Tomato Sauce Making Equipment

Find innovative production technology for making tomato sauce and connect directly with world-leading specialists

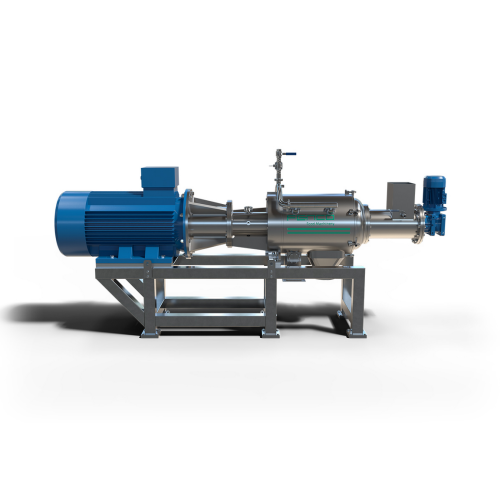

Tomato sauce is a popular ingredient for adding a sweet, slightly acidic touch of flavor to food and recipes. Sauce production involves cooking the tomatoes, removing the seeds and stems with a strainer, using a grinder or milling machine, and then further cooking to the desired consistency. Tomato sauce making equipment is used in industrial production to speed up the various preparation steps while maintaining the quality of the sauce.

Tell us about your production challenge

Steps for success and tomato sauce making equipment

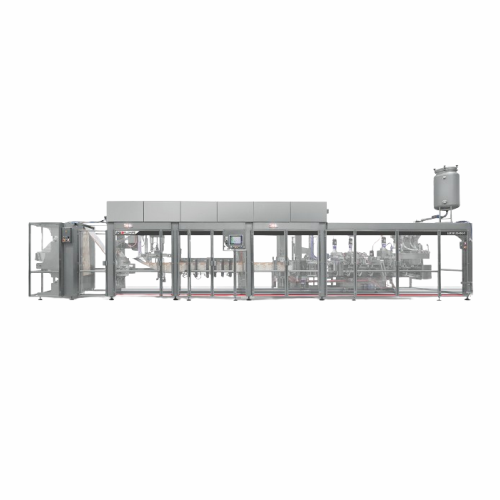

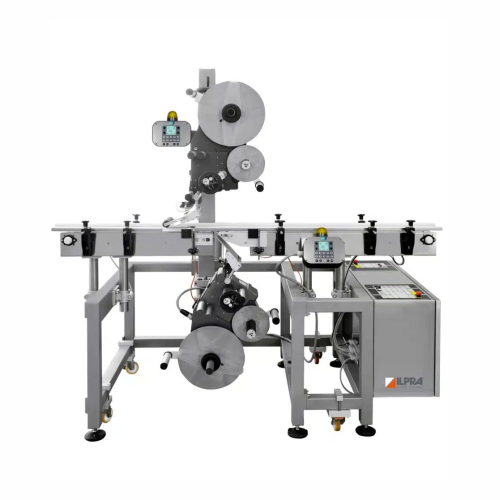

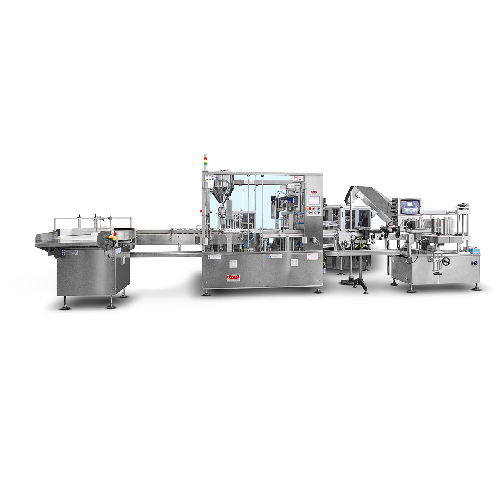

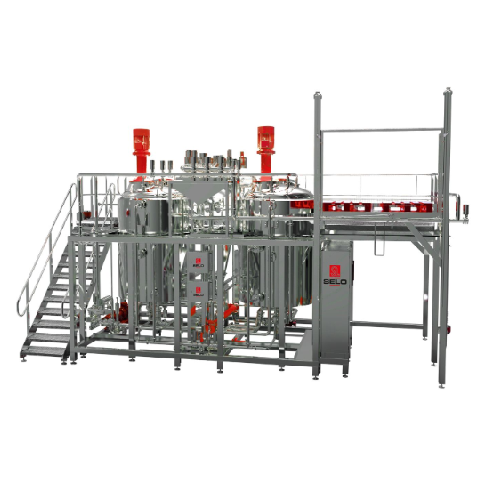

Tomato sauce production is a fairly straightforward process involving the preparation and mixing of ingredients. Sauce makers soften the skin and seeds for ease of removal, after which pressing machines extract the juice and tomato solids used in making sauce. Additional ingredients such as herbs and oil are typically added to a mixer with the pressed tomatoes to improve taste and create a sauce ready to cook with. Finally, the latest tomato sauce making equipment is for labeling and bottling, which provides a rapid and efficient system for preparing your finished tomato sauce for distribution.

Considerations of content, how do conditions and constituents affect your sauce?

Ingredients and other factors readily influence tomato sauces. Storing tomatoes in cool dark places can permanently eliminate the flavor. Sugar, salt, and oil are added to further develop the flavors of tomato sauce. Sugar levels in tomato sauce are quantified by their Brix number as 1 gram of sugar to 100g of solution. The acceptable Brix range for fresh tomatoes is between 3.5 and 5.5, but tomato sauce requires a Brix number of at least 4.5. This can differ depending on the tomato varieties used.

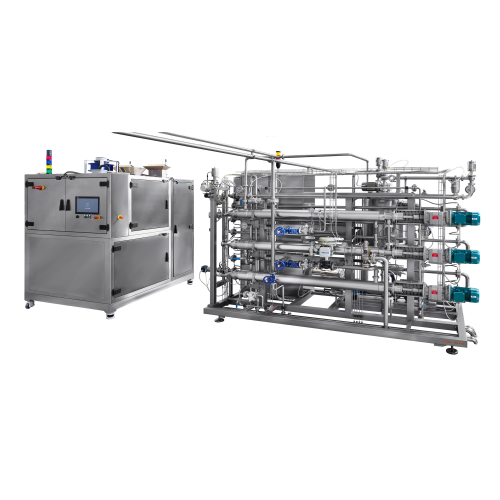

Refractometry is the method used to measure this quality. Fruit pectin influences the thickness of the sauce, while protein content helps to stabilize the taste qualities of the final sauce. The temperature treatment of tomatoes inactivates pectin methylesterase, which is one of the most important enzymes affecting the quality of such products. Without this treatment, the enzymatic reactions will continue unchecked even after bottling or canning.

Temperature breaks a tomato sauce makes

Temperature plays an important role in the processing of tomatoes, and offers a convenient way to manipulate their properties. In the processing of tomatoes, there exist a “hot break,” “warm break,” and “cold break” method for preferential preservation of attributes. The hot break is performed at 100 °C preserving only the pectin for a thick and highly viscous paste. The warm break heats to about 79 °C, and while flavour is preserved, colour is not. Finally, the cold break method at 66 °C preserves both colour and flavor. This method is best for producing tomato sauce, which may then also be reconstituted into tomato juice or pulp.

Paste and purée and sauce, oh my!

The tomato is a versatile but volatile fruit with great potential and plentiful pitfalls. Processed tomatoes are generally broken down into paste, purée, and sauce according to their viscosity. Tomato paste often requires many hours of reduction in a sauce making machine to concentrate its characteristic potency and flavor. To contrast, tomato sauce may be produced in practically minutes from raw tomatoes, requiring only the preparation and some time in a tomato press, before mixing.

Tomato purée offers something in between, with a thicker body and richer taste thanks to its higher concentration of tomato solids. Producing paste will require equipment such as stainless steel food mills and pressing machines capable of meeting the pre-processing needs, like temperature breaking and skin removal. Producing quality sauce necessitates an understanding of the many factors such as density sugar and ingredients influencing the final taste.

Processing steps involved in tomato sauce making

Which tomato sauce technology do you need?

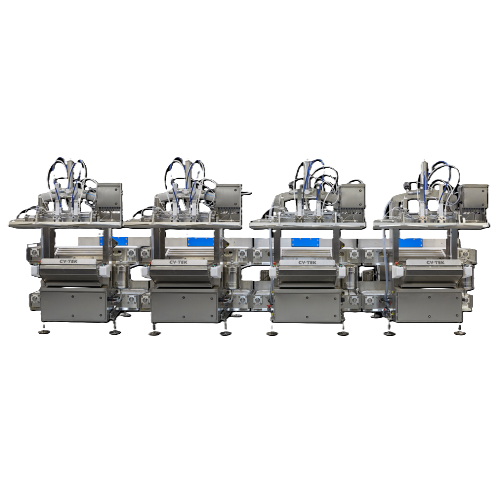

Pizza topping system for tomato sauce and ingredients

Streamline your pizza production with precise depositing of sauces ...

Vacuum de-aeration unit for liquid to pasty products

Optimize your product consistency and stability with continuous de-a...

Industrial agitation and mixing solutions

Enhance your production line efficiency with engineered agitation and mixing sys...

Batch processing systems for industrial applications

Optimize batch production with versatile systems that enhance energy...

Industrial cooling vessel for ready meal components

Enhance your production with precise cooling and gentle handling of t...

Vacuum packaging system for food products

Optimize your packaging process with high-speed vacuum technology designed to pr...

Aseptic buffer tanks for pilot scale process lines

Ensure seamless production flow and quality control in sterile environ...

Batch food processing cookers

Achieve precise temperature and pressure control for small-scale food production with modular ...

Lab Uht/htst system for r&d activities

Optimize your R&D with a versatile, modular system allowing precise control ove...

Uht/htst aseptic processor for pilot plants

Achieve precise heat treatment and aseptic processing with flexible pilot syst...

Lab-scale fermenter for simultaneous batch processing

Optimize your lab-scale fermentation process with a versatile solut...

Pilot homogenizer for high-pressure inline homogenization

Achieve precise homogenization and emulsification across vario...

Manual Cip unit for lab and pilot plant cleaning

Need thorough cleaning without disassembling your pilot plant? This compa...

Bench-top carbonation system for postmix drink production

Achieve precise carbonation in small batches with a reliable b...

Lab-scale carbonation system for beverage filling

Streamline your beverage development with precision carbonation and ver...

Sterile carbonation system for beverages

Achieve precise carbonation for both common and specialty beverages with this vers...

Professional food cutter for various ingredients

Streamline your food preparation with a versatile cutter designed to effi...

High-capacity pouch cooling system

Move pouched foods swiftly through critical temperature zones, ensuring rapid cooling fo...

Cryogenic freezer for food processing

Achieve rapid, precise freezing for your diverse food production needs, ensuring qual...

Cryogenic tunnel freezer for optimized food freezing

Enhance your production line with advanced cryogenic freezing techno...

Cryogenic tunnel freezer for continuous food processing

Optimize product quality and retention with advanced cryogenic fr...

Cryogenic food freezer

Achieve rapid and precise freezing for diverse food products, ensuring optimal texture and moisture re...

Cryogenic chilling systems for food processing

Efficiently maintain precise temperatures to enhance product quality and sa...

Cryogenic chilling for meat mixing and blending

Ensure precise temperature control during mixing and blending to prevent b...

Jars and bottles rinsing solution

Ensure impeccable hygiene and particle-free cleanliness for your jars and bottles by inte...

Jam kettle for preserve and marmalade production

Ensure consistent flavor and texture in your jams and marmalades with pre...

Pet bottle stretch blow molding with coating and filling

Extend the shelf life of your beverages and liquid products with...

High-performance distribution and combining system

Streamline your packaging operations with a versatile system designed ...

Modular labeling system for beverage containers

Easily adapt to evolving labeling needs with this flexible system, designe...

Industrial code verification system for product packaging

Ensure flawless packaging integrity with high-speed code verif...

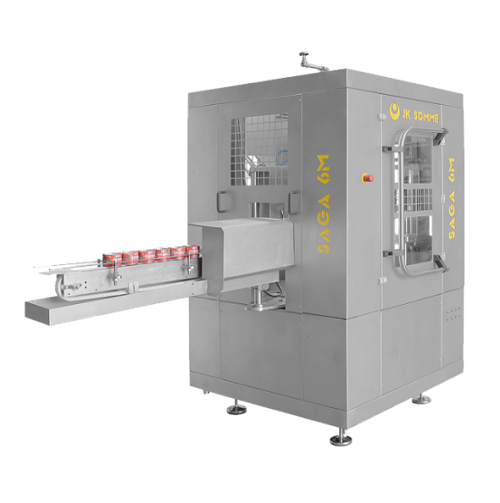

Rejection system for standing bottles and cans

Ensure seamless quality control by precisely rejecting defective bottles an...

Crossflow filter for liquid filtration in food industry

Enhance your liquid filtration process with a versatile crossflow...

Industrial vacuum cooker for sauces

Enhance your sauce and jam production with an industrial vacuum cooker that offers cutt...

Industrial cooking kettle for food processing

Achieve seamless integration of cutting, mixing, and cooking processes to cr...

Steam jacketed kettle for cooking sauces and dressings

Enhance your sauce production with a steam jacketed kettle that en...

High-speed drift-dwell motion doypack forming system

Optimize your liquid packaging efficiency with a dual-motion system ...

Automatic vertical casepacker for efficient packaging integration

Streamline your packaging process with a vertical cas...

Tray sealer for packaged food products

Optimize your food packaging with precise sealing and advanced Modified Atmosphere P...

Traysealer for medium production

Streamline your packaging process with high-speed traysealing, ensuring freshness and exten...

Compact thermoforming packaging system for food industry

Revolutionize your packaging line with a space-saving solution t...

Linear and auger weighing systems for non-free-flowing products

Optimize your production line with precise weighing and ...

Automatic c-wrap labelling for packaged products

Enhance your production line with precise C-wrap labelling, seamlessly in...

Automatic top & bottom labelling system

Enhance your packaging line efficiency by applying precise top and bottom labels to...

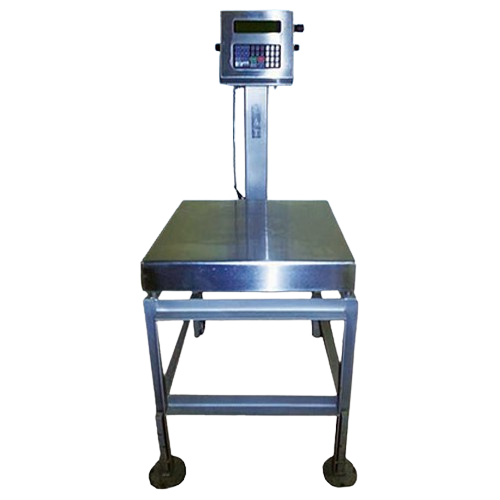

Industrial check-weigher for accurate product weight verification

Ensure precise weight compliance and reduce waste wit...

Semi-automatic tray sealer for skin packaging

Optimize your small-scale food packaging with a compact tray sealer designed...

Vacuum filler for sausage and ham production

Achieve precision in filling and portioning pasty and fluid products with a s...

Product aligning and stacking solution

Enhance process stability and resource efficiency by integrating precise product ali...

Stainless steel skids for food process integration

Optimize your production process with compact stainless steel skids th...

Stainless steel agitators for pharmaceutical and food applications

Optimize your production line with tailored agitator...

Pulper finisher for tomato and cold extraction

Enhance your production line efficiency with a pulper finisher designed to ...

Steam-heated hemispherical bottom cookers for sauce production

Streamline your sauce and condiment production with multi...

Industrial evaporators for multi-product processing

Optimize your production line with customized evaporators designed fo...

System for receiving, sorting, and destoning fruit

Enhance your fruit and tomato processing efficiency with an integrated...

Industrial dicer and peeler for fruit processing

Achieve seamless integration in your processing line with a dicing and pe...

Tomato juice pre-concentrator

Achieve higher concentration levels with less energy use by utilizing accelerated juice circul...

Enzyme inactivators for tomato processing

Efficiently inactivate enzymes to preserve nutritional value and organoleptic qu...

Forced circulation evaporators for tomato concentration

Achieve significant energy savings and enhance production efficie...

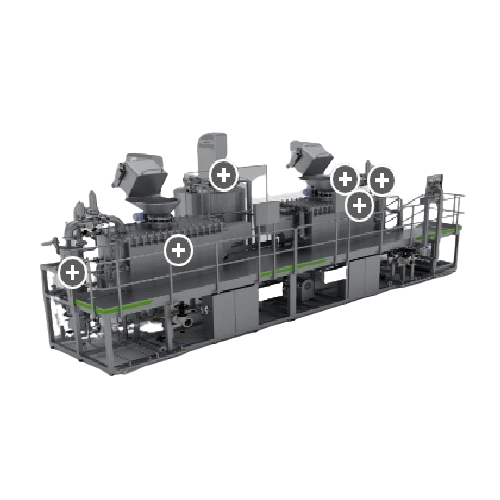

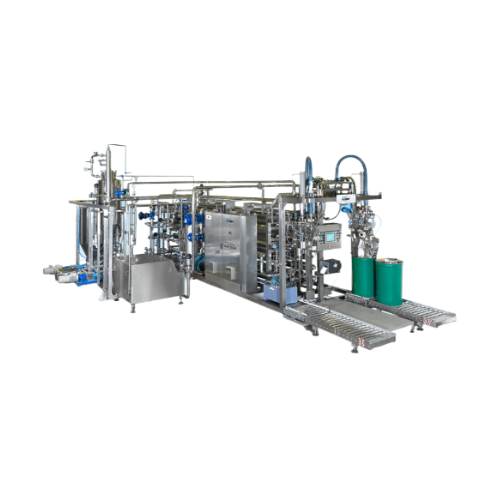

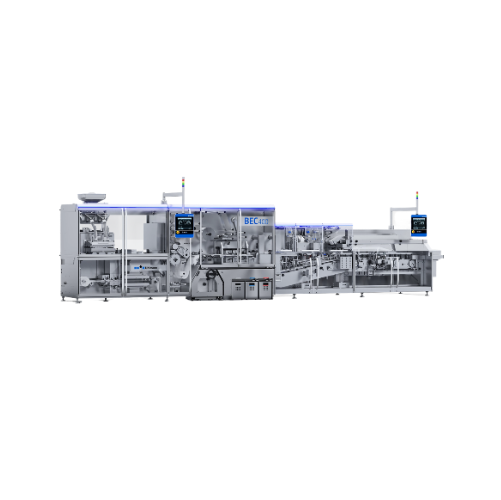

Ketchup and sauce processing line

Achieve precise mixing, cooking, and concentration for your sauces and purees, ensuring o...

Tomato juice extractor

Achieve optimal juice extraction with efficient separation and minimal waste—ideal for producers aimin...

Tomato receiving and sorting system

Ensure top-quality tomato products by efficiently handling unloading, washing, and sort...

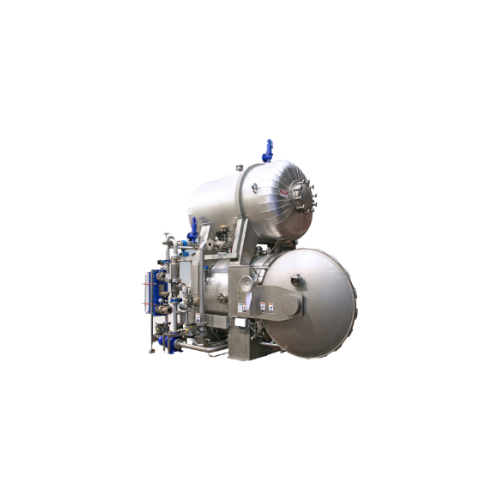

Aseptic sterilizers for tomato products

Ensure your tomato-based and fruit products remain safe and shelf-stable with advan...

Radiofrequency sterilizer for delicate food products

Streamline your food processing with radiofrequency technology, offe...

Sterilizer for liquid and viscous products

Effortlessly process and sterilize diverse liquid products, from concentrated j...

Flash cooler sterilizer for tomato paste

Maximize your production capacity and preserve flavor integrity in high-viscosity ...

Aseptic filler for liquid and particulate products

Achieve precise, sterile filling of both liquid and chunky products wi...

Aseptic bag-in-box filler for juices and purees

Enhance your filling operations with a high-speed aseptic solution designe...

High-capacity tomato dicer

Achieve high-capacity precision dicing of tomatoes and minimize juice loss with cutting technolog...

Fermenter for microbial fermentation processes

Optimize your fermentation and biopharmaceutical production with stainless ...

Cleaning and sterilization system for food factories

Ensure optimal hygiene and safety in your production line with advan...

Electronic filling system for non-carbonated beverages

Optimize your bottling process with precision filling technology t...

Industrial evaporators for diverse applications

Maximize energy efficiency and reduce operational costs with cutting-edge ...

Combination cooker-dosing kit for food packaging

Optimize your small-scale food production with seamless cooking-to-packag...

Multi-station modified atmosphere packaging system for bulk products

Optimize your packaging efficiency with a system d...

Vertical form fill seal packaging for high washdown environments

Ensure optimal packaging in demanding environments with...

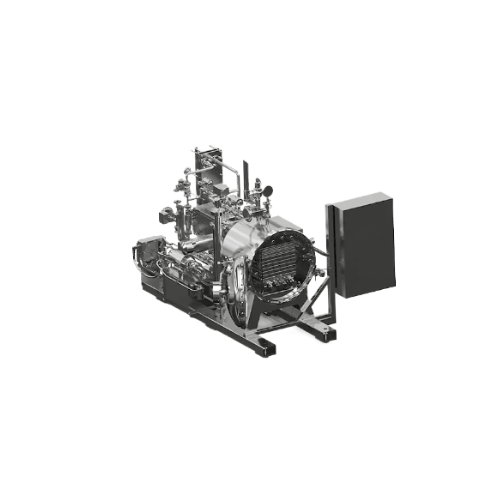

Large-scale industrial freeze dryer

Achieve precise moisture control and preserve product integrity with a large-scale free...

Industrial food mixer for high-volume processing

Achieve consistent mixing and precise blending of diverse food ingredient...

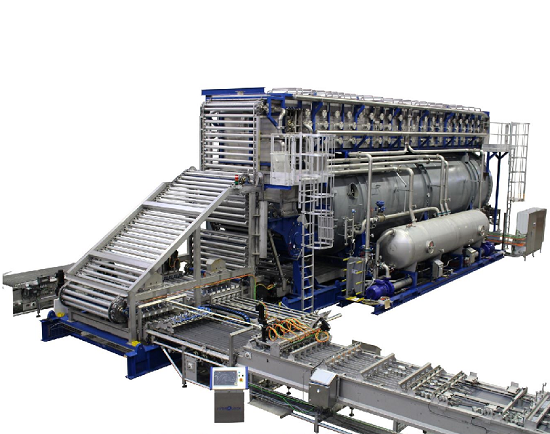

Tunnel for thermal treatment of packaged foods and beverages

Optimize your thermal processing with this customizable tun...

Robotic palletizer for material handling

Experience seamless and efficient palletizing with advanced robotic solutions desi...

Robotic case packers for bags and pouches

Efficiently pack a variety of bagged and pouched products with precision handlin...

Robotic handling systems for beverage containers and bins

Streamline your container handling with precision-engineered r...

Industrial can seamers for food and beverage packaging

Streamline your canning process with precision seaming solutions d...

Sterilizers and pasteurizers for industrial food processing

Optimize thermal processing for viscous foods and beverages ...

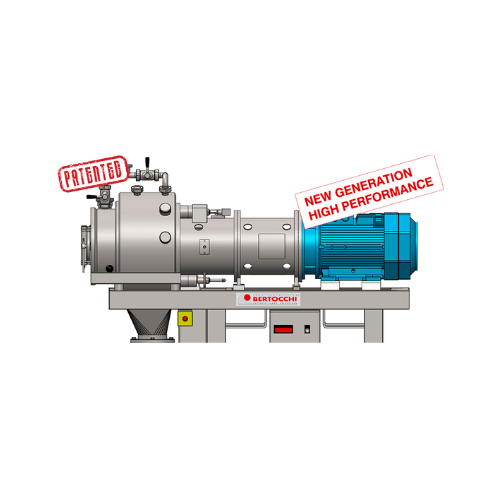

Tomato processing crushing mill

Optimize your production line with efficient chopping and refining, ensuring uniformity and ...

Energy efficient tomato evaporator

Achieve up to 98% steam savings in your evaporation process while ensuring minimal CO2 e...

Compact wet glue labeling system for low volume production

Achieve precise, high-quality labeling with compact machinery...

Semi-automatic filler for bag-in-box packaging

Streamline your liquid packaging process with a versatile filler that integ...

Manual filling system for bag-in-box packaging

Streamline your liquid filling process with a manual system designed for pr...

Semi-automatic aseptic filler for single bags

Ensure aseptic integrity and flexibility for your liquid and semi-liquid pro...

High speed continuous motion liquid filling and capping system

Achieve high-speed, precision filling and capping for liq...

Vacuum filler for glass jars and cans

Ensure precise filling and equal headspace for your products with this vacuum filler,...

Horizontal evaporation bowl for fruit jams and purees

Optimize thermal exchange and preserve product integrity during jam...

Frozen product cleaning and sizing system

Achieve precise cleaning and sizing of frozen goods effortlessly, enhancing prod...

Vacuum degasser for juices and purees

Enhance the quality of your liquid products with efficient degassing and flavor recov...

Heater for enzymatic inactivation of fruit and vegetable pulp

Optimize your puree and concentrate production with effici...

Vibrating tables for dewatering and sizing

Optimize your processing line with versatile vibrating tables designed to effic...

Continuous cooker for vegetables and fruits

Optimize your production line with a continuous cooker designed to defreeze an...

Shelling mill for Iqf and frozen fruit lumps

Effortlessly process frozen fruit and vegetable conglomerations into shelled ...

Shelling mill for Iqf and frozen lumps

Precision-engineered for the seamless transition from frozen state to process-ready ...

Pasteuriser and cooler for fruit and vegetable juices

Ensure optimal thermal treatment for your fruit and vegetable produ...

Drum blancher for continuous cooking and blanching

Optimize your production line with a continuous drum blancher, designe...

Horizontal mixer for creams

Achieve optimal and uniform mixing of creams, pasty products, and powders with advanced horizont...

Vertical mixer for creams and desserts

Achieve uniform mixing and precise temperature control for diverse creamy and liquid...

Sterile cooling system for fruit preparations

For manufacturers seeking aseptic conditions, this cooling system ensures ra...

Industrial jam processing line for fresh fruit or puree

Streamline your jam production with a versatile line capable of p...

Ketchup production line

Optimize your sauce production with advanced equipment designed to ensure consistent blending, precis...

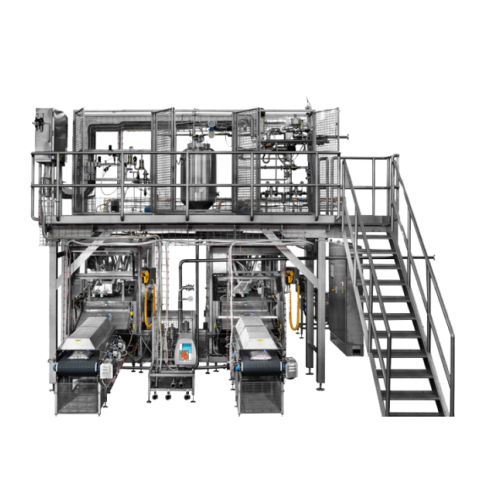

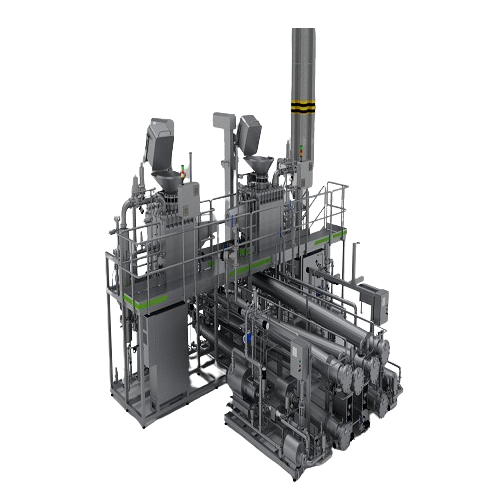

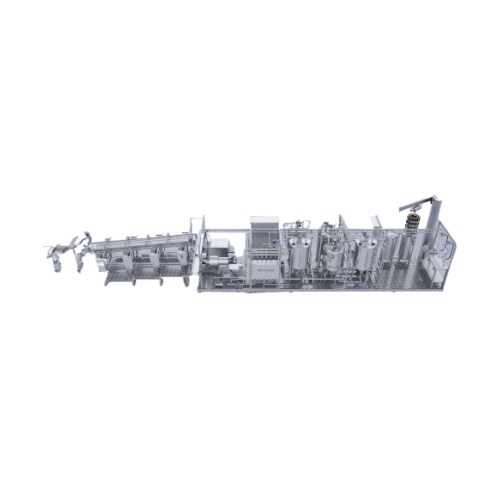

Tomato processing plant for sauce and paste

Efficiently transform raw tomatoes into a variety of high-demand products, fro...

Laboratory homogenizer for pharmaceutical and biotech applications

Achieve precise homogenization for your laboratory n...

Industrial homogenizer for food and beverage applications

For manufacturers seeking consistent quality, this homogenizer...

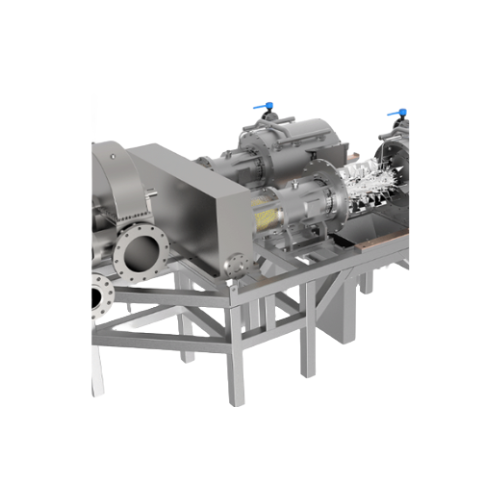

Turbo extractor for tomato and fruit puree processing

Optimize your production line with high-capacity turbo extraction f...

Turbo extractors for tomato and fruit hot extraction

Optimize your fruit and vegetable processing with high-capacity turb...

Depositing solutions for liquid and semi-liquid foods

Ensure consistent portioning and minimize waste with advanced depos...

Depositing line for cake production with paper cup denester

Optimize your cake production by seamlessly depositing marbl...

Multifunctional dessert line for layered dessert production

Effortlessly create complex, multi-layer desserts or meal co...

Industrial mixer for liquid and viscous products

Achieve precise mixing and homogenization of high-viscosity liquids and s...

Ultra-clean vertical bag filler for viscous and particle-containing products

Streamline your viscous product packaging...

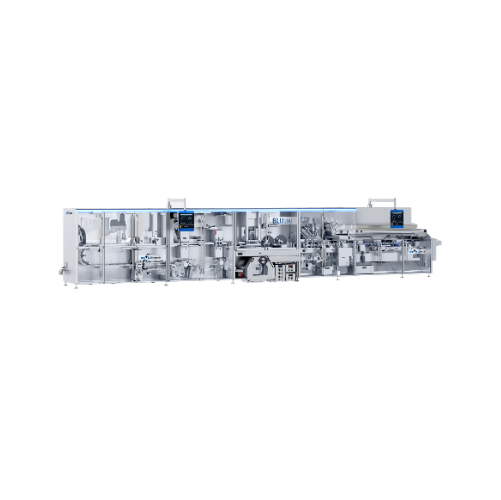

Aseptic cooking line for plant-based products

Enhance your production efficiency and product quality with an advanced doub...

Aseptic filler for bag in drum or box

Enhance product shelf life and maintain quality without preservatives by employing as...

Aseptic cooking and filling line with two reactors

Streamline your production with a versatile line that combines high-ef...

Automatic detergent shampoo filling solution

Streamline your filling process with precise volume control, achieving consis...

Automated butterfly valve actuator for hygienic processing

Streamline your flow control operations with a robust and mai...

Benchtop mixer for lab-scale product development

Easily scale up your formulations with precise and repeatable lab-scale m...

Steam shrink tunnels for versatile packaging

Enhance your packaging efficiency with this adaptable steam shrink tunnel, de...

Accurate net weight filling for liquid and semi-liquid products

Ensure precise filling of diverse viscosities, from thin...

Bottomless conveyor for 90° bottle transfer and coding

Efficiently connect disparate production systems in your bottling ...

Cooling tunnel for Pet container hot fill cooling

Ensure product integrity with a cooling tunnel that swiftly reduces PET...

Semi-automatic piston injector for bakery products

Enhance your bakery production with precise delivery of a wide range o...

Accumulation turntable for bottling lines

Optimize your production line’s efficiency with a 42-inch diameter accumul...

Beverage thermal treatment systems

Optimize beverage production by ensuring precise thermal treatment, enhancing flavor sta...

Industrial crate washing system

Optimize your production line with a solution that ensures pristine cleanliness of crates an...

Industrial weight tracking system for injected products

Optimize your production line by accurately tracking product weig...

High-speed tray sealer for food packaging

Streamline your packaging process with high-speed tray sealing, reducing labor c...

Automatic tray sealer for high-speed production

Ensure your product packaging stays fresh and secure with this high-capaci...

Bench mounted tray sealer with gas flush

Optimize your production line with a compact tray-sealing machine designed for pre...

High-speed tray sealer for food

Enhance your packaging line’s efficiency with a high-speed, in-line tray sealer design...

In-line tray sealing system

Streamline your packaging line by implementing a high-speed, in-line tray sealing system designe...

Large-capacity automatic tray sealer

Optimize your production line with this tray sealer, designed for high-speed sealing a...

Customizable storage tanks for industrial use

Optimize your production with versatile storage tanks designed for precise c...

Industrial pressure vessels

Ensure product integrity and regulatory compliance with engineered-to-order pressure vessels, de...

Ergonomic melt systems for solid food and personal care products

Eliminate manual lifting and enhance safety by integrat...

Powder induction system for efficient liquid powder mixing

Achieve precise and dust-free powder incorporation into liqui...

Tomato steam pressure peeler

Efficiently peel and process large volumes of tomatoes while maintaining product quality with a...

Multi-purpose laboratory sterilizer for food processing

Achieve precise thermal process design and flexibility with a ste...

Aseptic processing system for food products

Streamline your food processing line with an efficient aseptic processing syst...

Rotary atmospheric sterilizer for high acid canned foods

Optimize your canning process with uniform heat penetration and ...

Coil heat exchanger for dairy and beverage processing

Quickly sterilize and retain product quality with this coil heat ex...

Uht sterilizer for dairy and high-viscosity products

Optimize your production of dairy alternatives and fruit-based drink...

Efficient agitation system for retort packages

Enhance product quality and reduce processing time with this advanced agita...

Layer pad for agitating retorts in food processing

Efficiently secure and process irregularly shaped containers in retort...

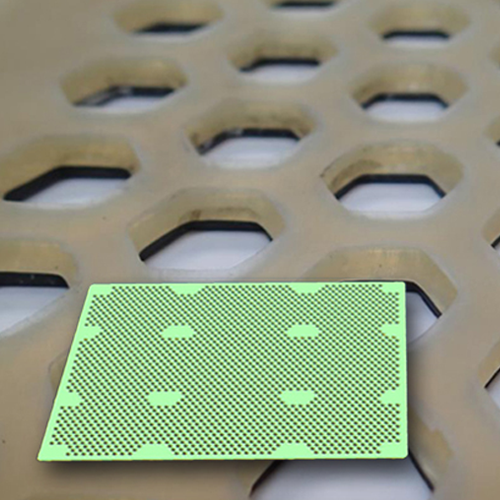

On-food traceability technology for produce

Enhance your product authenticity with a revolutionary traceability technology...

Industrial cooker for soups and ready meals

Streamline your cooking operations with a versatile system capable of mixing, ...

Cold break system for tomato processing

Enhance product quality and consistency in liquid processing by utilizing precise t...

Thermal treatment system for tomato purees

Eliminate pectin enzyme activity and prevent syneresis in your purees and conce...

Juice extractors for variety of fruits and vegetables

Streamline your juice and puree production with advanced extraction...

High pressure food processing solution for medium-scale producers

Achieve reduced operational costs with high-pressure ...

High pressure processing for diverse food products

Maximize production versatility and ensure product safety with a high-...

Volumetric piston filler for liquid and viscous products

Achieve precise volume control and enhance product integrity wit...

Rotary can filler and closer for metal cans

Achieve seamless integration in your production line with a solution that sinc...

Volumetric filler for various food products

Achieve high precision and flexibility in your filling processes with a volume...

Forced circulation evaporator for tomato and fruit paste

Optimize your high-viscosity tomato and fruit paste production w...

Evaporator for citrus juice concentrate

Optimize juice concentration and reduce thermal damage with advanced short-time eva...

Aseptic filler for fluids, concentrates, and particulates

Optimize your fluid and concentrate filling process with a hig...

Granular filler for wide mouth containers

Ensure precise filling and minimize product loss with this granular filler, expe...

High capacity volumetric filler for pumpable products

When you need high-speed, precise filling for diverse liquid and sl...

Automated clipped netting system for meat packaging

Enhance your packaging line with a system designed for rapid and prec...

High pressure pumps for viscous fluid transfer

Optimize fluid transfer with high pressure pumps designed to handle viscous...

High shear mixer for dairy and personal care products

Achieve consistent emulsification and stable homogeneity with high ...

High shear mixer for low viscosity products

Achieve precise mixing and dispersion for diverse liquid applications with a h...

High pressure industrial homogenizer

Enhance liquid formulations with precision and efficiency—our high-pressure homogenize...

Filling and seaming groups for aluminium and tin plate cans

Smoothly synchronize filling and seaming of liquid and dense...

Integrated filling and capping system for food and soft drinks

Streamline your bottling operations with an integrated sy...

Ultraclean filling monoblocks for food industry

Enhance product safety and quality with monoblocks designed for ultraclean...

Complete filling and closing line for food containers

Optimize your production line with a versatile solution that ensure...

Pv processing vessels for liquid and cream mixing

Optimize your mixing operations with versatile processing vessels desig...

Efficient ribbon mixers for precise powder blending

Achieve consistent and uniform blending with this advanced U-Trough m...

Industrial mixers for hire

Optimize your production line with versatile mixers designed for precision blending, heating, and...

Agitator for horizontal storage tanks

Efficiently blend various viscosities in horizontal tanks, ensuring optimized flow pa...

Inline mechanical homogenizer for food processing

Achieve precise particle size and uniform texture in your emulsions and...

Multifunctional industrial mixer for processed cheese and sauces

Optimize your batch production with a versatile solutio...

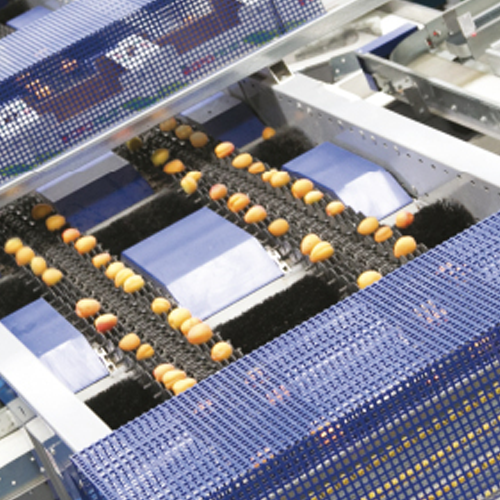

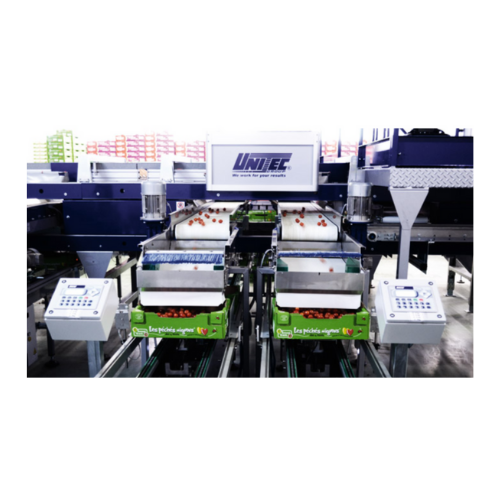

Rubin cherry tomato sorting and grading system

Efficiently sorting and grading Rubin cherry tomatoes, this system ensures ...

Tomato sorting and grading technology

Enhance tomato processing efficiency with cutting-edge sorting and grading systems de...

Grading and sorting solutions for apricots

Optimize your fruit production with precise grading and sorting technologies de...

Sorting and grading systems for cherry tomatoes

Ensure uniform quality and size of cherry tomatoes with advanced sorting a...

Single piston food filler

Achieve precise portioning and consistent product flow with a versatile solution perfect for handl...

Food grade transfer pump for semi-solid products

Streamline your production with a high-speed transfer pump designed for s...

Industrial food filling and depositing equipment

Optimize your production line with precise, gentle depositing and filling...

Layered food production line

Effortlessly streamline your production of layered foods with versatile technology that pumps, ...

Bakery batter depositor for efficient, consistent depositing

Enhance your bakery production with precision depositing fo...

Hopper transfer pump for bakery production

Effectively transfer and maintain the integrity of various food products, from ...

Compact food depositor for direct container use

Streamline your depositing process with a versatile solution that handles ...

Multi piston food depositor for sauces and dips

Efficiently fill and deposit sauces, dips, and more with precision across ...

High-speed piston depositor for food applications

Achieve precise portioning and rapid depositing of diverse food product...

Bakery transfer pump for smooth and chunky products

Ensure consistent product quality with this transfer pump that gently...

Traysealer for modified atmosphere packaging

Enhance your food packaging line with precise traysealing and modified atmosp...

Tubular pasteurizers for fruit pulp and tomato concentrate

Enhance your fruit and tomato product preservation with effic...

Tunnel pasteurizers for high and low viscosity fruit juices

Optimize your production with versatile tunnel pasteurizers,...

Forced circulation fruit juice concentrator

Optimize your fruit juice production with advanced forced circulation technolo...

Multi-fruit extraction line for mango, guava, and passion fruit juice

Optimize your fruit processing with high-yield ex...

Small-scale fruit processing line for juices and sauces

Streamline your small-scale production with a versatile line that...

Multifruit processing line for wholemeal pulps and juices

Optimize your fruit processing capabilities with a skid-based ...

Multifruit processing line for tropical and temperate fruits

Optimize your fruit processing operations with a versatile ...

Nectar formulation line for fruit juices

Optimize your fruit-based product lines with a seamless process that integrates hi...

Peach, plum, and apricot juice processing line

Optimize your fruit processing capabilities with a multifunctional solution...

Pineapple juice extraction line

Streamline your pineapple processing with a complete solution designed to efficiently transf...

Tomato paste production line

Maximize tomato yield and flavor retention with this robust processing line designed to ensure ...

Aseptic sterilizers for fruit concentrates and pulp

Optimize your fruit processing by maintaining product quality and she...

Banana purée production line

Maintain banana pulp quality by processing in a nitrogen atmosphere, ensuring fresh, oxidation-...

Batch evaporators for fruit juice and tomato concentration

Achieve high-quality fruit and tomato concentrates while pres...

Aseptic storage tanks for food liquids

Ensure the sterility and quality of your liquid food products by utilizing advanced ...

Automatic banana peeling solution

Struggling with banana oxidation during puree production? This solution ensures swift, hi...

Continuous effect evaporators for tomato concentrate

Achieve high degrees of concentration for tomato paste and fruit jui...

Falling film concentrators for low viscosity fruit juices

Achieve high concentration levels in fruit and dairy products ...

Acai berry processing line

Enhance your acai berry production efficiency with an automated line that transforms traditional ...

Apple, pear, and kiwi juice extraction line

Achieve high-yield juice production from apples, pears, and kiwis while retain...

Aroma recovery system for natural juice extraction

Maximize aroma recovery in your juice production with a fully automate...

Aseptic filling solution for fruit juice and dairy products

Ensure product integrity and safety with this aseptic fillin...

Vertical slow juicer for producing cold pressed juice

Achieve optimal juice quality and versatility with low-speed crushi...

Cold press juicer for tough vegetables

Effortlessly handle tough produce with this twin gear, cold press juicer, designed f...

Jumbo twin gear slow masticating juicer for high-yield juice extraction

Achieve optimal nutrient retention and extended...

Single-serving blender for quick personal blends

Transform your favorite ingredients into nutritious smoothies, soups, and...

In-line filling and closing system for pre-formed containers

Looking to enhance production efficiency with a solution th...

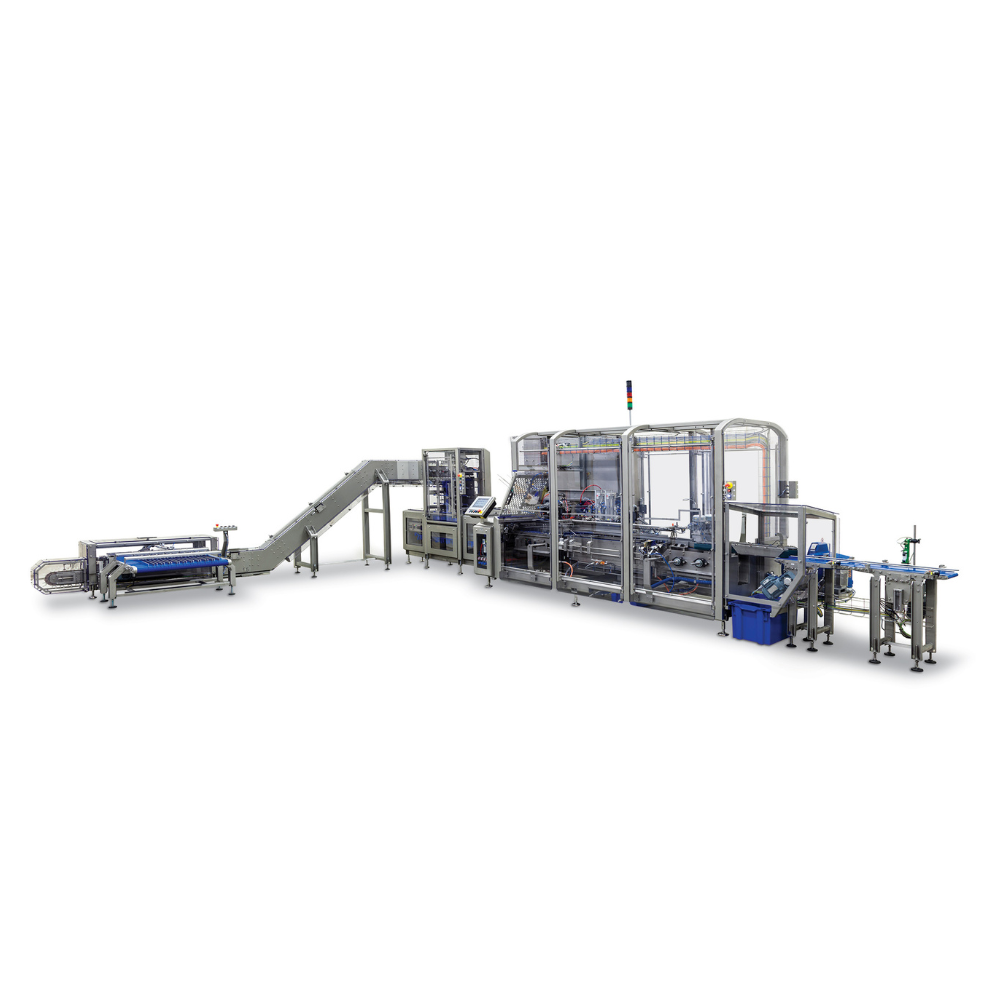

Fully automated packaging lines

Streamline your production with versatile packaging lines designed to handle a range of good...

Grinder and grater combination for professional kitchens

This versatile meat processing and cheese grating solution integ...

Vacuum sealing system for glass jars with metal lids

Efficiently vacuum seal glass jars with metal lids to transform pres...

Electric tomato squeezer for large-scale production

Optimize your tomato processing with this high-capacity electric sque...

Tomato squeezer for efficient fruit and vegetable pressing

Streamline your fruit and vegetable processing with a versati...

Tomato squeezer for efficient food processing

Efficiently transform raw tomatoes and other fruits into smooth sauces and p...

Electric tomato squeezer for family and small community use

Ideal for crafting homemade sauces and preserves, this elect...

Cooking kettles for efficient industrial food preparation

Optimize your cooking processes with these versatile kettles d...

Integrated stirring cooking kettles for commercial kitchens

Streamline your culinary operations with innovative cooking ...

Industrial cooking kettle for heating, stirring, and chilling

Streamline your kitchen operations with a versatile cookin...

Rotary pouch filling system

Looking to efficiently manage pouch filling for diverse products? This rotary system seamlessly ...

High-volume industrial blender for large-scale food processing

Effortlessly blend and transfer high-volume liquid produc...

Medium volume bottle and jar filling system

Efficiently manage filling operations for diverse liquid and semi-dense produc...

Food pasteurizer for prepared foods

Optimize your prepared food production with precise temperature control and automated o...

Homogenizer for high-capacity food processing

Achieve superior emulsification and suspension handling with this high-press...

Autonomous ingredient dissolver for high-volume dry ingredient mixing

Efficiently mix multiple high volumes of dry ingr...

Aseptic tank with blending function for liquid food storage

Achieve seamless integration of aseptic buffering and in-lin...

Ibc rack for storing and discharging intermediate bulk containers

Optimize liquid handling in your production line with...

Continuous carbonator for beverage production

Optimize your beverage production with seamless continuous carbonation, ensu...

Water treatment system for aseptic blending in Jnsd production

Ensure a reliable aseptic blending process for your bever...

Industrial homogenizer for dairy and beverage applications

Enhance product quality and reduce operational costs with a h...

Coiled heat exchanger for viscous and particulate products

Optimize heat treatment of viscous and particulate foods with...

Aseptic tank for intermediate storage

Ensure safe and sterile storage for liquid and slurry products, minimizing product lo...

Blending tank for food preparations

Optimize your production line with a tank designed for efficient blending and storage o...

Ibc rack for storing and discharging ingredients

Optimize ingredient management with efficient storage and discharge of bu...

High-speed form and seal machine for retortable food packages

Streamline your production with a machine engineered for h...

Filling solution for water packaging

Achieve efficient packaging for a variety of beverages with this high-speed filling so...

Versatile filling system for aseptic packaging

Achieve seamless integration in high-speed aseptic packaging with this flex...

Volumetric piston fillers for liquid and dense products

Perfect for diverse packaging needs, these volumetric piston fill...

Vertical package accumulator for food and beverage production

Ensure seamless flow and precise order tracking of package...

Pneumatic dosing syringes for precise liquid dispensing

Achieve precise and reliable liquid dosing with pneumatic syringe...

Accurate volumetric filler for liquid and semi-dense products

Achieve precise dosing and filling of various liquid and s...

Vacuum bottling equipment for wineries and breweries

Optimize your bottling process with a vacuum solution that fills up ...

Continuous fluid bed dryers for various industrial applications

Achieve precise moisture control with fluid bed dryers, ...

Automatic line for filling and capping spouted pouches

Streamline your production line with high-speed filling and cappin...

Tomato paste processing line

Streamline your tomato processing with our comprehensive production line, ensuring high-quality...

Stainless steel peanut butter grinder

Optimize your production line with high-speed emulsification and grinding, achieving ...

Automated cup filling solutions for liquid and viscous products

Ensure precise and hygienic filling of dairy, baby food,...

Cascading water sterilizer for optimized food preservation

Reduce sterilization times significantly while preserving foo...

High-shear mixer for emulsions, dispersions, and foams

Achieve precise emulsions and dispersions effortlessly with high-s...

Film shrink wrappers with 90° infeed

Easily adapt to compact spaces while efficiently wrapping various container shapes, fr...

Integrated linear blowing and filling system for Pet containers

Streamline your PET container production with integrated...

Homogenizers for creams and ointments

Achieve superior consistency and particle size reduction in skincare creams, sauces, ...

Dosing system for packaging lines

For producers looking to optimize their packaging lines, this dosing system offers precis...

Automated sauce production lines

Streamline your sauce production with flexible lines designed for rapid recipe changeovers,...

High-speed moisture analyzer for liquid and pasty samples

Ensure precise moisture analysis with rapid microwave drying, ...

Aseptic tank for liquid food storage

Store and maintain the sterility of low and high acid liquid foods while ensuring prod...

Continuous sugar dissolver for high brix solutions

Optimize your beverage production with a system that dissolves sugar u...

Pasteurization solution for food liquids

Extend the shelf-life of your liquid products while maintaining their quality with...

Custom syrup preparation systems

Optimize your beverage production with precision-engineered syrup preparation systems desig...

Industrial solutions for beverage mixing and carbonation

Optimize your beverage production with precise mixing and carbon...

High pressure plunger pump for continuous food processing

Achieve consistent texture and quality in spreads and sauces w...

Energy-saving cooling system for vegan products

High-viscosity products like hummus or chunky pasta sauces must be cooled ...

Vegan Sauce Processing System

Having a multipurpose machine allows one to perform different tasks like cooking, frying, brai...

Semi-manual can sealer

When starting out in the canned product business, you do not necessary want to invest in industrial sc...

Vacuum and pressure cooker for fruits and vegetables

When producing fruit-based products such as marmalades or ice cream ...

Autoclave sterilizer for food cans and jars

An autoclave is a must-have machine for canned food production lines. It perfo...

Shrink wrapping machine for PET bottles

During a shrink-wrapping process, a change of reel can slow down the production cyc...

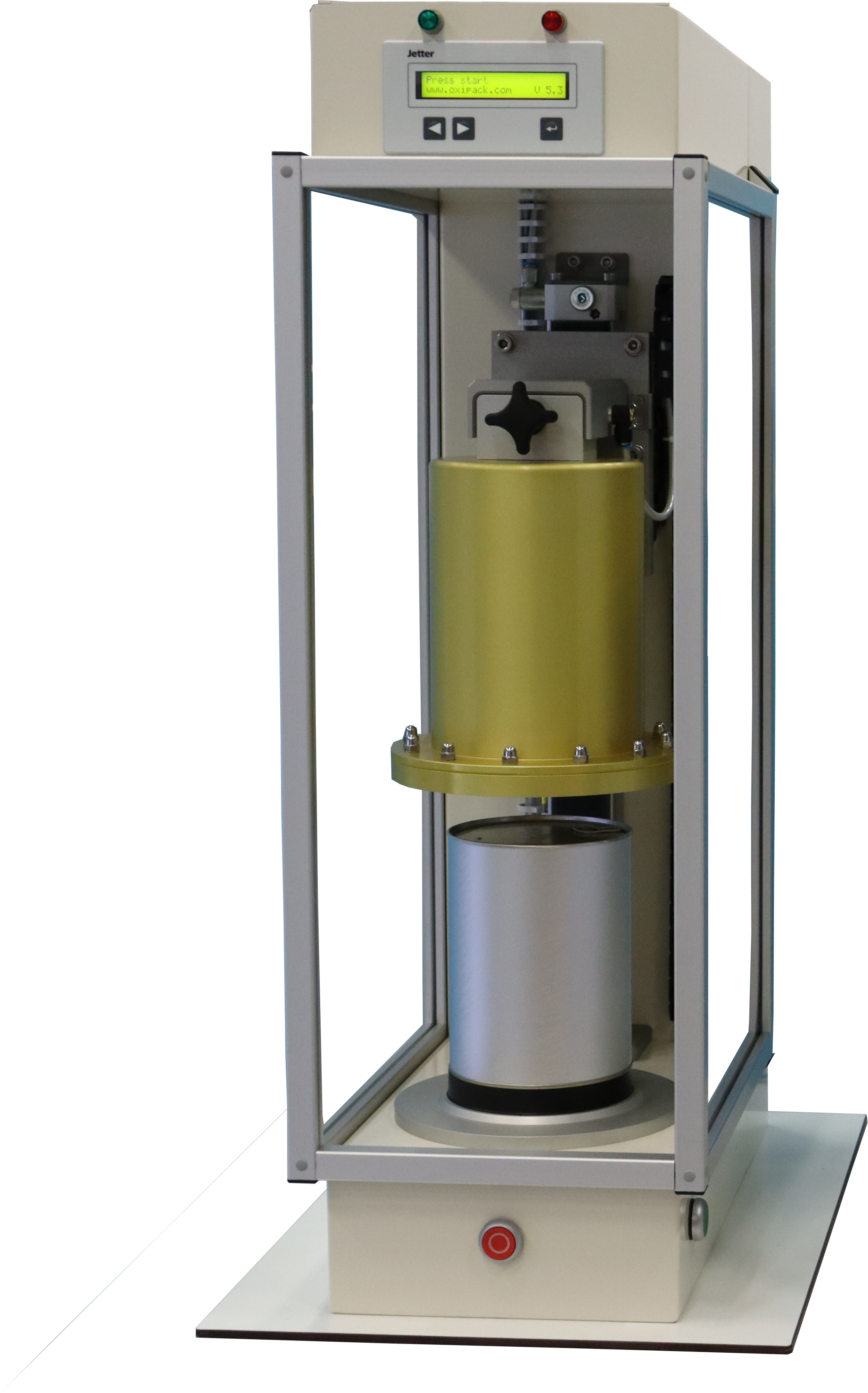

Can leak tester

Every canned pet food producer knows that their product should avoid the growth of microorganisms that could s...

High speed can seamer

Tin plate thickness for cans has gradually reduced over the years, which makes it a hassle to use new c...

Medium scale round can seamer

Automatic seaming of cans of craft bear can be quite the hassle with the movement from the cen...

Industrial vacuum cooker

Batch cookers can be highly inflexible and inefficient, relying on maximum fill levels to operate we...

Continuous sterilizer for tin cans and jars

A concern in the coffee industry is maintaining the freshness, taste, and qual...

Automatic filling machine for sauce

Traditional sauce filling units can struggle to maintain a high quality of output in ca...

Industrial bottle washing machine

Polyethylene terephthalate (PET) and glass bottles are widely used in the beverage indust...

Industrial bottle sterilizer

Sterilization is an important process in the beverage industry to kill microorganisms. It is im...

Air knife system for bottling lines

Wet containers are unacceptable and can be problematic in the food and beverage industr...

Pipeline metal detector for sauces

Ensuring liquid and viscous products such as sauces, soups, juices and meat are contamin...

Vacuum based homogenizer

When producing liquid and viscous products such as mayonnaise, sauces, dressings and ketchup it’s vi...

Universal Mixer and Cooker for Sauces

Sauce cookers and mixing machines have traditionally been designed to suit one proces...

Modular HFFS Machine

A large range of sizes and types is available, with traditional horizontal form fill and seal machines b...

HFFS machine with servo-control system

Traditional HFFS machines use mechanical cams to drive the production path through t...

High Speed Premade Pouch Packaging Machine

Pre-made pouches can be problematic for traditional cam-driven mechanical HFS m...

Retort Pouch Packaging Machine

A wide variety of products that were previously canned are now able to be more economically p...

High-end empty bottle inspection system

If you are looking for a system with empty bottle inspection; base, residual liquid...

Vacuum cooker for concentrating sauces and purees

When producing high quality prepared food, concentrating products for s...

Industrial pressure cooker

Optimizing production processes and human resources to reduce energy consumption and save time an...

Empty crate inspection system

Extensive and much-differentiated inspection of both the crate and the bottle that allows you ...

Smart Industrial Sauce Cartoning System

Large volume producers of sauces and ready meals continuously pack different produc...