Corn Flakes Equipment

Find innovative production technology for making corn flakes and connect directly with world-leading specialists

First developed by Will Kellogg in 1894, corn flakes’ popularity grew exponentially. Made from toasting flakes of corn (maize) and served with cold milk, corn flakes have become a favorite breakfast cereal snack for millions around the world. Corn flakes production begins with milling raw corn, creating cornmeal which is then extruded to create corn flakes.

Tell us about your production challenge

Corn flakes manufacturing process: extrusion takes over from the traditional method

Although there are many different varieties of corn, dent corn, also known as field corn, is the most widely used corn when making cornflakes. The traditional method involves mixing the coarse flaking-grade corn grits with the other ingredients, cooking and drying them to about 21% of moisture, tempering, and then rolling them into flakes before toasting (final moisture range 1-3%).

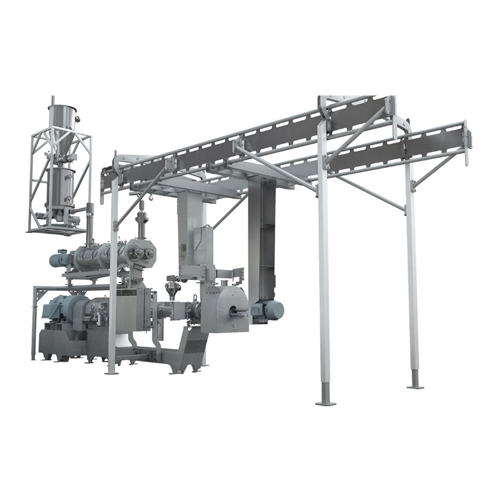

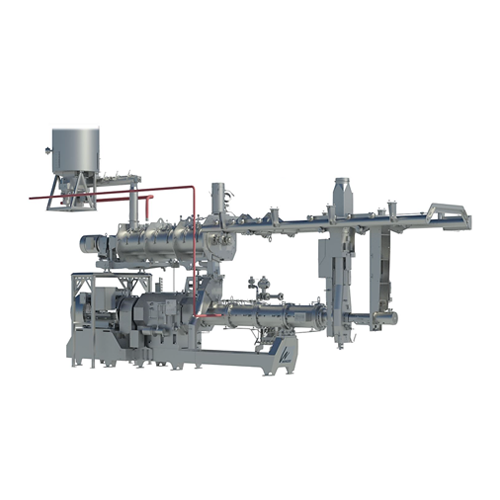

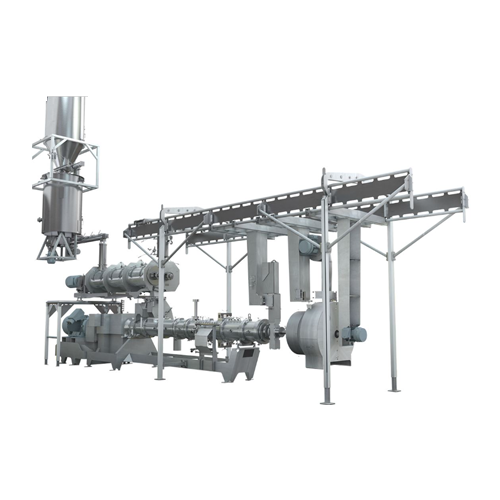

Nowadays, corn flakes are made by extrusion cooking, however. The extrusion process begins by cleaning and milling dent corn into cornmeal often using a twin screw extruder. The cornmeal is then transferred onto a feeding conveyor that loads it into a sifter and then into an extruder. Then, extrusion takes place: a process that combines mixing, cooking, kneading and forming.

The ingredients are fed into the extruder barrel and subjected to heating, compression and mixing. The raw material comes out of the extruder in form of strands that are then cut to form the pellets. After drying, pellets are flaked using a flaking roller and toasted

Production process of corn flakes: flaking

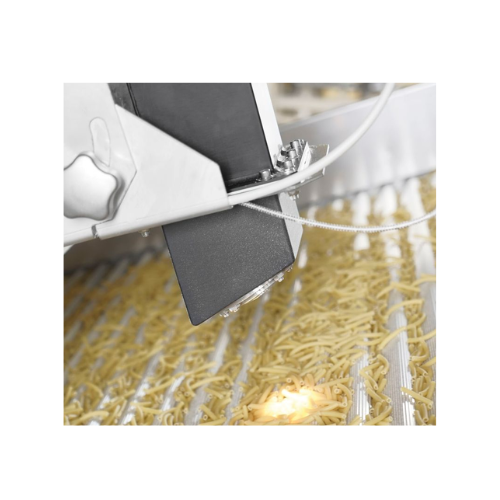

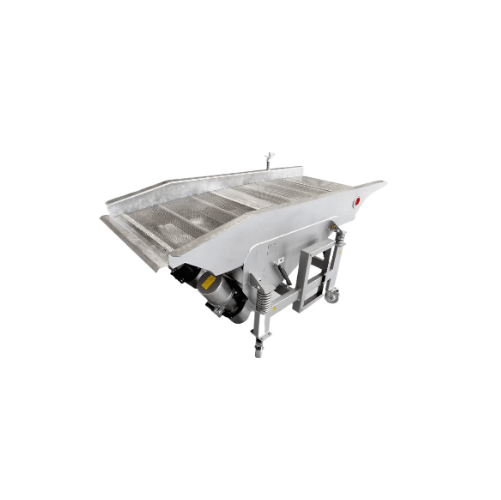

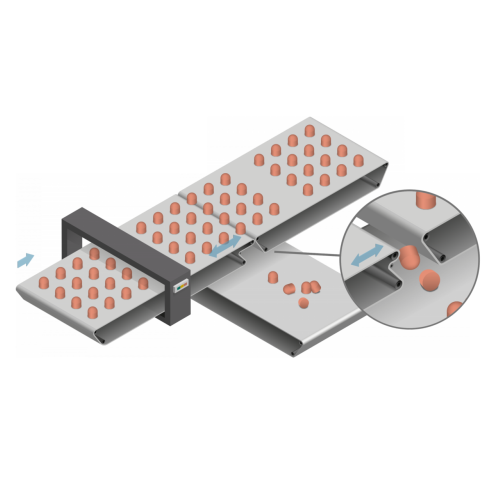

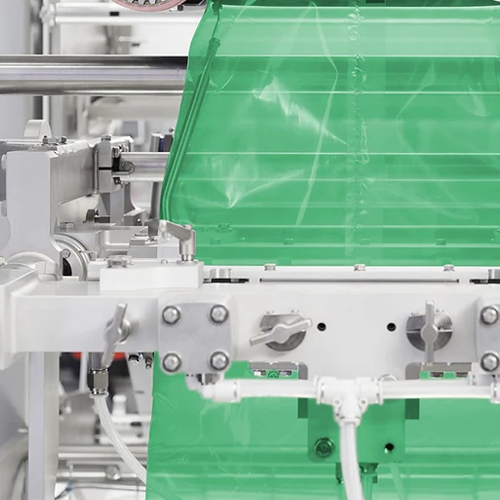

After extrusion, the semi-finished cooked mass is formed into pellets. They have a water content of approximately 22-24% that interacts with starch, making them sticky and viscous which is why they are transferred onto a vibrating feeder that prevents sticking.

The vibrating conveyor belt then brings the pellets into a flattening machine were they are flaked with steel rollers. The rollers’ surface is heated to 43-48 ̊C to avoid sticking or overheating of the mass. The delicate balance between heat and moisture is paramount for flaking- too much heat and the mass becomes too sticky and clings to the rollers and if the moisture is lower than 10%, the mass must be steamed so that flaking can be successful.

When the flakes are formed, they are put into an industrial dryer. High-temperature drying ensures that the water that still remains in the flakes evaporates before they are transferred to a baking sheet and put into an oven at 215 ̊C to receive their golden color. Once this process is finished, the cornflakes are transported to the cooling drum.

Loss of phenolic acids when making corn flakes – How to avoid it?

Grains such as corn, whole wheat and oats contain phenolic acids. Phenolic acids are anti-inflammatory and work as antioxidants, preventing cellular damage. Phenolic acids in grains such as corn are concentrated mostly in the bran; sadly the bran is either partially or wholly removed during corn processing, which significantly decreases the amount of phenolic acids in corn flakes. The largest loss of phenolic content happens during three stages dry milling- whole kernel, flaking grit and toasted cornflake.

In order to find out how to retain phenolic acids in corn flakes, researchers from the University of Illinois conducted a series of studies focusing on phenolic acids in processed corn. They are currently trying to increase the amount of phenolics in processed corn-based products with an experiment that reintroduces heated starch to processed corn-based products. This experiment is testing whether heating of the starch can release bound forms of compounds that would increase the quantity of antioxidants in corn-based foods. These developments are crucial for food science, food processing and represent future improvements.

Using food waste for improving nutritional properties of corn flakes

Processing corn flakes includes many steps and among them is the repurposing of food waste to fortify the end product.

A group of researchers from the University of Novi Sad and the University of Belgrade have successfully increased the amino acid content in corn flakes by adding dry residue of wild oregano and sunflower. They increased the total phenolic content (TPC) to 2.84mg/g by adding 9g/100 g of sunflower and 1g/100 g of wild oregano residue to cornmeal before extrusion.

Reusing by-products for the fortification of corn flakes increases the sustainability of the product by minimizing food waste in general and is proven to have great health benefits. If you’re looking for your next corn flakes machine or production line, contact us now and we will connect you directly with leading machine manufacturers worldwide

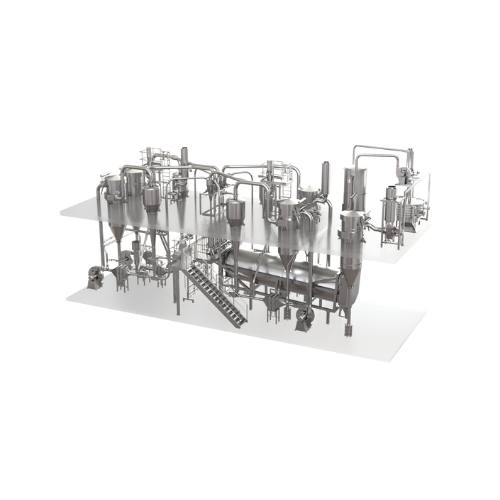

Processing steps involved in corn flakes making

Which corn flakes technology do you need?

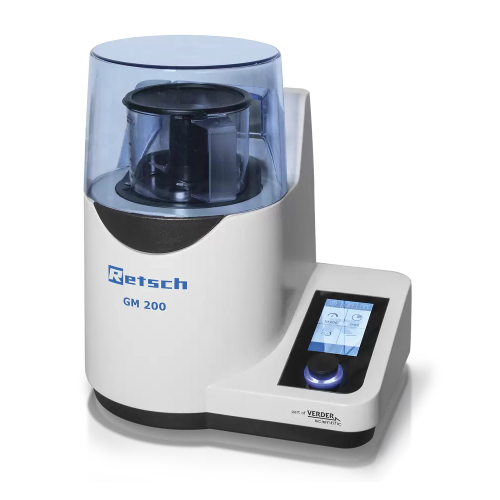

Cyclone mill for Nir analysis sample preparation

Ensure accurate NIR analysis by optimally preparing samples with efficien...

Ultra centrifugal mill for size reduction of soft and medium-hard materials

Achieve precise particle size reduction an...

Knife mill for food and feed sample grinding and homogenization

Achieve consistent texture and precise size reduction of...

Industrial continuous heat treatment for dry ingredients

Optimize your production line with a continuous system that ensu...

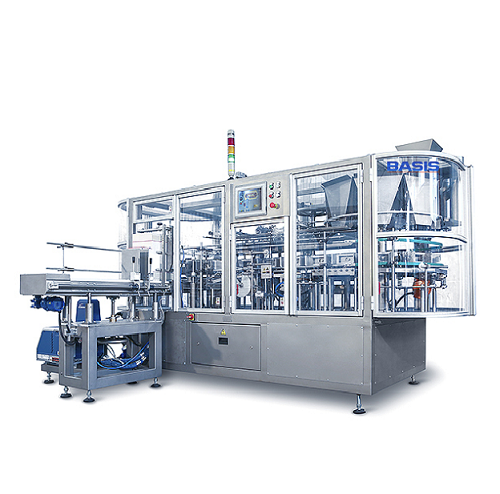

Rotary indexing sealer for cup filling

Streamline your production line with precise cup filling and sealing, ideal for a wi...

Food processing blower systems

Optimize your production line with precise air handling and moisture control to ensure qualit...

Grain flow regulator for roller mills

Achieve consistent grain distribution and safeguard your roller mills from wear and c...

Chain conveyors for long-distance bulk material transport

Efficiently transport challenging bulk materials across long d...

High-speed wrap-around case packer for beverage industry

Optimize your packaging line with a high-speed case packer that ...

Roasting and pasteurization system for nuts and seeds

Ensure optimal pasteurization and roasting of nuts, seeds, and drie...

Unloader for non-free-flowing materials in flat bottom silos

Facing challenges unloading non-free-flowing materials? Thi...

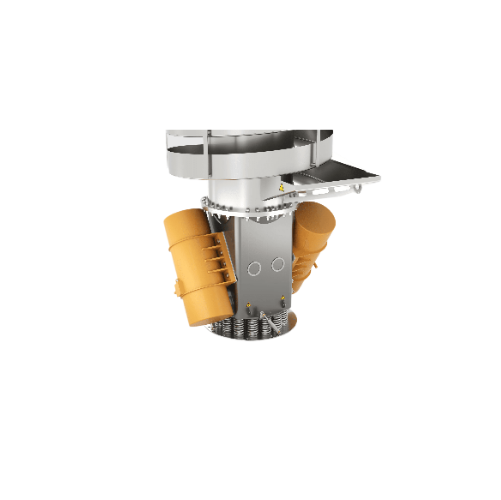

Vibratory bowl feeder for bulk items

When precision and speed are crucial, ensure your production line efficiently handles ...

Centrifugal bowl feeder for high-speed bulk item feeding

Optimize your production line with high-speed feeding of diverse...

Industrial metal detector for food production lines

Ensure product safety and compliance by seamlessly detecting metal co...

Gravity fed metal detector for dried foods

Ensure product purity and safety with metal detection between gravity feed hopp...

X-ray food inspection system for loose products

Ensure contaminant-free loose products by integrating a versatile inspecti...

Metal detector conveyor system for food safety

Ensure product integrity across high-speed production lines with robust met...

Laboratory mixer granulator

Achieve high-quality mixtures in R&D and small-batch production with versatile laboratory m...

High-speed centrifugal sifter for food and pharma applications

Optimize your powder processing with a high-speed centrif...

Double cone blender for fragile and abrasive material

Achieve homogeneous blends of fragile materials while minimizing da...

Filling and sealing solution for pre-formed cups

Optimize your liquid and solid product filling with a continuous-motion s...

Rotary doypack packaging system for various materials

Enhance your packaging line with versatile doypack machines designe...

High-pressure homogenizers for dairy and beverage industries

Achieve precise emulsion stability and consistent particle ...

Compactors and granulators for powdery products

Transform loose powders into dense, free-flowing granules that enhance han...

Table roller mills for mineral raw material comminution

Achieve precise mineral raw material comminution and energy-effic...

Roller press for fine-grained material compaction

Achieve optimal density and stability in your solid press agglomerates ...

Multiprocessing system for flexible research and production

Optimize your process development with a versatile system th...

High-speed hammer mill for continuous operation

Achieve precise particle size reduction with high-speed hammer milling, id...

Flake crushers for gentle crushing of brittle materials

For processes needing precise granule control, our equipment ensu...

Flake crusher for hygroscopic substances and lumped salts

Efficiently turn fragile, aggregated materials into manageable...

Air classifier for fine powder processing

Enhance your production line with precise particle size control and energy-effic...

Gravity classifier for precise particle separation

Achieve sharp separations in particle processing with minimal maintena...

Automatic bulk material filling system

Ensure precise, contamination-free filling of various bulk materials with an advance...

Fine impact mills for particle size reduction

Achieve precise particle size reduction with fine impact mills, essential fo...

Powder flowability and compressibility analysis

Ensure accurate powder flowability and compressibility data with this adva...

Ball mill for dry comminution of hard materials

Achieve ultrafine particle sizes and precise material breakdown with this ...

Wafer cutting system for cream-filled wafers

Achieve precise cuts on filled and coated wafer products with high-speed effi...

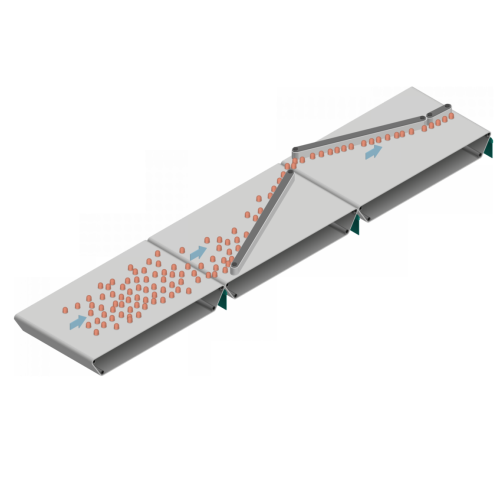

Wafer distribution device for chocolate coating plants

Enhance your chocolate coating operations with precision wafer dis...

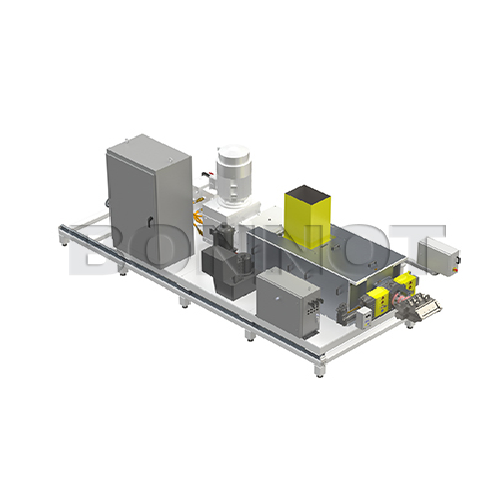

Intermediate container for raw material preparation

Streamline your snack and cereal production with this solution that e...

Industrial raw material mixer for complex recipes

Struggling with complex raw material mixtures? This advanced mixing sol...

Industrial metal detector for gravity feed applications

Ensure the purity of your products by detecting and removing both...

Ferrous-in-foil metal detection system

Enhance quality control for foil-packaged goods with precise ferrous metal detection...

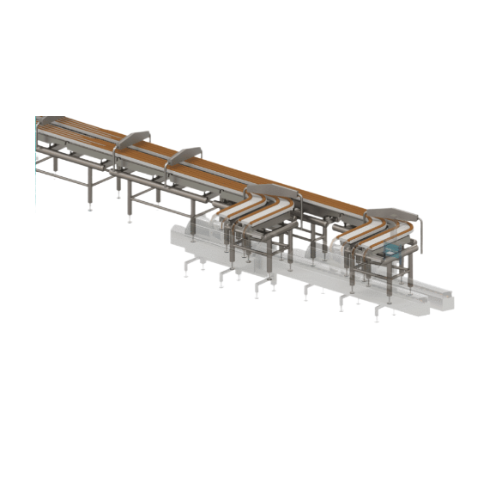

Conveyor systems for snack production

Streamline your snack production with advanced conveyor systems designed for seamless...

Checkweigher for packaged goods inspection

Ensure precision and compliance with this high-speed checkweigher, perfect for ...

Advanced metal detection for food processing

Maximize your production line’s safety and efficiency with a cutting-ed...

X-ray inspection system for identifying foreign bodies in food products

Ensure precise detection of foreign materials i...

X-ray inspection system for detecting foreign objects in food products

Ensure product safety and quality by detecting e...

Accumulation conveyor for snacking industry

Optimize your production line with a space-saving accumulation conveyor that r...

On-machine seasoning system for potato chips

Achieve uniform seasoning coverage for various snack foods with minimal wasta...

Incline transfer conveyors for dry, fresh, and frozen food products

Efficiently transfer a variety of solid and granule...

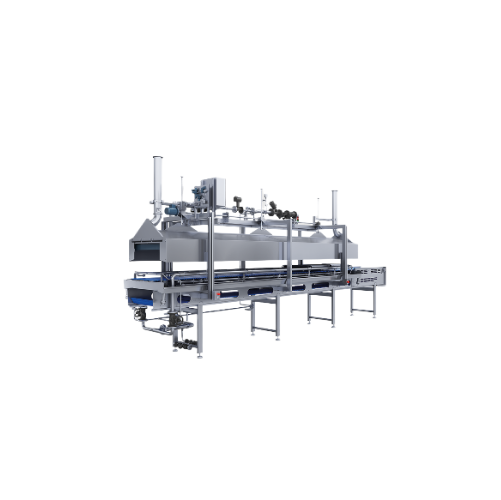

Continuous belt dryer for industrial production

For operations requiring precise moisture control, this continuous belt dr...

Double shaft powder batch mixer

Achieve high homogeneity and gentle handling with a double shaft mixer designed for efficien...

Consumables for elemental analyzers

Optimize your laboratory’s elemental analysis with high-quality consumables desig...

Carbon/nitrogen analyzer for organic samples

Optimize your lab’s efficiency with fast, reliable nitrogen and carbon ...

Vibration transport system for hygienic conveying of bulk goods

Optimize your production line with efficient and hygieni...

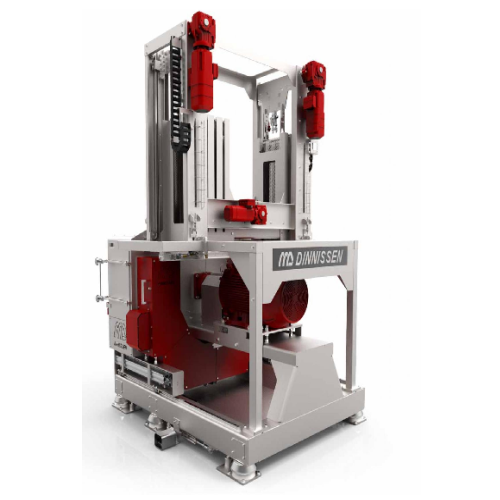

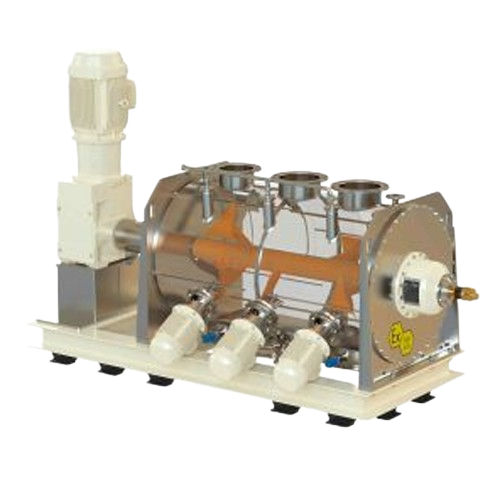

Industrial mixer for batch granules or grains

Achieve precise mixing with seamless integration of heating, sterilization, ...

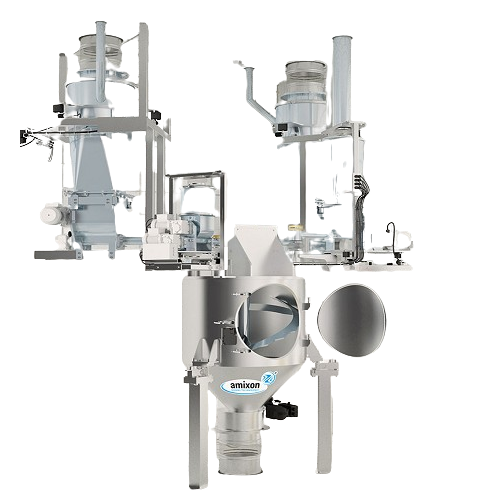

Product handling system for big bags and containers

Optimize your production line with a comprehensive system for transpo...

Micro dosing system for precise powder weighing

Achieve unparalleled dosing accuracy in your production line with a system...

Hammer mill with automatic screen exchange

Optimize your milling operations with a high-speed solution that ensures seamle...

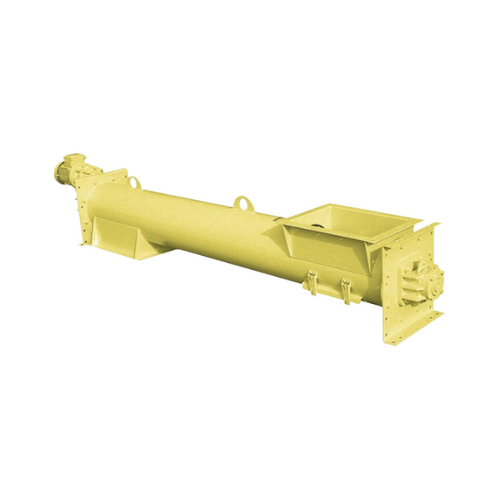

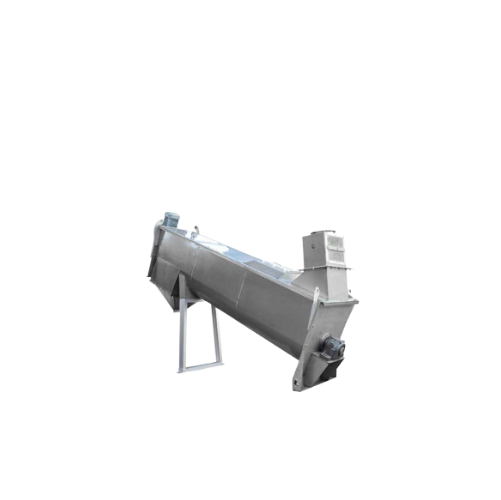

Mechanical horizontal conveyor for powders and granulates

Efficiently handle and transport your delicate powders and gra...

Vertical transport for bulk goods

Efficiently move bulk goods vertically with minimal energy usage, ensuring seamless integ...

5-in-1 industrial mixer for food and chemical industries

Streamline your production with a multifunctional system that ef...

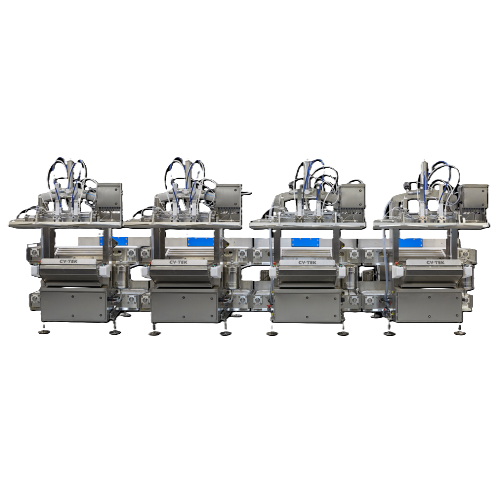

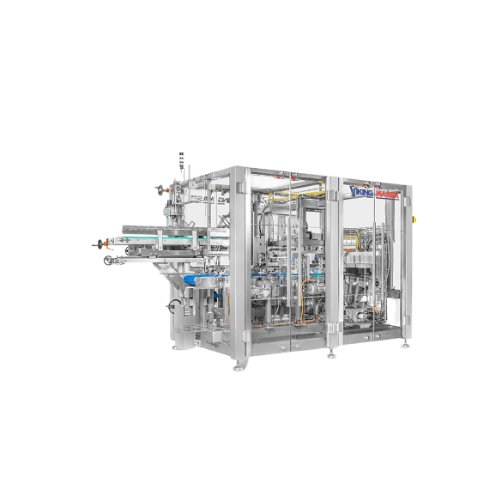

Multi-station modified atmosphere packaging system for bulk products

Optimize your packaging efficiency with a system d...

Vertical form fill seal packaging for high washdown environments

Ensure optimal packaging in demanding environments with...

Large-scale industrial freeze dryer

Achieve precise moisture control and preserve product integrity with a large-scale free...

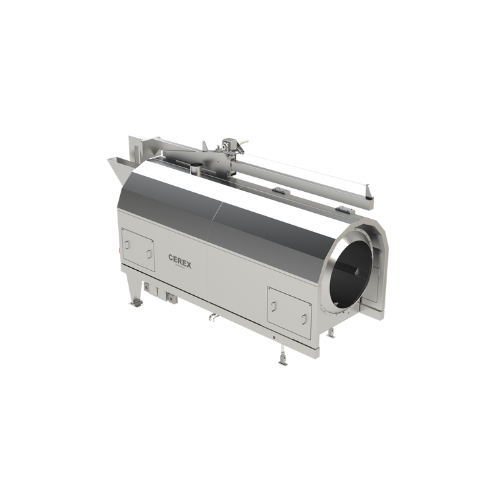

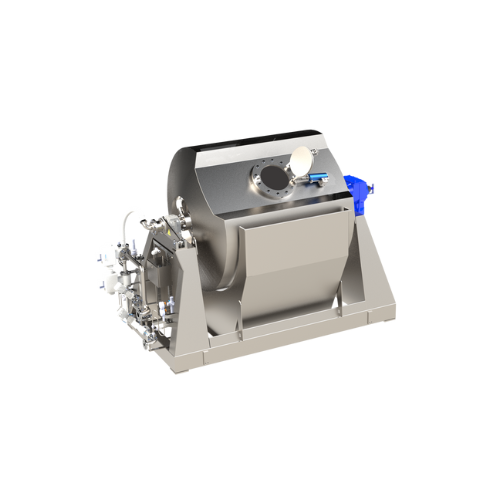

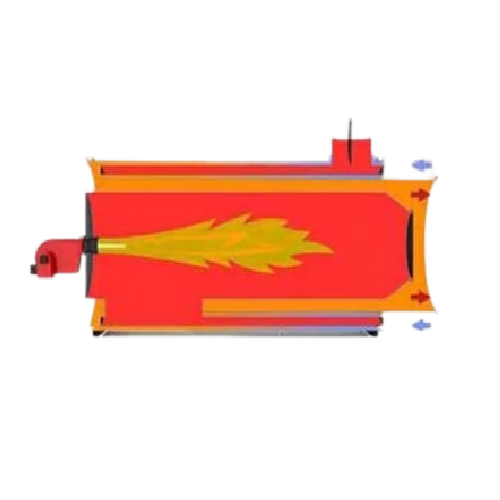

Steam chambers for grain expansion in steam-flaking

Ensure precise grain expansion with steam chambers, designed for unif...

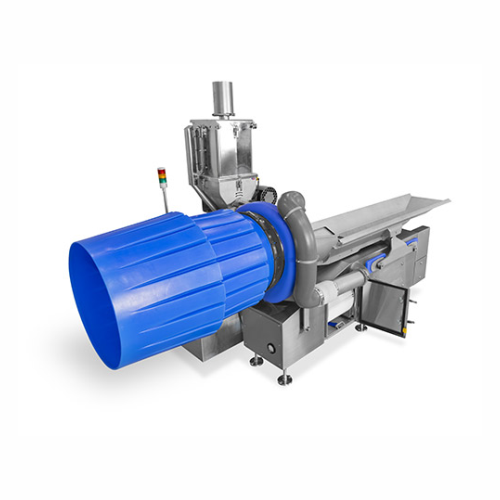

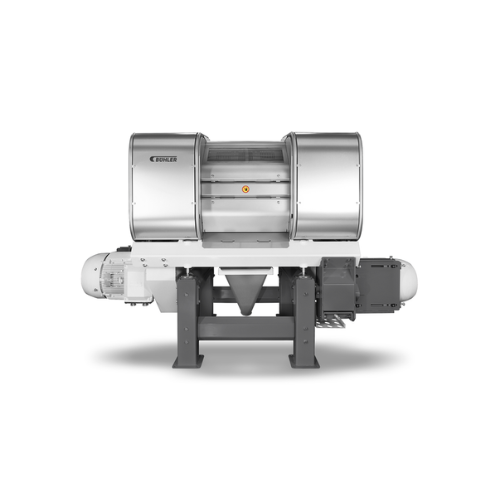

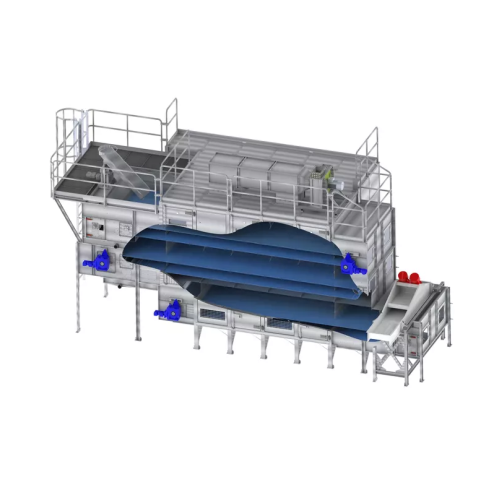

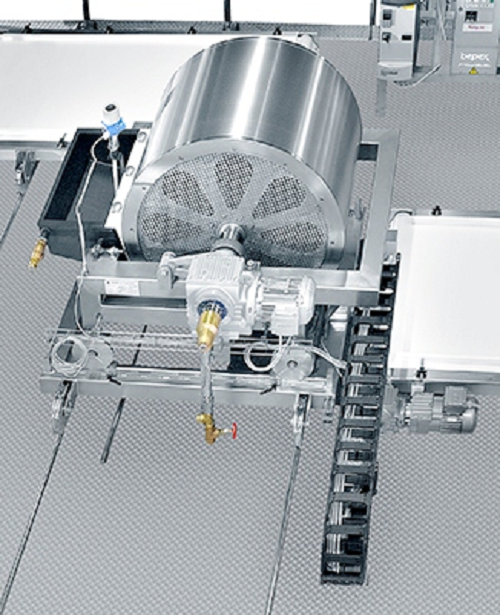

Industrial grain flaking solution

Enhance grain processing efficiency with precision-engineered flaking solutions, designed...

Industrial food mixer for high-volume processing

Achieve consistent mixing and precise blending of diverse food ingredient...

Industrial moisture and temperature control conditioner

Optimizing moisture absorption and temperature management, this c...

Horizontal screw loader for food processing

Optimize your production flow with a smooth-loading solution designed to effic...

Overlapping paddle mixer for precise food processing

For precise and thorough mixing in food processing, this solution en...

Bulk material mixer for high-speed homogenization

Achieve fast and gentle homogenization of bulk materials with a high-sp...

High throughput twin screw extruder for low bulk density products

When handling low bulk density materials, achieving m...

Vacuum sequencing blower for industrial conveying systems

For manufacturers handling bulk materials like powders and gra...

Food extruders for pet food production

Achieve precise control in food production with advanced twin screw extruders, desig...

Centric pelletizer for direct extrusion

Effortlessly transform materials into uniform granules with our high-speed pelletiz...

Precision weigh filler for food and pharma industries

Optimize precision in multi-component dosing with seamless integrat...

Industrial 2-zone toaster for optimal cereal processing

Achieve precise toasting of cereals and seeds with the 2-zone toa...

Single-zone toasters for raw grain processing

Optimize your cereal and snack food production by achieving consistent toast...

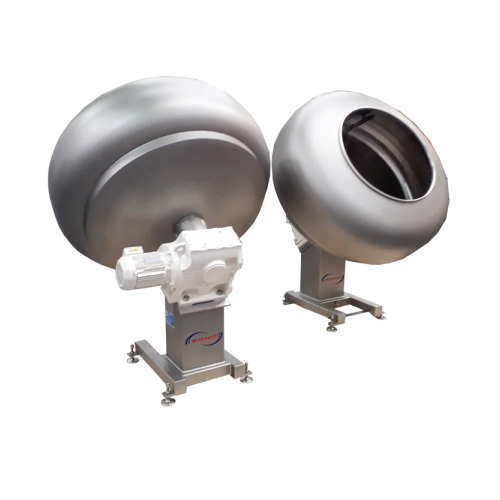

Industrial coating drum for breakfast cereals

Optimize your cereal production with a coating drum designed to enhance prod...

Coating dryers for breakfast cereal production

Achieve precise moisture control in coated cereal production with these mod...

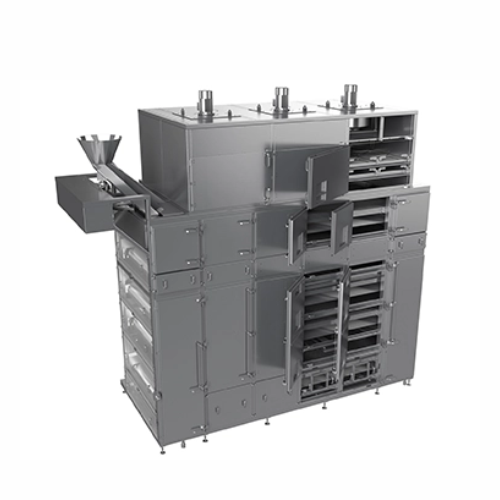

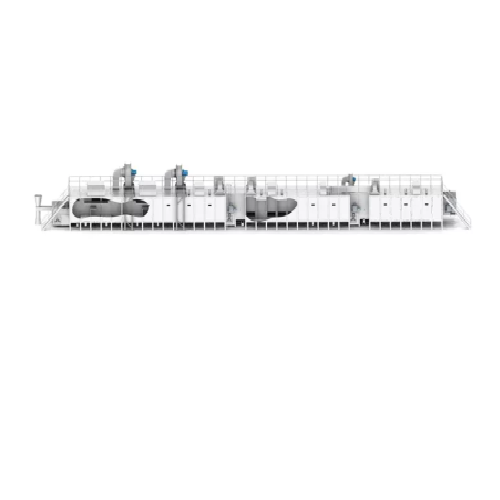

Multi-tier dryers for modern breakfast cereals

Optimize dry and cool cereal, nuts, and seed production with a compact modu...

Grain puffing system for breakfast cereals

Achieve precise and efficient grain expansion in breakfast cereals with this ad...

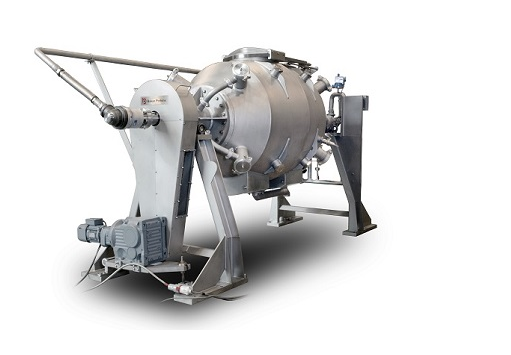

Rotary cooker for uniform steam heating in cereals production

Achieve consistent product quality in high-volume cereal p...

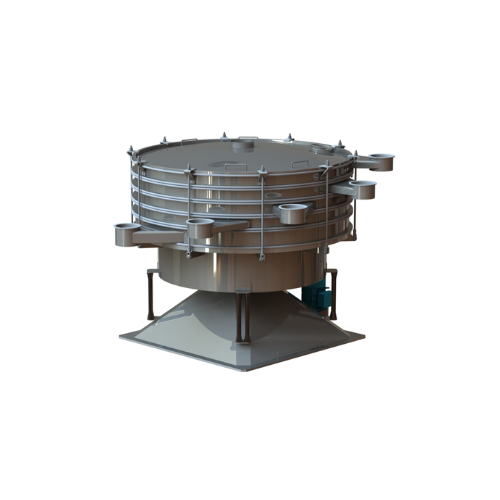

Industrial screeners for grain product processing

Optimize your cereal production line with specialized industrial screen...

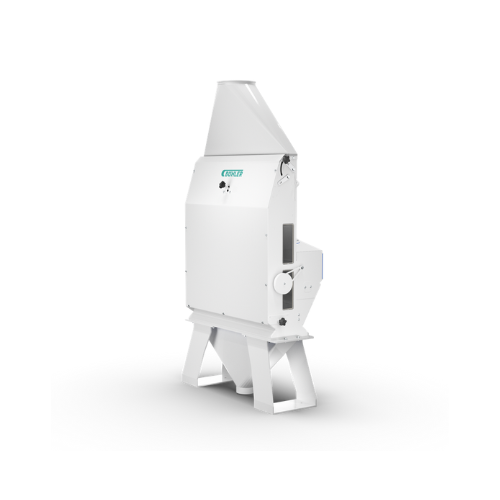

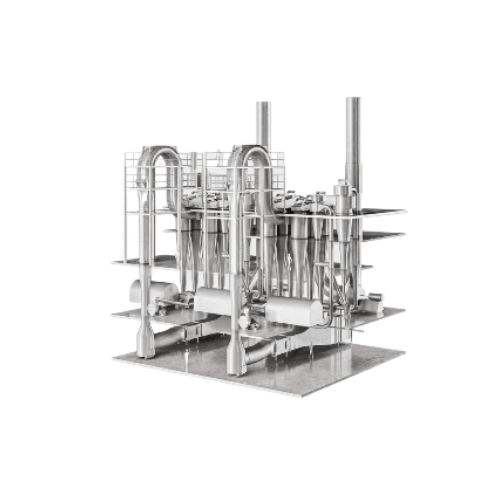

Grain cleaning system for high-quality processing

Optimize your grain processing with a versatile cleaning system designe...

Efficient grain destoning and concentrating system

Optimize your grain processing with a solution that ensures precise se...

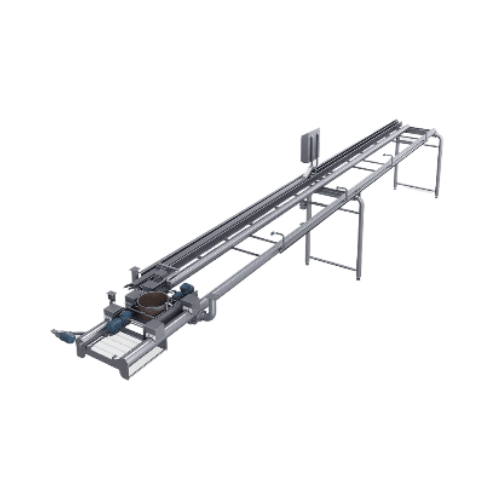

Chain conveyor for grain and floury products

Ensure seamless material handling with a versatile chain conveyor designed fo...

Advanced superheated steam drying solution

Harness the power of consistent drying technology to achieve optimal moisture c...

Four-roller and eight-roller mill for wheat and grain grinding

Optimize your grinding operations with this versatile rol...

Grain scourer for wheat, durum, and rye

Enhance grain processing by efficiently removing impurities like dust, sand, and so...

Optical sorter for grains, seeds, and plastics

Enhance sorting efficiency with cutting-edge optical technology that distin...

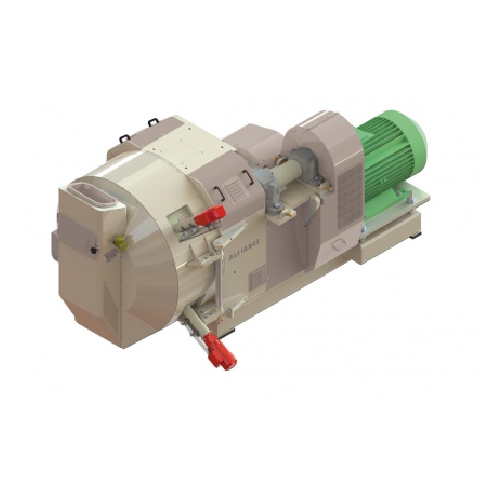

Flaking mill for grain and cereal production

Achieve consistent flake thickness and high throughput with advanced roller t...

Real-time quality analyzer for flour and semolina

Ensure consistent flour and semolina quality with a cutting-edge online...

Moisture control system for grain milling

Optimize moisture levels precisely within your grain milling process, ensuring c...

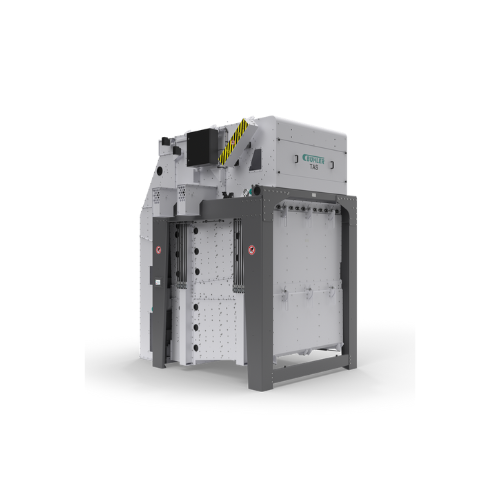

Laboratory plansifter for particle-size distribution

Optimize your grain milling and brewing operations with precise part...

High-throughput hammer mill for animal feed production

Ideal for high-throughput operations, this hammer mill ensures pre...

Heavy-duty trough chain conveyor for high throughput applications

Optimized for high-capacity operations, this robust c...

High-efficiency cooling tunnel for confectionery production

Optimize your product cooling process with high-efficiency t...

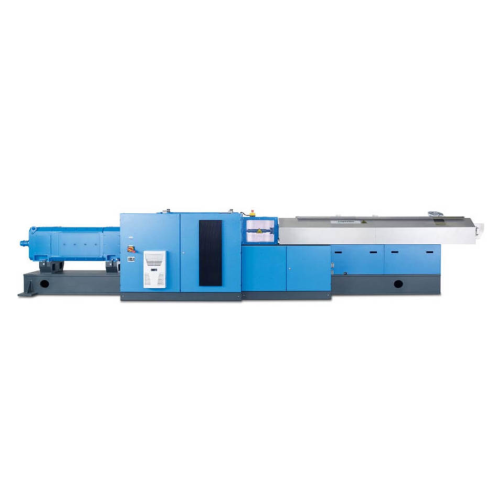

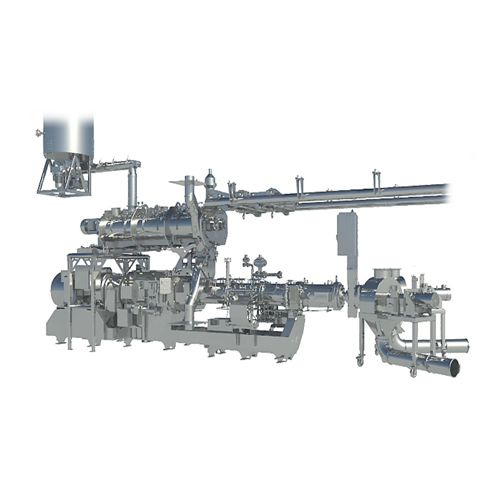

Twin-screw extruder for breakfast cereals production

Enhance your product range with flexible twin-screw extrusion techno...

Oilseed flaking and milling system

Optimize your oilseed processing with a flaking system that enhances extraction efficien...

Industrial grain flaking mill

For efficient grain processing, achieve uniform flake quality with advanced temperature-contro...

Four-roller and eight-roller mill for grains

Optimize your grain processing with precise roller configurations, ensuring c...

Discharge station for bags and big bags

Ensure consistent material flow and hygiene in your production line with a versatil...

Control systems for wet grinding industry

Enhance precision and efficiency in your production line with advanced control s...

Digital process service for regulating water in dough preparation

Achieve consistent dough moisture levels with this di...

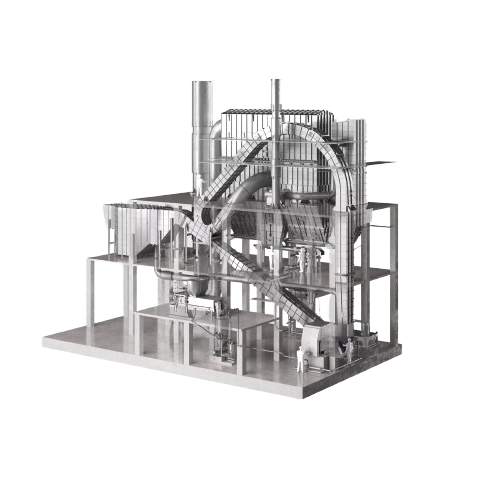

Integrated grinding system for wheat and grain

Optimize your grinding process with a system that delivers consistent parti...

Aspiration channel for grain cleaning

Achieve superior product quality by efficiently removing light impurities from granul...

Batch scale for high accuracy weighing of powdery products

Achieve unparalleled precision in powder dosing with our batc...

Fully automatic batch scale for powdery and granular products

Achieve precise and repeatable dosing for powdery and gran...

Fluid-bed toaster for cereal processing

Achieve precise control over texture and taste while reducing operating costs with ...

Square plansifter for flour and semolina rebolting

Achieve superior flour and semolina quality by efficiently sifting and...

Twin-screw extruder for breakfast cereal

Optimize your production with a robust twin-screw extruder that accommodates high ...

High-capacity horizontal conveyor for bulk storage

Optimize your high-speed bulk material handling with a durable and eff...

Laboratory plansifter for grain milling and brewing

Achieve precise particle-size distribution and quality control across...

Compound rolling unit for dough sheets

Achieve unparalleled precision in dough formation with our high-speed compound rolli...

Air cleaners for grain dust removal

Enhance safety and operational efficiency by effectively removing dust and light partic...

Vertical grain conveying solution for animal feed and bulk materials

Efficiently transport and elevate various bulk mat...

Versatile steam distillation unit for laboratory applications

Achieve reliable analysis of complex samples with this ste...

Nitrogen determination system for laboratory analysis

Ensure precise nitrogen content analysis with cutting-edge steam di...

Lab-scale twin screw extruder

Optimize your material testing and production efficiency with our versatile twin screw extrude...

Vertical forced feeder for extruders

Enhance your extrusion process with a vertical forced feeder designed for precise dosi...

Small twin screw extruder

Optimize your lab and pilot production with a versatile twin screw extruder, designed for precise ...

Gluten quality testing solution

Ensure optimal flour quality by rapidly assessing gluten properties, allowing you to refine ...

Lab- and pilot-scale twin screw extruders for small-scale production

Optimize extrusion techniques with lab and pilot-s...

High-speed case packer for flexible bags

Streamline your packaging process with a solution designed for high-speed, error-f...

V shape mixer for solids and powders

Ideal for preserving the delicate structures of fragile materials, this mixer ensures ...

Vertical ribbon mixer for solids and powders

Achieve rapid, uniform mixing of powders and solids while preserving particle...

Double shaft paddle mixer for solids and powders

Achieve unparalleled mixing precision for fragile and diverse materials w...

Horizontal ploughshare mixer for solids and powders

Achieve uniform blends of diverse solids and powders with precision a...

Double cone mixer for powders and solids

Ensure gentle mixing of fragile powders and solids with a low-speed, non-forced bl...

Mill sifter for precise bulk density and particle size distribution

Achieve precise particle size and uniform bulk dens...

Continuous powder mixer for dry, moist and suspended goods

Achieve precise homogenization and deagglomeration with a con...

Pilot scale mixers for product development and small production runs

Optimize your mixing processes with precision cont...

Automatic granular product weighing system

Effortlessly achieve precise fills for dry granular products and powders while ...

Automated scoop insertion system for powder containers

Streamline your container filling operations by ensuring precise s...

Vibrating sifter for chemical applications

Achieve precise particle separation with this vibrating sifter, ensuring optima...

Food product sifter

Ensure precise separation with vibratory sifters designed for continuous operation, delivering gentle han...

Industrial powder sifter with sanitary compliance

Optimize your powder processing with this versatile sifter, ensuring pr...

Vacuum powder sampler for particle size distribution control

Ensure precise quality control with a vacuum powder sampler...

Circular distribution feeder for fragile product handling

Achieve precise dosing and reduced product damage with a versa...

Vibratory spiral elevator for vertical transport

Achieve efficient vertical transport with precise temperature control, su...

Vibrating feeder for food and pharmaceutical industries

Optimize your production line with precision dosing and gentle ma...

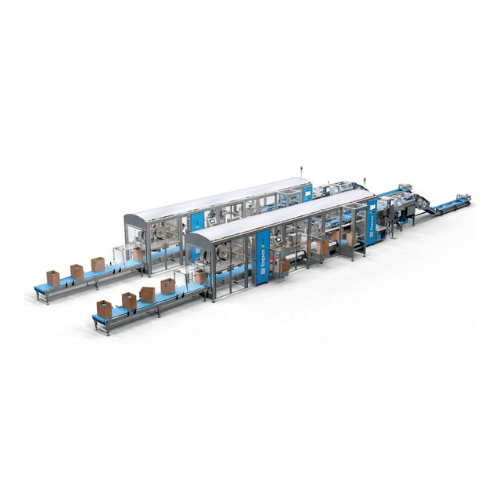

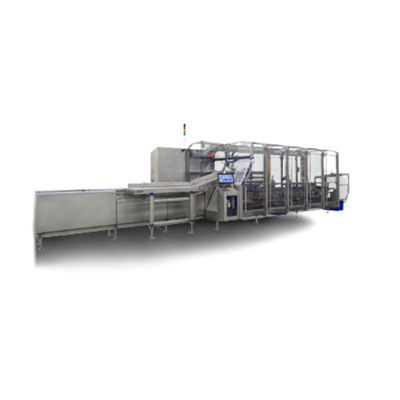

Continuous motion packaging for short-cut pasta

Optimize your packing line with a high-speed solution designed for efficie...

Packaging system for short-cut pasta and dry granular food

Streamline your packaging process with a versatile system des...

Eco-friendly vertical packaging for pasta

Reduce plastic waste and enhance sustainability in pasta packaging with high-spe...

Vertical packaging system for fragile food products

Handle delicate food items like pasta nests and bakery products with ...

Intermittent motion packaging system for dry granular food

Achieve precision packaging for dry foods with an advanced sy...

Industrial predryer for humidity reduction in food processing

Ensure optimal shelf life and prevent product sticking wit...

Industrial cooling system for packaging temperature control

Achieve precise temperature control and maximize energy effi...

Industrial pasteurizer for efficient bacterial reduction

Ensure your food products are safe with an industrial pasteurize...

Industrial spiral cooler for thermal treatment

Improve your final conditioning and packaging process with a spiral cooler ...

High-accuracy package weigher for pasta and granular products

Optimize your packaging line with precision weighing and i...

Extruder for short-cut pasta and lasagna production

Achieve seamless pasta and snack production with an extruder designed...

Surface drying system for pasta production

Ensure optimal surface drying of pasta and snacks post-pasteurization, preventi...

Batch standing mixer for dough preparation

Enhance your mixing precision with a batch standing mixer that optimizes paddle...

Dough distribution system for multiple mixing points

Ensure precise dough allocation across multiple production stages wi...

Water cooker for fresh pasta processing

Enhance cooking precision and product quality with this water cooker, designed to c...

Round die washer for pasta and snack production

Ensure impeccable hygiene with a specialized washer that streamlines die m...

Powdered product shelf-life enhancement through inert gas packing

Extend the shelf life of sensitive powder products by...

Industrial ring dryer for efficient particle processing

Control particle size and drying efficiency with precise recircul...

Flash dryer for industrial moisture removal

Optimize your production with rapid moisture removal, efficiently transforming...

Vibratory buffer system for line efficiency

Enhance your production line by efficiently managing downstream stoppages and ...

Industrial coating pans for sweets and confectionery

Ensure even and consistent coatings with high-capacity pans designed...

Coating pans for precision culinary coatings

Achieve consistent, high-quality coatings on a diverse range of products, fro...

High capacity horizontal dryers and coolers for industrial applications

Achieve consistent moisture levels and uniformi...

Sanitary dryers for textured vegetable proteins

Optimize drying and sanitation for textured vegetable proteins and pet foo...

Extruder for aquatic feed production

Efficiently produce a wide range of aquatic and pet feed with precise control over pel...

Conical twin screw extruder for pet food and aquatic feed

Precision-engineered for high-speed extrusion and drying proce...

Forming extruders for flaked cereals

Optimize your production line with versatile forming extruders designed for precision ...

High-sme extruder for structured meat analogs

Enhance production versatility with precise extrusion control, accommodating...

Single screw extruder for pet food and aquatic feed

Maximize production capacity and optimize product quality with advanc...

Extruder for high-volume pet food production

Maximize production efficiency with an advanced extrusion system designed for...

Twin screw extruder for pet and aquatic feed

Achieve exceptional cooking precision with our twin screw extruder, designed ...

Coating and enrobing system for pet foods and treats

Achieve precise coating and flavoring of various food and feed produ...

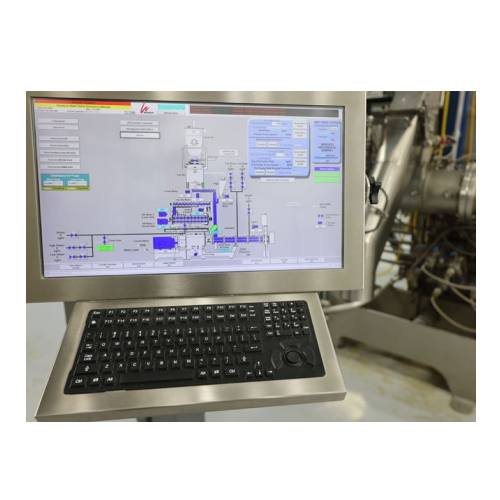

Automated process management system for industrial extrusion

Optimize your production line with precise control and moni...

High intensity preconditioner for textured vegetable proteins

Optimizing your production with precise moisture control a...

Convection roaster for pet food and delicate food products

Achieve optimal texture and moisture control in delicate food...

Atex certified flanged round dust collectors

Designed for potentially explosive environments, these flanged round dust col...

Trough screw conveyor for flour mills

Optimize your flour processing with efficient material handling, precisely designed f...

Pneumatic linear vibrators for bulk material flow

Prevent bridging and rat-holing in your production process with silent,...

Cushioned pneumatic linear vibrators for bulk solids

Combat material bridging and rat-holing with silent vibratory techno...

High capacity vertical conveying for grains and cereals

Ensure efficient vertical transport of bulk materials like cereal...

Tubular trough screw conveyors for gentle powder and granular material handling

Achieve precise powder and granular ma...

Stand-up pouch filling and sealing system

For packaging lines that demand quick, efficient, and flexible pouching, this hi...

Horizontal flat pouching solution for foods and chemicals

Achieve precision in pouching liquids and powders with high-sp...

Stand-up pouch packaging for various products

For manufacturers seeking versatile packaging solutions, this machine delive...

Continuous stand-up pouching solution for up to 1000ml

Maximize efficiency in high-speed production lines with precise st...

Rotary pouch packaging system for food and powder products

Streamline your packaging process with a rotary system that e...

High-speed vertical form fill seal packaging machine

Optimize your packaging line with this high-speed vertical form fill...

Vertical form fill seal for dusty and liquid products

Optimize your packaging line with a versatile solution designed to ...

High-speed vertical form fill seal for various packaging needs

Streamline your packaging process with an advanced vertic...

Vertical form fill seal for bulk bag packaging

Streamline your bulk bag packaging with efficiency and precision, ideal for...

Top load cartoner for various carton shapes

Optimize your production line with a versatile cartoning solution, perfect for...

Topload cartoner for packaging cartons

Efficient flap closing for diverse carton sizes, ensuring gentle handling of sensiti...

Automatic rotary filler and sealer for premade pouches

Enhance your production line efficiency with a dual-lane system th...

Automatic rotary premade pouch filler and sealer

Optimize your production line with high-speed pouch filling and sealing, ...

Automatic rotary premade pouch filler for various industries

Streamline your pouch packaging process with precision fill...

Automatic rotary premade pouch filler for food products

Enhance your packaging line with a high-speed solution designed t...

Product inspection systems for contamination control

Ensure product safety and compliance with precision inspection techn...

Support structures for packaging lines

Enhance safety and efficiency in your production line with robust support structures...

Modified atmosphere packaging solutions for perishables

Extend the freshness and shelf life of perishable goods with prec...

Robotic palletizing and depalletizing systems

Enhance your production efficiency by automating the repetitive and labor-in...

Industrial printers and labelers for packaging

Ensure precise package identification and traceability with robust printing...

Industrial product fillers for precise packaging

Achieve consistent package weights and volumes with precision filling sol...

Robotic packaging integration for automated systems

Enhance your production line efficiency with seamless robotics integr...

Sleeve cartoners for ready meals and salads

Optimize your packaging line with a high-speed sleeve cartoner designed to eff...

Industrial milling systems for food processing

Streamline your food production line with robust milling and cutting soluti...

Double deck roller mill for grain milling

Achieve superior milling results with increased efficiency and hygiene in proces...

Industrial extraction scale for accurate material weighing

Ensure precise ingredient proportions in your milling operati...

Bucket elevator for grain and powder products

Efficiently transport bulk materials like grain and powder vertically with p...

Maize flour and semolina milling solution

Efficiently transform corn into diverse food products by combining precision cle...

Industrial impact detacher for semolina processing

Optimize your grain processing line with a solution designed to enhanc...

Inclined intensive dampener for grain processing

Ensure consistent moisture levels for optimal grain processing and enhanc...

Blower for vertical and horizontal grain transport

Efficiently transport grains, legumes, and flour both vertically and h...

Volumetric single-screw feeders for free-flowing products

Achieve precise and continuous feeding of free-flowing powders...

Gravimetric single-screw feeder for free-flowing products

Optimize your dosing precision for powders and granulates with...

Industrial metal detector for food and beverage applications

Ensure your production line is free from metal contaminants...

Metal detector for packaging lines

Ensure product purity and safety with precision metal detection, seamlessly eliminating ...

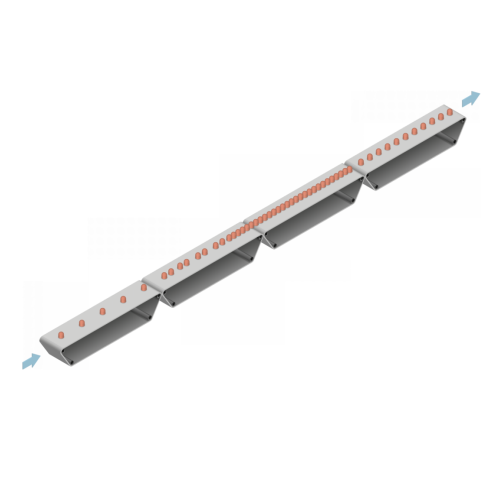

Separating and aligning conveyor for packaging systems

Efficiently manage the flow of diverse solid products like confect...

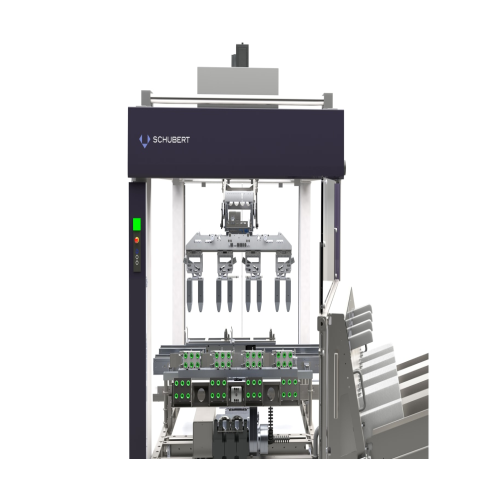

Vision-based robotic feeding system

Enhance your production line with precise robotic feeding, optimizing product placement...

High-speed double twist packaging system for soft caramels

Streamline your confectionery packaging process with a high-s...

Accumulation conveyor for controlled feeding in packaging lines

Ensure seamless product flow and enhance efficiency in y...

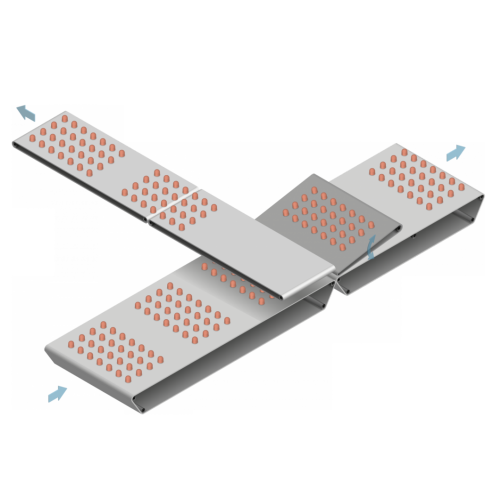

Cross transfer station for mould configuration products

Streamline the transfer of mould-configured products across your ...

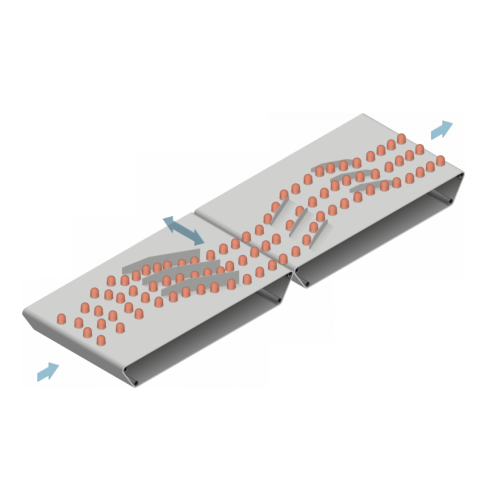

Lane arrangement for efficient product transfer

Optimize your production line’s efficiency with seamless integration...

Flexible high-speed wrapping machine for chocolate products

Optimize your confectionery production line with a flexible ...

Flexible high-speed wrapper for confectionery products

Streamline your packaging process with a versatile machine designe...

High-speed cartoning system for primary wrapped products

Optimize your packaging line with this high-speed cartoning syst...

Linear weigher for dry free flowing powder

Optimize your packaging line with precise weighing for free-flowing granular pr...

Cooking extruders for continuous food processing

Optimize your extrusion processes with cooking extruders designed for con...

Cold forming extruder for food manufacturing

Achieve precise shape and density control in cereal and snack production by i...

Custom extruder for specialized industrial applications

Experience unparalleled customization in extrusion technology, en...

Airflow grain puffing machine

Unlock the potential of versatile snack production with precision-engineered airflow puffing t...

Vffs packaging solution for diverse bag styles and high hygiene standards

Enhance your packaging operations with high-...

Centrifugal sifter for efficient particle separation

Enhance your material throughput by efficiently separating particles...

Low profile flow-thru separator for wet or dry scalping

Efficiently handle high-capacity separation with a compact design...

Sanitary separator for food processing applications

Ensure efficient separation and prevent contamination in food product...

Thermal conditioning for improved meal flow and starch digestibility

Ensure optimal meal flow and starch digestibility ...

Small batch mixing rotosphere blender for food industry

Achieve precise mixing of small batch powders and granules with a...

High-capacity pre-cleaner drum for grain silo storage

Optimize your pre-cleaning process with a high-capacity drum that e...

Industrial hammermill for fine grinding applications

Elevate your milling efficiency with hammermills designed for precis...

High-capacity sleeve filters for silo dedusting

Optimize your production with filtration systems that ensure efficient dus...

Pellet mill for powdery animal feed products

Maximize plant efficiency and product quality with a versatile pelleting solu...

Agricultural cleaner-separator for grain processing

Optimize your grain processing with a versatile cleaner-separator eng...

Mobile circulating dryer for agricultural products

Optimize your drying processes with a mobile circulating dryer, design...

Grain dryer with air circulation system

Enhance efficiency and product quality with our versatile grain dryer, designed to ...

Stationary grain dryer with biturbo system

Optimize your drying processes with a system that efficiently manages air flow ...

Low-emission belt drying systems for timber industry

Optimize moisture control and energy efficiency in drying processes ...

Industrial air heater for agriculture and industry

Optimize energy efficiency and maintain high air quality in your produ...

Belt dryer for timber industry

Optimize moisture removal and ensure consistent drying in your production line with advanced ...

Layer dryer for food and pet food applications

Optimize drying efficiency with multi-layer technology that minimizes space...

Belt dryer for food and pet food products

Optimize drying processes with customizable belt dryers, engineered to handle ro...

Belt dryer for sawdust

Optimize your drying process with advanced technology engineered for precise moisture reduction in div...

Hybrid dryer for agriculture and industrial applications

Achieve efficient moisture reduction in varied materials, from f...

Mobile belt dryer for sawdust and biomass

Efficiently reduce moisture in a variety of materials, from sawdust to cereal sn...

High-force texture analyser for precise measurement

Achieve unparalleled precision in texture analysis for high-force app...

Portable texture analysis for low force applications

Easily perform precision texture measurements on low-force applicati...

Powder flow measurement system

Achieve precise control over powder consistency and prevent process disruptions by assessing ...

Texture analyzer for high force applications

Achieve precise texture measurement across a vast array of products with a so...

Texture analyser for food and cosmetics testing

Ensuring consistent product quality across diverse food and cosmetic appli...

Advanced cooling tunnel for confectionery production

Optimize your confectionery production with a cooling system that en...

In-line metal detector for pneumatic systems

Ensure product purity and operational efficiency with a solution that effecti...

Conveyor belt metal detection system

Ensure seamless product safety with a system that detects and separates metallic conta...

Metal detector systems for conveyor belts and chutes

Ensure the integrity of your production line by efficiently detectin...

Single shaft horizontal batch mixer

Achieve consistent, high-quality blends with precise homogenization using a single shaf...

Twin shaft horizontal batch mixers for homogenous material mixing

Achieve consistent and rapid mixing of diverse materi...

Modular packaging systems for diverse industries

Effortlessly adapt to market demands with versatile packaging systems, de...

Batch mixers for raw material preparation in extrusion processes

Optimize your extrusion process with precise raw materi...

Cooling drum for breakfast cereals production

Ensure even cooling and product separation with optimized airflow for higher...

Infrared dryer for breakfast cereals

Optimize your snack production with precise moisture control, energy-efficient infrare...

High-accuracy moisture analyzer for lab weighing

Achieve precise and reproducible moisture content determination for diver...

Fast and accurate moisture meter for various samples

Quickly determine moisture content in solids, liquids, and pastes wi...

Compact case packer for secondary packaging

Optimize your secondary packaging process with a case packer that operates cle...

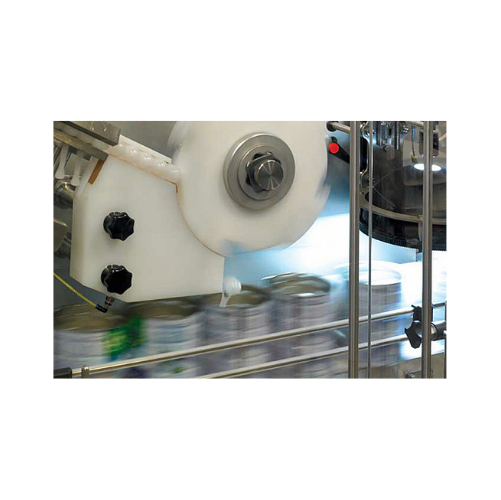

Side Load Case Packer For Packaged Food

Accuracy is a primary concern for case-packing pre-packaged foods such as milk or p...

Intelligent Continuous Food Cartoner

Fully automated robotic packing solutions enable larger-scale food producers to pack a...

Temperature-treatment mixer for bakery & gastronomy

The production of creams, sauces, ragouts, ready-to-bake, and sim...

High speed carton closing machine

Choosing a carton closing machine becomes a significant consideration when the closing of...

Continuous vertical cartoner

When producing cereals, it is paramount to stay on top of market trends. New packaging forms ca...

Batch cooker of cereal foods

Controlled steam cooking of whole or milled grain products is the best way to ensure best textu...

Extruder for large-scale production of breakfast cereals

Shaped and filled extruded breakfast and snack products are extr...

Cooling drum for soft and caramel mixtures

Cool your product to the temperature required for further processing. This is a...