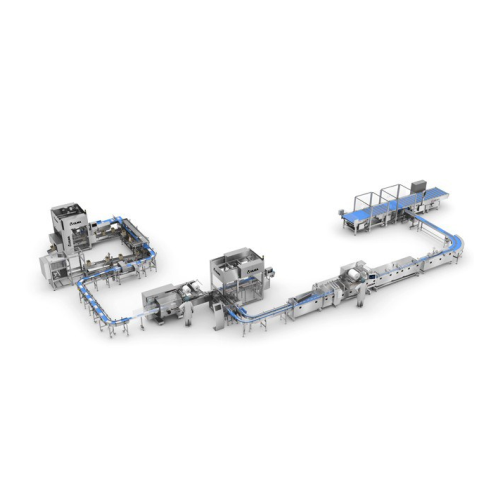

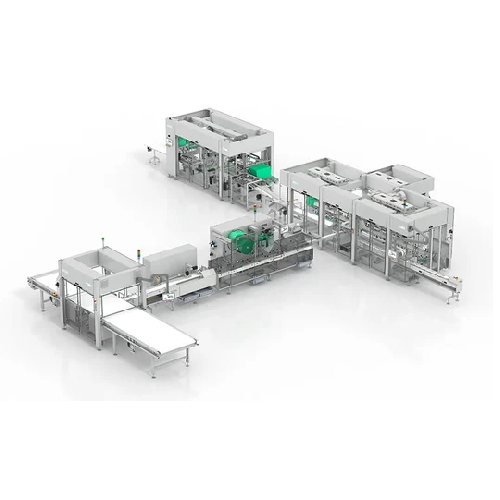

Biscuit packaging and boxing solution

Streamline your biscuit production line with a fully automated system that ensures pr...

Complete solution for packaging of bakery products

Streamline your bakery’s packaging process with a fully automate...

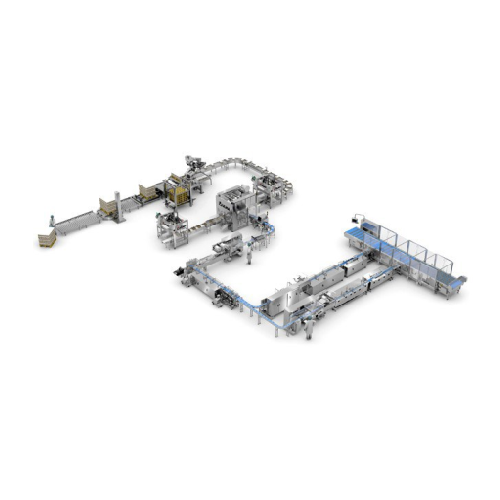

Complete primary and multipack packaging solution for bars

Enhance your bar production efficiency by seamlessly integrat...

Sweet baked goods packaging solution

Optimize your sweet baked goods packaging process with a fully automated solution desi...

Automated packaging and case packing for snack bars

Optimize your snack bar production line with this high-speed solution...

Automated packaging line for wafers

Optimize your wafer production with high-speed, fully automated packaging and versatile...

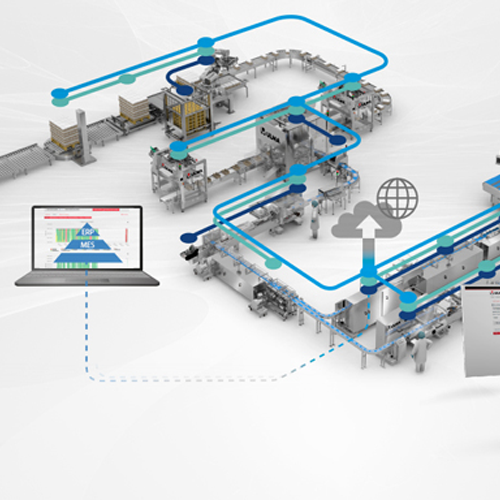

Real-time packaging process tracking solution

Achieve seamless connectivity and control across your packaging processes wi...

Automated line for baked goods packaging

Enhance your packaging efficiency with a seamless integration of precise loading a...

Sustainable biscuit packaging line

Enhance your biscuit production with a fully automated packaging line that leverages sus...

Ecluse for pneumatic conveying systems

Ensure seamless and leak-free material flow in continuous and high-speed operations ...

Semolina purifier for milling operations

Achieve precise separation and classification of semolina and bran with this purif...

Inclined intensive dampener for grain processing

Ensure consistent moisture levels for optimal grain processing and enhanc...

Flexible high-speed wrapping machine for chocolate products

Optimize your confectionery production line with a flexible ...

High-speed chocolate wrapping system

Optimize your confectionery packaging process with a versatile, high-speed wrapping so...

Big bag discharger for powder handling

Effortlessly discharge large bags of powdered ingredients with a modular, safe syste...

Lump breaker for dry powders and granulates

Optimize the consistency of your production line by efficiently breaking up lu...

Ingredient doser for ice cream with large inclusions

Achieve precise and uniform inclusion of fruits, nuts, and candies i...

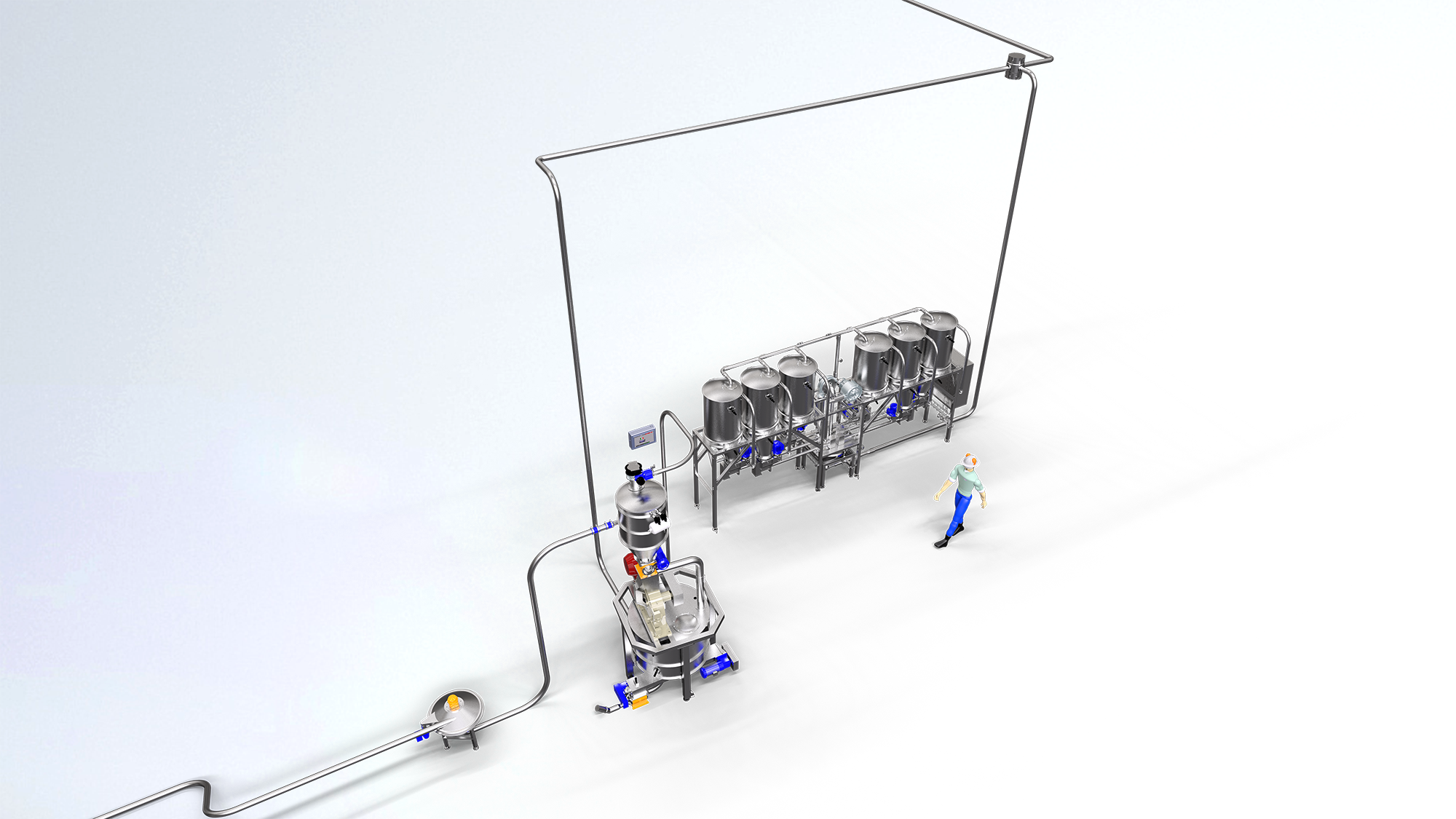

Automated cleaning in place system for bakery production lines

Ensure unmatched hygiene and operational efficiency in fo...

Buffer tank for consistent product temperature control

Ensure consistent product temperatures and streamline your product...

Full-automatic biscuit & cookie production line

Streamline your biscuit and cookie production with a comprehensive solutio...

Commercial crispy roll biscuit maker

Enhance your snack production with our advanced equipment that efficiently molds and s...

Commercial cookie depositor wire cutter

For bakeries looking to diversify product offerings, this machine shapes and cuts d...

Industrial egg breaking and separating solution

Streamline your egg processing with precision egg breaking and liquid sepa...

Industrial biscuit baking tunnel oven

Achieve consistent, high-quality baked goods with our tunnel oven, designed for effic...

Industrial biscuit making solution

Enhance your biscuit production with precision engineering that seamlessly integrates do...

Horizontal flow wrapper for food packaging

Simplify your packaging process with our high-speed horizontal flow wrapper tha...

Robotic pick and place platform for food packaging

Enhance your packaging efficiency and product quality with a scalable ...

Industrial bag sealing solution for medical and food applications

Enhance your packaging line with reliable and versati...

Reliable cartoning solution for food and non-food products

Achieve seamless product packaging with a cartoning solution ...

Stainless steel drying tunnel for packaging lines

Optimize your packaging line efficiency by ensuring products are thorou...

Powder flow measurement system

Achieve precise control over powder consistency and prevent process disruptions by assessing ...

Texture analyser for food and cosmetics testing

Ensuring consistent product quality across diverse food and cosmetic appli...

Lay-on systems for precise sprinkling and nut depositing

Optimize your confectionery production with precision sprinkling...

Sprinkling system for decorating confectionery products

Enhance your confectionery line with precision sprinkling systems...

Bulk chocolate storage for confectionery production

Maximize space efficiency while maintaining product quality with our ...

Chocolate storage tanks for confectionery production

Optimize your confectionery production with state-of-the-art storage...

Sieving system for chocolate processing

Ensure product purity and consistency by seamlessly removing unwanted particles fro...

Decrystallization for tempered chocolate

Ensure your chocolate is perfectly smooth and free of fat crystals with an advance...

Confectionery rework tempering solution

Improve confectionery production efficiency by integrating a compact rework temperi...

Chocolate tempering solution for superior gloss and shelf life

Achieve consistent sheen and extend the shelf life of cho...

Precise metering system for dry confectionery ingredients

Achieve precise dosing of granular and dry ingredients like nu...

Automatic feeder for enrobing solid articles

Ensure seamless feeding for large-scale enrobing operations, enabling efficie...

Biscuit feeder with exact row alignment

Streamline your production line with precise biscuit and wafer alignment for seamle...

Praline and bar product take-off system

Streamline your confectionery production with a versatile take-off system designed ...

Transverse cutting systems for confectionery production

Achieve precise cutting and slitting with high-speed transverse s...

All around sprinkling systems for confectionery

Enhance your confectionery production with a system that ensures precise a...

Chocolate decoration systems for confectionery production

Enhance your confectionery production with precision chocolate...

Automated chocolate decoration system

Elevate your confectionery production with precision chocolate decoration, seamlessly...

Chocolate lentil, ball, and egg production system

Achieve consistent and precise shaping of chocolate lentils, balls, and...

Continuous bar production line for confectionery

Streamline your confectionery production with a seamless system for craft...

Chocolate shell molding system

Optimize your confectionery production with precision shell formation, enabling diverse and i...

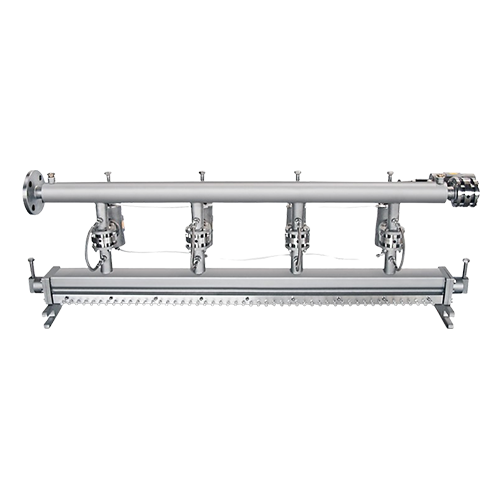

Manifold system for producing weight-accurate ropes of chocolate or fruit masses

Achieve precise weight and shape in c...

Volume-precise moulding for chocolate and fat masses

Achieve precise and consistent moulding for chocolate and confection...

Continuous mixer for confectionery and bakery ingredients

Maximize production efficiency by seamlessly integrating mixin...

Caramel enrobing system for biscuits and wafers

Achieve consistent caramel coverage with precise temperature control, ensu...

Sugar and fondant coating solution

Achieve precise, multi-color or single coat applications with thin, uniform layers, seam...

Retractable mass carriage enrober for chocolate coating

Improve production flexibility with a versatile enrober that allo...

Ice cream coating system for enrobing applications

Achieve seamless chocolate and nut coatings on ice cream bars and conf...

Compact chocolate enrobing system

Achieve perfect chocolate coatings in minimal space with precise control, enabling high-q...

Enrobing system for full, half, and bottom coating of chocolates

Achieve precise and consistent chocolate coating with a...

Enrobing system for biscuits and baked goods

Achieve consistent and precise chocolate coatings with the versatility you ne...

Integrated tempering enrober for chocolate coatings

Enhance your chocolate production line with an integrated solution fo...

Bucket sheeter for confectionery masses

Efficiently form thin, precise layers of flowable confectionery masses with ease, e...

Industrial spreading systems for sticky products

Effortlessly manage the spread of sticky confectionery products with prec...

Cooling tunnel for center cooling in confectionery production

Efficiently manage center cooling in confectionery product...

Advanced cooling tunnel for confectionery production

Optimize your confectionery production with a cooling system that en...

High-precision biscuit sandwiching system

Efficiently align, fill, and sandwich high-speed biscuit rows while ensuring pre...

Weight-accurate depositor for confectionery refinement

Achieve precise filling and refinement of biscuits and confections...

Bottom coating system for confectionery production

Optimize your confectionery line with precision bottom coating, ensuri...

Dough kibbler for bakery production

Effortlessly transform large batches of dense dough into uniform, manageable pieces wit...

Single sigma arm bakery mixer

Streamline complex mixing tasks with precision using a mixer designed for optimal batch contro...

In-line metal detector for liquids & pastes

Ensure product safety by seamlessly integrating a metal detection system into ...

In-line metal detector for pneumatic systems

Ensure product purity and operational efficiency with a solution that effecti...

Conveyor belt metal detection system

Ensure seamless product safety with a system that detects and separates metallic conta...

Metal detector systems for conveyor belts and chutes

Ensure the integrity of your production line by efficiently detectin...

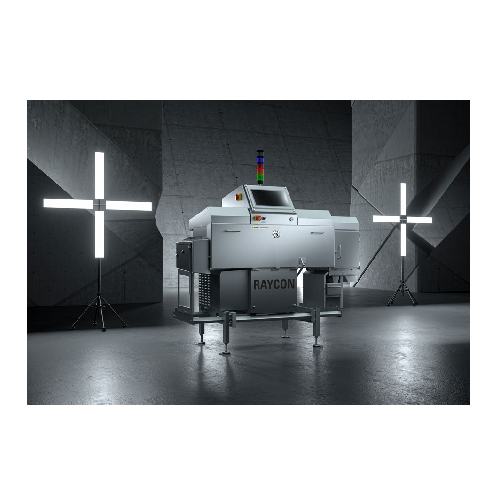

X-ray inspection system for unpackaged bulk products

Ensure product purity and safety in high-speed production lines with...

Cryogenic freezing tunnel for crust-freezing delicate foods

Enhance your production with rapid crust-freezing, expertly ...

Simultaneous chocolate and ice cream dispenser

Unite the worlds of chocolate and ice cream with a machine capable of seaml...

Flow-wrapping solution for varied packaging needs

Gain unmatched flexibility and sustainability with a cutting-edge flow-...

Pick and place robots for efficient product handling

Enhance your production line with high-speed pick and place robots c...

Pick & place vision system for packaging quality control

Ensure flawless product packaging with a vision system that enha...

Compact carton packing solution for standardized tasks

Streamline your packaging workflow with a preconfigured solution d...

Flexible transport robot for packaging lines

Enhance your packaging efficiency with a transport robot engineered to seamle...

Flow wrapper with quick format change

Streamline your packaging operations with a machine that offers rapid format changeov...

Carton Tray Forming Machine for Biscuits

Trays used as packaging for products for biscuits, cookies, chocolates and other s...

Cartoning Machine For Snacks and Sweets

When producing different snacks and sweets, each product will match a different car...

Planetary mixer for confectionery and bakery production

For the best quality confectionary and bakery products, controlla...

Temperature-treatment mixer for bakery & gastronomy

The production of creams, sauces, ragouts, ready-to-bake, and sim...

High speed carton closing machine

Choosing a carton closing machine becomes a significant consideration when the closing of...

Horizontal cartoner for food products

Depending on the primary product packages, food products like confectionery (biscuits...

High capacity spiral cooler for food

Cooling baked goods and food products can be problematic for sliced baked goods. A cru...

High speed decorator for filled biscuits

Filling or decorating biscuits was always a difficult task. Sometimes biscuits are...

Conveyor belt metal detector for food products

Inspecting and rejecting finished food products for metal contamination is ...

Strand forming machine for 2 masses

Form two-ingredient mixes into the shapes and layer combinations required for your fina...

Strand forming machine for 3 masses

Form three ingredient mixes into the shapes and layer combinations required for your fi...

Strand forming machine for creamy mixtures

Turn your ingredients mixture into strands and slabs for further processing int...

Chocolate coating machine

Coat your product with chocolate or caramel. This is a chocolate coating machine born of many year...

Hygienic chocolate coating machine

Coat your product with chocolate or caramel. This is a next-generation chocolate coating...

Hygienic chocolate cooling tunnel

Quickly cool your product after cooking in preparation for further processing. This is a ...

High capacity decorator

Enhance the appearance of your product by applying final finishing touches and designs. This is a ser...

ATEX confirmed outdoor silo for flour

Bulk outdoor storage of flour, dry milk and other powder ingredients for the bakery i...

Automatic rework system for biscuit and bread scrap

Scraps are an inevitable byproduct of biscuit and bread production. W...

Manual bag discharger for bakery industry

Many minor and intermediate ingredients for bakery products are delivered in bag...

Microdosing system for bakery industry

Storage and dosing of powdered minor ingredients such as flavourings, colours and si...

Small sugar mill for entry level production

Sugar powder is a key ingredient in a wide range of bakery, confectionery, and...

Strand forming machine

Form ingredient mixes into strands and slabs for further processing into bars, and other final product...

Enrobing attachment for an automatic tempering machine

Used in the confectionery industry to coat nuts, ice cream, toffee...

Chocolate enrober for medium production capacities

Premium enrober for capacities from 100 to 500 Kg/h.

Case packer for stackable products

Are you packing square or stackable products into corrugated cases? An automated case pa...

Metal detection system

The inspection system automatically determines the best frequencies to maximize sensitivity for both f...

Versatile X-ray inspection system

Versatile X-ray inspection system for product weight, quantity and shape to detect the pr...