Essential Oil Production Equipment

Find innovative essential oils equipment and connect directly with world-leading technology suppliers

Essential oils are known as the liquid gems of nature. The sweet-smelling essences impact not just our senses but also our biochemical and cellular make-up. Besides aromatherapy, the products of an essential oil extraction system found applications in pharmaceuticals and foods.

Innovative technology solutions for essential oils

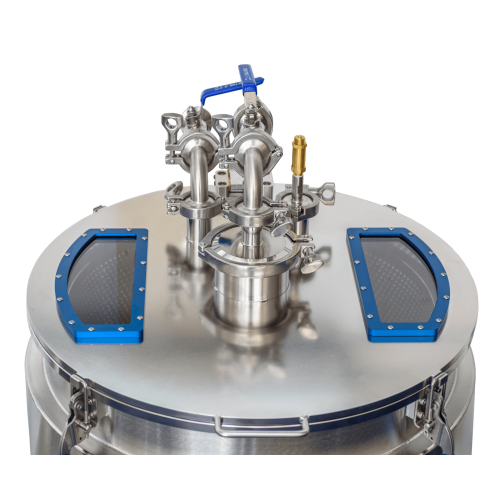

300l stainless steel dual-jacketed reactor for winterization

Enhance your extract processing with precision temperature ...

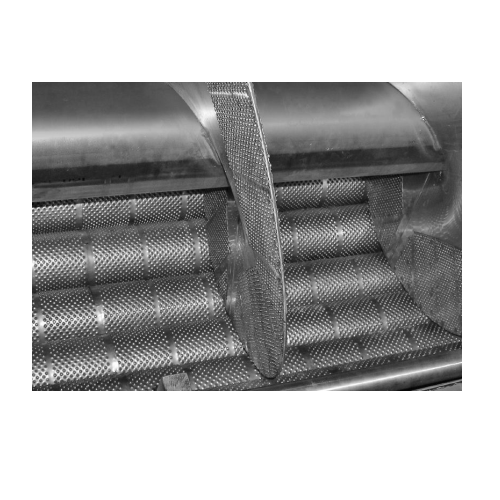

Essential oil extraction from citrus fruit peel

Optimize your citrus fruit essential oil extraction process with a versati...

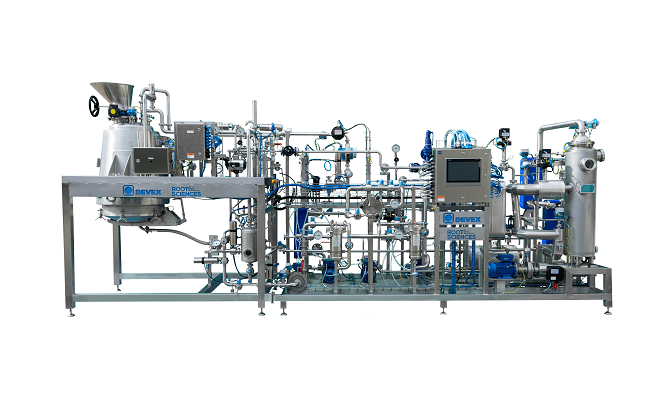

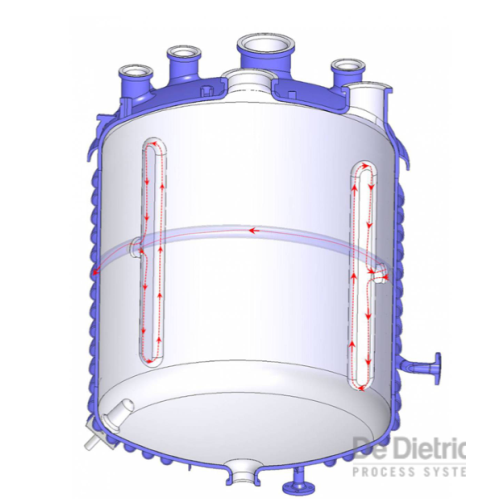

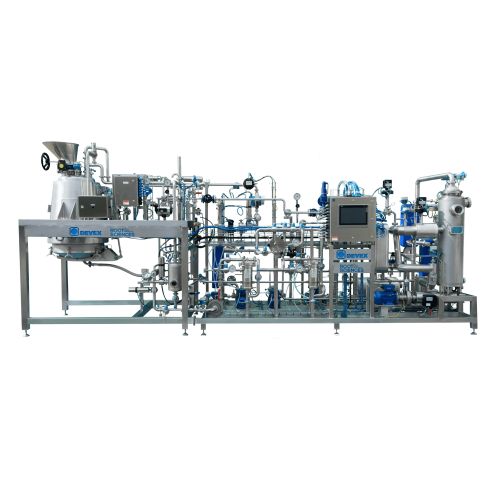

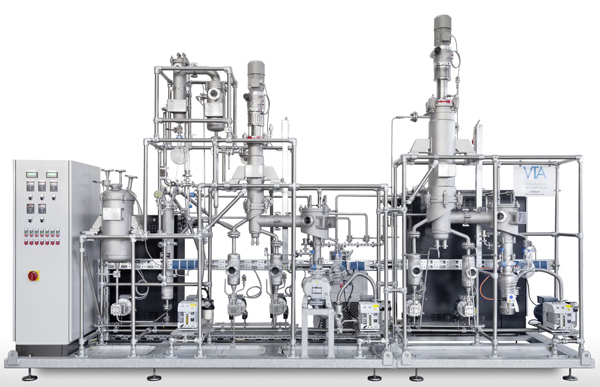

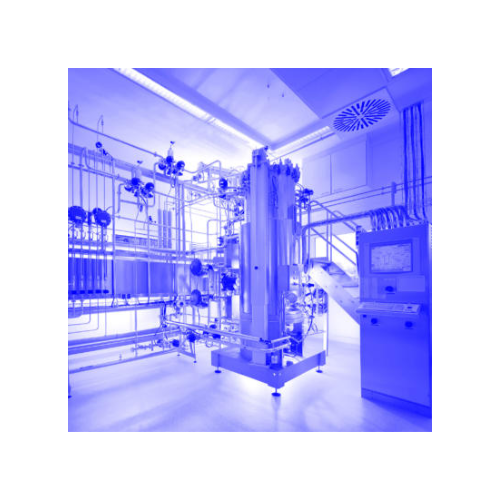

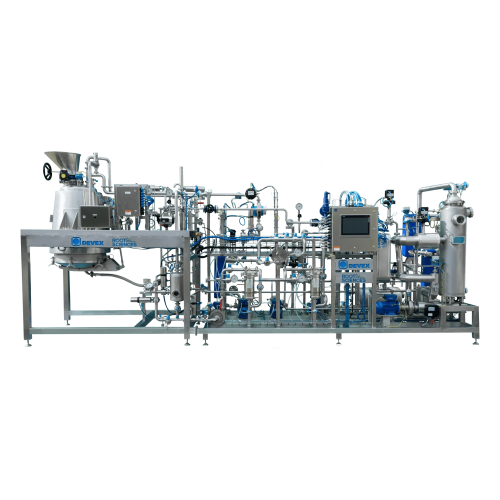

Extraction plant for natural ingredients

Bespoke extraction plants using the latest technology can improve your efficiency ...

What are you making?

Tell us about your production challenge

Keep temperatures to a minimum in the hydrodistillation process

Hydrodistillation techniques employ hot water to isolate the essential oil from the aromatic plant. In the case of extraction by thermal decomposition, you heat a mixture of water and plant material allowing the oils to evaporate. However, since almost all constituents of essential oils are unstable at high temperatures, heat levels need to be kept to a low.

The vapor is then liquefied in a condenser and collected in a tank. The immiscibility of water and oil forms a natural separation of the two liquids. High extraction temperature can lead to thermal decomposition reactions of some plant constituents.

Essential oil extraction system using microwave technology

Microwave-Assisted Extraction (MAE) applies heat to the plant’s cell wall through radiation. The technology hits the raw material with non-ionizing electromagnetic waves at frequencies between 300 MHz to 300 GHz.

The cells swell up, causing the plant walls to rupture and the oils to leach out. Essential oil extraction systems using MAE may be either closed or open units. Closed systems reach a maximum power range between 600 W and 1000 W, while open systems operate at around 250 W.

Fill up your storage tanks to prevent oxidation

Storing the essential oil in half-filled tanks exposes the material to oxidization and may trigger a change in its chemical profile.

At low temperatures, oxidation is driven by peroxyl radicals and hydroperoxides. On the other hand, as high temperatures reduce oxygen availability, the process is caused by alkyl or hydroxyl radicals.

The antimicrobial properties of essential oils can be formulated into pesticides.

Essential oils perform several pharmacological activities, such as antifungal and antimicrobial effects. The extracts are being used as protective additives in crop production. Their natural antioxidant properties can control fungi growth in cereals and other agricultural produce.

Biocides made from essential oils can be combined with conventional pesticides to extend the shelf lives of traditional fungicides.

Which essential oils technology do you need?

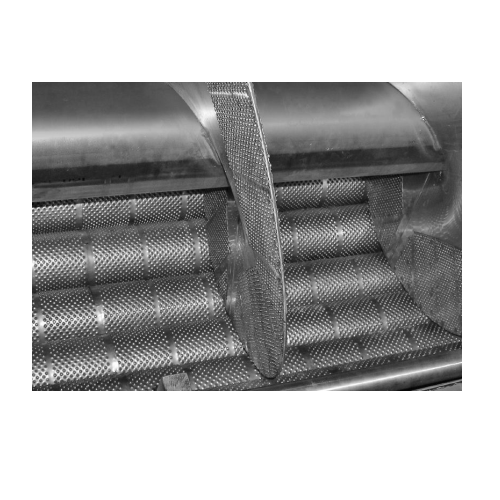

Wiped film evaporator for high boiling point materials

For challenging separations of high boiling, viscous, or heat-sens...

Rolled film distillation system for cannabis oil refinement

Achieve high-quality cannabis distillates with impressive cl...

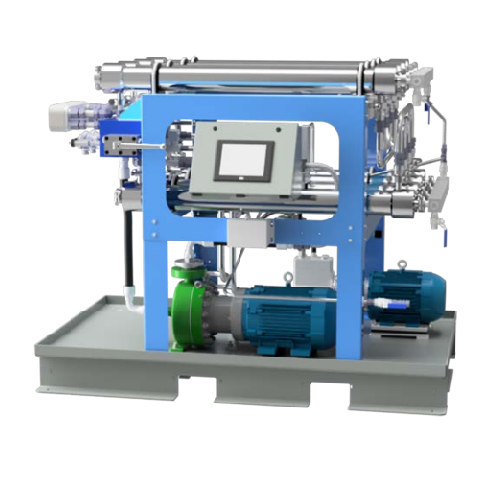

Filtration skid for ethanol extraction of cannabis and hemp oil

Enhance the clarity and color of your ethanol-extracted ...

Falling film evaporator for botanical oil separation

Optimize your ethanol recovery and botanical oil production with hig...

Rectification column for close boiling point separation

Achieve high-purity separation and distillation for compounds wit...

Oilseed cooker/conditioner for optimal seed preparation

Achieve consistent oil extraction and enhanced product quality wi...

Industrial oil degumming process

Achieve optimal oil purity and maximize yield with this advanced system designed to streaml...

Hemp Cbd oil extraction system

Achieve maximum CBD oil recovery while maintaining product purity with scalable extraction ca...

Mineral oil absorption system for solvent vapor recovery

Optimize solvent recovery and reduce atmospheric emissions with ...

High-volume oilseed extraction system

Achieve optimal extraction efficiencies with a versatile system that handles various ...

Two-phase decanter centrifuge for olive oil production

Achieve optimal clarity and yield in olive oil extraction with a h...

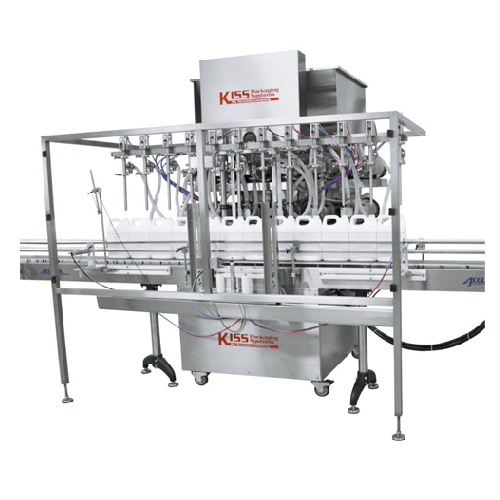

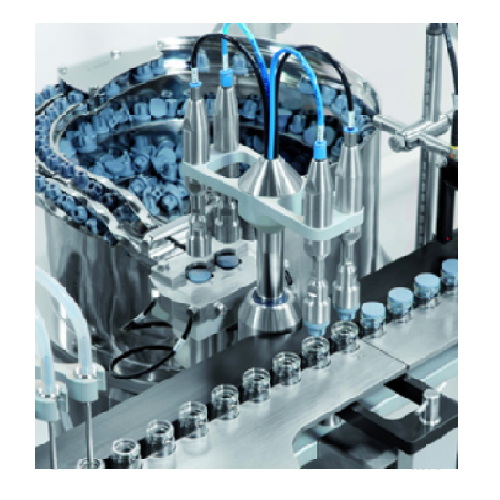

Auto-indexing filler for aqueous solutions and light oils

Streamline your bottling process with this six-head filler, pe...

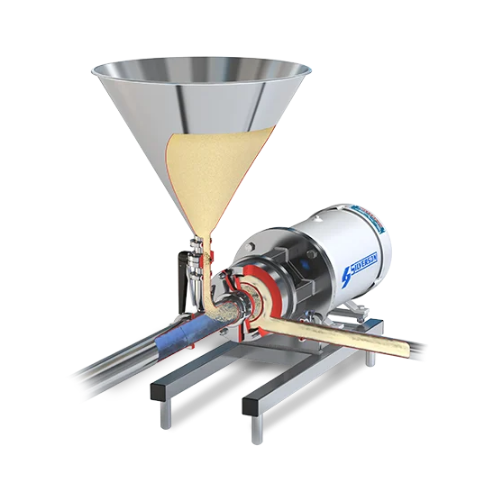

Modular oil recovery extractor for citrus essential oils

Achieve maximum yield and purity in citrus essential oil extract...

Reboiler for distillation plants

Efficiently manage energy input and temperature control in your distillation processes with...

Essential oil extraction from citrus fruit peel

Optimize your citrus fruit essential oil extraction process with a versati...

Cannabis oil nanofiltration system

Achieve high-purity cannabinoid extracts with advanced nanofiltration, ensuring precise ...

Fully certified CBD crude oil extraction machine

Traditional extraction processes involving hot solvent (ethanol) or Co2 m...

Flower oil extraction machine

The production of “essential oils” has traditionally involved using heat and distillation to e...

Pharma extraction clarifier

Achieve superior purity in pharma extraction with efficient separation of solids and liquids, se...

Vacuum cold trap for lab applications

Ensure efficient separation and purification in biopharmaceutical applications with t...

Pressure control monitor for laboratory vacuum systems

Effortlessly maintain precise vacuum pressure in your lab operatio...

Diaphragm vacuum pumps for laboratory applications

Optimize your lab processes with oil-free diaphragm vacuum pumps, ensu...

Fraction finder for optimized fractional distillation

Achieve unparalleled precision in your distillation process with a ...

Gas compressor for solvent recovery in hydrocarbon extraction

Need efficient, explosion-proof gas recovery for butane or...

Heating mantle system for round bottom glassware

Optimize your lab’s heating and stirring processes with a snug-fit system...

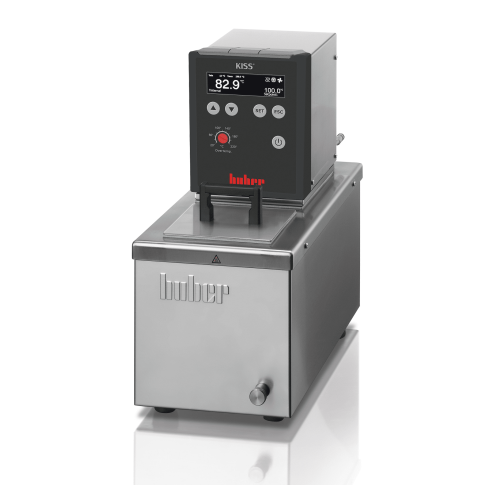

Heated circulator for laboratory temperature control

Achieve precise temperature control for demanding applications like ...

Immersion chiller for laboratory applications

Achieve precise temperature control in extraction labs and research environm...

Dry scroll vacuum pumps for laboratories and manufacturing

Ensure a clean, oil-free environment with advanced dry scroll...

Continuous feed solvent evaporator for cannabis and hemp industries

Streamline your extraction process with a system de...

Moisture analyzer for precise and reliable measurements

Ensure precise moisture control in high-value products like lyoph...

Color remediation column for cannabis extracts

Ensure the purity of your cannabis extracts by efficiently removing contami...

Digital vapor temperature monitor for fractional distillation

Achieve precise temperature monitoring during fractional d...

2-stage rotary vane vacuum pump for laboratory applications

Ensure reliable and efficient vacuum conditions for distilla...

2-stage rotary vane vacuum pump for distillation processes

Achieve precise control and efficiency in distillation and fr...

Vertical leaves pressure filter for wine and viscous liquids

Ensure optimal clarity and consistency in your liquid produ...

Automatic bottle and vial blower

Ensure purity and compliance in your liquid bottling line with this integrated blowing syst...

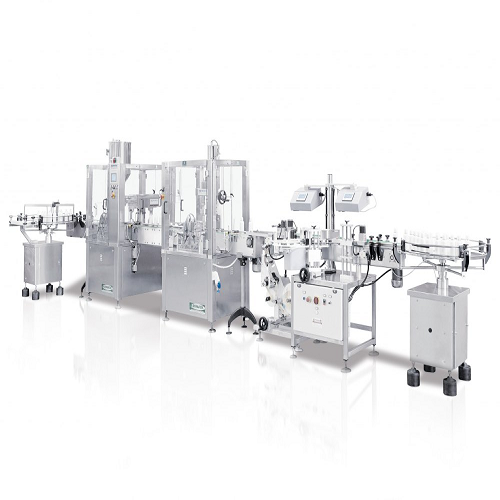

Bottle filler and capper

Achieve precise liquid filling and secure capping with high-speed, intermittent motion, ensuring con...

Volumetric filling system for cosmetic products

Streamline your production line with precise volumetric control, ensuring ...

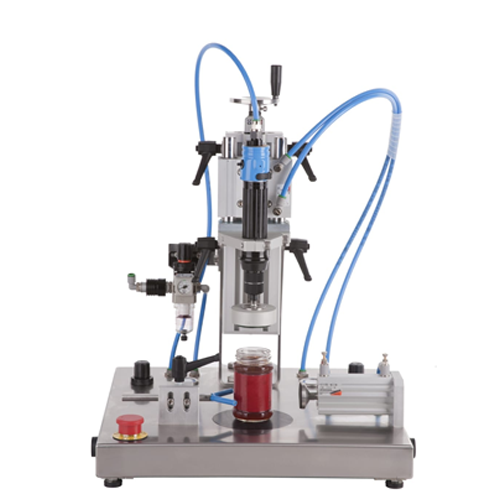

Jar sealing system for plastic and glass containers

Achieve precise and efficient sealing of plastic and glass jars with ...

Semi-automatic capper for twisting and screwing metal and plastic caps

Effortlessly achieve precise cap tightening with...

Industrial sheet filter for liquid filtration

Optimize your liquid product purity with precise filtration, maintaining int...

Vacuum rotary filter for liquid filtration

Enhance your production line’s efficiency with precise filtration, ensuri...

Lab nutsche filter for small scale filtration

Efficiently manage filtration and drying needs in fine chemical and pharmace...

Spouted bed processing for food, feed, and fine chemicals

Tackle the challenge of processing temperature-sensitive and s...

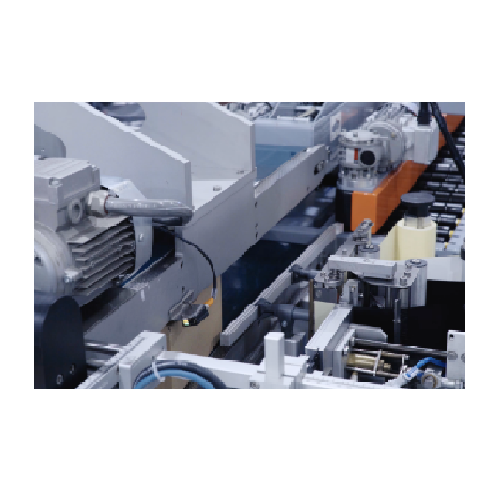

Complete bottling lines for beverage industries

Optimize your bottling process with high-speed, precision-engineered lines...

Industrial liquid filler for small to medium volume operations

Ensure accuracy and efficiency in liquid formulation with...

Liquid dosing system for powders and granulates

Achieve precise liquid addition with this dosing system, ideal for integra...

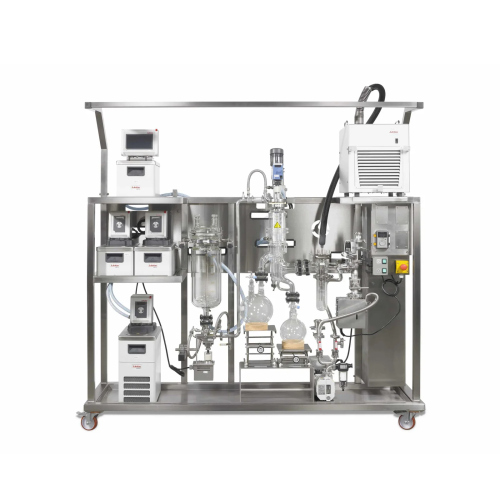

Portable ethanol extraction processing lab

Accelerate your extraction process with a fully portable and compliant lab solu...

Extraction plant for natural essences and active ingredients

Optimize your extraction processes with a versatile system ...

Thermal process plants for liquid treatment

Achieve precision thermal processing with systems designed to optimize the hea...

Ethanol alcohol extraction system for botanical compounds

Achieve high-purity extractions efficiently with a closed-loop...

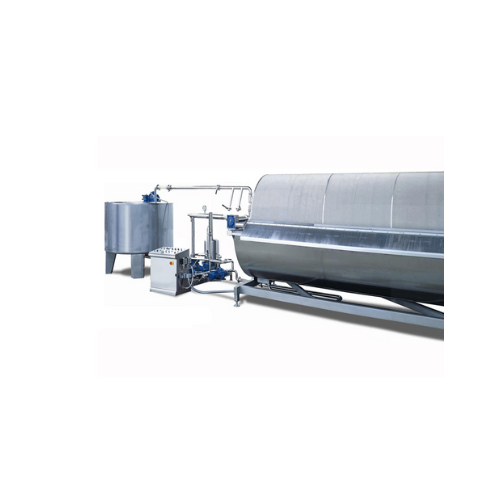

Rotary vacuum filters for wine and beverage filtration

Efficiently filter and clarify wines, juices, and industrial fluid...

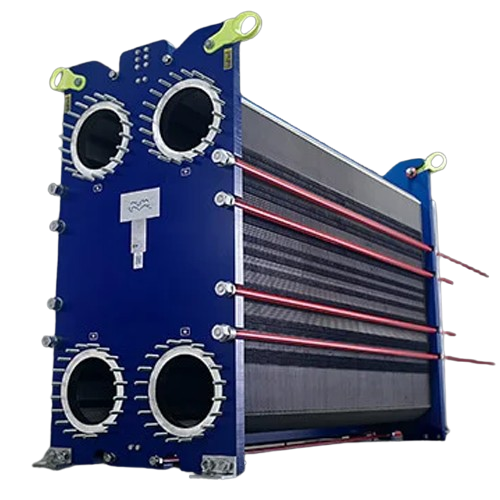

High performance heat transfer system

Enhance your production efficiency with a system that shortens cycle times by increas...

Heat exchanger for corrosive substance handling

Optimize your process of handling corrosive substances with a heat exchang...

12l solid/liquid extractor for pilot plant solutions

Optimize your extraction processes with a versatile extractor that a...

Solid/liquid extraction system for industrial applications

Optimize your solid-liquid extraction needs with a compact mu...

Supercritical Co2 extraction system

Optimize your extraction processes with environmentally friendly and efficient supercri...

Percolation extractor for high-volume vegetable protein extraction

Optimize extraction efficiency across diverse materi...

Seed hull removal and condition system

Optimize your seed processing efficiency by effectively removing hulls and foreign m...

Dryer-cooler for solvent-extracted meal

Achieve optimal moisture and temperature control for solvent-extracted vegetable-oi...

Continuous motion liquid filling and capping monobloc

Optimize high-speed liquid filling with seamless transitions from f...

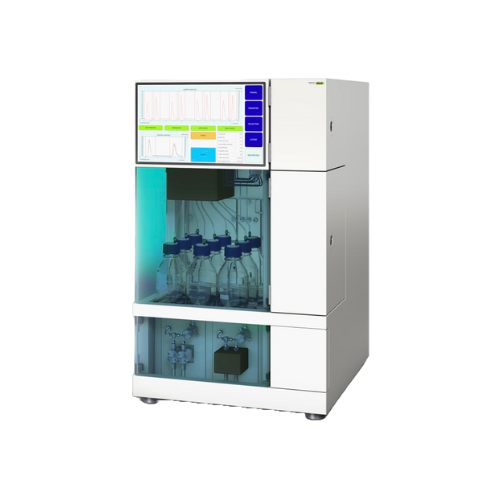

Supercritical fluid chromatography system for preparative separations

For complex substance formulations requiring rapi...

Recirculating chiller for evaporation and extraction

Streamline your laboratory processes with a chiller that efficiently...

Citrus juice extractor

Achieve unparalleled juice purity and essential oil separation with a system that elevates your fruit ...

Filling and closing solution for plastic bottles

Efficiently sort, fill, and close a variety of plastic bottles with preci...

Linear filling and capping for stable bottles

Enhance your production efficiency with a solution designed for precise liqu...

Centrifugal evaporator for medicinal chemistry

Achieve precise evaporation and crystallization with innovative anti-bumpin...

Solid/liquid extractor for high-yield functional nutrient extraction

Maximize extraction efficiency and elevate product...

Olive paste preparation crushers

Optimize oil yield and flavor quality with crushers designed for efficient olive paste prep...

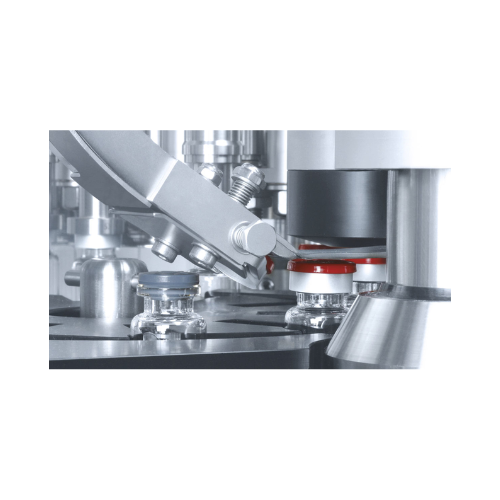

Compact filler and closer for vial processing

Efficiently streamline your vial filling and closing processes with a compac...

Automatic flowmeter filler for liquid packaging

Streamline your liquid production with precise filling capabilities, reduc...

Drum decanting unit for high viscosity liquids

Efficiently decant high viscosity liquids like solvent-based paints and ess...

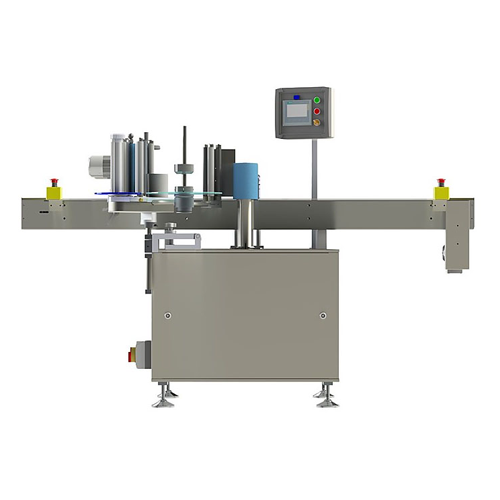

Compact wraparound labelling system for bottles

Streamline your packaging process with a fast and reliable wraparound labe...

Pneumatic bottle capping solution

Efficiently secure a variety of bottle caps with ease, using a pneumatic system that acco...

300l stainless steel dual-jacketed reactor for winterization

Enhance your extract processing with precision temperature ...

Ice water extraction system for solventless extract production

Optimize your plant-based extraction processes with a mod...

Decarboxylation package for botanical extraction

Optimize decarboxylation and reaction processes with precise temperature ...

Decarboxylation package for botanical extraction

Ensure precise temperature control and efficient reaction conditions in y...

High-temperature forced convection oven for drying and sterilization

Achieve precise drying and sterilization for sensi...

50l jacketed glass reactor with explosion-proof motor

Enhance your reaction processes with precise temperature and pressu...

50l jacketed glass reactor for synthetic reactions

Achieve precise control over chemical reactions and material synthesis...

Dual-jacketed reactor for decarboxylation processes

Streamline your decarboxylation process with a dual-jacketed reactor ...

50l stainless steel dual-jacketed reactor for chemical processes

Optimize your laboratory’s efficiency with a dual...

100l laboratory jacketed glass reactor

Optimize your batch processing with this 100L jacketed glass reactor, designed for p...

10l glass reactor system for synthetic reactions

Achieve consistent reaction control with efficient temperature and vacuum...

150l jacketed glass reactor for chemical synthesis

Achieve precise control over complex chemical processes with this sing...

20l jacketed glass reactor system for laboratory synthesis

Achieve precise chemical synthesis and enhanced material reco...

Large capacity jacketed glass reactor

Achieve precise control over temperature and vacuum conditions with this versatile re...

2l single jacketed glass reactor system

Enhance your laboratory’s efficiency with a versatile reactor system, ideal f...

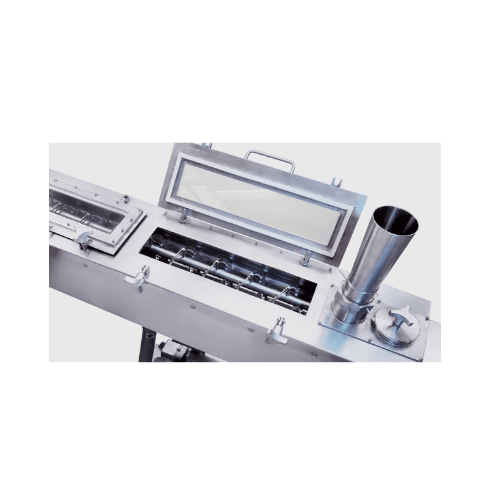

Liquid capsule filling for r&d and pilot-scale production

Optimize liquid capsule production with a compact machine that...

Automatic timed flow volumetric filling machine

Streamline your liquid packaging process with precise volumetric filling o...

Rotary overflow filler for non-carbonated liquids

Achieve precise fill levels effortlessly with a high-speed rotary overf...

High precision automatic mini dose filler

Achieve unparalleled precision when filling small volumes, from 0.1 ML to 200 ML...

Semi-automatic volumetric piston filler

Achieve precise filling of diverse liquids and viscous products while minimizing wa...

Accurate net weight filling for liquid and semi-liquid products

Ensure precise filling of diverse viscosities, from thin...

Semi-automatic timed flow filler for aqueous solutions

Handle diverse liquid filling needs with precision, from thin oils...

Semi-automatic overflow liquid filler

Optimize your production line with a reliable filling solution for low to medium visc...

D-limonene extraction system for citrus processing

Enhance your citrus processing capabilities by efficiently extracting ...

Citrus juice finisher

Optimize your juice and essential oil production with precision separation and finishing technology, en...

Spray cooler for food and chemical industry applications

Achieve precise particle size control and encapsulation for melt...

Batch distillation plants for diverse compound mixtures

Optimize your separation processes with flexible batch distillati...

Industrial distillation testing services

Ensure optimal purity and performance by utilizing advanced pilot and mobile disti...

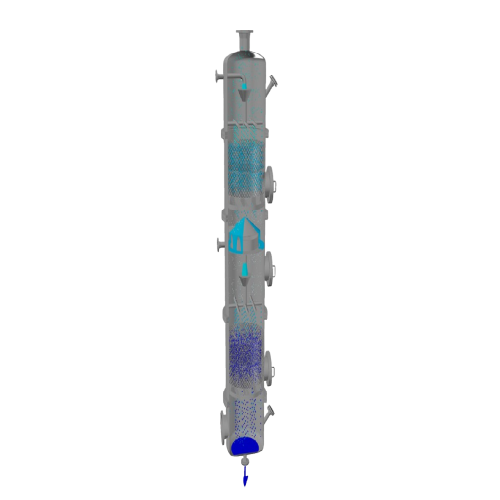

Industrial tray and packing column solutions

For efficient separation and product purification, tray and packing columns o...

Solid-wall bowl separators for pharma extraction

Optimize your extraction processes with precision solid-wall bowl separat...

Pharmaceutical drops and sprays filling system

Streamline your liquid formulation process with precision filling and seali...

Direct drive centrifuges for dairy and beverage processing

Optimize energy efficiency in high-speed liquid separation wi...

Self-cleaning separator for industrial liquid/solid separation

Optimize your production line with self-cleaning separato...

Self-priming centrifugal pump for entrained air handling

Effortlessly manage entrained air and foam in fluid processing w...

Mechanical vapor recompression evaporator for pre-concentration in food industry

Achieve efficient energy use by utili...

Centrifugal evaporators for medicinal chemistry

Streamline your solvent evaporation and drying processes with this solutio...

Automated centrifugal evaporator for robotic sample handling

Streamline your laboratory workflows with this cutting-edge...

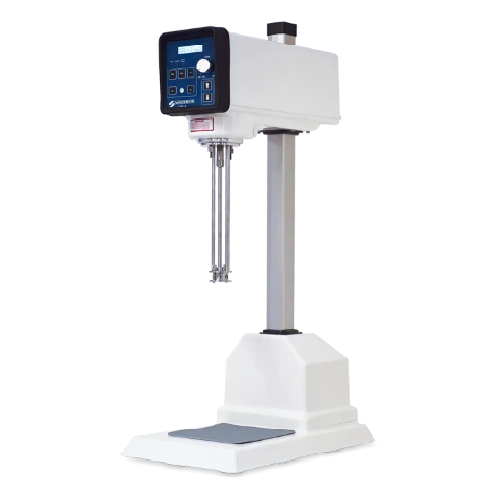

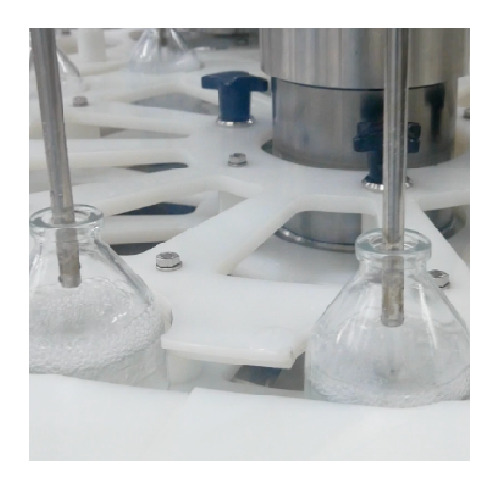

Laboratory in-line mixer for precise mixing and reproducibility

Achieve precise laboratory-scale mixing with rapid proce...

Automatic labelling system for pharmaceutical vials

Ensure precise and efficient packaging for cylindrical containers wit...

Automatic labelling system for pharmaceutical vials and bottles

Optimize your bottle labelling process with precision al...

Industrial vacuum batch dryer for reducing moisture content

Achieve precise moisture control with a solution that handle...

Wiped-film short-path distillation equipment for cannabis processing

Achieve up to 99% cannabinoid purity with this dis...

Cannabis and hemp processing nanofiltration system

Enhance the clarity and potency of your extracts with advanced membran...

Membrane nanofiltration for cannabis and hemp processing

Optimize your extraction processes with advanced nanofiltration,...

Solvent recovery and decarboxylation system

Enhance solvent recovery and streamline decarboxylation processes with an inno...

Custom distillation builds for cannabis processing

Achieve precise cannabinoid separation and purity in large-scale disti...

Short-path wiped-film distillation for cannabis

Achieve optimal cannabinoid purity with precise thermal separation, perfec...

Cold processed ethanol extraction system

Streamline your extraction process by integrating an all-in-one system that combin...

Hydrocarbon extraction system for cannabis

Optimize your cannabis concentrate production with a flexible hydrocarbon extra...

High capacity cannabis cryo-ethanol extraction line

Boost extraction efficiency with high-capacity cryo-ethanol technolog...

High-speed decanting centrifuges for solid-liquid and liquid-liquid separation

Optimize your separation processes with...

Evaporator for heat sensitive products

The removal of solvents when making products in industries like food, cosmetics, pha...

Cosmetic cream filler

From thin liquid baby oils and perfumes to thicker lotions and creams for hair and skincare, cosmetic p...

Medicinal plant extraction machine

Traditional methods for extracting active compounds from medicinal plants or herbs use h...

Extraction plant for natural ingredients

Bespoke extraction plants using the latest technology can improve your efficiency ...

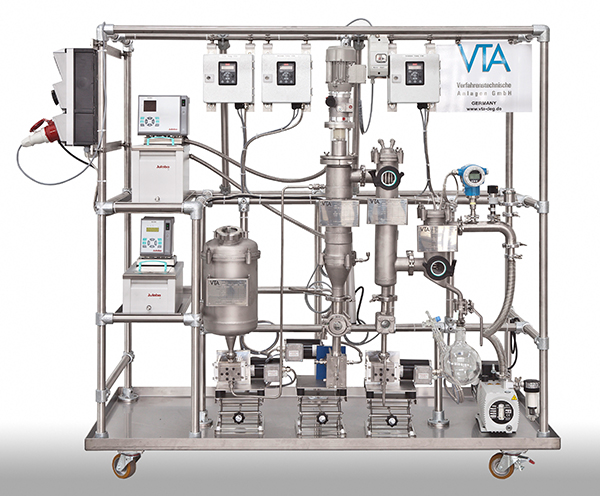

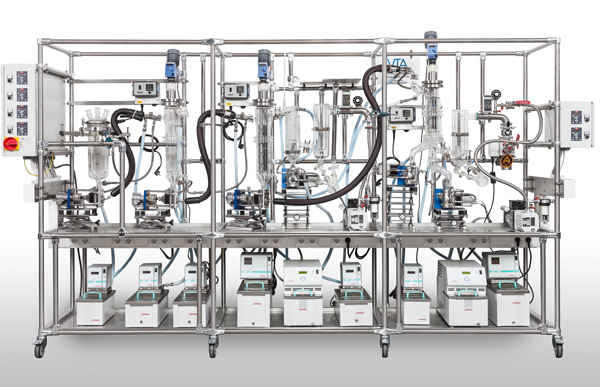

Pilot extraction plant for natural ingredients

Before purchasing a full-scale extraction plant you need to exactly determi...

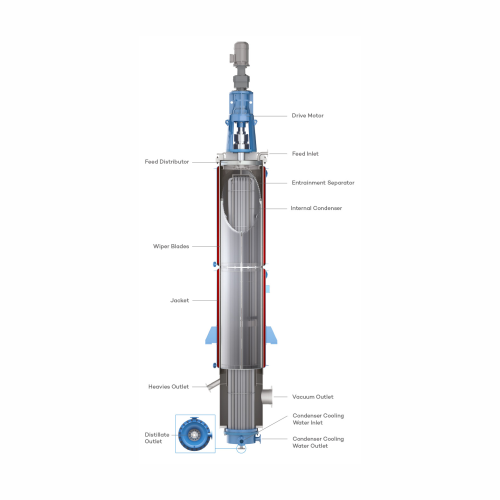

Wiped film evaporator

With wiped film distillation, a substantial decrease of boiling temperature is obtained by reducing the...

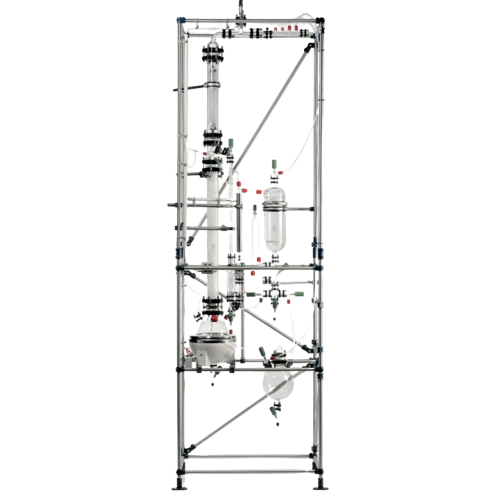

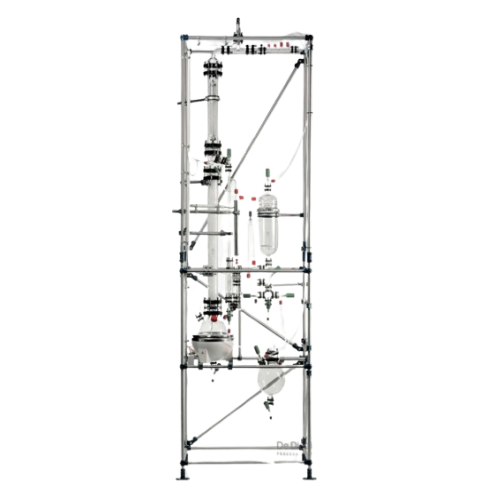

Pilot multi-stage distiller

If generating an scalable data and bring in results with small sample quantities of high-boiling...

Pilot wiped film distiller

Generate scalable data and results during the pilot tests with wiped film distillation, distill ...

Pilot short path distiller

Generate scalable data and results during the pilot tests with short path distillation, distill o...

Laboratory multi-stage distiller

A laboratory multi-stage distillers that combines the wiped film and short path distillatio...

Laboratory wiped film distiller

Reach reliable conclusions testing the distillation of high-boiling or highly viscous materi...

Laboratory short path distiller

Get to reliable conclusions for the separation of high-boiling and heat-sensitive products u...

Short path evaporators

With short path distillation, a substantial decrease of boiling temperature is obtained by reducing th...

Clarifiers for biochemical separation

Achieve seamless liquid-solid separation with high-speed disk-type clarifiers, ensuri...

Clarifier for beverages

Enhance beverage clarity and purity with high-performance centrifugal separation, expertly designed t...

Spray dryer performance optimization system

Achieve unparalleled spray drying efficiency with real-time monitoring and con...

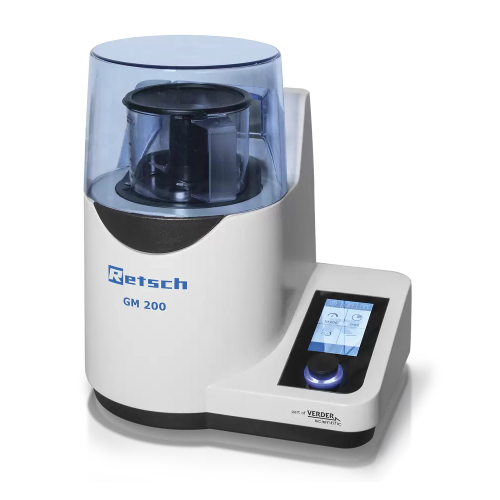

Knife mill for food and feed sample grinding and homogenization

Achieve consistent texture and precise size reduction of...

Vacuum cold trap for efficient purging and drying

Optimize your laboratory’s efficiency by integrating high-perform...

Laboratory heated circulator for precise temperature control

Achieve precise temperature control for your liquid formula...

Hydrocarbon solvent distillation unit for extractors

Ensure high purity levels in your extraction process by integrating ...

Laboratory vacuum cold trap for extract purification

Optimize your vacuum purging and drying applications with this advan...

Deep water bucket bath for lab heating applications

Achieve precise temperature control and uniform heating for delicate ...

Digital stir controllers for laboratory applications

Achieve precise stirring and mixing control with this digital soluti...

Laboratory automation software for distillation and extraction

Optimize your distillation and extraction processes with ...

Automatic bag folding solution for bulk packaging

Enhance your production line efficiency and product protection by integ...

Pneumatic and electric lift for industrial mixing tanks

Enhance operational efficiency and safety with versatile lifts fo...

Mounting configurations for industrial agitators

Optimize your mixing processes with versatile agitators designed for effi...

High shear mixer for emulsification

Achieve precise emulsification and dispersions with magnetic high shear technology, ens...

Versatile magnetic mixer for pharmaceutical and biotechnology applications

Optimize your biopharmaceutical mixing proc...

Automatic horizontal cartoning solution for various products

Optimize your packaging line with this advanced cartoning s...

Jars and bottles rinsing solution

Ensure impeccable hygiene and particle-free cleanliness for your jars and bottles by inte...

High pressure homogenizer for pharma applications

Achieve precise particle size reduction and stability in liquid formula...

Industrial ultrasonic liquid processor for high volume applications

For large-scale liquid formulations, achieving cons...

Industrial skids for liquid processing

Efficiently manage large-scale liquid and solid processing in your production line w...

In-line high shear mixing solution

Achieve precise emulsification and particle size reduction with high shear capabilities,...

Positive displacement gear pump liquid filler

Optimize your liquid filling operations with precision gear pump technology,...

Discharge systems for difficult bulk materials

Achieve seamless bulk material discharge with our advanced systems that eff...

Foreign matter detection for syrup and medicine bottles

Ensure the quality and safety of your liquid products with precis...

Full container inspection for pharma and food industries

Ensure precise fill levels and secure closures in your productio...

Industrial continuous distillation system

Enhance product purity and efficiency with a robust continuous distillation syst...

Glass-lined mixing systems for pharmaceutical industry

Achieve consistent mixing and thorough agitation for complex formu...

Asme glass-lined reactors for chemical processing

Optimize your chemical processes with high-pressure, corrosion-resistan...

Cooked ham steaker

Achieve precise meat texture and uniformity with solutions designed for controlled cutting and pressing. I...

Schnitzel tenderizer with adjustable cutting pressure

For precise meat preparation, equip your production line with a sch...

Vacuum marinater for meat production

Streamline your marinating process with precise vacuum control, enhancing flavor absor...

Emulsifying plant for pasty and liquid products

Optimize your production line with seamless emulsification processes, desi...

Heavy duty rotary valves for powder handling

Ensure precise material flow and safety in harsh processing environments with...

Double shaft powder batch mixer

Achieve high homogeneity and gentle handling with a double shaft mixer designed for efficien...

Quick-clean hygienic rotary valves

Ensure seamless cleaning and minimal downtime in your production line with rotary valves...

Hygienic flexible sleeves for food and pharmaceutical use

Say goodbye to contamination risks with this tool-free, quick-...

Fermenter for microbial fermentation processes

Optimize your fermentation and biopharmaceutical production with stainless ...

Vacuum dryer for free-flowing and pasty solids

Achieve precise drying and mixing with this vacuum dryer, optimizing heat t...

Pharmaceutical reactor for efficient cleanability

Optimize your production with this reactor, designed for efficient mixi...

Big bag emptying station for powder handling

Ensure safe and efficient powder discharge with precision containment, adapta...

Rotary evaporator for solvent evaporation

Achieve precise solvent recovery and concentration control with this rotary evap...

Condensation and separation unit for solvent handling

Enhance solvent management and VOC recovery with this compact conde...

Universal dryer for herbal medicine production

Ensure optimal drying of plant-based pharmaceuticals, achieving precise moi...

Solid/liquid extraction unit for process development

Optimize your extraction processes with flexible operation modes for...

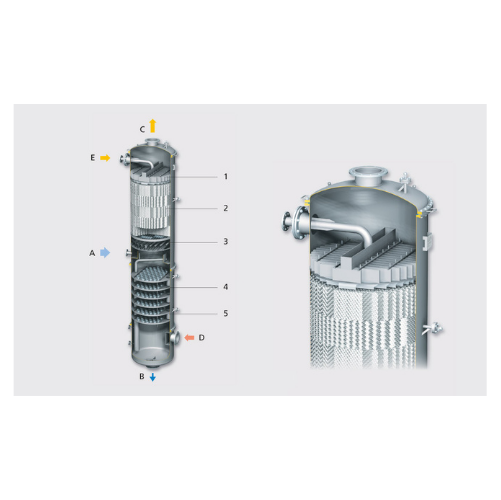

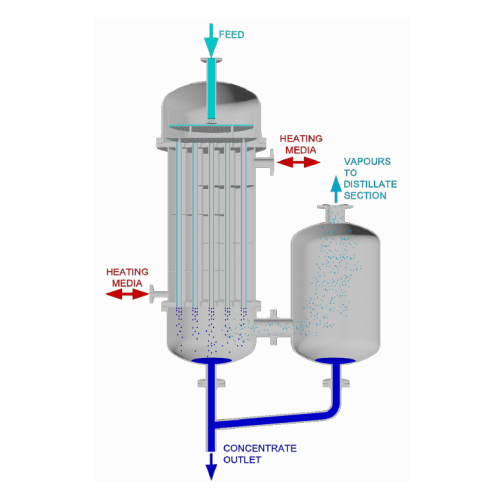

Falling film evaporator for thermal separation

Optimize energy efficiency in separation processes by utilizing gravity-dri...

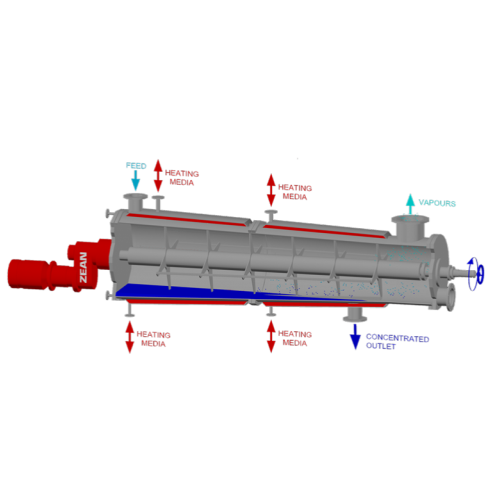

Horizontal thin film evaporator for continuous distillation

Experience precise control over evaporation and distillation...

Large-scale industrial freeze dryer

Achieve precise moisture control and preserve product integrity with a large-scale free...

Laboratory oven for accurate thermal processing

Achieve precise thermal control for sensitive formulations, ensuring consi...

High speed continuous motion liquid filling and capping system

Achieve high-speed, precision filling and capping for liq...

Volumetric filling and capping system for pharmaceuticals

Optimize your liquid filling and capping operations with a ver...

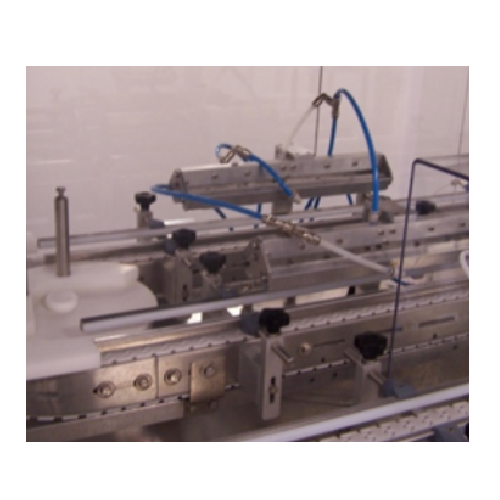

Linear intermittent motion filling system for high-density liquids

Ensure precise dosing of high-density liquids like c...

Rotary continuous motion bottle cleaning solution

Ensure pristine product integrity by effectively eliminating particles ...

High-speed continuous motion horizontal cartoner

Achieve seamless high-speed cartoning with precision cartoner systems des...

Industrial rotary evaporator for distillation

Optimize your distillation efficiency with a solution designed for precise c...

Rotary evaporation for laboratory applications

Achieve precise evaporation and concentration with modular, high-speed rota...

Industrial fume scrubber for safety compliance

Enhance workplace safety by efficiently neutralizing hazardous fumes and va...

Parallel sample evaporator

Process multiple samples efficiently with precise control, ensuring quick evaporation and consist...

Industrial recirculating chiller for laboratory applications

For consistent distillation results, maintain accurate temp...

Industrial rotary evaporator for large-scale distillation

Ideal for scaling up laboratory processes, this robust rotary ...

Versatile steam distillation unit for laboratory applications

Achieve reliable analysis of complex samples with this ste...

High-speed tubular centrifuges for liquid-solid separation

For efficient component separation in high-viscosity fluids, ...

Organic solvent nanofiltration for liquid separation

Optimize your process streams with solvent recovery that minimizes e...

Bioreactors for cell culture processes

Efficiently cultivate sensitive cell lines with customizable bioreactors designed to...

Lab-scale fermentors for microbial cultivation

Optimize microbial cultivation with lab-scale fermentors designed for preci...

Industrial solutions for cap closures on bottles and containers

Achieve precise sealing for diverse bottle types with ou...

Pharmaceutical container closing solution

Ensure precise capping and inspection of pharmaceutical containers, reducing con...

Automated filling and closing system for vials and bottles

Optimize your vial and bottle filling line with precise liqui...

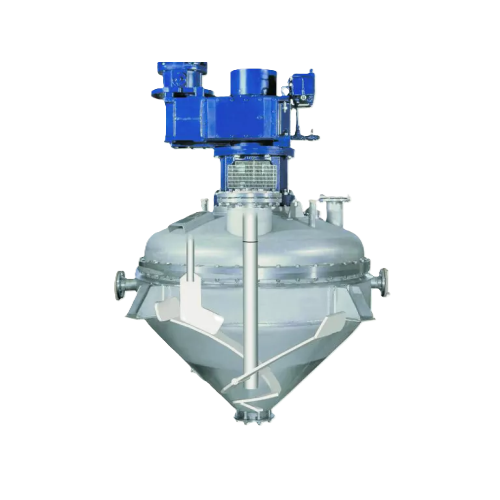

Agitated nutsche filter dryer for solid-liquid separation

Achieve high-purity solid-liquid separation with optimized thr...

Shell and tube heat exchangers

Efficiently manage heat transfer in your production line with custom-engineered shell and tub...

Vacuum mixer reactor for liquids and semi-solids

Achieve precise mixing and emulsification of complex liquid formulations ...

Cip system for process tanks

Ensure high-level cleanliness and compliance in your production line with an efficient in-place...

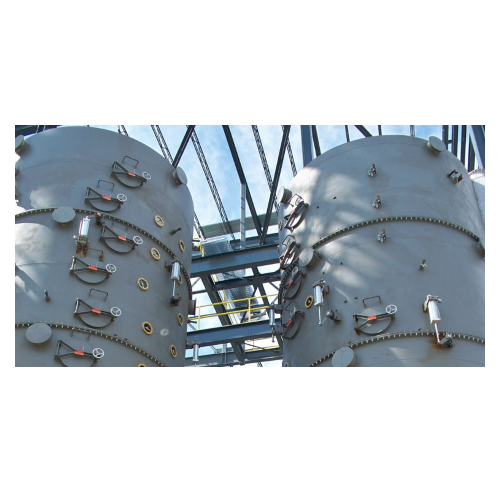

Industrial columns and towers for chemical processing

Optimize your chemical production with robust columns and towers, d...

Conical screw mixer for solids and powders

Achieve precise homogenization of your solid and powder mixtures with minimal e...

Industrial under vacuum homogenizer

Optimize your batch production with an under-vacuum homogenizer that ensures precise mi...

Alternate movement bottle filling and capping system

Enhance your production line with a versatile filling and capping so...

Automatic bottles and jars filling and capping line

Streamline your liquid product packaging with this high-speed solutio...

High-throughput vacuum evaporator for laboratory applications

Achieve precise solvent removal and efficient sample handl...

Servo type Pet bottle blowing molding solution

Optimize your production with high-speed PET bottle molding, designed to st...

Gasketed plate-and-frame heat exchangers for industrial applications

Optimize your production with precise thermal mana...

Pneumatic cap press for bottles and jars

Streamline your packaging process with a pneumatic solution designed for precision...

Automated bottle and jar filling solution

Streamline your production and minimize waste with a versatile filling solution,...

Bag and pouch filling solution for liquid products

Efficiently package diverse liquid products with precision and speed, ...

Benchtop screw capper for diverse bottle sizes

Ensure precision and efficiency in your capping process with this adaptable...

Semi-automatic flowmeter boom filler for large volume containers

Effortlessly handle large volume liquid filling with pr...

High precision three-roller wraparound labeller

Achieve precise label placement on round containers effortlessly with a th...

Winterization reactor for botanical extraction

Achieve precise temperature control and efficient separation during winteri...

Sterilization pilot systems for small batch heat treatment

Optimize product safety and quality in small batch production...

20l glass reactor for crystallization and isolation processes

Optimize your lab’s crystallization and isolation pr...

Dual-jacketed reactor for botanical extraction winterization

Optimize your production with precise temperature control a...

20l jacketed glass reactor

Optimize your chemical reactions with precise temperature control and adaptive stirring capabilit...

Controlled atmosphere muffle furnace

Achieve precise temperature and atmosphere control for critical processes like sinteri...

Automatic positive displacement filler for various liquids

Achieve precision and versatility in liquid filling operation...

Inspection-rejection station for bottled products

Ensure your bottled and packaged products ship defect-free by automatic...

Accumulation turntable for bottling lines

Optimize your production line’s efficiency with a 42-inch diameter accumul...

Container unscrambler for filling lines

Streamline and automate the loading of containers onto your production line with th...

Custom fabricated industrial tanks

Optimize your production with these industrial tanks, designed to handle a diverse range...

Multi-stage steam jet vacuum pumps for industrial applications

Achieve precise vacuum conditions for evaporation, distil...

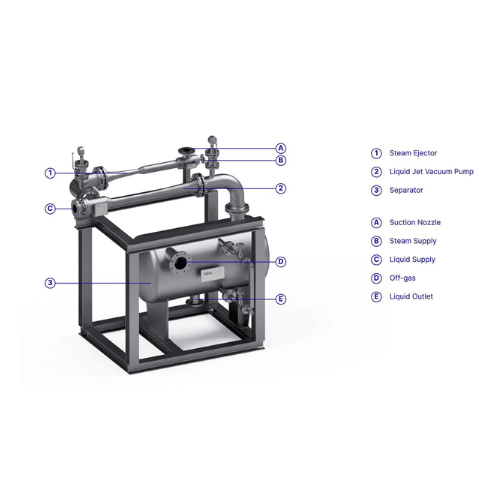

Steam jet liquid ejector vacuum system for chemical applications

Achieve reliable vacuum under challenging conditions wi...

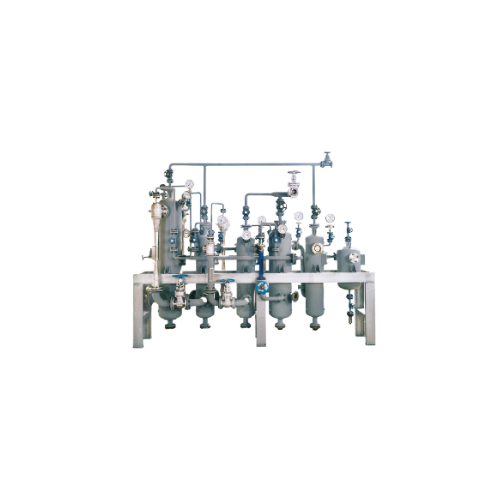

Combined steam jet and liquid ring vacuum pump systems

Optimize vacuum creation and maintenance in processes like distill...

High pressure pumps for viscous fluid transfer

Optimize fluid transfer with high pressure pumps designed to handle viscous...

Screw conveyor for raw material handling

Ensure seamless and continuous transport of raw materials with our customizable sc...

Industrial bucket elevator for efficient product conveyance

Enhance production efficiency by elevating and transferring ...

Very high pressure homogenizer compression block

Experience reliable performance at extreme pressures with a compression b...

Spring loaded overpressure safety valve with pneumatic actuator

Ensure safe pressure regulation with advanced spring-loa...

Laboratory homogenizers for nanoparticles and emulsions

Tackle the challenge of achieving consistent nano-scale dispersio...

Inline real-time fluid quality monitoring system

Optimize fluid quality control with continuous, inline measurements that ...

Loose package conveyor systems for packaging lines

Optimize your packaging line operations with advanced conveyor systems...

Falling film evaporator for temperature-sensitive products

Ensure consistent concentration and quality of heat-sensitive...

Compact plate evaporator for temperature-sensitive products

Ensure optimal heat transfer and minimal space usage with th...

Freeze concentration system for liquid food products

Achieve precise concentration while preserving volatile components a...

Mvr and Tvr heated distillation system

Achieve superior energy efficiency and reduced steam consumption in your distillatio...

Coffee extractor for optimal flavor preservation

Unlock the potential of your extracts with a continuous system that ensur...

Industrial chiller with high part-load efficiency

Optimize your cooling processes with a versatile chiller designed for p...

Aroma recovery system for natural juice extraction

Maximize aroma recovery in your juice production with a fully automate...

Medium torque mixer for chemical processing

Achieve optimal mixing efficiency and process consistency in demanding applica...

High pressure homogenization system for dairy and creams

Optimize your high-speed homogenization processes with precise c...

Sanitary gasketed plate heat exchangers for clean applications

Ensure product purity and maintain hygienic standards wit...

High-throughput vacuum evaporator for laboratory evaporation

Streamline your lab’s drying processes with an innova...

Benchtop evaporator for parallel chemistry and environmental testing

Enhance lab efficiency with a compact evaporator t...

High shear powder mixing solution

Achieve agglomerate-free, homogeneous mixing of powders and liquids with high shear effic...

Laboratory scale powder/liquid mixer

Easily integrate powders into complex liquid formulations at a laboratory scale, ensur...

High shear mixer for efficient particle size reduction

Achieve rapid and precise blending and particle reduction in your ...

High shear lab mixer for laboratory work and r&d

Achieve unparalleled precision and consistency in laboratory and pilot-sc...

Rotary stoppering and capping for vials

Achieve precise and efficient stoppering, capping, and crimping for high-speed vial...

Rotary vial filling and stoppering system

For high-speed production of sterile injectable vials, this continuous motion ro...

External washing and drying system for sealed vials

Ensure contamination-free packaging of liquid vials with this precise...

Automatic linear filling stoppering system for large volume vials

Ensure precise vial filling and secure sealing with a...

Vertical case packer for bottles and vials

Efficiently pack hard-to-handle items like bottles and vials with precision aut...

Ductless fume hood for medium chemistry experiments

Eliminate the need for cumbersome air duct installations while ensuri...

Single-use batch chromatography systems for biopharmaceuticals

Streamline your purification process with high productivi...

Cannabis nanoemulsification system

Transform your cannabis extracts into fast-acting, shelf-stable products with advanced n...

Solventless cannabis extraction system

Optimize solventless extraction of cannabis and hemp with precise agitation and filt...

Solventless terpene extractor for cannabis processing

Preserve the most volatile aromatic compounds during extraction, en...

Hydrocarbon extraction system for cannabis extraction

Achieve high-efficiency extraction with precise solvent control, op...

Hydrocarbon extraction system for cannabis and hemp

Streamline your extraction process with a versatile system capable of...

Hydrocarbon extraction system for cannabis industry

Optimize your extraction process with cutting-edge technology designe...

High capacity cannabis cryo-ethanol extraction system

Accelerate your extraction efficiency with a system that drasticall...

Supercentrifuge for solid-liquid separation and liquid phase separation

Optimize your separation processes with advance...

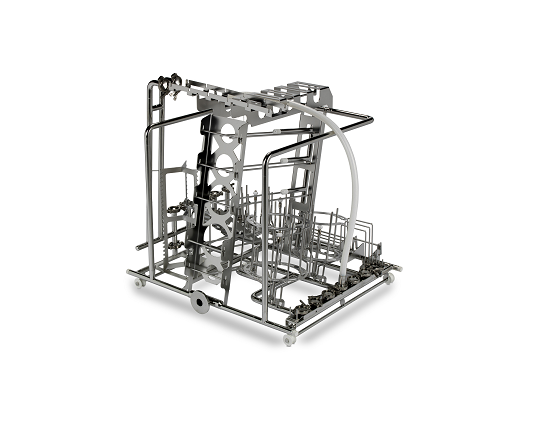

Loading basket for GMP washer

To ensure perfect cleaning of contact parts they must be placed in the GMP washer in such a wa...

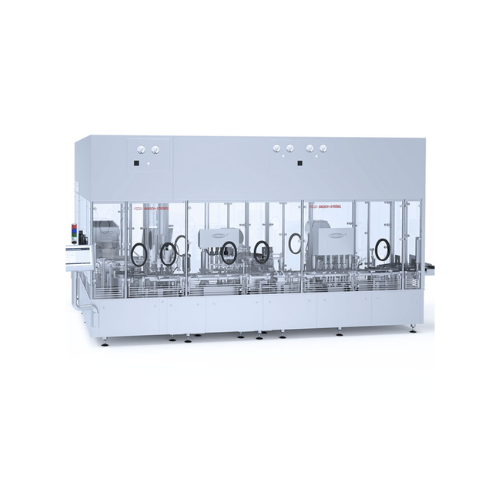

Bulk chamber washer

The production of cosmetics, nutraceuticals or unregulated pharmaceuticals often requires the cleaning an...

Entry-level chamber washer

When cleaning smaller products contacting filling or compressing components used in the productio...

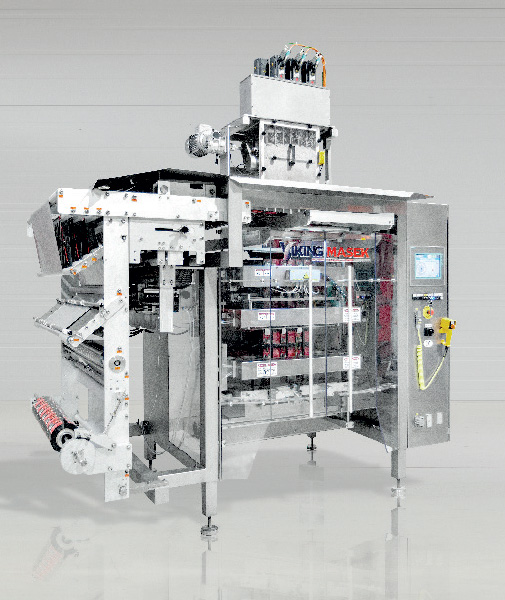

Stickpack Machine

If you are looking to pack your product into stick packs from 17 x 40 mm to 100 x 200 mm in size, you may b...

Sachet Machine

If you want to pack into eye-catching 4-side sealed sachets between 40×50 mm and 250×200 mm in size, ...

Horizontal thin film evaporators

Horizontal thin film evaporators can increase the residence time of the product and achieve...

Thin film dryers

Dry dissolved or slurried crystallizing or amorphous products to a pourable powder.