Fruit Puree Equipment

Find innovative production technology for making fruit puree and connect directly with world-leading specialists

Made from bananas, apples, strawberries and other tasty fruits, fruit purees are beloved by both children and adults around the world. Fruits that make it into the puree go through a strict selection process. Fruit puree processing line incorporates all machinery used for selecting, washing, cleaning, crushing and sieving the fruit which ensures the quality of the fruit puree.

Select your fruit puree process

Tell us about your production challenge

Fruit puree processing line: how does it work?

After being picked at just the right point of ripeness, fruit is intensely processed before pureeing- it is washed, cleansed from contaminants, inspected for any irregularities and peeled with an automatic peeler on the fruit puree processing line. After these initial steps, the fruit is chopped into smaller pieces and ground into a pulp with an industrial disk mill. A similar but slightly different process is followed when making fruit juice on an industrial scale.

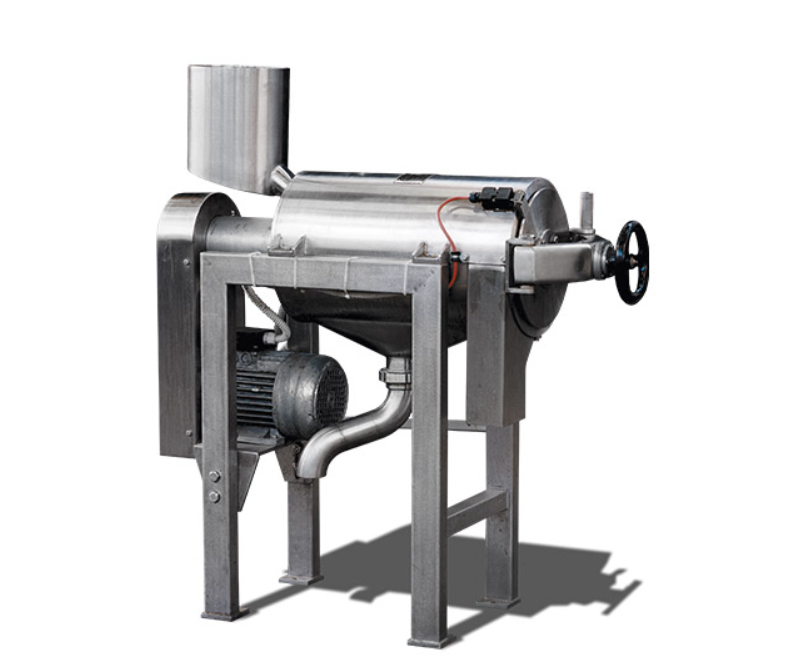

The pulp is then strained to further purify the mash. Homogenizing fruit puree is another important step. The pulp goes into a high-pressure homogenizer, which reduces the fruit particles and creates that silky smooth texture of fruit puree.

Some of the fruit purees have to go through a deaeration process. Some fruits, like apples and bananas, oxidize very fast because of their high iron content. That’s because when exposed to air, their enzymes turn polyphenols into melanin, a iron-containing compound that gives them the brown color. So removing the air from fruit puree is a key step. The deaerator stops the fruit from changing its color and taste and postpones oxidation by extracting dissolved oxygen in the puree.

Pasteurize your fruit puree

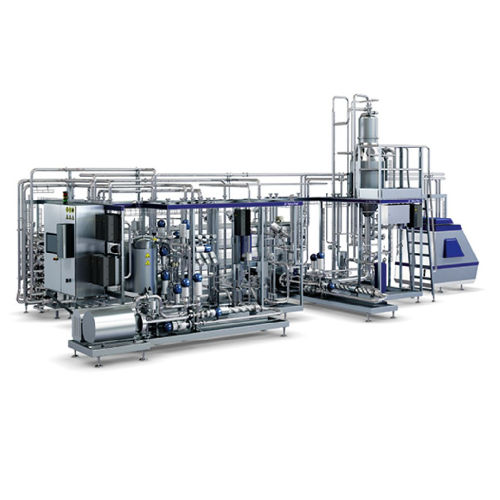

Before packaging, fruit puree is pasteurized and completely sterilized to make it thoroughly safe for human consumption. Pasteurizing the fruit puree is critical for eliminating any potential microorganisms that might still exist in the puree. Pasteurization also prolongs the shelf life of the product and keeps it from spoiling prematurely.

Fruit puree is pasteurized at high temperatures, ranging from 60°C to 100°C. The puree is then cooled and packaged in aseptic (sterile) conditions.

Hydrodynamic cavitation for fruit puree

In 2015, a group of scientists from Canada started researching hydrodynamic cavitation (HC) and its impact on fruit puree and fruit juice. They developed an innovative Venturi tube-based HC technology that can simultaneously crush, homogenize and pasteurize the fruit. Scientists found that by using HC, the fruit particles were finer than in traditional pureeing methods.

The same study found that HC completely eradicated heat-resistant molds that could still grow and develop into mycotoxins after pasteurization at 96°C. Moreover, by using hydrodynamic cavitation, scientists remarked the puree’s longer shelf life and retention of nutrients. With the HC device, fruit processing manufacturers can lower production costs and reduce production time because three previously separate steps could be done simultaneously.

Fruit puree for brewing

Fruit puree is versatile and can also be used for brewing alcoholic beverages like craft beer and fruit wine. Manufacturers of wine and beer generally prefer to use fruit puree instead of fruit juice for brewing because the puree is much more concentrated and boosts the natural fruity taste in alcoholic drinks.

In winemaking, fruit puree is often diluted with water to reduce the fruit’s acidity, that can make the flavor of the alcoholic drink too sour. Afterwards, the diluted puree is mixed in with wine must, water, sugar and yeast before fermentation begins.

For brewing beer, the chosen fruit puree is added directly to the fermenter where, together with yeast, it creates craft beer with a touch of fruit.

Aseptic fruit purees are used both in brewing craft beer and winemaking – they are shelf stable, easily storable and convenient to use. The product, whether it is wine or beer, is considered sterile when aseptic fruit purees are used. However, some craft beer brewers prefer to use pasteurized fruit puree as they have the most preserved original taste and color.

Processing steps involved in fruit puree making

Which fruit puree technology do you need?

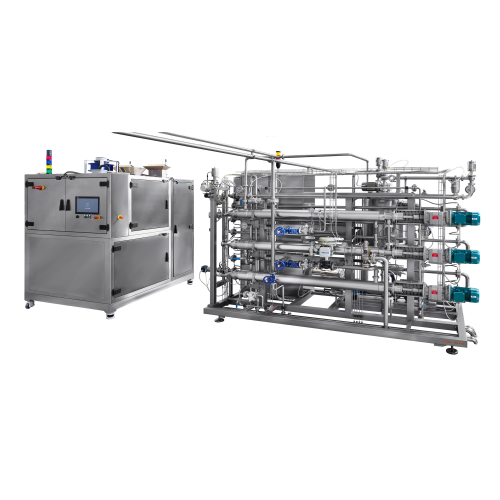

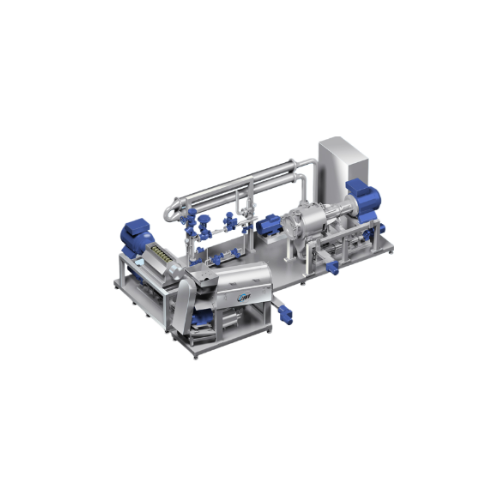

Precise liquid cooling solution for food processing

Ensure high-quality preservation of flavors and textures in liquid fo...

Efficient cooling and cooking systems for food processing

Streamline your production with integrated cooling and cooking...

Continuous tahina production line

Streamline your tahina production with precise grinding and controlled cooling, ensuring ...

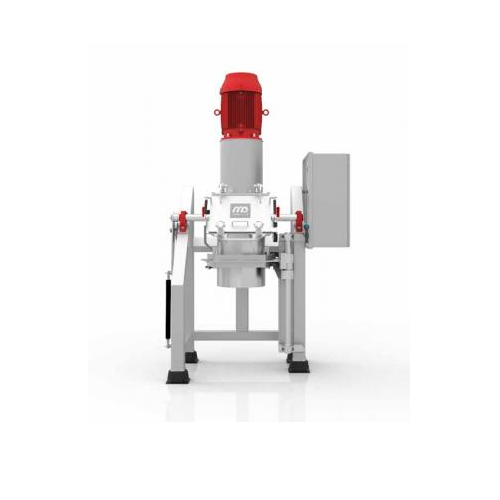

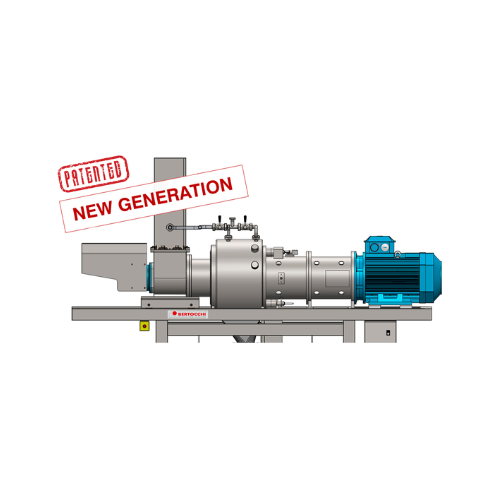

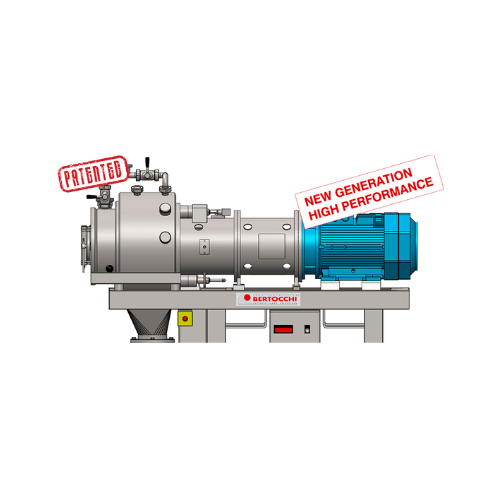

Perforated disc mill for food and chemical processing

Streamline your processing workflow with a versatile solution that ...

Perforated disc mill for pre-comminution and mashing

Achieve precise granulating and mashing of diverse materials with th...

Multistage mixers for emulsions and dispersions

Experience efficient emulsification and dispersion processes with this ver...

Food product smoothing system for dairy and purees

Achieve unparalleled texture and fineness in viscous food products wit...

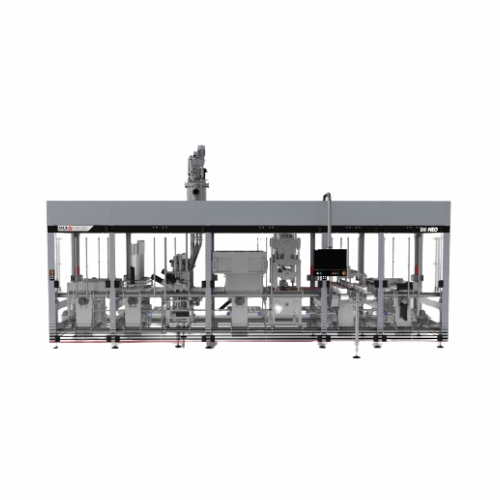

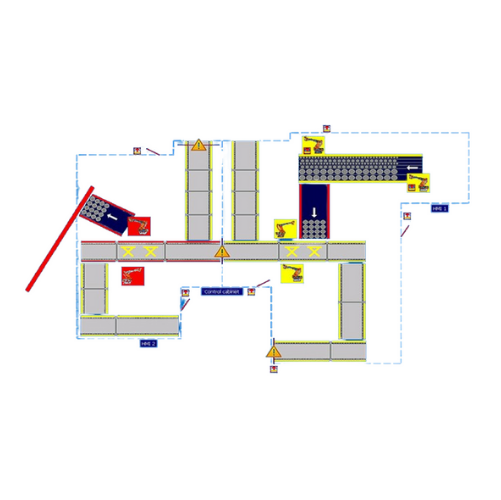

Automation for food processing

Optimize your food production with cutting-edge automation, enhancing efficiency and precisio...

Mayonnaise production system

Ensure precise emulsification for low to full-fat mayonnaise and similar cold emulsions with a ...

Hygienic fluid storage tanks for food industry

Ensure impeccable hygiene in fluid storage with our customizable tanks, des...

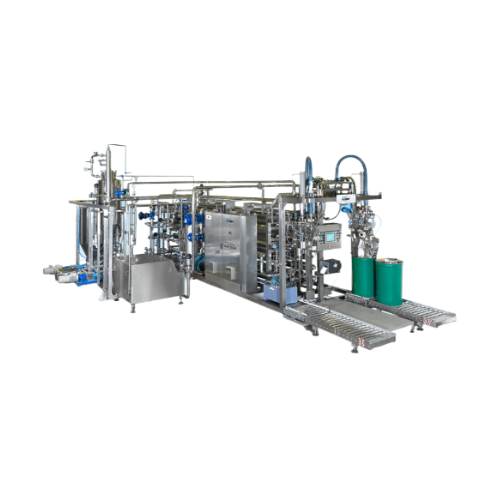

Aseptic thermal processor for high viscosity products

Optimize your processing of high viscosity products with precise te...

Direct steam injection system for heat treatment

Achieve precise thermal processing and enhance product quality for comple...

Customized process plants for plant-based beverages

Efficiently scale your production of plant-based beverages with modul...

Cryogenic tunnel freezer for optimized food freezing

Enhance your production line with advanced cryogenic freezing techno...

Cryogenic freezing systems for food processing

When you need precise and rapid freezing for diverse food products, these a...

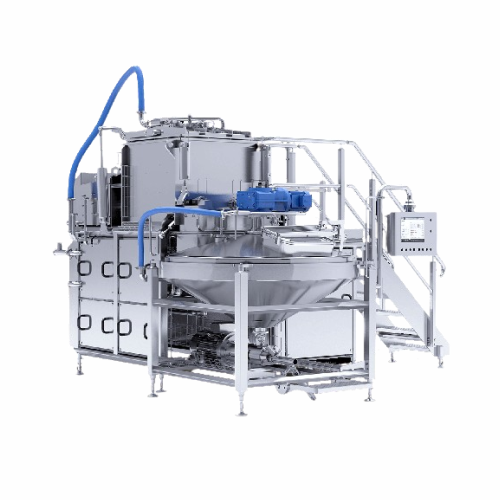

Conical buffer tank for hygienic dairy and food processing

Achieve efficient processing of high-viscosity products with ...

Food mixing and blending system

Enhance your production line with a versatile system designed for gentle processing needs, o...

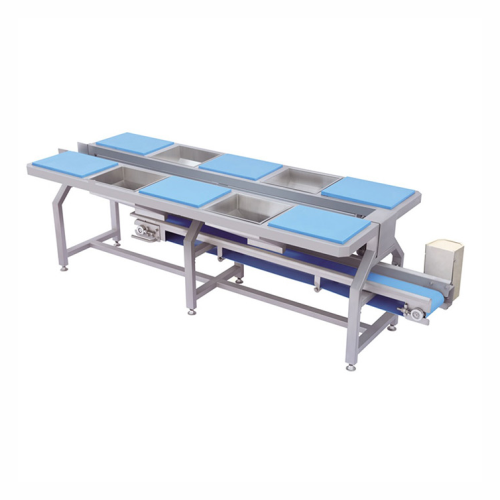

Vegetable and fruit preparation table

Optimize your food processing line with a versatile preparation table designed for ef...

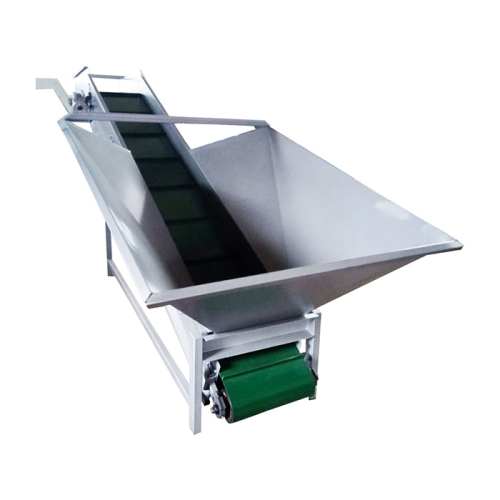

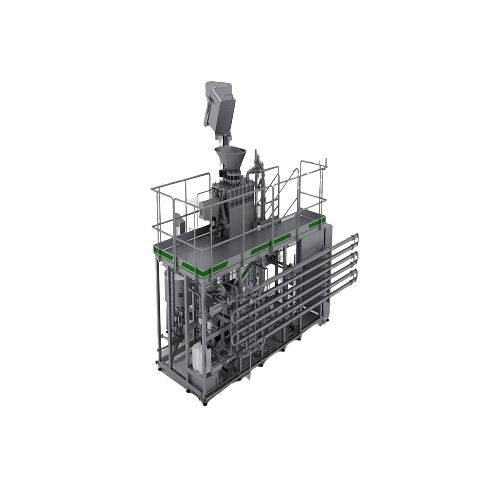

Receiving hopper for jumbo boxes

Efficiently unload and handle bulk agricultural products with ease, streamlining your pre-p...

Hydraulic juice press for fruit and vegetables

Streamline your juicing operations with this hydraulic solution, expertly d...

Syrup room for customized beverage ingredient preparation

Achieve unparalleled flexibility in beverage production with a...

Vegetable and fruit cutting solution for slices, segments, and sticks

Streamline your pre-processing with a versatile c...

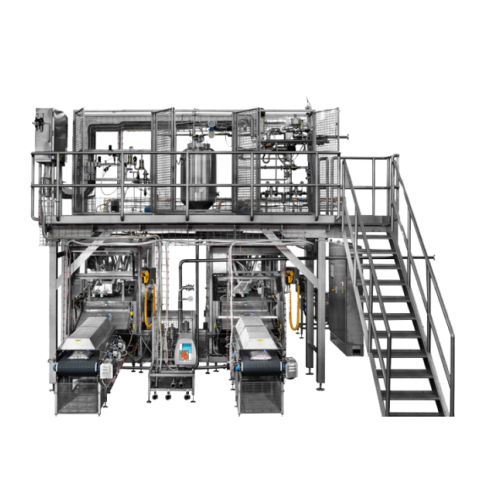

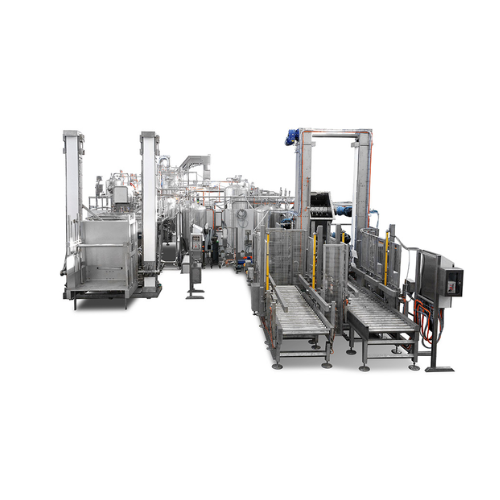

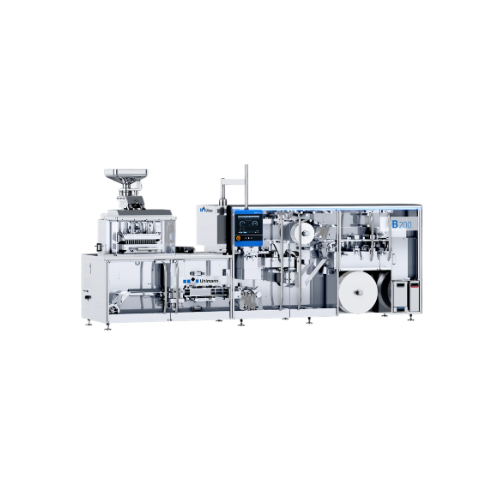

Fruit processing and packaging line

Streamline your fruit and vegetable processing with this semi-automatic system designed...

Grape destemming solution for efficient fruit processing

Streamline your fruit preparation process with a versatile machi...

Pasteurizing units for fruit and vegetable juices

Ensure your juices and purees remain fresh and safe by effectively past...

Stationary belt press for fruit juice extraction

Achieve optimal juice yield from fruits and vegetables through precise co...

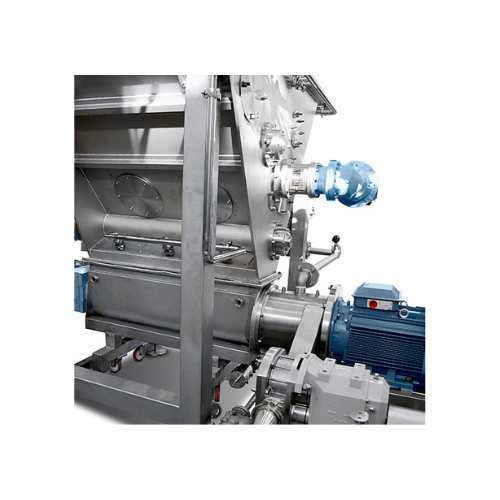

Washing and grinding system for fruit and vegetables

Efficiently wash and grind fruits and vegetables to streamline your ...

Citrus fruit juicing system

Efficiently extract and refine citrus juices and oils with a streamlined system designed to hand...

In-line disperser for high-volume liquid processing

Streamline your emulsification process with powerful rotor-stator hom...

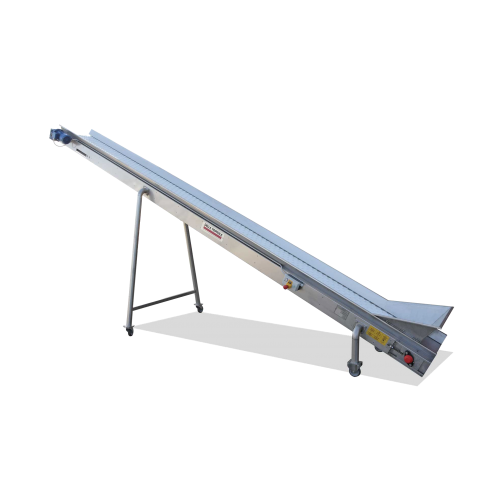

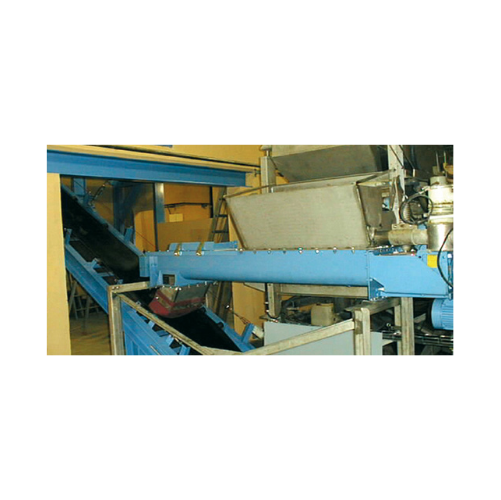

Feed conveyors for efficient product presentation

Optimize your production line with feed conveyors designed to streamlin...

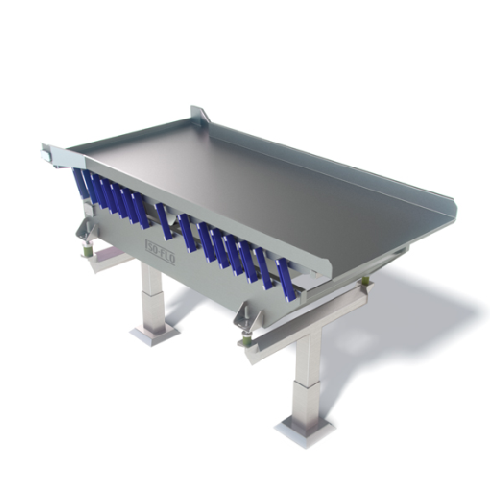

Vibratory conveyor for efficient bulk material transportation

Optimize your processing line with robust vibratory convey...

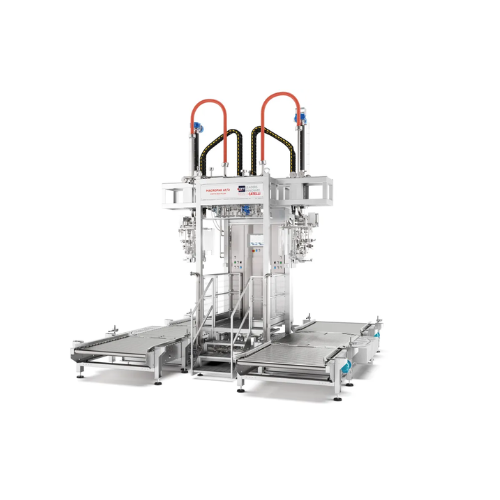

Hot-fill dosing system for soups and sauces

Ensure precise and efficient dosing of hot and cold liquid foods with integrat...

In-line high shear mixing solution

Achieve precise emulsification and particle size reduction with high shear capabilities,...

Industrial cooking kettle for food processing

Achieve seamless integration of cutting, mixing, and cooking processes to cr...

Rotary filling and sealing for liquid to pasty products

Boost production efficiency with a flexible rotary solution that ...

Stick pack forming, filling, and sealing solution

Enhance packaging efficiency with a high-speed solution designed for pr...

Filling and sealing system for pre-formed cups

Experience seamless integration of hygienic filling and sealing with adapta...

Flexible filling and sealing system for pre-formed cups

Achieve precise portioning and consistent quality in your product...

Rotary filling and sealing system for pasty products

Efficiently streamline your cup and tub packaging process with a ver...

Multifunctional batch cooker for various food products

Optimize your production line with a versatile batch cooker design...

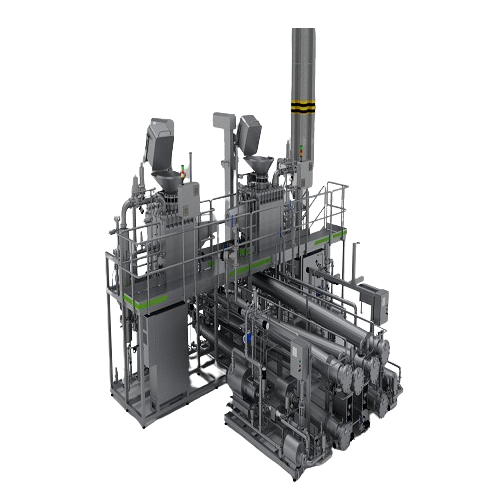

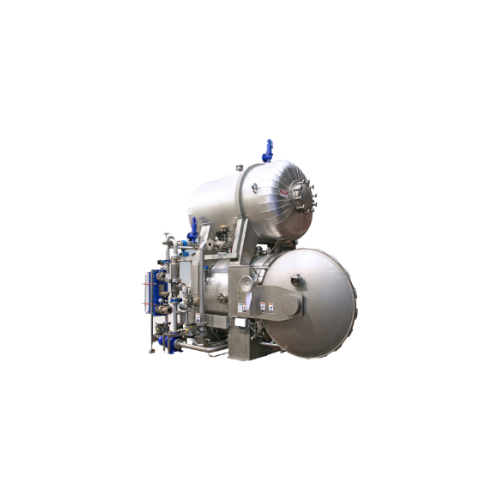

High pressure processing for bulk liquid beverages

Streamline your liquid processing with high-pressure in-bulk technolog...

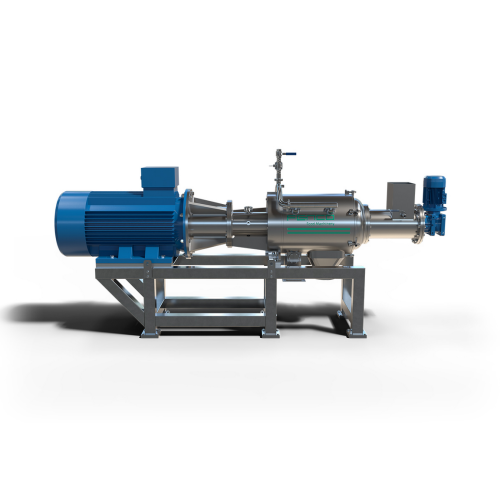

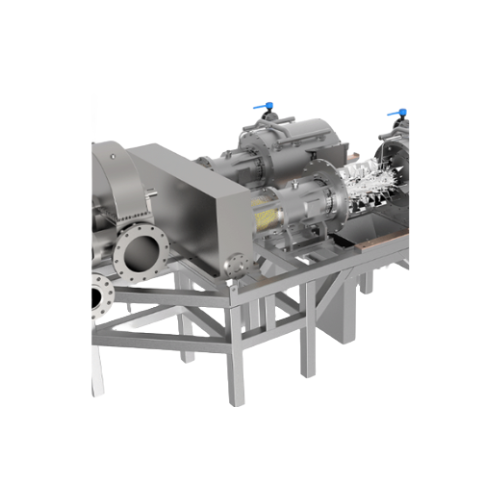

Industrial grinder for ultra-fine grinding and homogenizing

Enhance your production line with versatile grinding technol...

Stainless steel buffer tanks for food, pharma, and cosmetics

Ideal for maintaining process fluidity, these stainless ste...

Stainless steel agitators for pharmaceutical and food applications

Optimize your production line with tailored agitator...

Pulper finisher for tomato and cold extraction

Enhance your production line efficiency with a pulper finisher designed to ...

Industrial aseptic fillers for food processing

Ensure sterile packaging with advanced aseptic fillers, designed for precis...

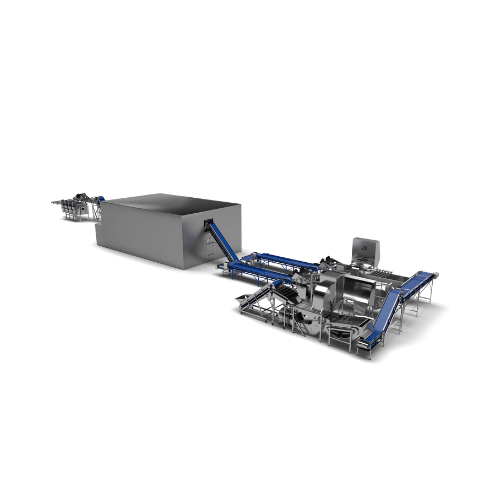

System for receiving, sorting, and destoning fruit

Enhance your fruit and tomato processing efficiency with an integrated...

Aseptic sterilizer for fruit-based products

Ensure product safety and extend shelf life with advanced sterilization techno...

Industrial dicer and peeler for fruit processing

Achieve seamless integration in your processing line with a dicing and pe...

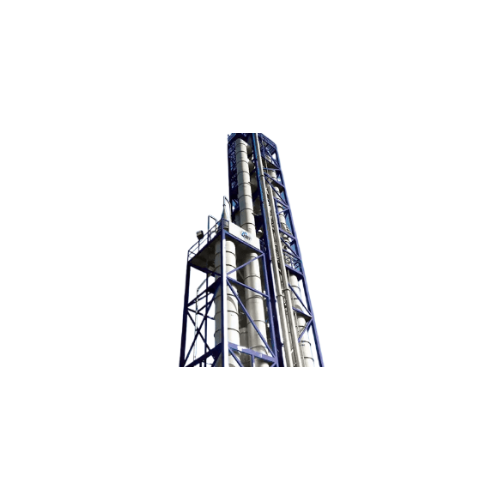

Tomato juice pre-concentrator

Achieve higher concentration levels with less energy use by utilizing accelerated juice circul...

Enzyme inactivators for tomato processing

Efficiently inactivate enzymes to preserve nutritional value and organoleptic qu...

Forced circulation evaporators for tomato concentration

Achieve significant energy savings and enhance production efficie...

Tomato receiving and sorting system

Ensure top-quality tomato products by efficiently handling unloading, washing, and sort...

Aseptic sterilizers for tomato products

Ensure your tomato-based and fruit products remain safe and shelf-stable with advan...

Radiofrequency sterilizer for delicate food products

Streamline your food processing with radiofrequency technology, offe...

Aseptic filler for bag-in-box packaging

Achieve unparalleled product safety and quality in liquid packaging with our advanc...

Automatic cartoning solution for 3-20l aseptic bags

Streamline your aseptic packaging with an integrated cartoning soluti...

Evaporator for pulpy juice concentration

Achieve efficient concentration with reduced energy consumption, thanks to innovat...

Marmalade, sauces, nectars, and baby food processing solution

Maximize flexibility in your production line with a system...

Aseptic filler for large bags

Ensure safe and sterile packaging of liquid and slurry products in large formats with this ase...

Sterilizer for liquid and viscous products

Effortlessly process and sterilize diverse liquid products, from concentrated j...

Flash cooler sterilizer for tomato paste

Maximize your production capacity and preserve flavor integrity in high-viscosity ...

Aseptic filler for liquid and particulate products

Achieve precise, sterile filling of both liquid and chunky products wi...

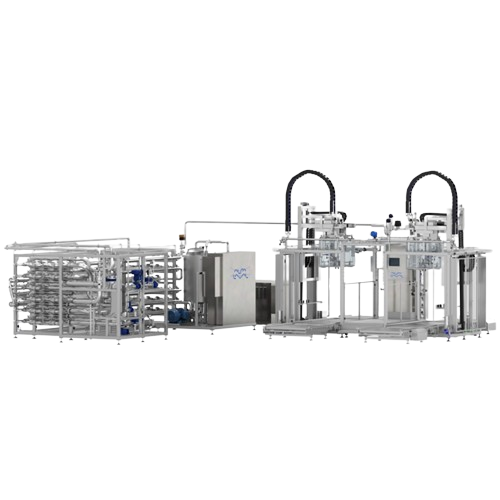

Aseptic treatment and filling for concentrates and purees

Optimize your processing line with a compact solution that com...

Aseptic bag-in-box filler for juices and purees

Enhance your filling operations with a high-speed aseptic solution designe...

Aseptic filler for liquids and semi-concentrates

Ensure maximum sterility and precision when filling liquids, concentrates...

Vegetable and fruit centrifugal slicer and shredder

Enhance your food processing with high-capacity slicing and shredding...

Fruit processing system for jams and marmalades

Optimize your fruit-based product manufacturing with equipment designed fo...

Industrial pulper for fresh produce

Achieve ultra-fine purees and pastes with this high-speed industrial pulper, designed t...

Rotary vacuum filters for wine and beverage filtration

Efficiently filter and clarify wines, juices, and industrial fluid...

Conveyor belts for grape processing

Streamline your grape processing with stainless steel conveyor belts, engineered for ef...

Concentrate drum emptying system

Efficiently extract every drop of fruit concentrate from your drums with precision and ease...

Pneumatic dosers for variable density products

Achieve precise dosing for liquid to dense products with versatile pneumati...

Freeze dryer for high sugar or acid content products

Achieve precise moisture control for challenging high sugar or acid ...

Industrial low temperature freeze dryer for high sugar or acid content products

For processing challenging high sugar ...

Tunnel for thermal treatment of packaged foods and beverages

Optimize your thermal processing with this customizable tun...

Leaf vegetable sorting and cooling system

Ensure optimal freshness and extended shelf life for leaf vegetables with precis...

Robotic case packers for bags and pouches

Efficiently pack a variety of bagged and pouched products with precision handlin...

Industrial spiral freezing system

Optimize your food processing line with a reliable spiral system, designed to efficiently...

Aseptic fillers for liquid and viscous products

Ensure sterile and precise filling of liquid and viscous foods with adapta...

Tomato processing crushing mill

Optimize your production line with efficient chopping and refining, ensuring uniformity and ...

Enzymatic inactivation system for fruits and vegetables

Achieve optimal product quality by maintaining vivid color, robus...

Energy efficient tomato evaporator

Achieve up to 98% steam savings in your evaporation process while ensuring minimal CO2 e...

Semi-automatic aseptic filler for single bags

Ensure aseptic integrity and flexibility for your liquid and semi-liquid pro...

Iqf strawberry processing line

Optimize your strawberry processing with a line designed to ensure gentle handling, precise s...

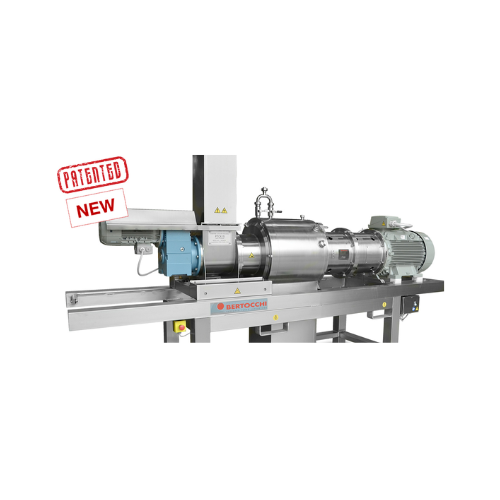

Crushing mill for berries and stone fruits

Optimize your juice production by achieving the finest mash from berries and st...

Mash heater for core fruits and berries

Improve juice extraction and color yield in your fruit processing line with this in...

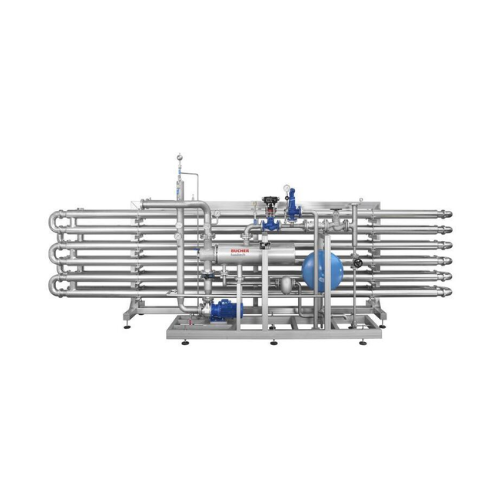

Industrial pasteurizer for juice, dairy, and vegetable purees

Ensure product safety and extend shelf life with this comp...

Roller table for sorting and cleaning pome fruit

Ensure thorough inspection and cleaning of pome fruits with rotating roll...

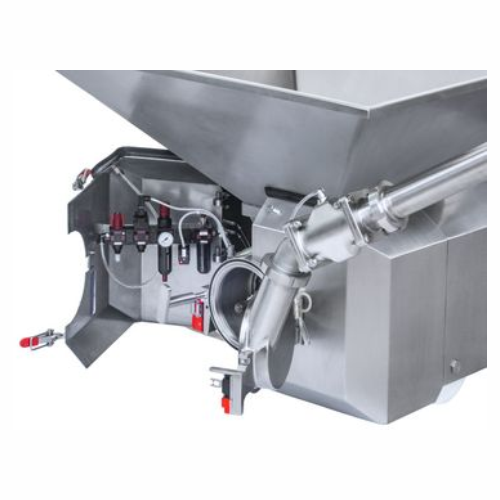

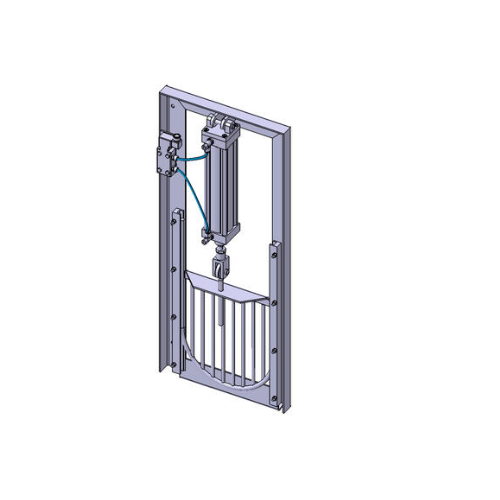

Pneumatically controlled dosing slide for pome fruit silos

Ensure consistent and controlled fruit discharge in your proc...

Vertical screw conveyor for pome fruit

Overcome significant height differences and clean pome fruits effectively in your pr...

Grinding mill for apple and pear mash

Optimize your fruit and vegetable processing with a high-speed, energy-efficient grin...

Citrus brush washer

Ensure optimal cleanliness of citrus fruits with a mechanical washer that combines rotating brushes and t...

Grinding mill for apples and pears

Optimize juice yield with tailored grinding for a variety of fruits and vegetables, ensu...

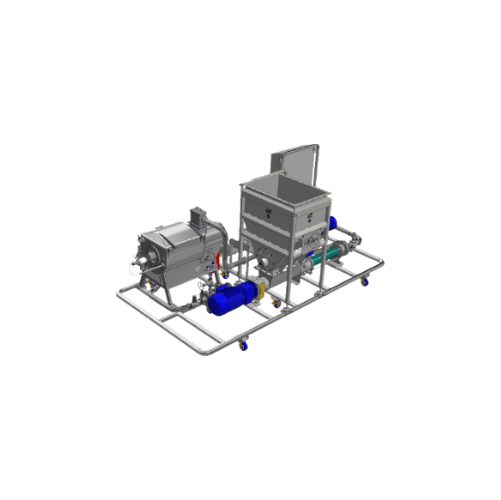

Defreezer for fruit and vegetable preparations

Optimize your fruit and vegetable processing with a versatile defreezer tha...

Horizontal evaporation bowl for fruit jams and purees

Optimize thermal exchange and preserve product integrity during jam...

Evaporator for juices and purees

Efficiently concentrate liquid products like apple juice, tomato puree, and chocolate sauce...

Evaporators for fruit and vegetable juices and purees

Optimize your juice and puree production with advanced evaporators ...

Hammer pulping system for fruit and vegetable processing

Optimize your fruit and vegetable pulping process with a high-sp...

Vacuum degasser for juices and purees

Enhance the quality of your liquid products with efficient degassing and flavor recov...

Heater for enzymatic inactivation of fruit and vegetable pulp

Optimize your puree and concentrate production with effici...

Continuous cooker for vegetables and fruits

Optimize your production line with a continuous cooker designed to defreeze an...

Shelling mill for Iqf and frozen fruit lumps

Effortlessly process frozen fruit and vegetable conglomerations into shelled ...

Turbo extractor for puree and concentrate production

Enhance your puree and concentrate production with a turbo extractor...

Pasteuriser and cooler for fruit and vegetable juices

Ensure optimal thermal treatment for your fruit and vegetable produ...

Pasteurizer and sterilizer for fruit and vegetable juices

Ensure the safety and quality of your fruit and vegetable juic...

Drum blancher for continuous cooking and blanching

Optimize your production line with a continuous drum blancher, designe...

Fruit and vegetable washing solution with agitating action

Experience efficient dirt removal and product agitation for f...

Vertical bowl for cooking, degassing, and concentration of fruits and vegetables

Optimize the cooking, degassing, and ...

Turbo mixer for homogeneous solutions in food and pharmaceutical industries

Effortlessly achieve uniform suspensions a...

Sterile cooling system for fruit preparations

For manufacturers seeking aseptic conditions, this cooling system ensures ra...

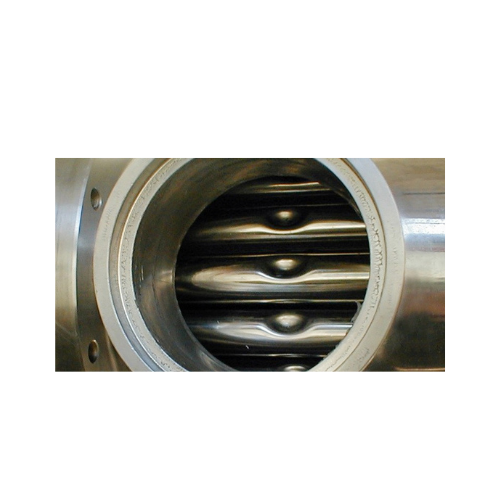

Scraped surface sterilizer for high viscosity liquid products

Optimize your production of high viscosity liquids with a ...

Aroma-batch blender for beverage production

Optimize your beverage formulation process with precise aroma dosing and effic...

Apple processing equipment for juice and puree production

Efficiently process apples and pears into high-quality juice a...

Avocado processing plant for puree and oil extraction

Optimize your avocado processing with a complete system designed fo...

Fruit base processing technology for yoghurt and bakery

Ensure the integrity of fruit preparations while maximizing varie...

Industrial jam processing line for fresh fruit or puree

Streamline your jam production with a versatile line capable of p...

Ketchup production line

Optimize your sauce production with advanced equipment designed to ensure consistent blending, precis...

Juice reconstitution equipment for concentrated juice

Revolutionize your beverage production with advanced equipment desi...

Industrial depitter for stone fruits

Effortlessly process stone fruits into smooth purees and nectars with a continuous, co...

Smoothies production line for fruits and vegetables

Optimize your smoothie production with a line designed for efficient ...

Industrial liquefying and crunching solution for frozen fruits and vegetables

Efficiently transform frozen produce int...

Turbo extractor for cold extraction of fruit and vegetable purees

Achieve high-yield, efficient cold extraction of frui...

Turbo extractor for tomato and fruit puree processing

Optimize your production line with high-capacity turbo extraction f...

Frozen extraction turbo extractor for fruit and vegetable purees

Efficiently transform frozen fruits and vegetables into...

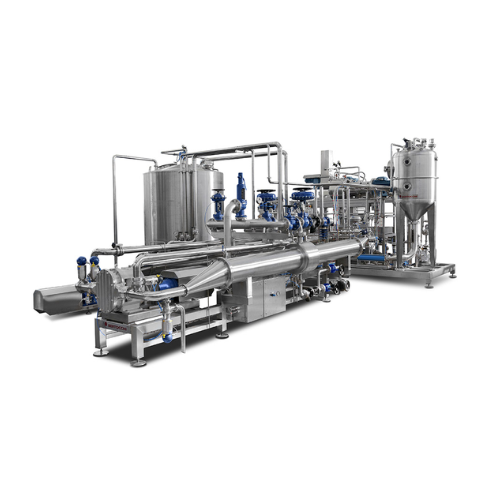

Cold extraction system for fruits and vegetables puree

Optimize your fruit and vegetable puree production with a versatil...

Washing and sorting line for fruits and vegetables

Efficiently achieve pristine fruit and vegetable cleanliness while enh...

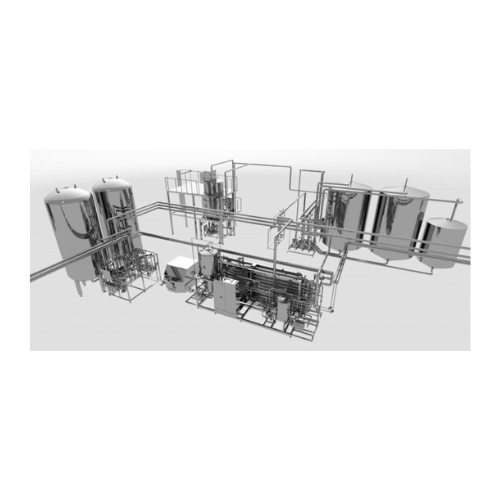

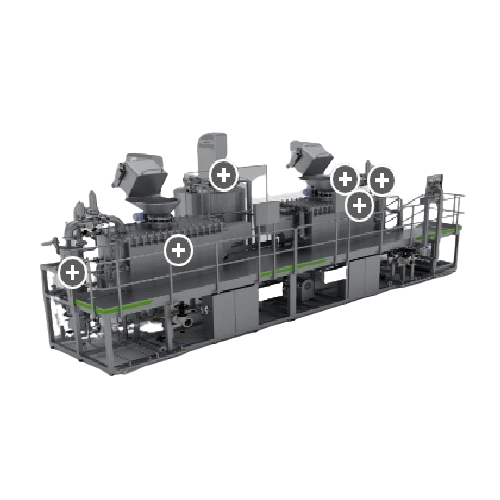

Line for production of fruit and vegetable purees by cold extraction

Streamline your puree production with innovative c...

Frozen extraction line for fruit and vegetable purees

Overcome challenges of processing frozen fruits and vegetables effi...

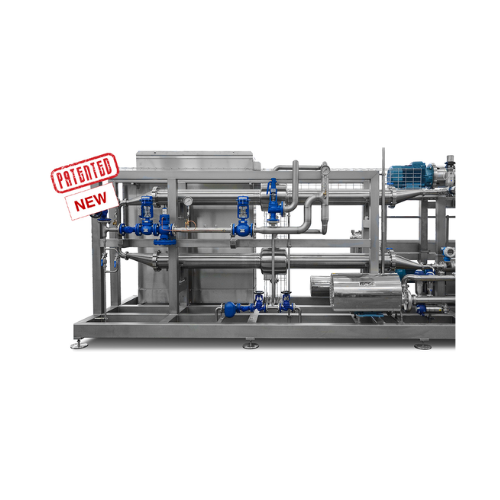

Cold extraction deaeration system for fruit and vegetable purees

Achieve superior puree quality with our system that ens...

Cold extraction system for fruit and vegetable purees

Optimize fruit and vegetable puree processing with cold extraction,...

Cold extraction line for fruit and vegetable purees

Enhance puree quality with minimal thermal stress through a seamless ...

Cold extraction and enzymatic deactivation for fruit and vegetable purees

Enhance your puree quality with advanced col...

Turbo extractors for tomato and fruit hot extraction

Optimize your fruit and vegetable processing with high-capacity turb...

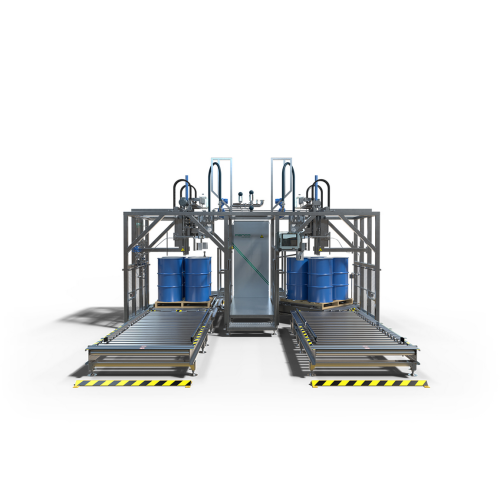

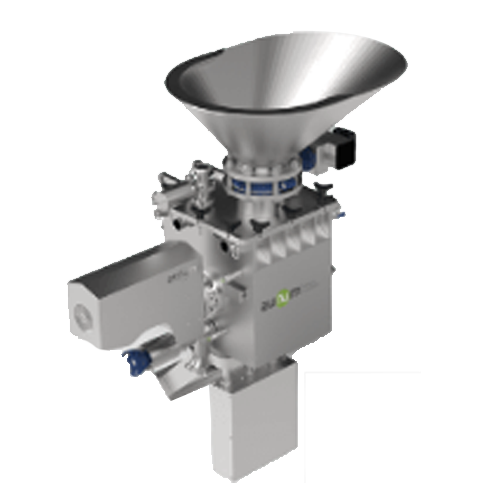

Multi feeding system for baby food and purees

Streamline your puree production with a versatile feeding system that expert...

Cold extraction and deaeration system for fruit and vegetable purees

Ensure high-quality fruit and vegetable purees wit...

Crunching and dosing solution for frozen fruits and vegetables

Streamline your processing line with a versatile system d...

Cold extraction turbo extractor for fruit and vegetable puree

Optimize your processing line with continuous cold extract...

Vacuum mixer reactor for liquids and semi-solids

Achieve precise mixing and emulsification of complex liquid formulations ...

Melter for vacuum turboemulsifiers

Achieve optimal mixing, dispersion, and temperature control with precision-engineered me...

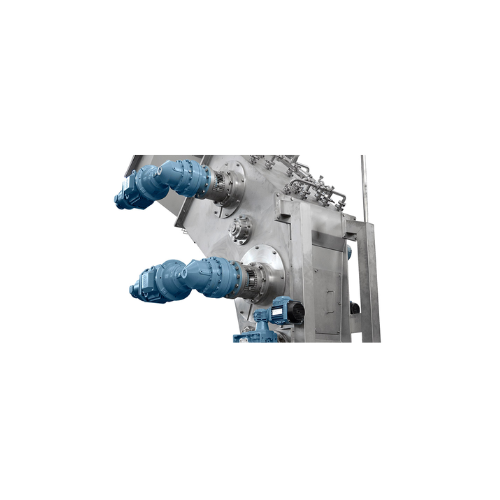

High-efficiency high-capacity reactor for industrial processing

Enhance production efficiency with a reactor system desi...

Aseptic cooking line for plant-based products

Enhance your production efficiency and product quality with an advanced doub...

Aseptic cooking line for industrial food processing

Achieve seamless aseptic cooking and filling for diverse food product...

Aseptic filler for bag in drum or box

Enhance product shelf life and maintain quality without preservatives by employing as...

Aseptic linear doypack filler

Ensure extended shelf life and preserve quality in liquid food products with this high-speed a...

Rotary filler for preformed containers

Ensure microbiological safety and extended shelf life for your liquid products with ...

Scraped-surface heat exchanger for industrial fruit processing

Optimize your production with this advanced scraped-surfa...

Aseptic cooking and filling line with two reactors

Streamline your production with a versatile line that combines high-ef...

Forced circulation evaporator for high viscosity liquids

Optimize your production by efficiently concentrating viscous an...

Aseptic processing equipment for food products

Optimize aseptic processing to ensure microbiological stability and product...

Plate flash evaporator for high-viscosity and high-fouling fluids

Efficiently concentrate challenging high-viscosity an...

Flat belt product transfer conveyor for food processing

Efficiently streamline your production line with a hygienically d...

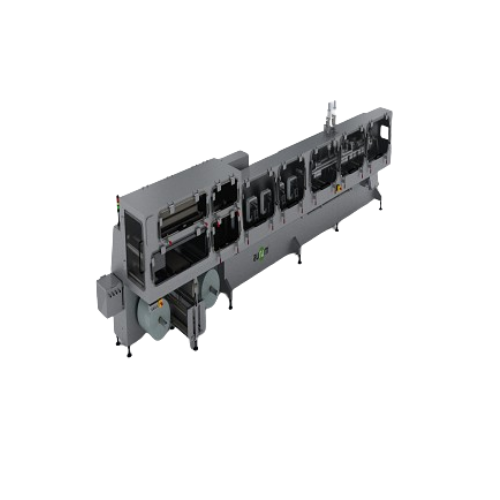

Linear conveyor tray sealing

Experience unparalleled flexibility and efficiency in tray sealing with high-speed integration,...

Flavor vats for ice cream and food production

Maximize your product line versatility with customizable flavor vats, design...

D-limonene extraction system for citrus processing

Enhance your citrus processing capabilities by efficiently extracting ...

Industrial extraction line for fruits and vegetables

Optimize your fruit and vegetable processing with a highly flexible ...

Basket tracking system for automated batch retort systems

Efficiently manage and monitor your batch processing with a sy...

Pump for products with large particulates

When handling products with large particulates, maintaining integrity is paramou...

Tube-in-shell heat exchanger for low viscosity products

Enhance your beverage and food processing efficiency with a cutti...

Multi-purpose laboratory sterilizer for food processing

Achieve precise thermal process design and flexibility with a ste...

Aseptic processing system for food products

Streamline your food processing line with an efficient aseptic processing syst...

Heat exchanger for dairy and beverage applications

Optimize your liquid product thermal processing by directly regenerati...

Heat exchanger for liquid and semi-liquid foods

Optimize your heating and cooling processes with superior heat transfer ef...

Aseptic flash cooling for tomato and fruit concentrates

Achieve seamless aseptic processing while minimizing product degr...

Cold break system for tomato processing

Enhance product quality and consistency in liquid processing by utilizing precise t...

High speed fruit and vegetable juicer

Optimize your production with a high-capacity juicer designed to efficiently process ...

Thermal treatment system for tomato purees

Eliminate pectin enzyme activity and prevent syneresis in your purees and conce...

Juice extractors for variety of fruits and vegetables

Streamline your juice and puree production with advanced extraction...

Screw finishers for citrus processing

Optimize your production line with screw finishers designed to efficiently separate l...

Vegetable and fruit processing skid

Optimize your fruit and vegetable processing with a compact skid that seamlessly integr...

High pressure food processing solution for medium-scale producers

Achieve reduced operational costs with high-pressure ...

Volumetric piston filler for liquid and viscous products

Achieve precise volume control and enhance product integrity wit...

Forced circulation evaporator for tomato and fruit paste

Optimize your high-viscosity tomato and fruit paste production w...

Hybrid evaporator for highly viscous tomato concentrate

Achieve superior concentration and energy efficiency with a versa...

Evaporator for citrus juice concentrate

Optimize juice concentration and reduce thermal damage with advanced short-time eva...

Aseptic filler for fluids, concentrates, and particulates

Optimize your fluid and concentrate filling process with a hig...

Aseptic filler for juices and beverages

Ensure sterile packaging with precision. This aseptic filler offers high-speed, con...

Aseptic bag filler for bulk containers

Eliminate spoilage events and ensure sterility in high-speed filling of bulk aseptic...

Forced circulation evaporator for highly viscous liquids

Optimize energy efficiency and minimize fouling in your evaporat...

Compact plate evaporator for temperature-sensitive products

Ensure optimal heat transfer and minimal space usage with th...

Clarifying decanter for starch recovery

Ensure optimal dewatering and separation of starch, pulp, and fibers with this high...

Industrial multifiller for fruit and vegetable salads

Need to efficiently fill diverse containers with fruit and vegetabl...

Continuous twin shaft paddle mixers for dust conditioning

Optimize your mixing process with twin shaft paddle mixers, en...

Grit classifier for wastewater treatment

Optimize your wastewater treatment process with a grit classifier that efficiently...

Fully automatic filling lines for liquids

Achieve precise dosing and filling of liquids with minimal cycle times using com...

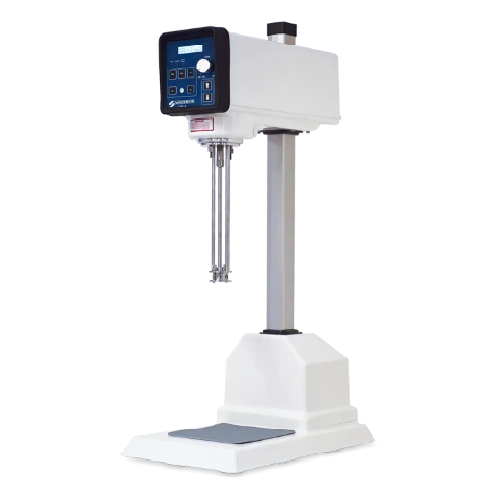

Homogenizer for low to medium viscosity media

Achieve uniform mixing and prevent air entrapment in low to medium viscosity...

Mechanical homogenizer for fine cutting and emulsifying

Achieve precise particle size control and consistent texture in y...

Inline mechanical homogenizer for food processing

Achieve precise particle size and uniform texture in your emulsions and...

Slicer for food processing applications

Efficiently achieve precise cuts and textures for a variety of food products, enhan...

Industrial particle size reduction processor

Optimize your production line with high-capacity, continuous particle size re...

Industrial food processor for diverse applications

Optimize your production line with a versatile processor capable of ch...

Industrial fruit bin washing system

Optimize your fruit and vegetable processing with a high-speed bin washing system that ...

Cucumber sorting and grading solution

Optimize cucumber handling with precise diameter, length, and shape sorting, enhancin...

Sanitary vessels for pharmaceutical applications

Ensuring the highest standards of aseptic processing, these sanitary vess...

Multifruit processing line for tropical and temperate fruits

Optimize your fruit processing operations with a versatile ...

Aseptic filler for fruit juice and dairy products

Ensure sterile, high-speed filling of liquids and creams with precision...

Aseptic sterilizers for fruit concentrates and pulp

Optimize your fruit processing by maintaining product quality and she...

Aseptic filler for fruit juices and purees

Ensure product integrity and shelf stability with a versatile filler designed t...

Banana purée production line

Maintain banana pulp quality by processing in a nitrogen atmosphere, ensuring fresh, oxidation-...

Aseptic storage tanks for food liquids

Ensure the sterility and quality of your liquid food products by utilizing advanced ...

Acai berry processing line

Enhance your acai berry production efficiency with an automated line that transforms traditional ...

Aseptic filler for various liquid and semi-liquid food products

For manufacturers focused on quality, this aseptic filli...

Aseptic filler for fruit juice and puree

Ensure optimal product safety and quality with this aseptic filler, designed to ha...

Single-serving blender for home use

Create smooth, nutrient-rich beverages and culinary delights effortlessly, whether you&...

Forming, filling, and sealing system for liquid food products

Achieve precise portion control and versatile packaging wi...

Tomato squeezer for efficient fruit and vegetable pressing

Streamline your fruit and vegetable processing with a versati...

Tomato squeezer for efficient food processing

Efficiently transform raw tomatoes and other fruits into smooth sauces and p...

Drum unloader for liquid ingredients

Streamline the unloading of viscous liquid ingredients with advanced water injection t...

Tubular heat exchanger for food processing

Optimize energy consumption and ensure unparalleled food safety during heat tre...

Indirect Uht treatment for high viscous products with particles

Optimize your production line with a unit that ensures h...

Continuous ultra-high temperature treatment for prepared food products

Optimize your prepared food production with cont...

In-line blender for beverage production

Enhance beverage production with a versatile solution that offers precise blending,...

Drum unloader for liquid ingredients

Unlock efficient unloading of viscous and liquid ingredients without the hassle of lif...

Contherm scraped-surface heat exchanger for viscous food products

Optimize your heating and cooling processes for stick...

Filling solution for water packaging

Achieve efficient packaging for a variety of beverages with this high-speed filling so...

Potato masher for making mashed potatoes

Transform cooked and raw ingredients into fine, uniform purees with precision. Ide...

Fruit pulping system for juice production

Optimize your fruit and vegetable juice production with a pulping system that en...

Rising/falling film plate evaporator for heat sensitive products

Efficiently concentrate heat-sensitive liquids with ris...

Scraped surface heat exchanger for high-viscosity products

Designed for handling high-viscosity products, this system en...

De-juicing unit for wine must processing

Optimize your winemaking process by effectively separating seeds and skins from wi...

High shear lab mixer for laboratory work and r&d

Achieve unparalleled precision and consistency in laboratory and pilot-sc...

Ketchup manufacturing line

Streamline your sauce production with precision-engineered efficiency, allowing for seamless reci...

High-speed moisture analyzer for liquid and pasty samples

Ensure precise moisture analysis with rapid microwave drying, ...

Sausage production line with in-line cutting system

Efficiently achieve precise portion control and separation in sausage...

Portioning and filling system for sausage production

Achieve precise portioning and efficient filling for a diverse range...

Industrial vacuum filler for large-scale food production

Enhance your production efficiency by integrating a vacuum fille...

Frontal discharge mixer for meat processing

Enhance your mixing process with an efficient solution that seamlessly combine...

Industrial grinder for fresh meat and food products

Optimize your fresh food processing with a versatile grinding solutio...

Marmalade and Jam Processing Machine

When producing jams and marmalades, preserving the natural flavours, aromas and colors...

Concentrator for fruit puree preparation

Fruit puree is often an ingredient of various fruit-flavored yogurts, which someti...

Vacuum and pressure cooker for fruits and vegetables

When producing fruit-based products such as marmalades or ice cream ...

Industrial vacuum cooker

Batch cookers can be highly inflexible and inefficient, relying on maximum fill levels to operate we...

Hygiene washer for food utensils

Thorough and quick cleaning of kitchen utensils, such as baskets, knives, trays, and other ...

Tunnel washer for food containers

With an increase in demand for production across food service and manufacturing companies...

Vacuum based homogenizer

When producing liquid and viscous products such as mayonnaise, sauces, dressings and ketchup it’s vi...

Fruit pulping machine

When making fruit pulp, a pulping machine helps you remove seeds, stems, and skins from your fruit. How...

Food processor for making fruit jams for pastries

In a bakery environment fruit jams are often used for the decoration or...