Croissant Making Equipment

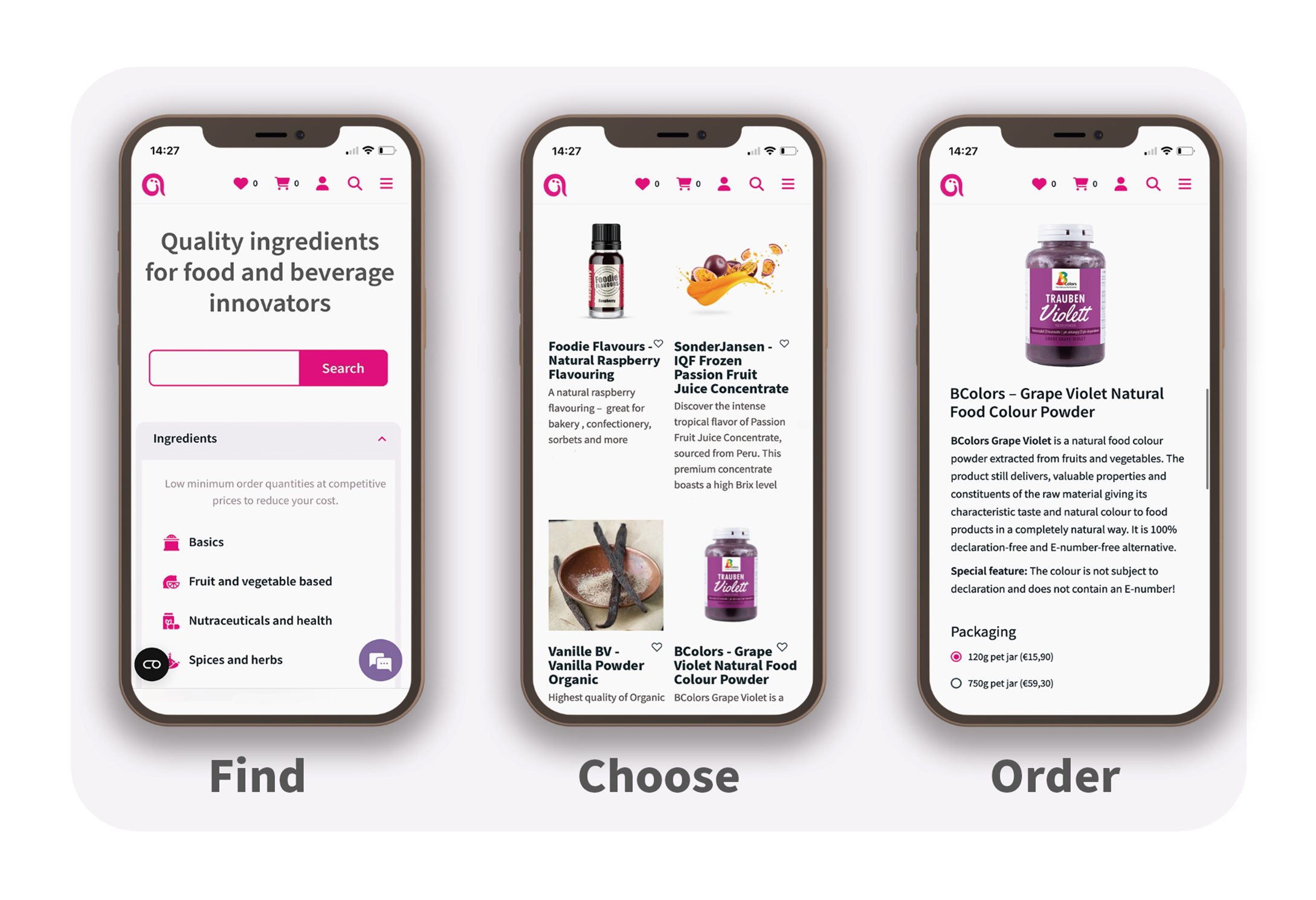

Find innovative production technology for making croissants and connect directly with world-leading specialists

Croissants have crossed global barriers to become a widely consumed pastry, unique for its rich buttery taste and crispy exterior. Regardless of location, the croissant production process involves creating laminated dough by repeatedly folding and rolling butter into dough. Temperature regulation is crucial to the croissant making process as too warm temperatures negatively affect the overall outcome.

Stories about croissants

Tell us about your production challenge

Why is lamination important in the croissant making process?

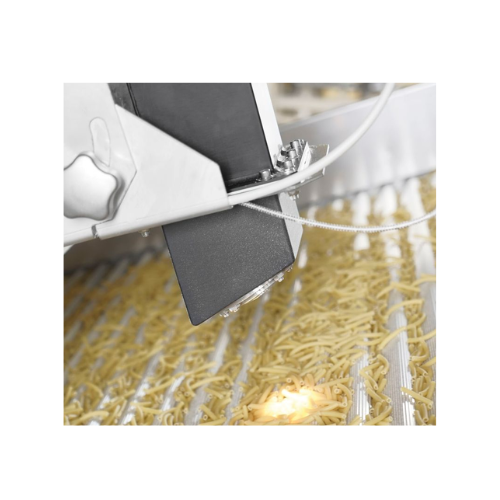

An ideal croissant has a flaky exterior and a delicate honeycomb appearance on the inside. These are direct outcomes of the process of laminating. During lamination, producers fold and roll butter into the dough to create multiple super-thin layers of dough. The fold pattern could be an envelope fold, single, letter, or book-fold. They can achieve this on a large scale production line with the help of bakery equipment such as a professional dough sheeter. Dough laminating ensures that open pockets form in the interior as the croissant bakes while the exterior develops uniform flaky stripes.

Varieties of croissants made from a croissant making equipment

Croissants come in two major forms; the straight croissants and the c-shaped or crescent-shaped ones. Although these shapes appear to reflect a baker’s choice and creativity, they actually represent the key ingredients in the croissant.

Generally, straight croissants contain 100% butter, while curved ones contain other fats such as oil or margarine. To create these varieties, bakers alter the cutting and rolling pattern of the dough. They could cut them into triangles or rectangles and might either roll or leave the edges straight. It’s important to ensure the dough is protected from heat during this process because too much heat will melt the butter and ultimately affect the texture of the croissant.

Croissants for vegans

Even though croissant making equipment will generally include ingredients like butter, milk, and eggs to create the ideal croissant, vegans can still enjoy this product by using plant-based alternatives to butter, eggs, and milk. Vegan butter, which is a combination of water and a plant-derived oil like olive or avocado, can help to achieve a buttery and chewy croissant. Olive oil and coconut oil are good substitutes for egg wash because they provide uniform browning. Dairy-free milk from almonds and oats does the job of providing a gorgeous sheen to the croissants.

The role of proofing when making croissant

Proofing is a crucial step in baking food items like croissants, which require incorporating air pockets into the mixture. During this stage, which is usually after cutting the doughs into shapes, the yeast cells release carbon dioxide gas after consuming sugar. This step is vital to achieving the optimal texture of the croissant. If it is over-proofed, the laminated layers will separate and cause the butter to leak out. On the other hand, under proofing creates a very dense croissant. Generally, achieving ideal proofing in frozen croissants is challenging because ice crystals form in the dough and affect yeast viability. However, a freezing rate of ≥ −3.19 °C min−1 is suitable to achieve the desired texture.

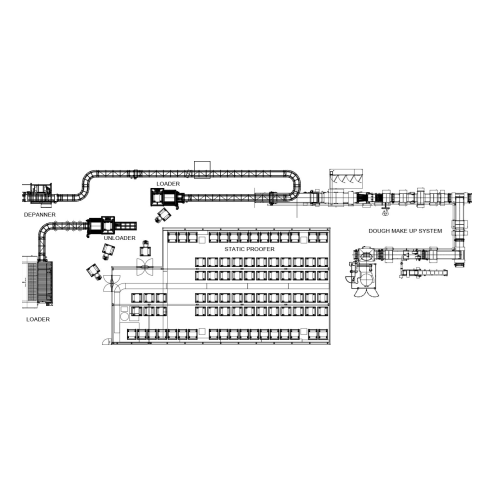

Processing steps involved in croissants making

Which croissants technology do you need?

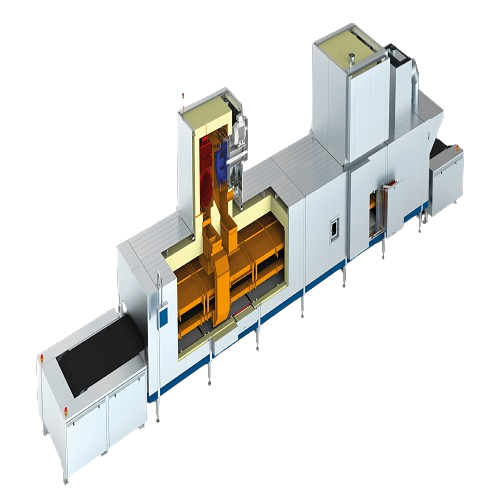

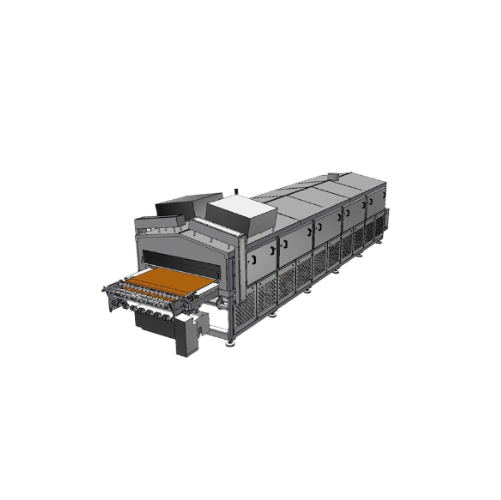

Industrial tunnel ovens for bakery products

Achieve precise control over baking processes with these industrial tunnel ove...

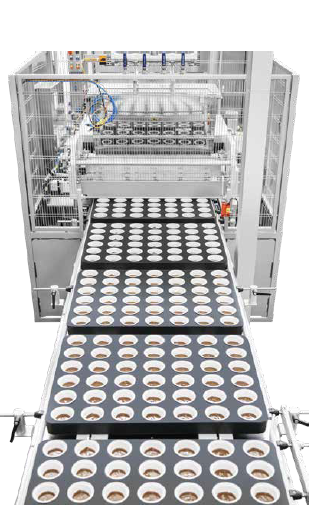

Cake and pastry depanner

Optimize your bakery’s output with this solution that seamlessly integrates into your production lin...

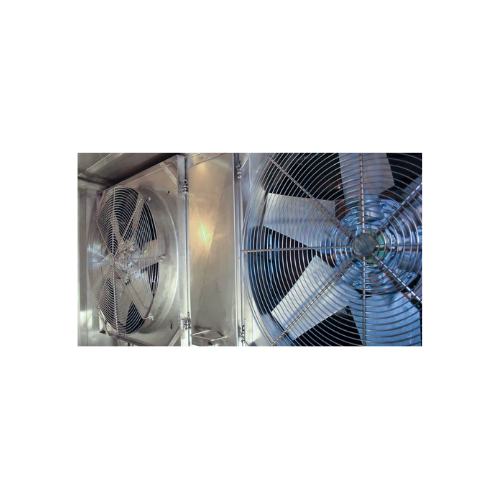

Freezing and cooling systems for bakery products

Enhance your bakery production line with advanced freezing and cooling sy...

Cakes and pastry side injector

Enhance your bakery production with precision side injection technology that efficiently fill...

Cakes and pastry fill injector

Achieve precise and efficient filling of a variety of bakery products, minimizing waste and d...

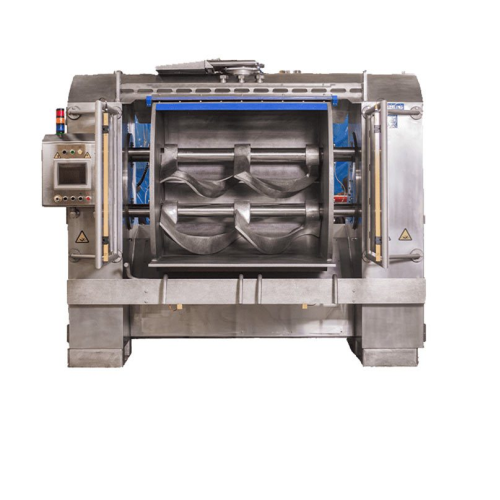

Industrial mixer for various dough types

Efficiently mix a wide range of doughs with precise temperature control to achieve...

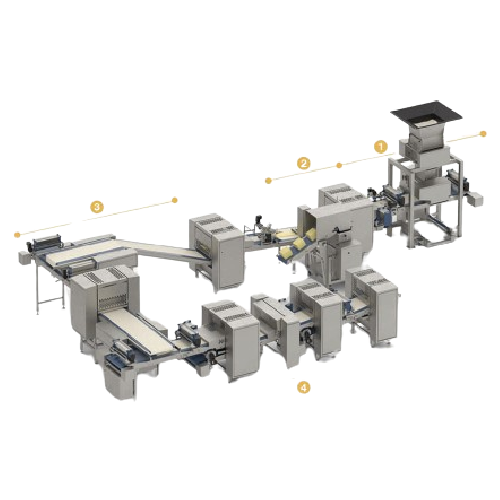

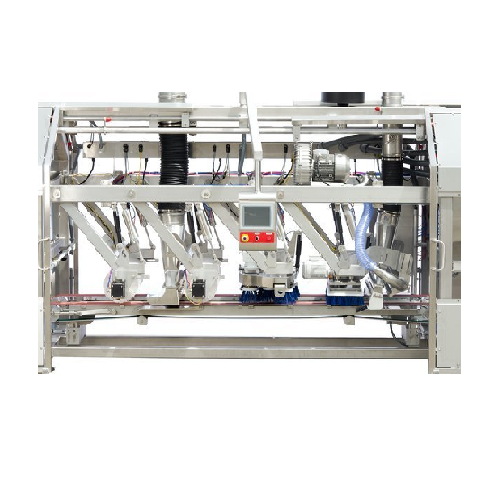

Croissant production module for pastry make-up lines

Enhance your bakery’s product range with a versatile module de...

Donut production line for various shapes and sizes

Optimize your bakery’s output with precision-engineered dough pr...

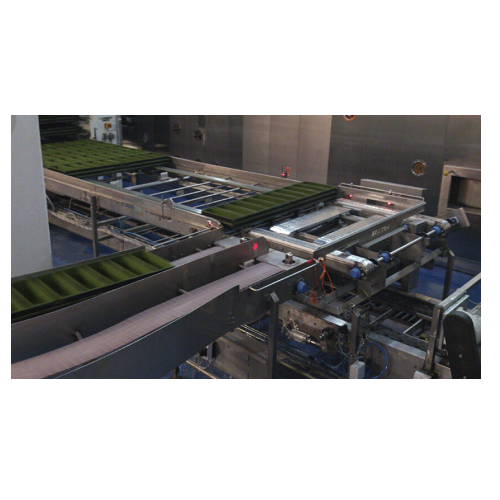

Industrial dough laminator for croissants and pastries

Achieve consistently light and flaky products with precision lamin...

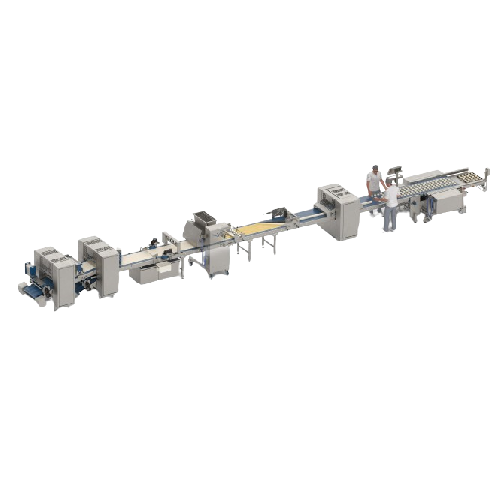

Pastry production line for large-scale bakeries

Streamline your bakery production with a versatile line designed to effici...

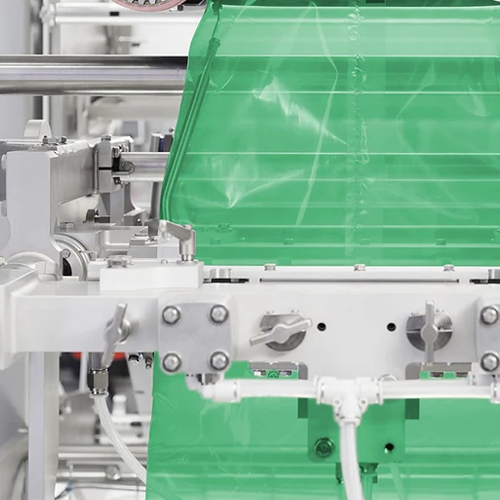

Dough laminating equipment for croissants and pastries

Optimize your bakery’s output with our advanced laminating e...

Industrial bread process line

Optimize your bakery operations with a versatile bread processing line, designed to handle a v...

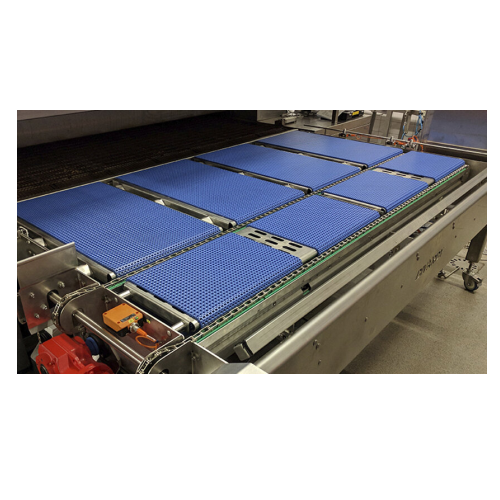

Industrial bakery conveying solutions

Ensure seamless, hygienic transport of bakery goods with precision-engineered conveyi...

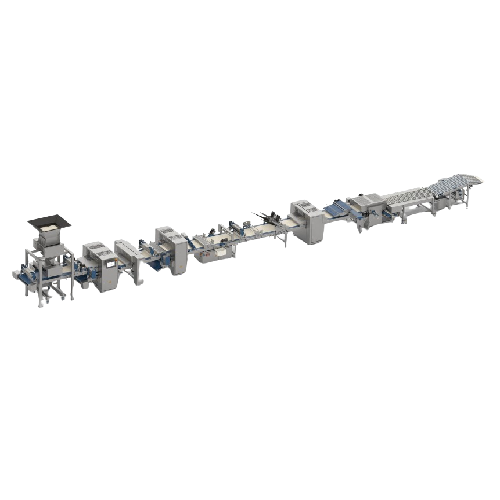

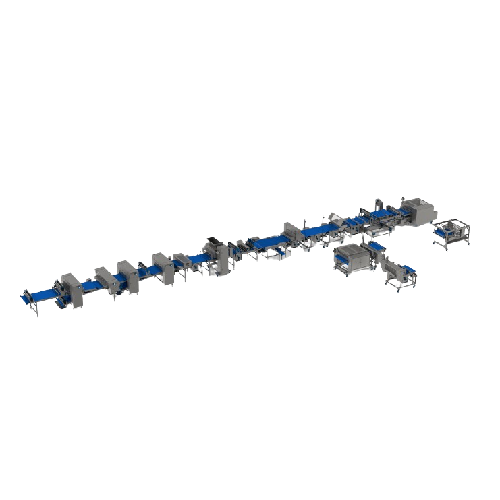

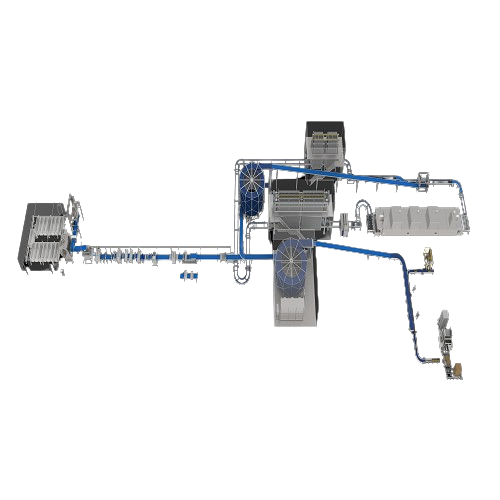

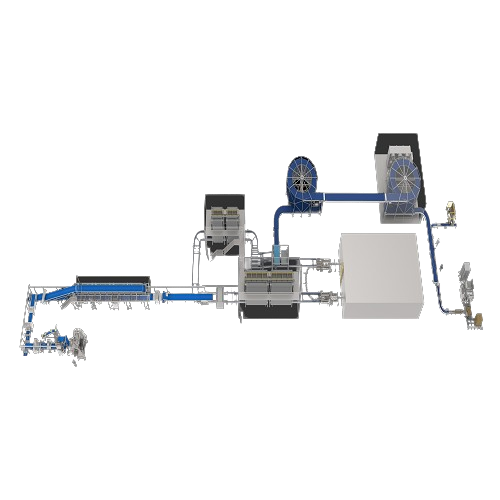

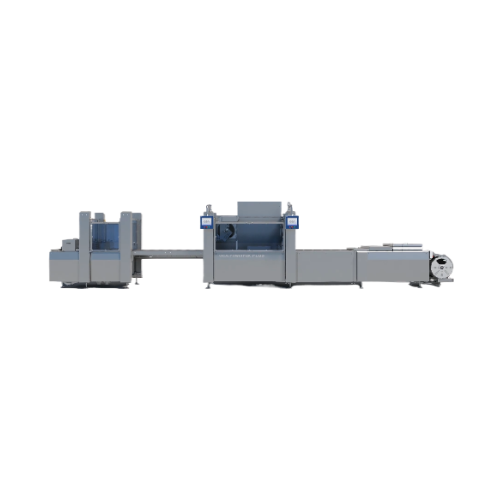

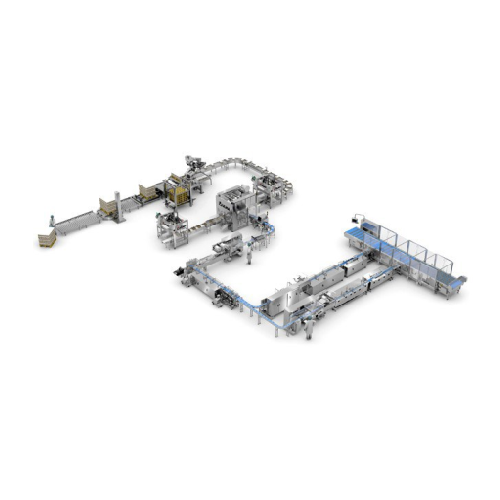

Industrial croissant production line

Streamline your bakery’s operations with a versatile solution capable of produci...

Advanced bakery depanning solutions

Streamline your bakery production with cutting-edge depanning technologies designed to ...

Automated bread production line

Optimize your bakery operations with precision-engineered systems that streamline every stag...

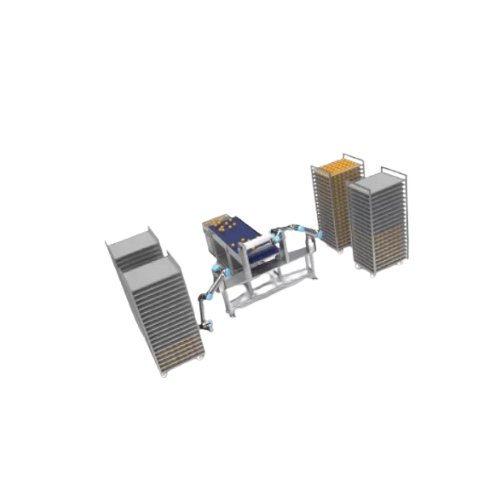

Automatic oven loading and unloading system

Streamline your bakery’s production efficiency with precise and synchron...

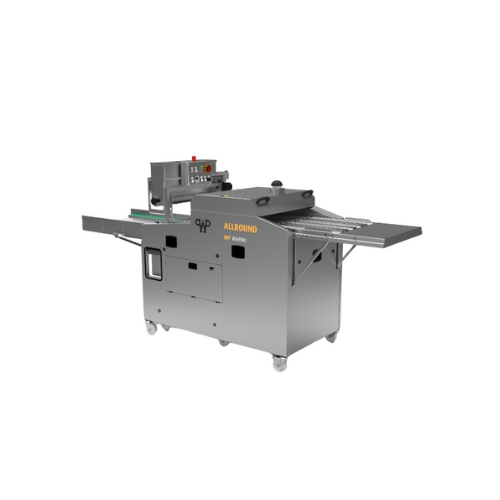

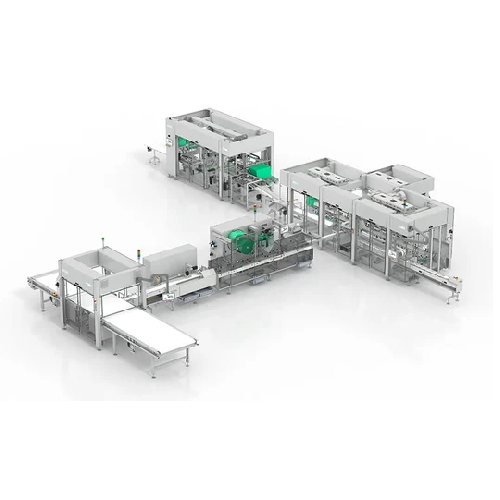

Universal pastry production line for industrial baking

Optimize your bakery operations with a versatile line capable of p...

High shear emulsifier for mayonnaise production

Streamline your production of high-quality emulsions with this high-capaci...

High shear emulsifier for food and pharmaceutical products

Optimize your production line with precise emulsification, ho...

Heat exchangers for efficient heat transfer in industry

Achieve precise temperature control across diverse viscosities wi...

Continuous nut paste production line

Elevate your production efficiency with a versatile preparation line designed to seaml...

Continuous heat exchanger for soups and sauces

Optimize your soup and sauce production with a continuous heat exchanger th...

Industrial cutting system for fine emulsions

Optimize your production line with precision cutting and emulsifying, ensurin...

Continuous caramel process line

Optimize your continuous food processing with an engineered-to-order line tailored for preci...

Open frame mixer for bread and pastry dough

Enhance your dough consistency and reduce production downtime with a robust, h...

Open frame mixer for bread and dough applications

Enhance baking productivity with a versatile mixer designed for efficie...

Medium duty mixer for breads and pastries

Achieve consistent dough development and uniform mixing for a wide variety of ba...

Traditional enclosed frame mixer for dough and batter preparation

Optimize your production with high-capacity mixing, e...

Industrial enclosed frame mixer for high-capacity dough mixing

Optimize your bakery’s output with a mixer designed...

Rotary dough feeder for bread and tortilla production

Optimize your dough processing by maintaining dough integrity and e...

Rotary dough feeder for uniform dough blocks

Efficiently feed consistent blocks of dough into your processing line without...

Vision counting system for bakery products

Achieve precise and consistent product counting with this advanced system, desi...

3d vision quality inspection system for bakery products

Streamline your bakery production with high-speed 3D vision inspe...

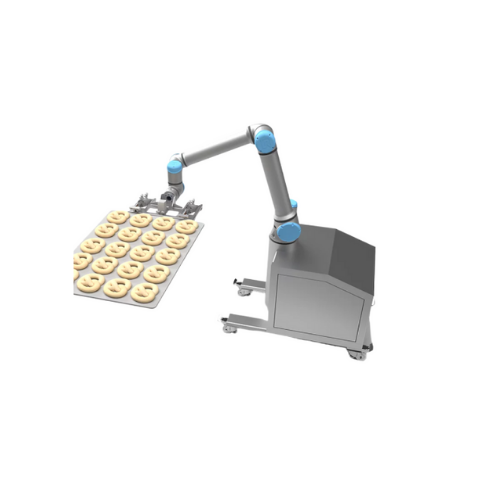

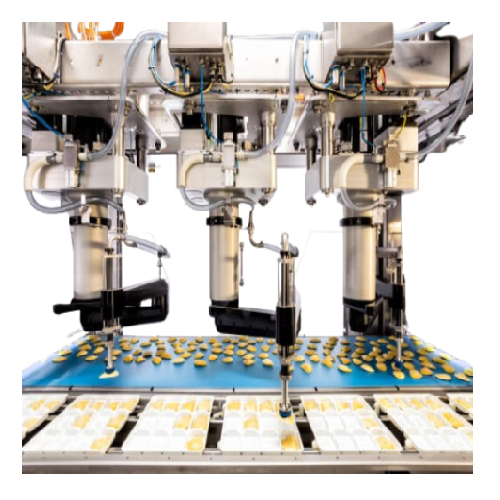

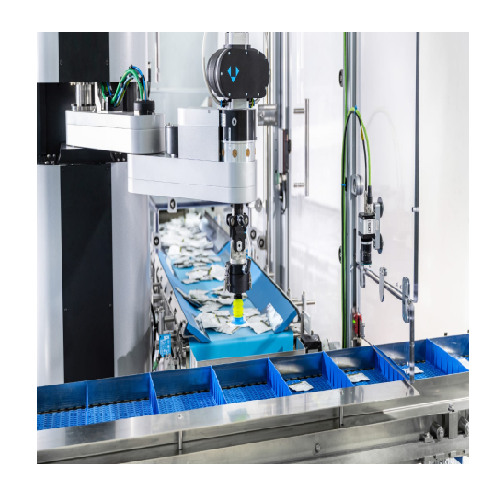

Industrial vision robot for optimized packing

Optimize your bakery production line with a system designed to efficiently p...

Bulk box filler for bakery and pastry products

Efficiently pack fragile bakery and pastry products with gentle handling an...

Industrial bakery bag dropper for boxes or trays

Enhance your bakery line with precision-based bag dropping solutions that...

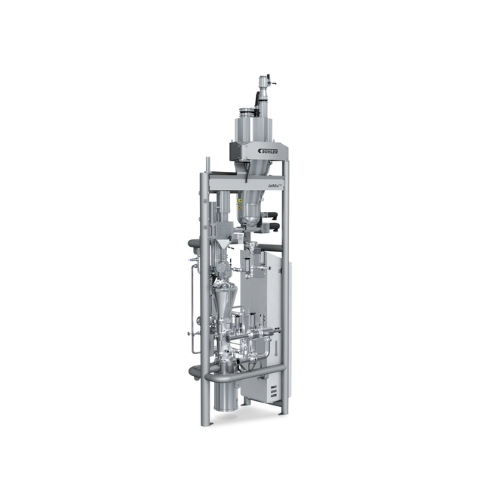

Vertical fill and seal bagging machine for bakery products

Streamline your bakery product packaging with this versatile ...

Vertical form fill seal packaging system

Enhance your packaging line with precision sealing and efficient throughput, ideal...

Automated bag sealing for packaging lines

Enhance your packaging efficiency by seamlessly integrating an automated bag sea...

Self-driving transport system for industrial packaging

Streamline internal logistics with a self-navigating vehicle desig...

Automatic box loader for fragile products

Ensure precise and gentle handling of delicate bakery goods with a compact case ...

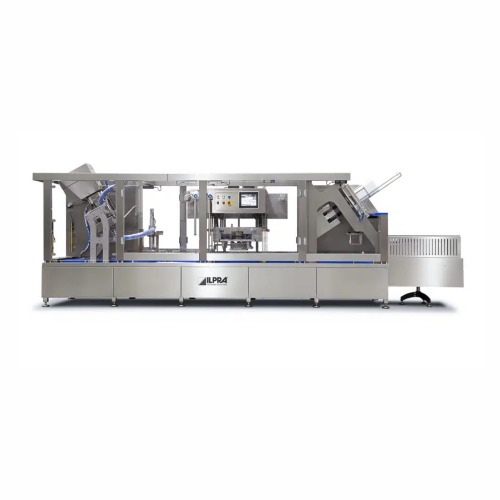

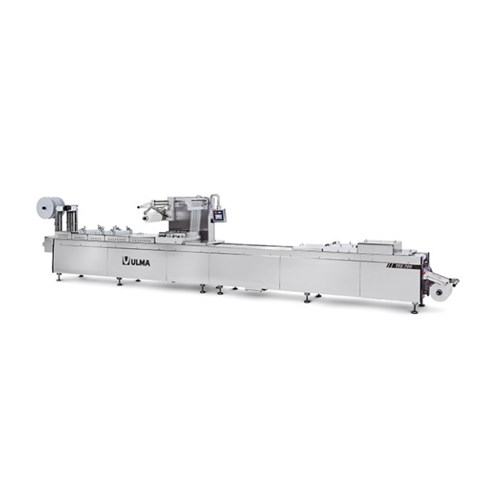

Automatic traysealer for food packaging

Optimize your packaging efficiency with this advanced traysealer, designed to enhan...

High-precision slicing for cheese and sausage products

Experience unparalleled slicing precision and efficiency with high...

Production line for coiled bakery products

Enhance your bakery’s efficiency with a versatile system designed to crea...

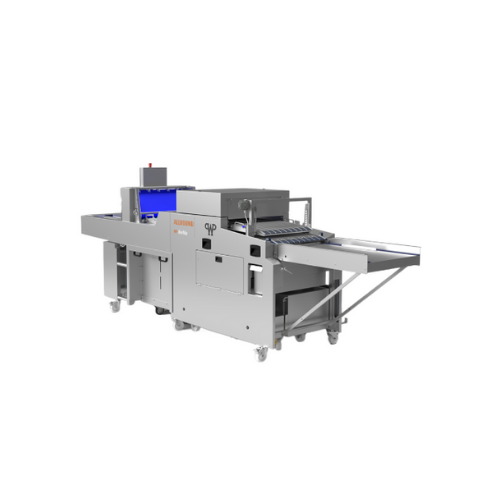

Flexible pastry production line

Maximize your bakery’s output with a versatile pastry line that handles everything fro...

X-ray inspection system for food packaging

Ensure product integrity and safety with advanced detection of foreign bodies i...

Labelling solution for thermoformed packaging

Ensure flawless labeling integration with high-speed, continuous production....

Label dispenser integration for packaging lines

Streamline labeling operations with precision and flexibility, ensuring yo...

Labelling and marking solutions on flowpackers

Achieve unmatched precision and flexibility in packaging with labelling and...

Marking solutions for traysealers

Ensure precise labeling and data printing on tray-sealed packages with integrated solutio...

Vacuum packaging chamber for industrial products

Achieve consistent sealing precision and extended shelf life for diverse ...

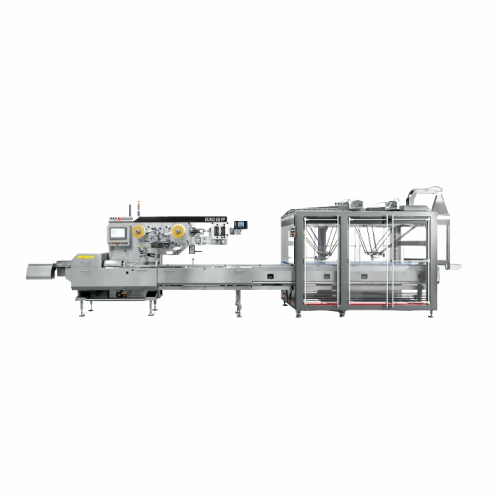

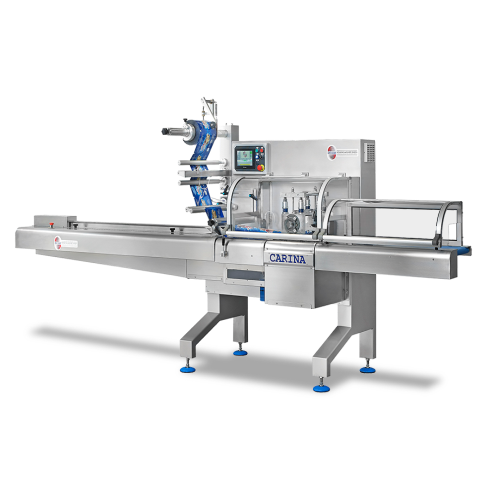

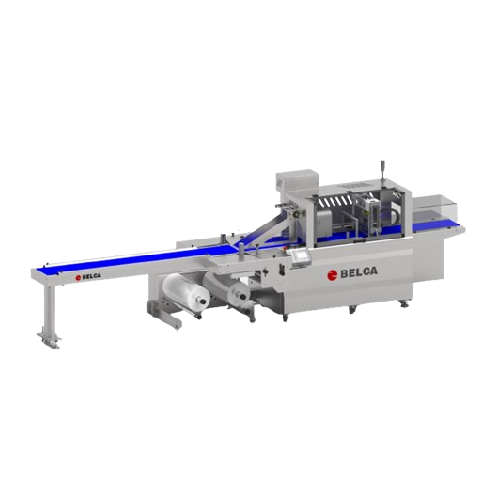

Flowpackers for efficient food packaging

Achieve seamless packaging with flowpackers designed for high-speed, sustainable o...

Industrial shrink and drying units for food products

Ensure optimal product integrity and extended shelf life by seamless...

Belt loaders for automated food packaging

Streamline your packaging line with precision-engineered belt loaders, designed ...

Mbs belt systems for seamless packaging integration

Optimize your packaging line with a system that seamlessly merges mul...

Automated conveyor systems for food packaging lines

Seamlessly integrate high-speed product transport and handling into y...

Automated pack stacker for packaging lines

Streamline your packaging line with a compact solution that stacks and organize...

Robotic loading systems for packaging applications

Enhance your production line with versatile robotic loading systems, d...

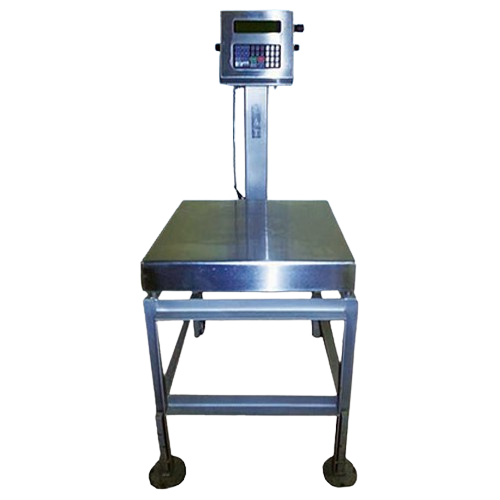

Automatic checkweighers for precise weight control

Ensure accurate weight compliance and enhance quality control with adv...

Compact dough depositor for artisan confectioneries

Ideal for crafting intricate and uniform pastries, this machine enhan...

Compact pastry kneading line

Optimize your pastry production with a flexible system designed to knead, cut, fill, roll, and ...

Industrial muffin production line

Maximize your bakery’s efficiency with a high-performance line engineered for preci...

Semi-automatic pastry production line

Elevate your pastry production with a solution that seamlessly combines cutting, fill...

Professional dosing system for creams and sauces

Streamline your production with precise dosing of creams and sauces, tail...

Intermittent pick and place solution for stackable items

Optimize your production line with high-speed, intermittent oper...

Dough divider for high-efficiency bakery production

Achieve precise dough division and high-speed production efficiency w...

Dough divider for high water absorption and fermented dough

Achieve uniform dough consistency and precise shaping with a...

Convection oven for bakery production

Optimize your baking with precise temperature and humidity control, ensuring perfect ...

Steam pipe oven for industrial bakeries

Achieve consistent baking results with efficient heat distribution and steam genera...

Electrical deck oven for bakery applications

For bakery operations seeking precise control, our deck ovens deliver optimal...

Electrical deck oven for high-efficiency industrial baking

Achieve precise temperature control and energy efficiency in ...

Advanced convection oven for bakery applications

Enhance your bakery’s production efficiency and product quality with a ve...

Industrial chocolate and dough sheeter

Streamline your chocolate and pastry production with robust dough sheeting and rolli...

Industrial long moulder for bakery production

Enhance your bakery’s efficiency with a high-speed long moulder ideal ...

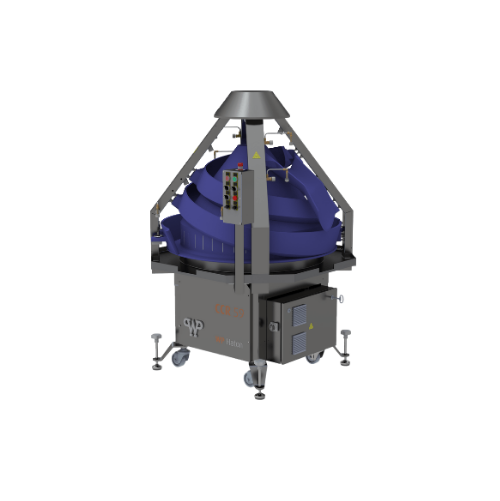

Conical dough rounder for bakeries

Achieve consistent dough rounding with precision and efficiency, enhancing your bakery’s...

Dough proofing solution for stress-free fermented dough

Ensure stress-free dough handling and optimal fermentation before...

Dough aligning system for bakery production

Enhance your bakery’s precision and efficiency with a system that ensure...

Fixed bowl spiral mixer for dough preparation

Ideal for perfecting dough consistency, this spiral mixer offers two-speed o...

Rotary rack oven for bakeries

Efficiently handle diverse baking needs with precise temperature and steam control, ensuring c...

Combinex for baking high-quality breads and pastries

Optimize your bakery or confectionery production with precise temper...

Industrial bakery oven with proofing cabinet

Optimize your bakery production with an all-in-one solution that seamlessly i...

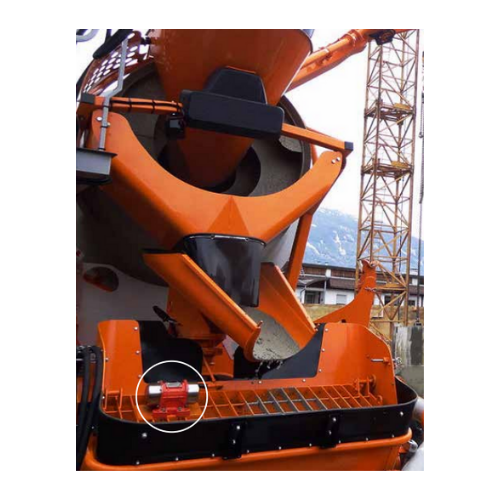

Flake ice weighing and batching system for dough processing

Optimize your dough’s freshness and consistency with p...

X-ray inspection system for large bulk products

Ensure consumer safety and product quality by efficiently detecting contam...

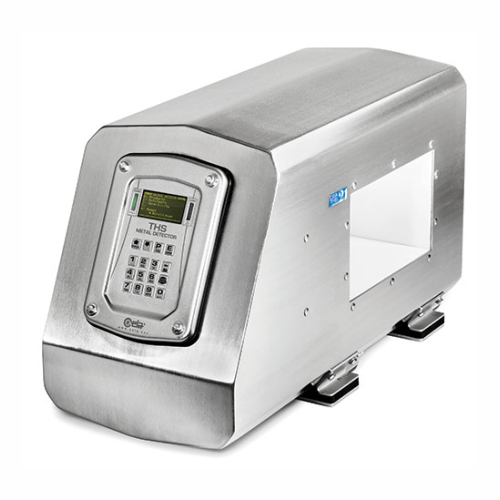

Metal detector for conveyorized applications

Enhance your production line by ensuring product safety with advanced metal d...

Industrial metal detector for food production lines

Ensure product safety and compliance by seamlessly detecting metal co...

Cryogenic tunnel freezer for optimized food freezing

Enhance your production line with advanced cryogenic freezing techno...

Cryogenic chilling systems for bulk food processing

Maintain optimal temperatures during high-volume food processing with...

Cryogenic food freezer

Achieve rapid and precise freezing for diverse food products, ensuring optimal texture and moisture re...

Cryogenic chilling systems for food processing

Efficiently maintain precise temperatures to enhance product quality and sa...

Cryogenic chilling for meat mixing and blending

Ensure precise temperature control during mixing and blending to prevent b...

Vibrating sorting table for pre-dewatering

Efficiently streamline your production with a versatile vibrating sorting table...

Industrial freezing tunnel for food products

Achieve rapid and precise freezing of diverse food products while maintaining...

Stiffening system for meat products

Achieve uniform cooling and extend the shelf life of various food products with precisi...

Flow wrapping with pick and place robots

Streamline your confectionery and bakery packaging with precision flow wrapping, u...

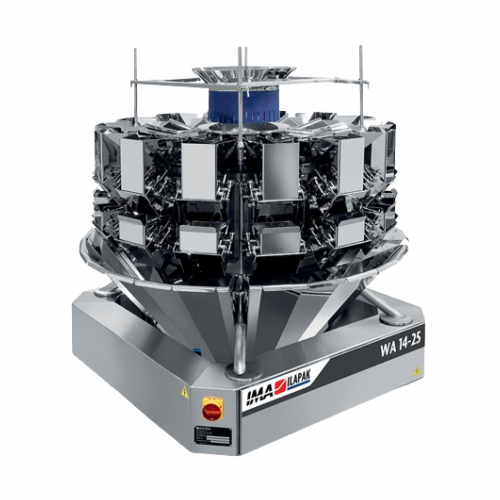

High precision multihead weigher for confectionery production

Achieve precise weighing and counting for varied product c...

High-speed multi-head weigher for confectionery products

Achieve precise measurements and minimize waste in high-speed fo...

Tray sealer for food packaging buckets

Enhance your packaging efficiency with a highly adaptable tray sealer, designed for ...

Industrial metal detector for gravity feed applications

Ensure the purity of your products by detecting and removing both...

Conveyor belt metal detection system for food processing

Enhance product safety and ensure compliance with the most strin...

Checkweigher for packaged goods inspection

Ensure precision and compliance with this high-speed checkweigher, perfect for ...

Advanced metal detection for food processing

Maximize your production line’s safety and efficiency with a cutting-ed...

Multi-spectrum metal detector for food industry

Achieve unmatched detection accuracy in your food processing line with thi...

X-ray inspection system for identifying foreign bodies in food products

Ensure precise detection of foreign materials i...

X-ray inspection system for detecting foreign objects in food products

Ensure product safety and quality by detecting e...

Continuous french fry fryer

Achieve optimal frying conditions with precise temperature control and rapid load adjustments, e...

Impingement oven for meat and baked products

Achieve faster cooking and greater uniformity with advanced airflow technolog...

Dough portioning system for bakery operations

Achieve precise dough portioning with minimal waste using our advanced syste...

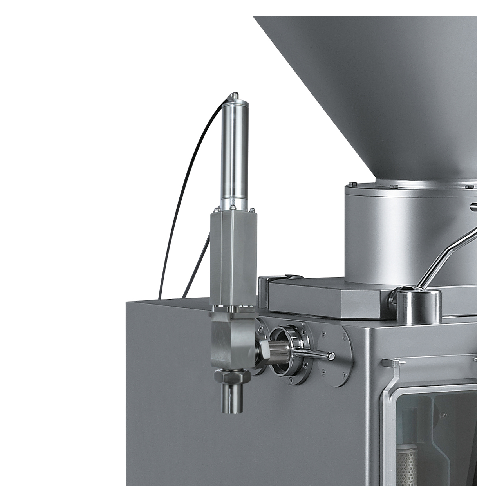

Compact vacuum filler for small to industrial scale food processors

Achieve precise portioning and high-speed productio...

Vacuum filler for medium-scale sausage production

Achieve precise portion control and optimal hygiene with a versatile fi...

Automatic tray washer for gummy production cleanup

Eliminate gummy residue efficiently with high-pressure tray washing, e...

Automatic packaging system for preformed bags

Enhance your bakery’s efficiency with advanced preformed bag packaging...

Horizontal partial cut slicer for bakery products

Achieve precision in your bakery with a horizontal partial cut slicer, ...

Industrial reciprocating blade slicer for high-speed slicing

Enhance your bakery production line with high-speed slicing...

Advanced dough mixing solution with removable bowl

Efficiently blending and kneading diverse doughs, this mixer enhances ...

Planetary mixer with double tool for pastry dough

Optimize your pastry production with precise mixing capabilities that e...

Double jacketed mixer for dough cooling

Achieve consistent dough quality and superior gluten development with precise tempe...

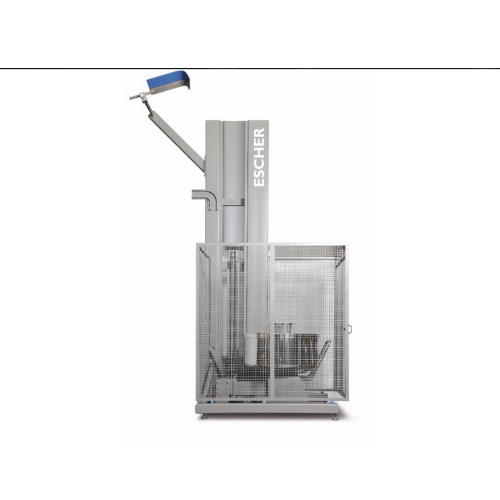

Industrial bowl lifter-tipper

Streamline your bakery production with a solution that simplifies dough handling by seamlessly...

Feeding hoppers for dough production lines

Optimize your dough production with precision feeding and portioning, ensuring ...

Spiral mixers with bottom discharge system

Ensure consistent dough quality while optimizing space and efficiency with a mi...

Industrial spiral mixer with bottom discharge system

Enhance dough quality and streamline operations with a dual-tool mix...

Spiral mixer with removable bowl for bakery production

Achieve consistent dough quality with advanced bowl locking and mo...

Large capacity cryogenic spiral freezer

Ensure consistent freezing quality and high yield in your continuous production lin...

Premium industrial mixer for dough production

Enhance dough production efficiency with a mixer that reduces kneading times...

Elevator tipper for flexible dough handling

Achieve maximum flexibility in your production line with a versatile lifting s...

Compact spiral mixer for small-scale dough production

For kitchens and bakeries needing precise control, this compact spi...

Horizontal flow pack packaging solution

Achieve seamless packaging with versatile flow pack machines, designed to efficient...

Flow pack packaging solution for flexible wrapping material

Optimize your packaging line with this compact flow pack sol...

Horizontal flow pack packaging system for flexible materials

Enhance your packaging line efficiency with a system design...

Flow pack packaging system for flexible wrapping material

Achieve seamless, high-speed packaging of solid foods with thr...

Flow pack packaging for flexible wrapping material

Achieve precise and secure packaging with three-sided sealed packages ...

Horizontal packaging system for high-speed operations

Achieve unmatched sealing precision and packaging speed with this h...

Compact biscuit depositor for small bakeries

For artisanal producers seeking precision and versatility, this compact equip...

Flow pack packaging for irregularly shaped products

Achieve precise packaging for irregularly shaped and delicate items w...

Horizontal flow-pack solution for flexible wrapping material

Simplify your packaging process with a high-speed, three-si...

Three-side sealing flow pack machine

Optimize packaging efficiency with a high-speed flow pack machine that ensures precise...

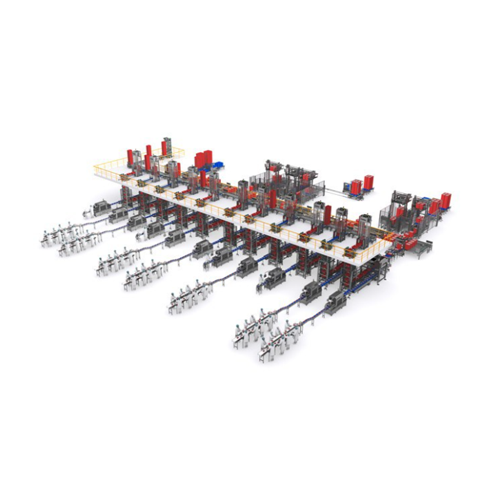

Automated modified atmosphere packaging solution for pre-wrapped trays

Streamline your packaging process with high-spee...

Product counting system for confectionery and food products

Achieve 100% counting accuracy and seamless integration in y...

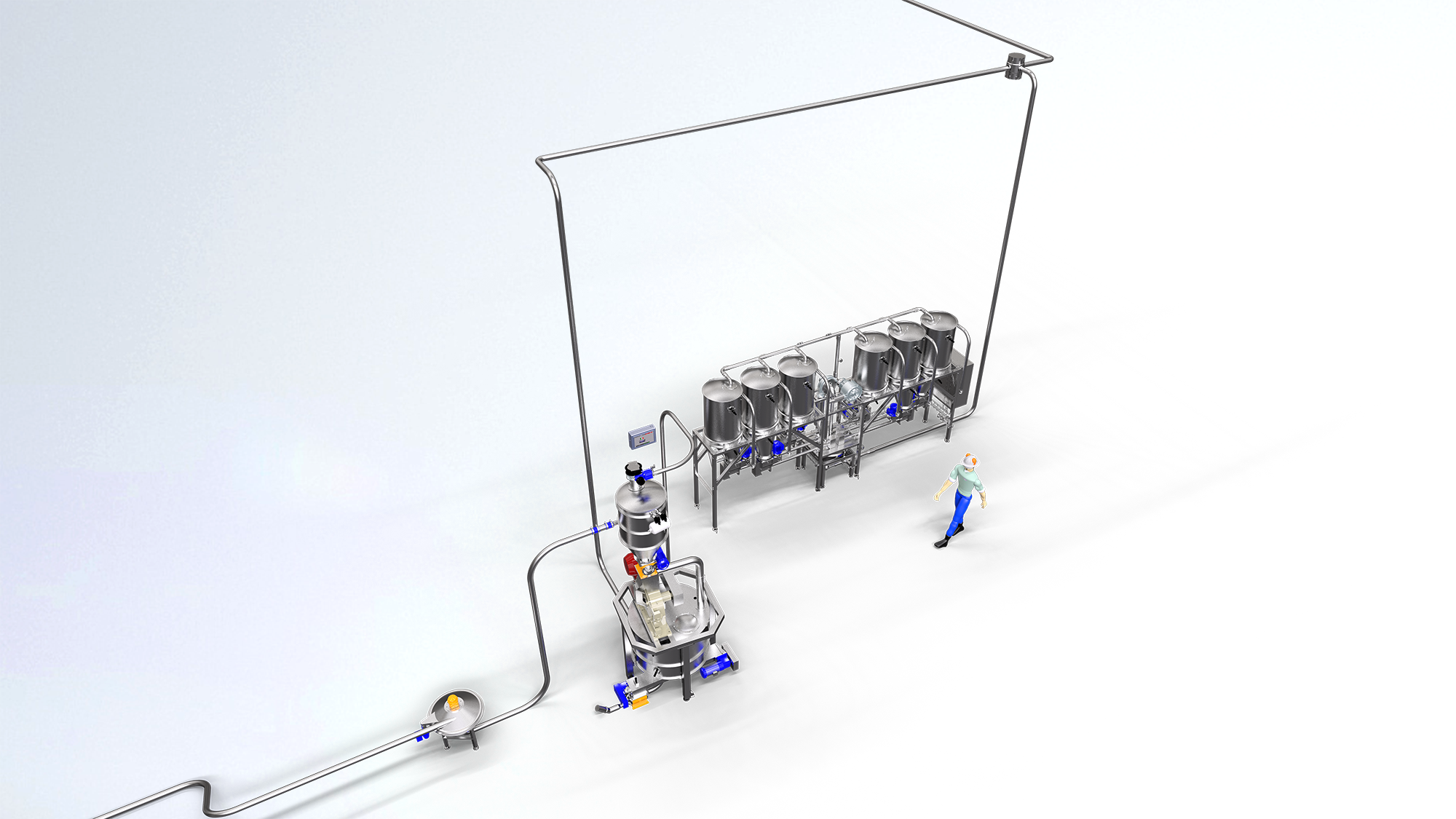

Cleaning-in-place system for oils and fats

Streamline your production line by efficiently cleaning oils and fats processin...

Process tanks for oils and fats

Optimize your oil and fat processing with versatile tanks designed for precise emulsificatio...

Continuous remelt systems for oils and fats

Optimize your production line with continuous remelt systems designed to effic...

Wafer block spiral cooler

Enhance your confectionery production with a modular spiral cooler that ensures gentle handling an...

Grain scourer for wheat, durum, and rye

Enhance grain processing by efficiently removing impurities like dust, sand, and so...

Premixer for confectionery masses

Achieve consistent ingredient blending with precision-premixing for candy and baked goods...

Vibration sprinkler for uniform dough decoration

Elevate your baked goods with precise, uniform decoration using a vibrati...

Hydration solutions for baked goods

Achieve consistent dough quality faster with a system that precisely hydrates and mixes...

Hybrid tunnel oven for biscuits and cakes

Enhance production efficiency and product consistency with a versatile oven syst...

High-efficiency cooling tunnel for confectionery production

Optimize your product cooling process with high-efficiency t...

High-speed mixer for dough production

Achieve consistent dough quality and streamline your production process with this ver...

Oilseed flaking and milling system

Optimize your oilseed processing with a flaking system that enhances extraction efficien...

Discharge station for bags and big bags

Ensure consistent material flow and hygiene in your production line with a versatil...

Dough ripening conveyor for stick and fried noodles

Ensure optimal dough maturity and consistency with this conveyor, des...

Continuous dough extruder for baked goods

Achieve optimal dough consistency and reduce production time by integrating cont...

Digital process service for regulating water in dough preparation

Achieve consistent dough moisture levels with this di...

Weighing and receiving container for floury products

Achieve precise and consistent ingredient proportions with this syst...

Fully automatic batch scale for powdery and granular products

Achieve precise and repeatable dosing for powdery and gran...

Extensograph for assessing dough rheology

Optimize dough quality with precise rheological analysis, ensuring your baking p...

Gluten quality testing solution

Ensure optimal flour quality by rapidly assessing gluten properties, allowing you to refine ...

Measuring mixer for flour farinograph tests

Achieve precise dough consistency with ease—this mixer ensures reliable testin...

Vision guided robotics case packer

Maximize efficiency with vision-guided robotics for versatile case and tray loading, red...

Glaze spraying system for bakery products

Achieve perfect glaze and finish on your bakery products with precision spraying...

Release agent sprayer for baking trays and moulds

Achieve perfect results in baking by ensuring efficient and uniform gre...

Inline ultrasonic slicer for bakeries

Achieve consistent precision in high-speed food portioning with this cutting-edge sli...

Ultrasonic slicer for precise food cutting

Achieve perfectly portioned bakery and food products with precision ultrasonic ...

Depositing solutions for liquid and semi-liquid foods

Ensure consistent portioning and minimize waste with advanced depos...

Ultrasonic cutter for pastry and bakery products

Achieve precise, high-quality cuts for your bakery and confectionery prod...

Ultrasonic cutting line for bakery products

Experience precise slicing and cutting efficiency with our high-capacity ultra...

Industrial glaze sprayer for high-volume bakery production

Enhance product appeal and extend shelf life with precise gla...

3-roll extruder for heavy dough products

Streamline dough processing for consistent, high-quality confections and baked goo...

Full production line with depositing and ultrasonic cutting

Streamline your baked goods and dessert production with this...

Dough lines for industrial bakery production

Optimize your bakery’s dough production with versatile solutions for pr...

Industrial dough mixer for high capacity food production

Enhance dough consistency and texture with a high-speed industri...

English muffin production system

Maximize your bakery’s output with our high-speed system designed to efficiently produce co...

Soft bread production system

Optimize your bakery operations by integrating a high-speed system for producing a wide variety...

High-speed bun and roll production system

Optimize your bakery’s output with this high-speed system designed to stre...

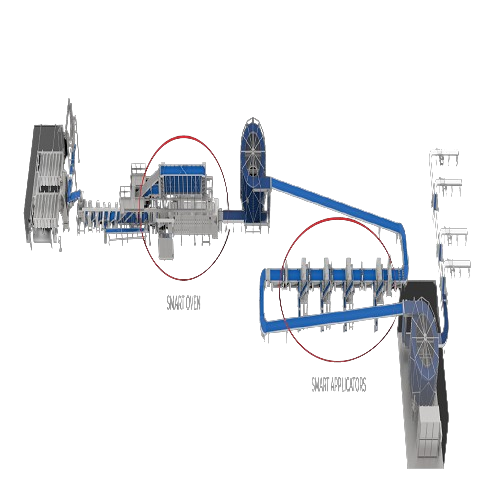

Energy-efficient oven monitoring system for bakeries

Optimize your baking operations with a smart oven system that enhanc...

Artisan bread production line for high-volume bakeries

Optimize your artisan bakery operations with a production line tha...

High-speed baguette production system

Achieve seamless, high-speed production of artisan baguettes with minimal downtime an...

Muffin and cake production line

Enhance your bakery production with a line that meticulously controls every stage, from mixi...

Pie production line for sweet and savory pies

Optimize your pie production efficiency with this integrated system, designe...

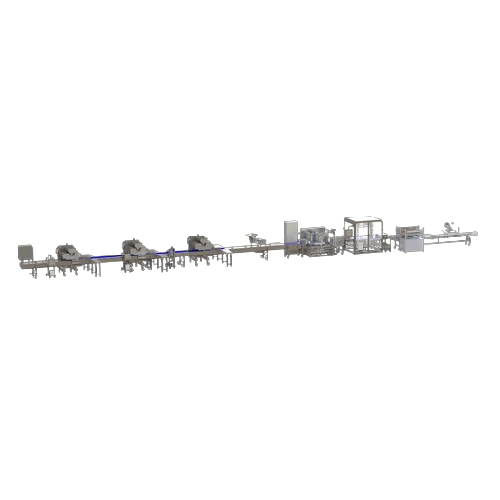

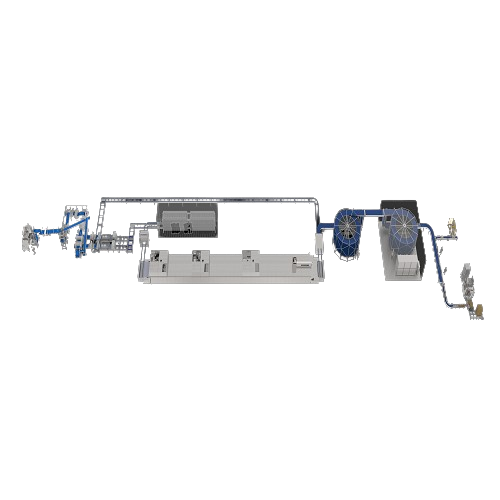

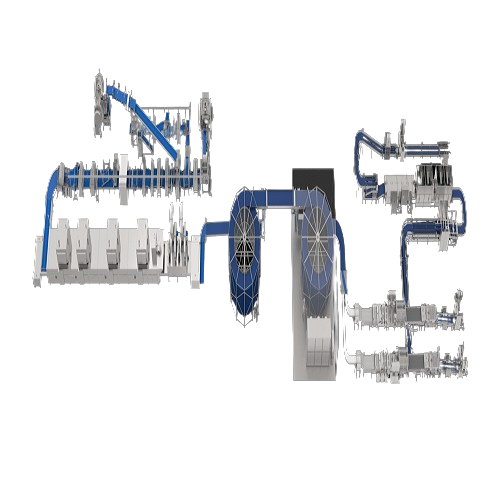

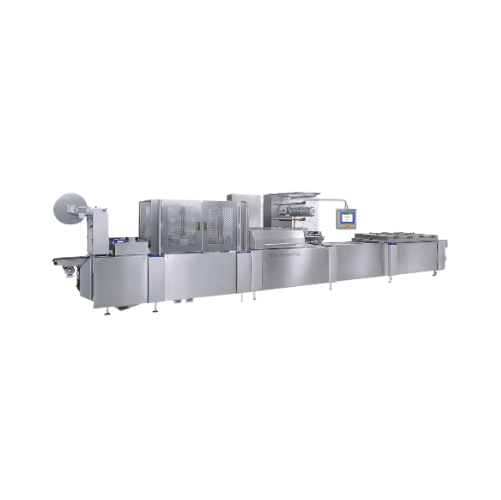

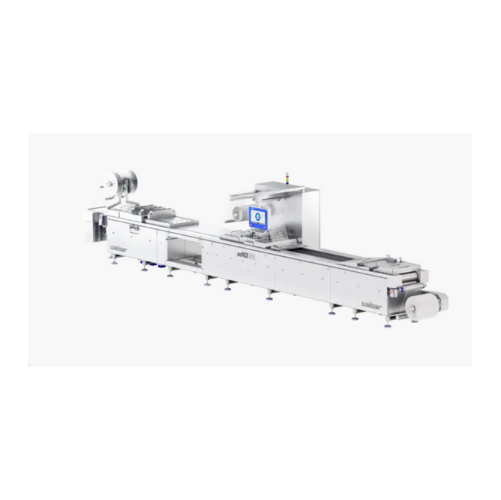

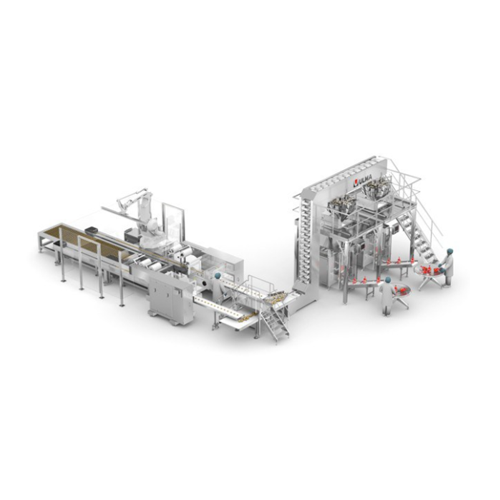

Advanced croissant production line

Streamline your bakery operations with a high-speed croissant production line, integrati...

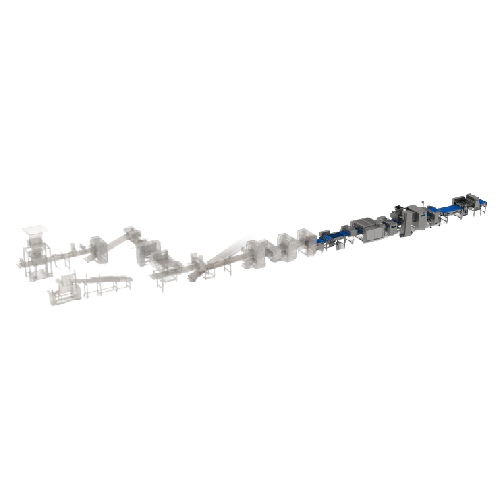

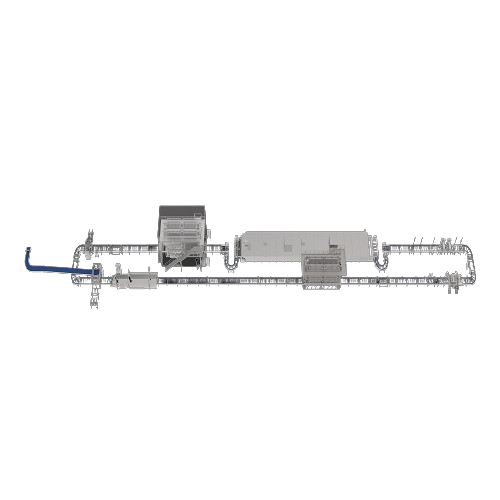

Danish and puff pastry production line

Enhance your pastry production with this integrated solution, designed to optimize t...

Automated sheeting and laminating solution for filled snack bread production

Enhance your bakery line’s efficien...

Continuous proofer and oven systems for commercial bakeries

Enhance product consistency and throughput in your bakery op...

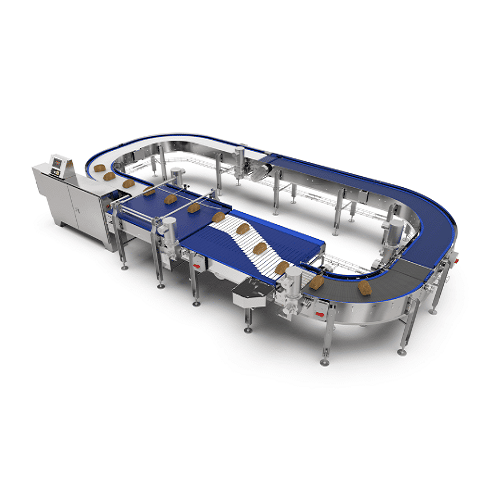

Bakery product conveying solution

Optimize your bakery’s production line by seamlessly transferring diverse products ...

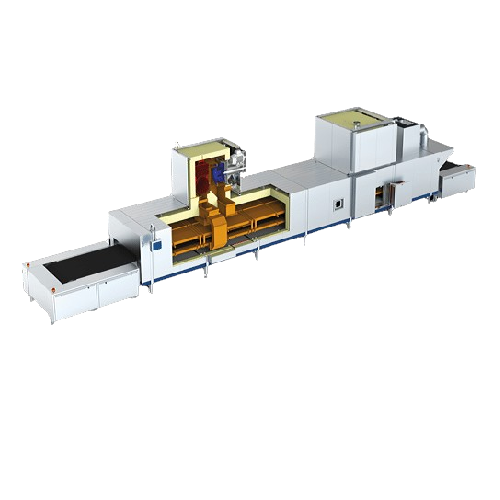

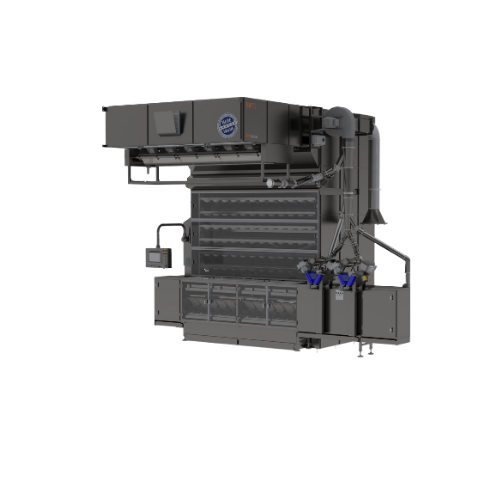

Industrial tunnel oven for baking and step proofing

Optimize your production line with modular tunnel ovens and step proo...

Precision dough dividing equipment for bread production

Achieve unmatched precision and speed in your bakery operations w...

Open frame mixer for industrial dough mixing

Streamline your bakery’s mixing process with precision control and enha...

Industrial sheeting and laminating systems for baked goods

Elevate your bakery’s production line with cutting-edge...

Spiral cooler for industrial baking

Enhance your bakery’s efficiency and product quality with modular cooling solutio...

Ai solutions for pizza production in bakeries

Bring unparalleled precision and efficiency to your bakery with intelligent ...

Industrial dough mixing system for bakeries

Enhance your bakery’s efficiency with a system that ensures precise doug...

Servo bakery tray depositor

Enhance production efficiency with precise dough placement, reducing manual labor and ensuring c...

Convection oven for uniform baking

Achieve precise, energy-efficient baking with this convection oven, offering fast heatin...

Dough feeder for flexible and gentle dough handling

Ensure precise, gentle handling and optimal integration with your pro...

Bi-directional frame scale for industrial weighing

Achieve precise product accumulation and streamlined batch processing ...

Industrial weight tracking system for injected products

Optimize your production line by accurately tracking product weig...

Twin lane separator for automated tray sealing

Optimize your production line with this conveyor system designed to effortl...

Carton sandwich wedge erecting and sealing solution

Streamline your sandwich packaging operations with precise carton wed...

Semi-automatic tray sealing for ready meals

Achieve versatile packaging with a semi-automatic tray sealing solution design...

Semi-automatic tray sealer for ready meals

Achieve optimal freshness with consistent sealing, maximizing shelf life for va...

Automatic tray sealer for high-speed food packaging

Optimize your production line with a high-capacity tray sealing solut...

High-speed tray sealer for food packaging

Streamline your packaging process with high-speed tray sealing, reducing labor c...

Hand operated tray sealer for small-scale food production

Optimize your packaging process with this compact tray sealing...

Bench mounted tray sealer with gas flush

Optimize your production line with a compact tray-sealing machine designed for pre...

High throughput tray conveyor system

Looking to streamline your tray sealing process? This modular conveyor system integrat...

High-speed tray sealer for food

Enhance your packaging line’s efficiency with a high-speed, in-line tray sealer design...

Industrial high speed tray sealer

Enhance your production line efficiency with precision sealing capabilities, accommodatin...

Automatic tray sealer

Maximize throughput and shelf life with our high-speed inline tray sealing solution, ideal for diverse ...

High-capacity tray sealer for vacuum gas packaging

Enhance your production efficiency with a versatile twin-lane tray sea...

Large-capacity automatic tray sealer

Optimize your production line with this tray sealer, designed for high-speed sealing a...

R&d vessels for research and development centers

Optimize your R&D operations with versatile vessels designed to hand...

Industrial melt tanks for butter and chocolate

Reduce manual labor and elevate safety in your production line with a melt ...

Clean-in-place system for diverse processing needs

Ensure the precision and consistency of your cleaning cycles with a ro...

Continuous contact cooker for bottom crust treatment

Enhance dough product integrity with precise bottom heating, ensurin...

Spiral freezer for frozen food production

Optimize your product’s shelf life and quality with advanced freezing tech...

Industrial spiral freezer for high-volume food processing

Optimize your production line with a modular spiral freezer th...

Industrial spiral freezer for high-volume processing

Optimize your high-volume food production with a robust spiral freez...

Impingement freezer for thin product freezing

Optimize your freezing process with advanced airflow, ensuring quick and uni...

Vertical packaging system for fragile food products

Handle delicate food items like pasta nests and bakery products with ...

Customized spiral freezer solution for food industry

Designed to enhance your freezing efficiency, our spiral solution ha...

Frozen food products control system

Ensure optimal freezing precision with a system that continuously monitors product crys...

Oxygen and leakage detection in Map packaging

Ensure enhanced food safety and reduce waste with precise oxygen and leak de...

Thermoforming packaging for meat and dairy products

Streamline your packaging process with advanced thermoforming technol...

Thermoforming packaging system for meat products

Enhance your packaging capabilities with a modular thermoforming system d...

Robotic pick and place system for bakery products

Enhance your bakery production line with advanced robotic systems that ...

Product manipulation and stacking systems

Efficiently transition products from flat to stacked on a conveyor while minimiz...

Laned product distribution for high-capacity wrappers

Efficiently distribute high-capacity product flow across multiple w...

Conveyor system for ambient product cooling

Ensure precise cooling of baked and confectionery products while maintaining l...

Shear stream mixer for dough and batter preparation

Efficiently mix and homogenize dry ingredients with liquids, preservi...

Sheet cleaning system for baking sheets

Effortlessly maintain baking sheet hygiene with precise cleaning and oiling, all in...

Industrial baking sheet cleaning system

Enhance hygiene and streamline operations with a system designed to clean, dry, and...

Robotic tray handling for baking production lines

Enhance production efficiency by seamlessly integrating advanced roboti...

Automated dough loading system for bakeries

Streamline your bakery operations with an automated system that efficiently lo...

Robotic gripper arm for bakery tray and product handling

Optimize your bakery’s efficiency by automating repetitive...

Custom deep frying system for unique product requirements

For bakeries tackling specialized frying needs, this customiza...

Industrial lye coating line for bakery products

Streamline your bakery operations with high-speed lye coating technology t...

Industrial lye dosing system with peelboard

Ensure consistent, high-quality lye coating for baked goods with a rapid, modu...

Automatic lye dosing system for pretzel production

Enhance your bakery’s efficiency with a lye dosing system that e...

Automated pretzel lye application system

Enhance your bakery’s output with high-efficiency lye application, achieving...

Lye application system for bakeries

Effortlessly achieve uniform lye coating and consistent salting with a compact solution...

Infrared oven for fast thawing and glazing

Streamline your donut production by seamlessly integrating rapid thawing and gl...

Lye application system for pretzel production

Achieve precise lye application for pretzel pastries with high-speed capabil...

High-efficiency pretzel lye application system

Achieve precise and uniform lye application for pretzel pastries with enhan...

High performance spiral mixer for dough preparation

Achieve consistent dough quality with ease by integrating a high-perf...

Automatic dough mixing system for high-quality doughs

Transform your dough production with a system designed for rapid, c...

Linear mixing system for high-capacity dough production

Achieve perfect dough consistency with precise mixing, rapid cycl...

Industrial spiral mixer for dough production

Achieve precise control in dough consistency and quality with this spiral mix...

Industrial bowl tipper for dough handling

Streamline your dough processing with a reliable solution that ensures safe, uni...

Dough divider for various dough types

Achieve precise portioning in your dough production with a solution designed to handl...

Three-pocket dough divider for high-output bakery production

Achieve precise dough division effortlessly with this robus...

Weight accurate dough divider for various dough types

Achieve high-speed, precise dough portioning with adjustable pressu...

Dough divider for varied dough types

Achieve precise and consistent dough portioning with a single pocket divider designed ...

Conical dough rounder for multiple dough types

Achieve consistent rounding for a variety of dough types with our equipment...

High-precision checkweigher for dough processing

Ensure consistent dough quality and reduce waste with precise weight corr...

Industrial dough divider for high-capacity production

Optimize your bakery’s throughput with a versatile dough divi...

Industrial dough proofer for high-capacity baking lines

Optimize your baking process with high-speed proofing, ensuring d...

Intermediate dough proofer for soft and pre-fermented dough

Optimize your proofing process with a solution that gently h...

Dough divider and round moulder for artisan bakeries

Experience seamless dough management with equipment designed for pre...

Industrial vacuum cooling system for bakeries

Achieve rapid cooling of oven-hot baked goods with minimal moisture loss, en...

Vacuum cooler for artisan baked goods

Rapidly cool artisanal baked goods with precision to maintain their freshness and vol...

Bakery refrigeration systems for controlled dough tempering

Achieve consistent bakery quality by precisely controlling y...

Dough divider and moulder for artisan bakeries

Achieve precise and gentle dough handling, ensuring exceptional product qua...

Manual loading system for deck ovens

Streamline your bakery’s workflow by simplifying the manual loading and unloading proc...

Automatic underlay system for food products

Efficiently placing paper or film underlays beneath food slices optimizes port...

Thermoforming packaging solution for medium production volumes

Optimize your medium-volume packing with a compact thermo...

Atex-certified flanged polygonal dust collectors

Ensure dust control and compliance in explosive environments with our com...

Food-grade round dust collectors

Maintain a clean production environment with this food-grade dust collector, designed to ma...

Fit-frame butterfly valves for dry bulk solids

Achieve precise control and minimize contamination in your dry bulk materia...

Food-grade tubular screw conveyors

Ensure complete hygiene in your production line with these stainless steel tubular screw...

Food-grade stainless steel tubular screw conveyors

Ensure contamination-free material handling with our tubular screw con...

Industrial vibrator for high-frequency vibration

Achieve efficient material flow and compaction across various production ...

Rotary turbine vibrators for bulk solids discharging

Enhance the efficiency of material handling with high-speed, low-noi...

Continuous impact vibrator for aggregate reclaiming

Tackle material flow challenges head-on by preventing common issues l...

External electric motovibrators for industrial material flow

Experience enhanced material flow and precise material disc...

Micro-batch feeders for powder and granular material

Struggling with clog-prone powders? Gain precise control and consist...

Hopper venting filter for efficient dust filtration

Achieve superior dust control and efficient material handling with a ...

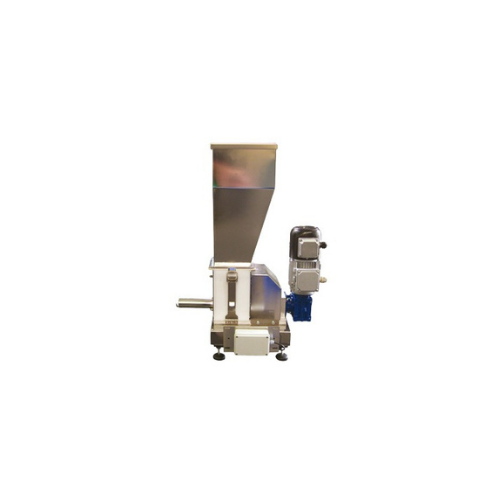

Loss-in-weight screw feeder for precise powder dosing

Achieve high precision in continuous dosing with this advanced scre...

High capacity vertical conveying for flour

For consistent, high-speed handling of delicate and powdery materials, this eng...

Food-grade bin activator for hygienic bulk solids discharge

Achieve consistent material flow and avoid contamination wit...

Rotary bin discharger for bulk solids

Efficiently manage bulk solids with a rotary bin discharger that minimizes residue an...

Vibratory outlet hopper for bulk solids discharge

Reduce material handling challenges with highly efficient vibration tec...

Fork mixers for bakery industry

Achieve consistent, high-quality dough mixing with fork mixers designed to enhance tradition...

Planetary mixers for baking and food industries

Achieve precise mixing and consistency across a range of products with adv...

Sourdough fermenter for artisanal bakeries

Streamline sourdough production with a solution that automates key processes li...

Fixed bowl vertical mixer for bakery and pastry

Optimize dough quality and consistency with a versatile vertical mixer tha...

Spiral mixers for bakery dough

Transform your bakery production with precise and consistent dough mixing, ensuring every bat...

Continuous motion liquid packaging system

Achieve precise and clean liquid packaging with advanced servo-driven squeegee s...

Endload automatic cartoning solution

Streamline your packaging line with this versatile cartoning solution, perfect for eff...

Topload cartoner for packaging cartons

Efficient flap closing for diverse carton sizes, ensuring gentle handling of sensiti...

Product inspection systems for contamination control

Ensure product safety and compliance with precision inspection techn...

Automated infeed and outfeed systems for packaging lines

Streamline your production line by integrating reliable infeed a...

Support structures for packaging lines

Enhance safety and efficiency in your production line with robust support structures...

Modified atmosphere packaging solutions for perishables

Extend the freshness and shelf life of perishable goods with prec...

Industrial spiral cooling and freezing system

Optimize your bakery operations with adaptable cooling and freezing systems ...

Bread and dough decorating equipment

Enhance the visual appeal and quality of your baked goods with specialized equipment d...

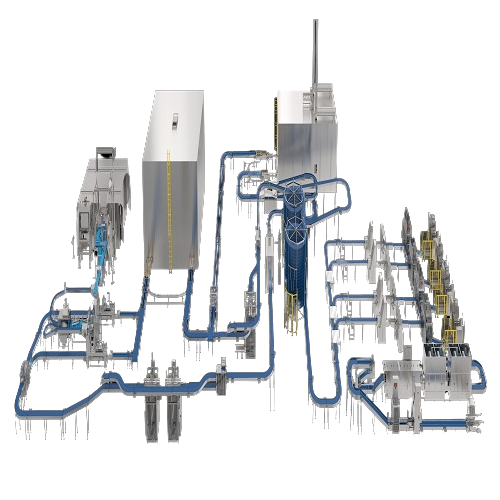

Industrial dough proofing systems

Optimize your bakery’s efficiency with customizable proofing systems designed to fi...

Conveyor belts for hot and cold product handling

Efficiently transport hot and cold goods with versatile conveyor solution...

Vacuum filling machines for cooked ham & sausages

Achieve precise portioning and enhanced product quality with this advan...

Multi piston depositors for bakery production

For bakeries seeking precision in depositing and filling, these multi piston...

Food transfer and dosing pumps for bakeries

Enhance efficiency in food processing with pumps designed for precise transfer...

Bakery and food grade conveyors

Enhance your bakery and food production with conveyors designed to seamlessly transport and ...

Thermoforming solution for flexible or rigid packaging

Optimize your packaging efficiency with a high-performance thermof...

Hygienic thermoformer for flexible film packaging

Streamline your packaging process with a hygienic thermoformer, offerin...

Automatic tray sealer for preformed trays

Enhance packaging efficiency with a high-speed tray sealer designed for precisio...

Automatic tray sealer for cut & seal and Map applications

Optimize tray packaging efficiency with a versatile solution f...

High-speed Map packaging for fresh food products

Ensure product freshness and safety with robust, high-speed packaging tha...

Flow pack wrapper for shrink and film wrapping

Optimize your packaging operations with a versatile solution capable of hig...

Horizontal flow wrapper for packaging trays and punnets

Optimize your packaging process with an adaptable flow wrapper, p...

Automatic hamburger packaging solution

Streamline your hamburger production with a fully automated packaging system that en...

Complete packaging solution for meat products

Achieve seamless packaging integration with a solution designed to streamlin...

Automated bagging system for confectionery products

Achieve seamless integration in your confectionery packaging line wit...

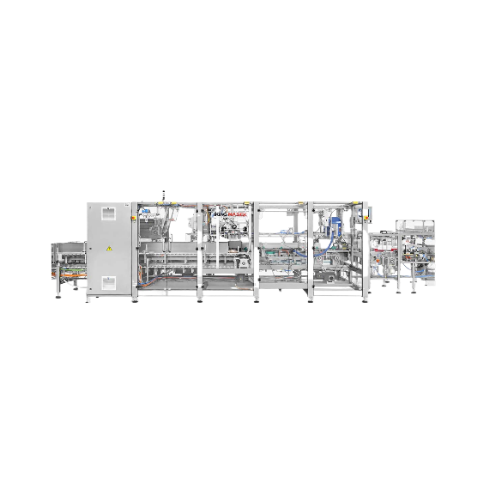

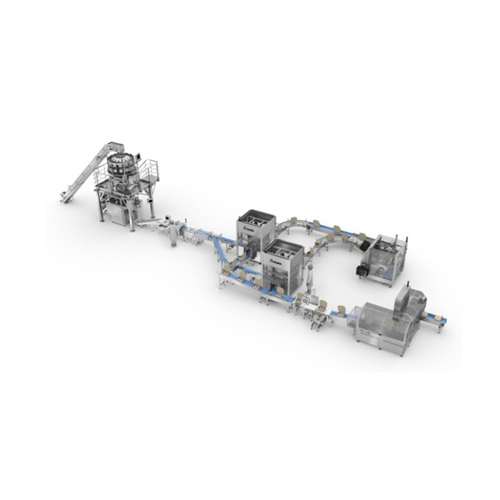

Complete solution for packaging of bakery products

Streamline your bakery’s packaging process with a fully automate...

Sweet baked goods packaging solution

Optimize your sweet baked goods packaging process with a fully automated solution desi...

Automated line for baked goods packaging

Enhance your packaging efficiency with a seamless integration of precise loading a...

Commercial bakery equipment for improved baking efficiency

Streamline your baking processes with commercial bakery equip...

Automated cleaning in place system for bakery production lines

Ensure unmatched hygiene and operational efficiency in fo...

Cleaning in place solution for food production systems

Optimize your cleaning process with an integrated clean-in-place s...

Buffer tank for consistent product temperature control

Ensure consistent product temperatures and streamline your product...

Dough mixer for pastry food processing

Achieve perfect dough consistency efficiently with this dough mixer, designed for se...

Industrial egg breaking and separating solution

Streamline your egg processing with precision egg breaking and liquid sepa...

Horizontal flow wrapper for food packaging

Simplify your packaging process with our high-speed horizontal flow wrapper tha...

Vffs packaging solution for diverse bag styles and high hygiene standards

Enhance your packaging operations with high-...

Industrial conical dough rounder

Streamline your dough production with a high-capacity rounder designed to optimize dough sh...

High-capacity dough cup elevator for industrial bakeries

Enhance your bakery’s efficiency with a dough cup elevator...

Intermediate proofing cabinet for dough resting

Optimize your dough resting with a versatile proofer that adapts to variab...

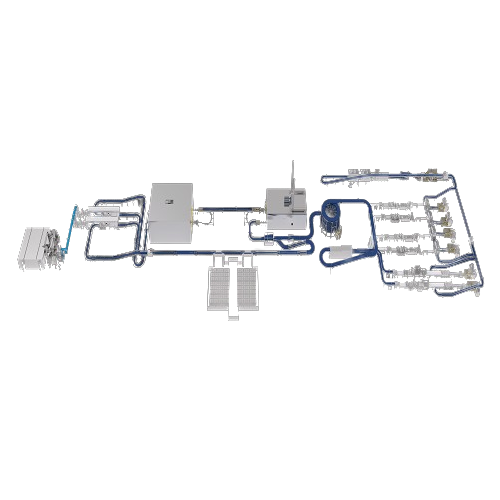

Flexible continuous dough processing line for bakeries

For bakeries aiming to streamline operations, this highly adaptabl...

Automated dough divider for high accuracy dough handling

Ensure precision in dough portioning with this solution, designe...

Conical dough rounder for perfectly round dough balls

Achieve impeccable dough rounding with precision-engineered technol...

Portable texture analysis for low force applications

Easily perform precision texture measurements on low-force applicati...

Texture analyser for food and cosmetics testing

Ensuring consistent product quality across diverse food and cosmetic appli...

Self-priming centrifugal pump for entrained air handling

Effortlessly manage entrained air and foam in fluid processing w...

Ultrasonic food cutting equipment

Experience precise and efficient ultrasonic cutting of various food products, optimizing ...

Flowpacker for packaging products

Achieve seamless packaging with high-speed, automated flowpacking that enhances product p...

Dosing system for bakery and convenience food

Achieve precise dosing and filling of liquids and slurries with this versati...

Refrigeration jacket for triple roller bar mixers

Enhance dough mixing performance by efficiently managing temperature co...

Continuous pan cleaner for bakery pans

Efficiently clean and prepare baking pans with precision by leveraging continuous, h...

Conveyor belt metal detection system

Ensure seamless product safety with a system that detects and separates metallic conta...

Efficient jam and marmalade production line

Optimize your fruit and bakery product lines with equipment designed for high-...

Pick & place vision system for packaging quality control

Ensure flawless product packaging with a vision system that enha...

Flowpacker for packaging products in flowpacks

Optimize your flowpack packaging line with a preconfigured solution that ac...

Automated pick and place cobot for packaging

Overcome packaging bottlenecks with an advanced cobot designed for high-speed...

Flow wrapper with quick format change

Streamline your packaging operations with a machine that offers rapid format changeov...

Industrial vacuum filler for large-scale food production

Enhance your production efficiency by integrating a vacuum fille...

Vertical dosing valve for accurate food portioning

Ensure precision in portioning liquid and semi-liquid food products wi...

Metal detection system for twisted sausages production

Ensure the safety of your twisted sausage production line by detec...

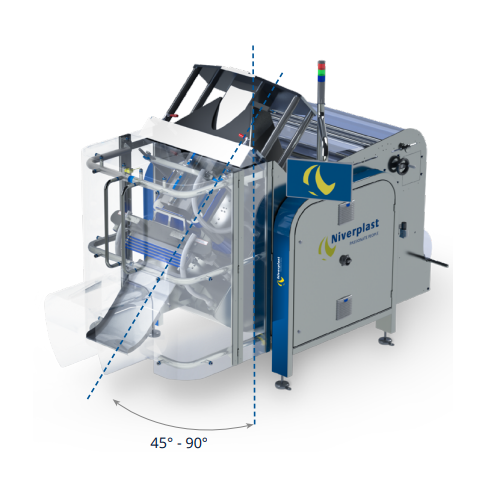

Moulding machine for croissant

Croissants are a popular line in commercial bakeries and are sold in high volumes. An automat...

Moulding machine for rolled bread

As great snacks and accompaniments to meals rolled bread is a staple product in commercia...

High capacity freezer for food

Freezing is one of the most important industrial methods for the long-term preservation of fo...

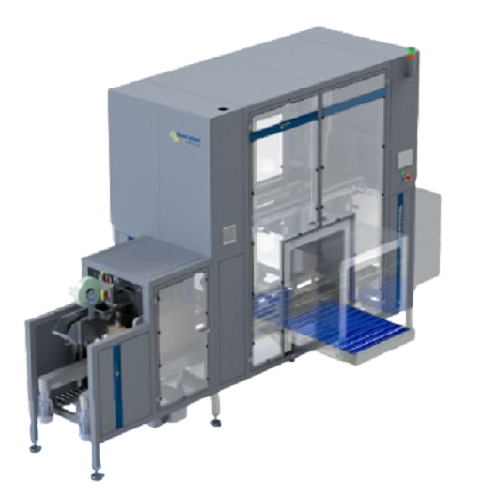

Industrial washer for plastic crates

In the food production sector, hygiene regulations are getting stringent by the day. E...

Cream filling machine for bakery industry

Cream and other fillings in bakery products must be injected in the right volume...

Sponge cake cooling tunnel

Exposed baked goods can develop bacteria from the circulating air in an area if left in the open ...

Cake batter and cream depositing machine

Whether you’re making muffins or cupcakes, you need just the right amount of...

Planetary mixer for confectionery and bakery production

For the best quality confectionary and bakery products, controlla...

Temperature-treatment mixer for bakery & gastronomy

The production of creams, sauces, ragouts, ready-to-bake, and sim...

Centrifugal mixer for batters and creams

Batters, creams and other delicate sauces and emulsions take time to mix, reducing...

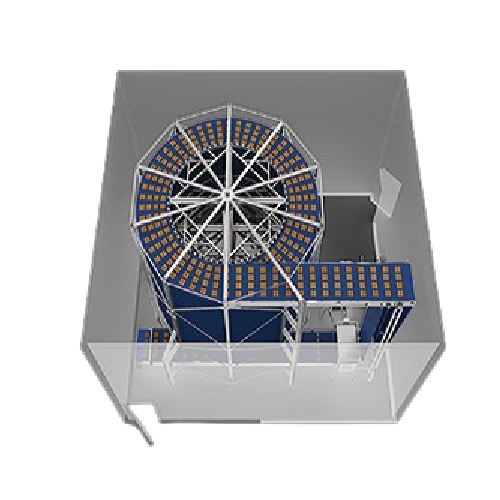

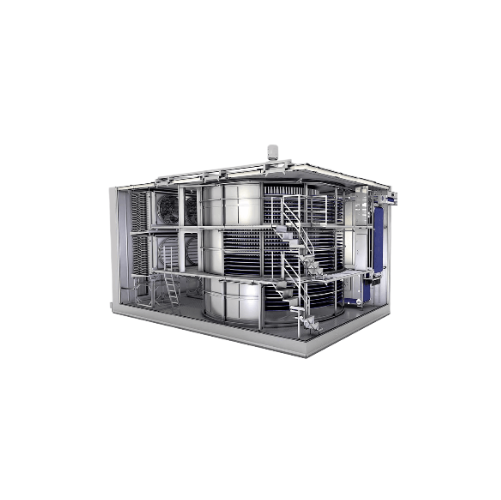

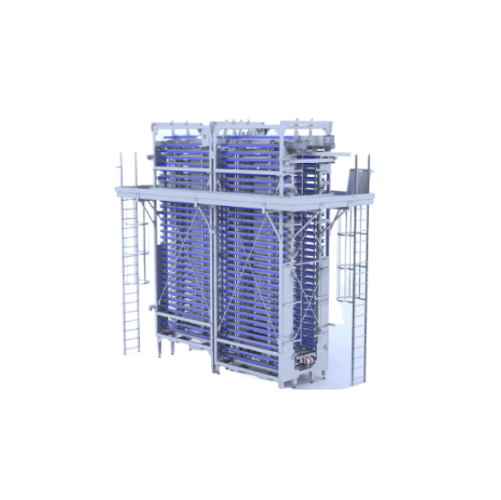

High capacity spiral proofer for pastry

Proofing is a phase in the baking production line that can’t be rushed. It’s an ess...

Hygienic and fully-welded spiral freezer for food

Food freezers are often the last step in the food production chain. The...

High capacity spiral cooler for food

Cooling baked goods and food products can be problematic for sliced baked goods. A cru...

Washing cabinet for trolleys

Food manufacturing facilities, bakeries, or restaurants are ridden with efficiency-related issu...

Washing cabinet for food bulk containers

With an ever-increasing demand for output and stricter hygiene regulations for foo...

Industrial crate washing machine

In order to meet the increasing demand of the beverage industry, it’s essential to find a c...

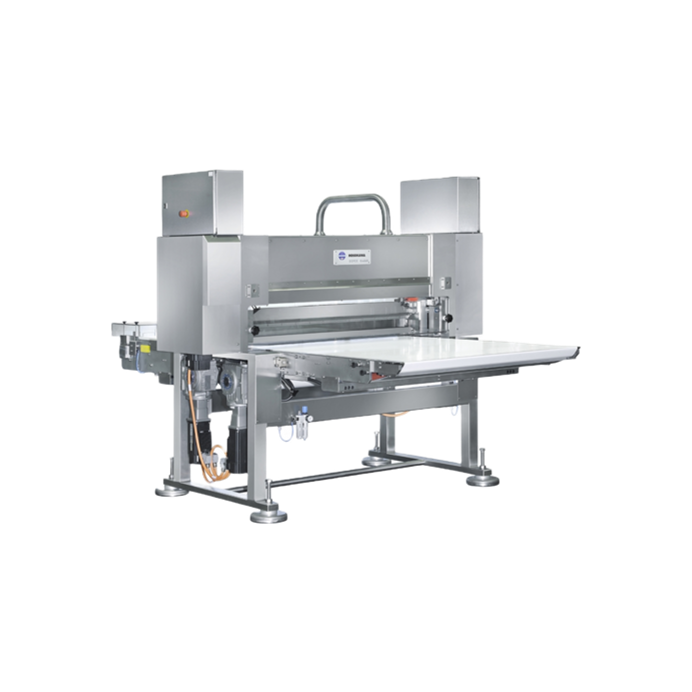

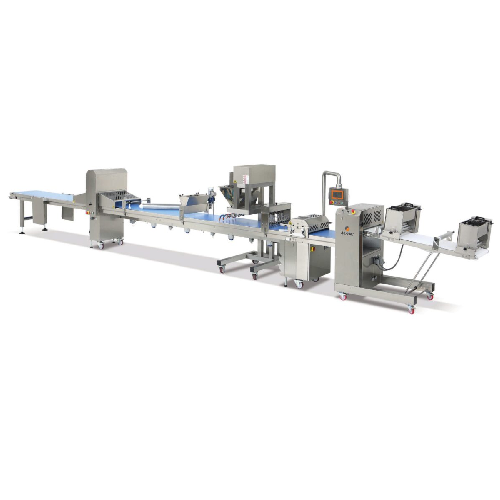

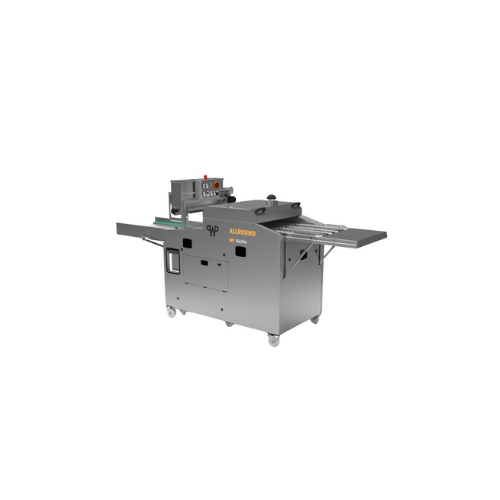

Automatic pastry dough sheeter

Industrial dough sheeters turn raw dough into sheets that match recipe thickness. This includ...

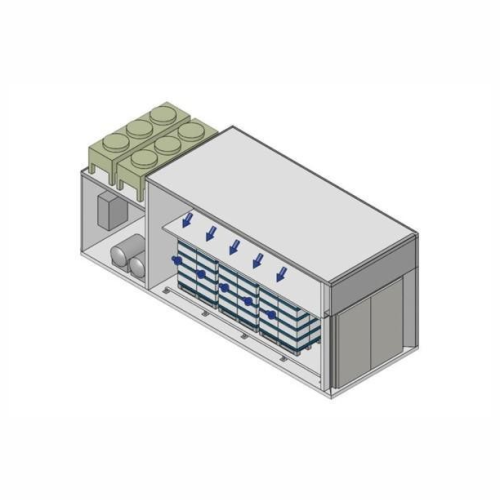

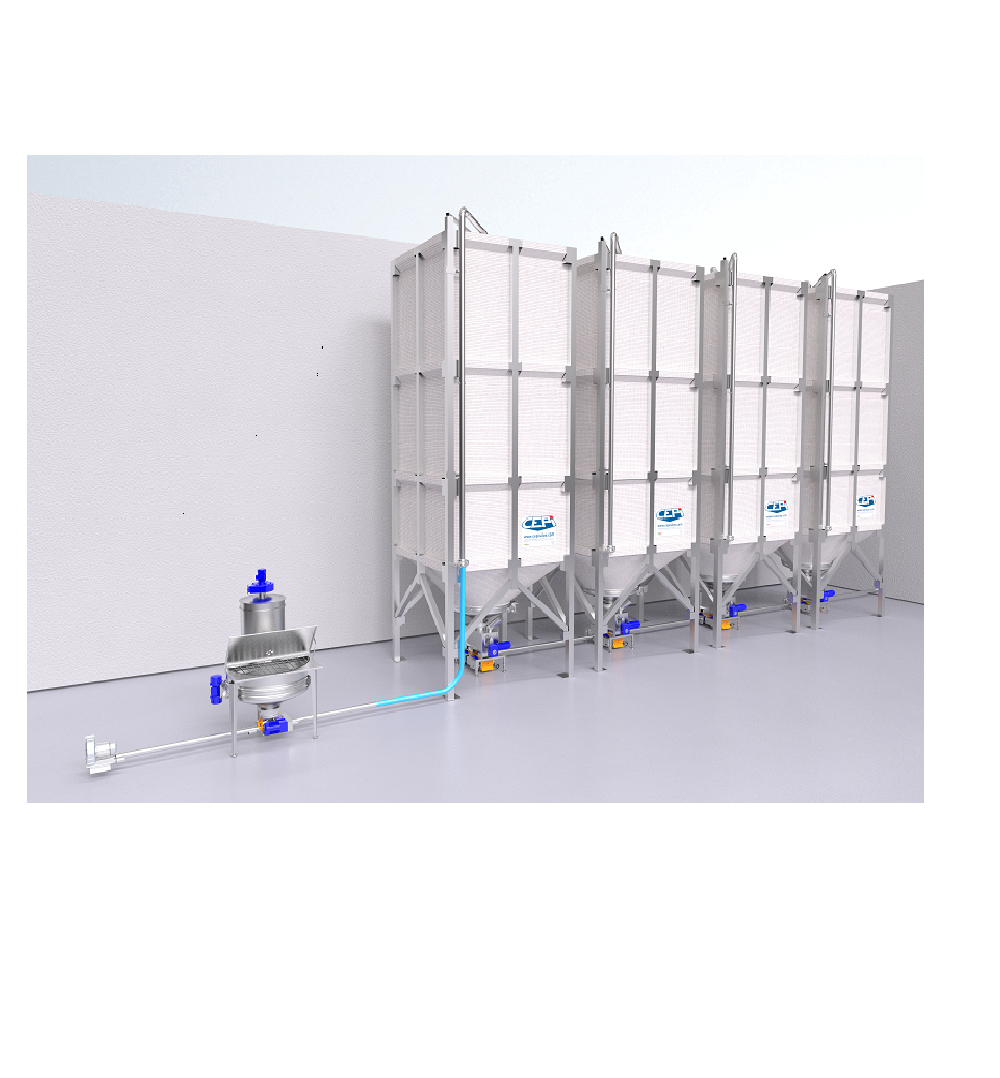

ATEX confirmed outdoor silo for flour

Bulk outdoor storage of flour, dry milk and other powder ingredients for the bakery i...

Manual bag discharger for bakery industry

Many minor and intermediate ingredients for bakery products are delivered in bag...

Microdosing system for bakery industry

Storage and dosing of powdered minor ingredients such as flavourings, colours and si...

ATEX Indoor silo for sugar and flour

Storing granulated or powdered materials such as sugar and flour prior to processing r...