Making Protein Bars

Find innovative production technology for making protein bars and connect directly with world-leading specialists

In NASA's early years, a research program was established on how to provide food for astronauts while in space. In fact, in the 1960s, nutrition bars were launched with a label called "Space Food Sticks" because they were designed to allow astronauts to eat them easily while wearing their helmets. Protein bar manufacturing equipment is used to mix ingredients, extrude the mixture at a set temperature, cool the product before cutting it to size, coating it, and allowing it to cool to prepare it for packaging.

Select your protein bars process

Tell us about your production challenge

What protein sources are used for your protein bar?

The protein content of a protein bar varies depending on the manufacturer’s recipe. But what makes one bar more protein than another? A complete source of protein contains all 9 essential amino acids. For instance, whey and casein, obtained from pasteurized milk processing, have all 9 amino acids. Other protein sources include dehydrated egg whites and plant-based proteins like soy, pea, brown rice, and hemp. However, plant-based proteins lack some essential amino acids; so to make them a complete source of protein, they are mixed with other proteins that contain the missing essential amino acids.

Aside from protein sources, protein powders used in the bars are also available in different types. Protein concentrate is a type of protein powder made up of 60-80% protein with the rest of the ingredients coming from fats and carbohydrates. Protein isolate powders have around 90-95%, so they have a higher protein content than protein concentrate. They come from protein concentrate but with the fats and carbohydrates removed. The last type of protein powder is protein hydrolysates. This type of protein goes through additional processes by heating with acid, or adding enzymes, for easy body absorption when consumed.

Mix, extrude, and cool your ingredients using protein bar manufacturing equipment

The protein bar manufacturing process starts with protein powders of your choice, such as whey or casein, mixed with other ingredients like dried fruits, nuts, and seeds in an industrial mixer. After thoroughly mixing the ingredients, the mixture has a paste-like texture; this may cause some parts of the product to stick to the surfaces of the mixer and then need to be scraped off. The mixture is then conveyed to an extrusion machine, where it is heated and extruded to a bar shape.

A conveyor belt transports the bars to a guillotine which cuts them into the required size where they will later be with chocolate or other flavors. After enrobing, they are cooled in preparation for packing.

How to increase the protein level in your date bars

To meet the demand for more nutritious and healthy snacks, a study was made about the protein level of date bars using two different sources of protein bars. Dates contain a good amount of carbohydrates and other nutrients but lack protein. During the development of the bars, protein sources such as whey protein concentrate and vetch protein isolate were incorporated.

It was found that the protein content of the date bars was significantly higher using both sources of protein. The level of protein content increased to 7.55%. The test also involves the evaluation of the physicochemical properties and sensory characteristics of the date bars over time. Their taste was not affected.

Insect protein as an alternative source for your protein bars

Another source of protein currently utilized in protein bars is insect protein. Insects, such as crickets are rich in protein. For making protein bars, these edible insects are roasted and ground to make high-protein flour. Then they are mixed with other ingredients to improve the flavor and go through the same extrusion process as with other protein bars.

Having crickets as a source of protein is more sustainable than whey or soy because whey is part of dairy production that contributes high levels of methane gas to the environment and soy that is used for production requires large amounts of pesticides. Crickets, on the other hand, require less food and water to produce making it easier for mass production.

Processing steps involved in protein bars making

Which protein bars technology do you need?

Clarifiers for plant protein recovery

Maximize protein yield and minimize waste with advanced clarification technology desi...

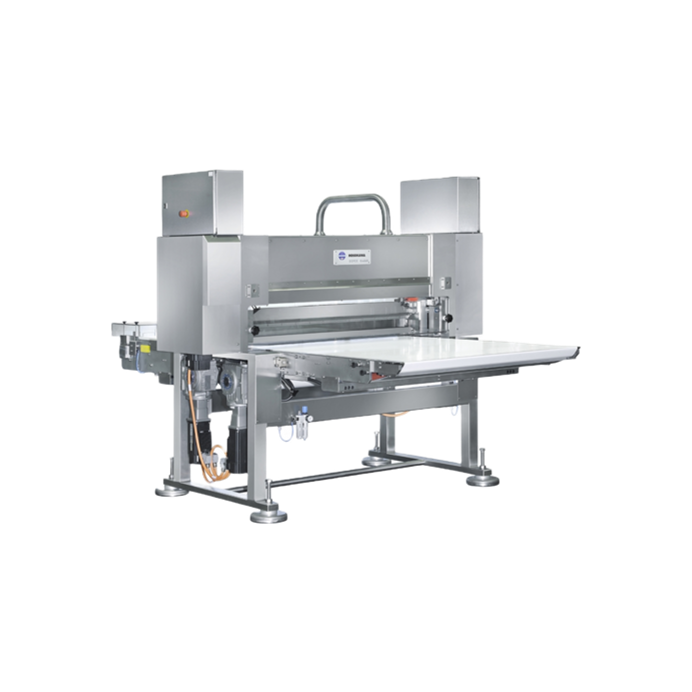

Cookie dough wirecut machine

Achieve precise control and flexibility in shaping a wide variety of cookies and bars with this...

Intermittent end load cartoner for baked goods and snacks

Optimize your packaging line with an efficient, space-saving c...

High efficiency milling solution for pharma and food industries

Achieve precise particle size control and enhance produc...

Cleaning and sterilization in place for hygienic control

Ensure maximum hygiene and sterility in your production line wit...

Medium duty mixer for breads and pastries

Achieve consistent dough development and uniform mixing for a wide variety of ba...

Medium duty mixer for dough preparation

Achieve perfect dough consistency across various products with a versatile medium d...

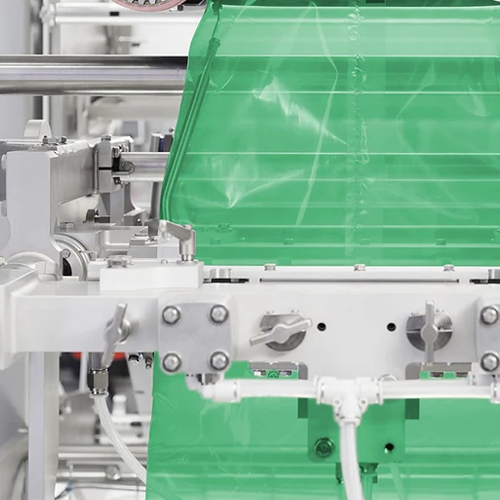

Flowpackers for efficient food packaging

Achieve seamless packaging with flowpackers designed for high-speed, sustainable o...

Horizontal cartoner for diverse industries

Streamline your packaging process with precise cartoning capabilities, effectiv...

Centrifugal bowl feeder for high-speed bulk item feeding

Optimize your production line with high-speed feeding of diverse...

Nougat and cereal bar forming drum

Streamline your snack production with precision forming of nougat and cereal bars, ensur...

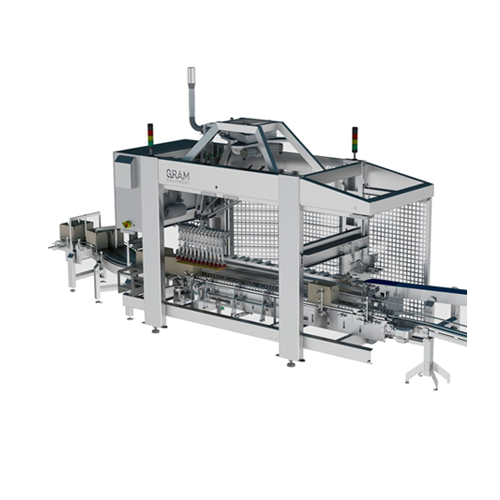

Top-loading cartoner for bar and confectionery packaging

Optimize your high-speed packaging operations with a flexible ca...

Fold wrapping solution for chewing gum tabs

Streamline your high-speed packaging line with a solution that expertly wraps ...

Twin station fold wrapping machine for chocolate bars

Efficiently transform diverse chocolate and confectionery items int...

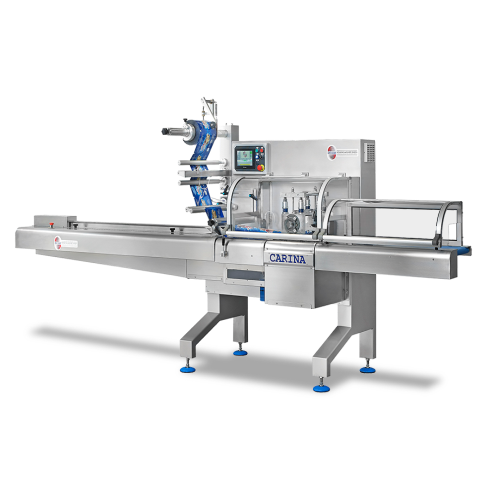

Horizontal flow wrap solution for chocolate bars

Achieve high-speed precision in packaging with a machine designed to hand...

Fold wrapping solution for round pharma tablets

Ensure precise and gentle packaging of round tablets with our innovative f...

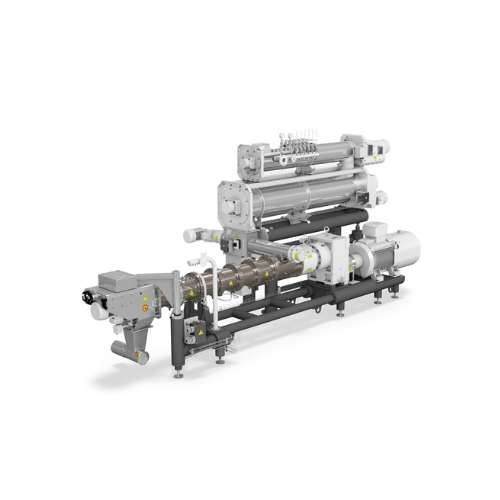

Industrial twin screw extruders for high torque and volume applications

Optimize your extrusion processes with high tor...

Entry-level moulding machine for small to medium production

Ideal for scaling new product lines, this versatile moulding...

Pick and place robotic system for confectionery decoration

For food producers seeking precision in snack decoration, thi...

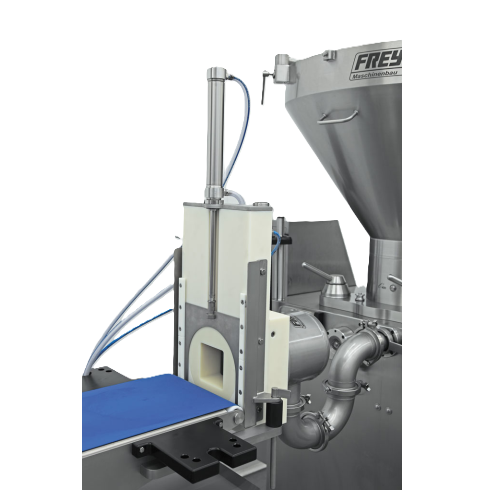

Extruder for pliable mixes in industrial applications

Achieve precision in creating diverse extruded food products with t...

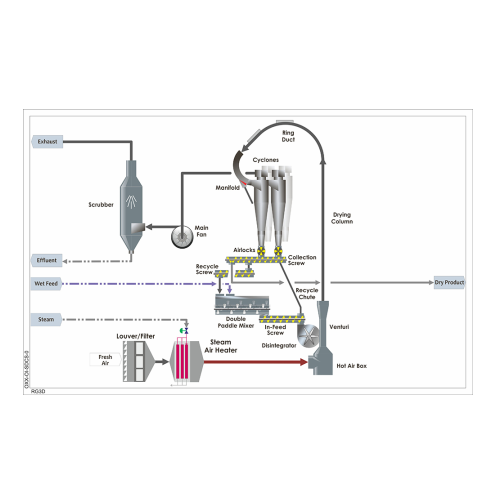

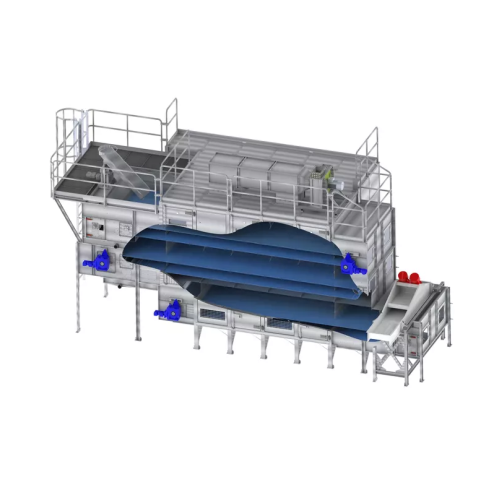

Protein drying system for dairy products

Optimize your dairy production with a customizable drying system designed for effi...

Rotary size grader for food processing

Enhance your production line by efficiently sorting and classifying produce to ensur...

Industrial transfer conveyor system

Efficiently transport and sort diverse food products with precision, ensuring seamless ...

Food processing mixing system for vegetables

Tackle complex product mixing challenges with a system that seamlessly integr...

Optical sorting platform for food processing

For manufacturers aiming to enhance quality control, this platform offers pre...

Optical sorter for food processing

Enhance your production line with advanced sorting technology that meticulously inspects...

Optical potato sorter

Ensure precise sorting with advanced optical technology that identifies and separates defects in a wide...

Collection conveyors for food processing

Optimize your production line by efficiently collecting and conveying solid produc...

High-speed centrifugal sifter for food and pharma applications

Optimize your powder processing with a high-speed centrif...

Intermittent motion cartoner for pharma packaging

Streamline your packaging line with versatile cartoning solutions that ...

Vertical baggers for confectionery packaging

Streamline your packaging operations with high-performance vertical baggers d...

Mixer/extruder for viscous pastes and plastic masses

Achieve seamless mixing, kneading, and extrusion of viscous material...

Compactors and granulators for powdery products

Transform loose powders into dense, free-flowing granules that enhance han...

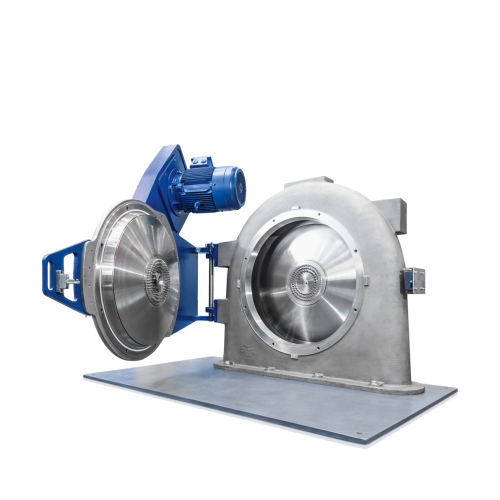

Pin mill for fine grinding of sticky materials

Achieve ultra-fine grinding of challenging materials with high speed and pr...

Laboratory system for powder and particle processing

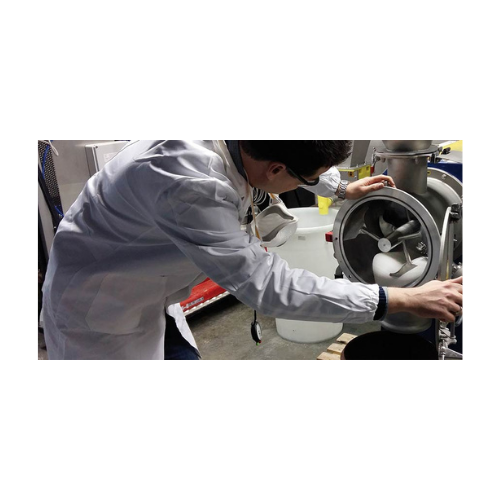

When precision in powder processing is crucial, this versatile labor...

R&d scale steam cooker for small batch processing

Optimize your R&D with a steam cooker that replicates large-scale ...

Cooling drum for seasoned extrudates

Ensure consistent texture and quality in your extruded snacks by effectively cooling s...

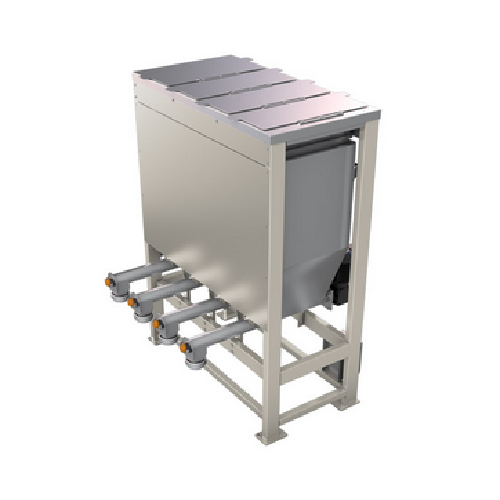

Intermediate container for raw material preparation

Streamline your snack and cereal production with this solution that e...

Multi-lane checkweigher for mixed-application production lines

Achieve precise weight verification across multiple lanes...

Continuous multi-lane wrapping solution

Achieve precision and speed in packaging with an advanced solution designed for con...

High-speed mixer for granulating and mixing powders

Achieve consistent granulation and mixing with precise temperature co...

Pneumatic knife for forming and cutting pasty products

Achieve precision and speed in forming and cutting various pasty p...

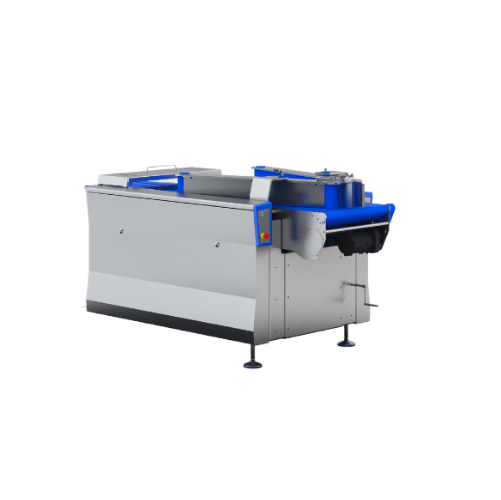

Cooling tunnel for confectionery extrusion

Optimize your production line with a versatile cooling tunnel capable of effici...

Confectionery cutting system for accurate results

Achieve precision and flexibility in modern confectionery production wi...

Industrial wendel mixer for dough production

Optimize your dough and bar production with reduced kneading times and increa...

Premium industrial mixer for dough production

Enhance dough production efficiency with a mixer that reduces kneading times...

Pea fiber drying solutions for food or feed applications

Ensure top-tier product quality with precise drying of pea fiber...

Three-side sealing flow pack machine

Optimize packaging efficiency with a high-speed flow pack machine that ensures precise...

Percolation extractor for high-volume vegetable protein extraction

Optimize extraction efficiency across diverse materi...

Loss-in-weight scale for micro ingredient batching

Enhance precision in your production line with advanced micro ingredie...

Vacuum mixer/blender for food processing

Achieve precise mixing and blending with air removal for consistent quality across...

Transfer hopper with stainless Pd pump for food processing

Eliminate spillage and maintain continuous flow with a positi...

Vertical screw conveyor for ground materials

Optimize floor space in food processing with this vertical solution, ensuring...

Horizontal screw loader for food processing

Optimize your production flow with a smooth-loading solution designed to effic...

Inclined screw loader for food processing

Optimize your food processing line with an inclined screw loader, designed for e...

Compact food emulsion and reduction system

Achieve precise control over product texture and temperature with a compact sol...

Coating dryers for breakfast cereal production

Achieve precise moisture control in coated cereal production with these mod...

Food and confectionery twin-screw extruder

Enhance your confectionery production with a versatile twin-screw extruder desi...

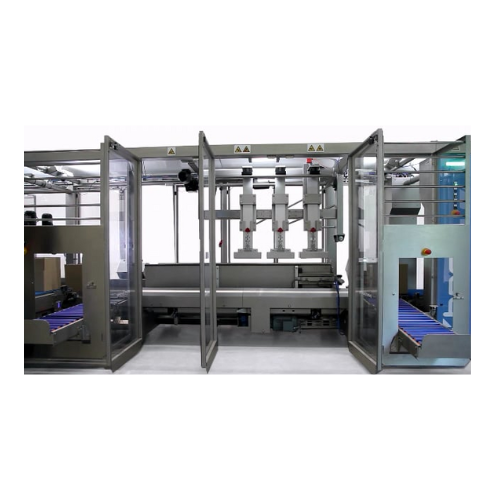

Horizontal case-packer for medium-sized shipping cases in pharma and food

Streamline your packaging line with a versat...

Analyze wet granulation properties for pharmaceutical formulation

Optimize your pharmaceutical and chemical formulation...

Transversal cutting for confectionery production

Achieve precise and customizable cuts in high-speed confectionery and bak...

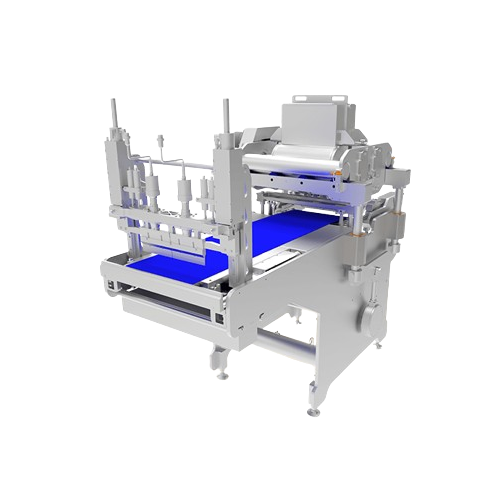

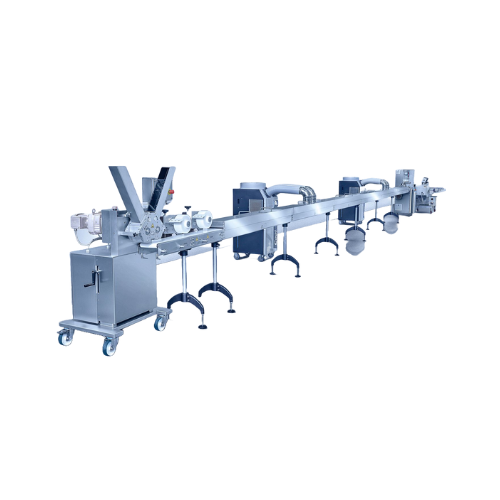

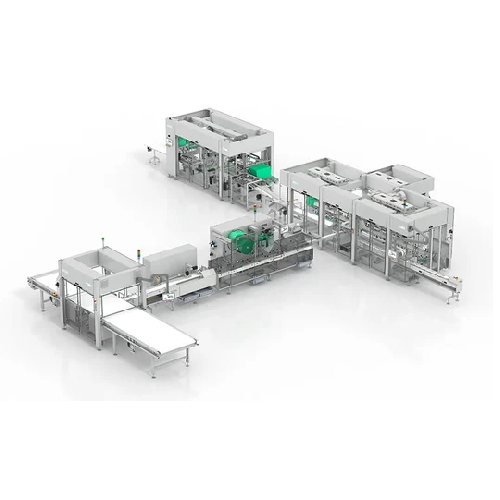

Small-scale cereal bar production system

For nimble snack producers, this system offers versatility by seamlessly integrati...

Single-screw extruder for pet food and aqua feed

For producers aiming to diversify their offerings, this single-screw extr...

Scraped surface heat exchanger for viscous liquids

Optimize heating and cooling of viscous liquids efficiently with conti...

Premixer for confectionery masses

Achieve consistent ingredient blending with precision-premixing for candy and baked goods...

High-efficiency cooling tunnel for confectionery production

Optimize your product cooling process with high-efficiency t...

Chocolate enrober for bars, cookies, and wafers

Ensure consistent and high-quality enrobing for confections with advanced ...

Twin-screw extruder for breakfast cereals production

Enhance your product range with flexible twin-screw extrusion techno...

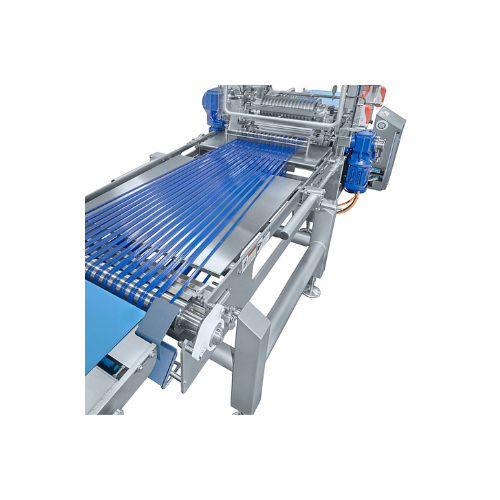

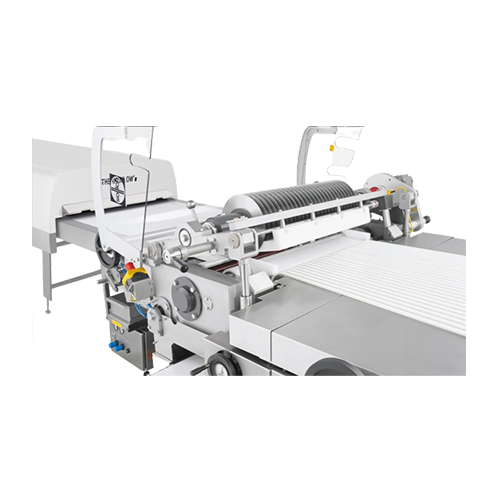

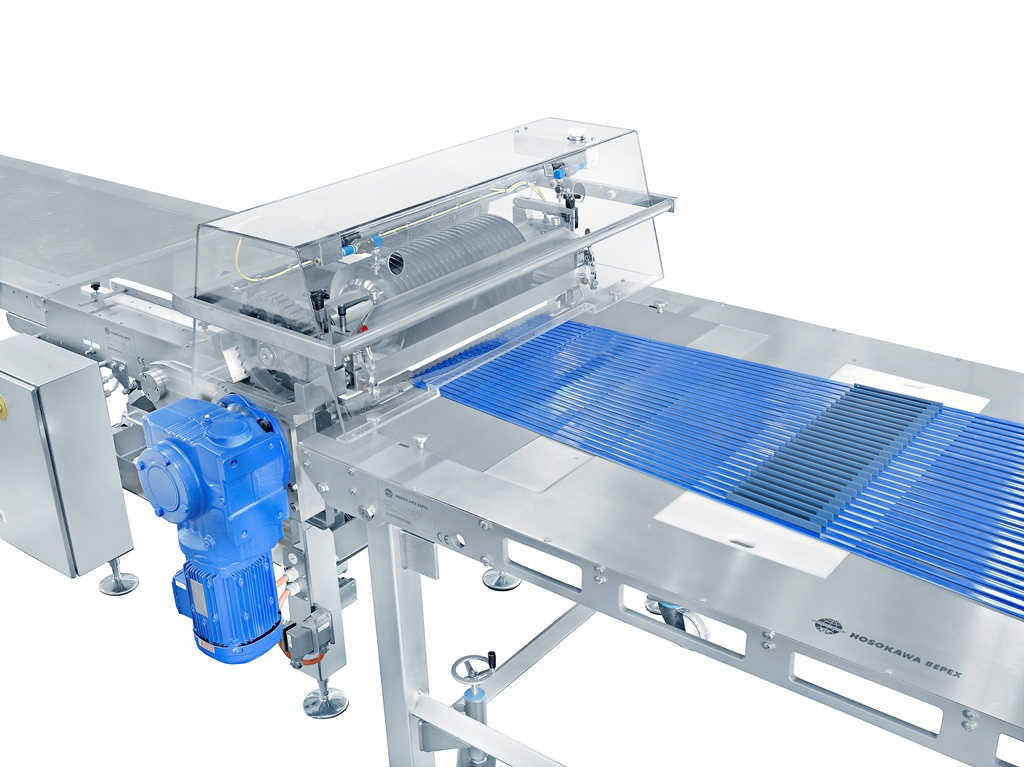

Industrial fanning belt for strand separation

Enhance your production line efficiency with precise strand separation, ensu...

Twin-screw extruder for breakfast cereal

Optimize your production with a robust twin-screw extruder that accommodates high ...

Ultra-fine pulverizer for aqua feed and pet food

Achieve precise granulation with high efficiency for your feed and food p...

High-speed case packer for snack bags

Optimize your packaging efficiency with a compact solution designed for seamless vert...

Horizontal load carton erector for food production

Enhance your production line with precise carton erecting, loading, an...

Flexible bag case packer with integrated case erector

Streamline your secondary packaging process with an efficient solut...

Full Rsc case shaker-compactor-sealer

Streamline your packaging line with a solution that compacts and seals cases to elimi...

Tray erecting system for various tray styles

Effortlessly configure diverse tray styles with an efficient system designed ...

Sanitary horizontal paddle vacuum dryer

For sensitive product drying, ensuring short cycles and high thermal efficiency is ...

Contamination-free docking system for bulk solids

Achieve contamination-free transfer of bulk powders and granules while ...

Combi x-ray and checkweigher for vertical products

Ensure precise weight control and contamination detection for vertical...

Multipack flowrapping system

Streamline your packaging process with a multipack flowrapping system that effortlessly handles...

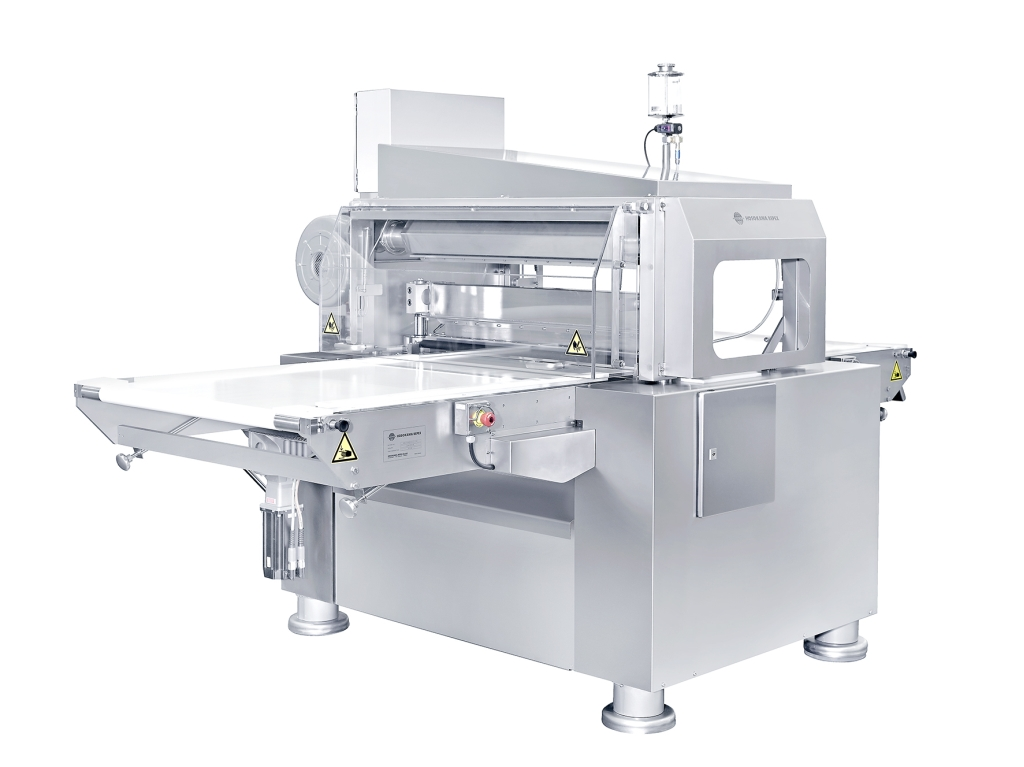

Bar forming line for protein bars

Efficiently form and process a wide range of snack and confectionery bars with our versat...

Hydro grind reactor for meat, vegetable, and vegan product processing

Achieve precision grinding and emulsification of ...

High speed horizontal flow wrapper for food products

Achieve precise, high-speed packaging for snacks with this versatile...

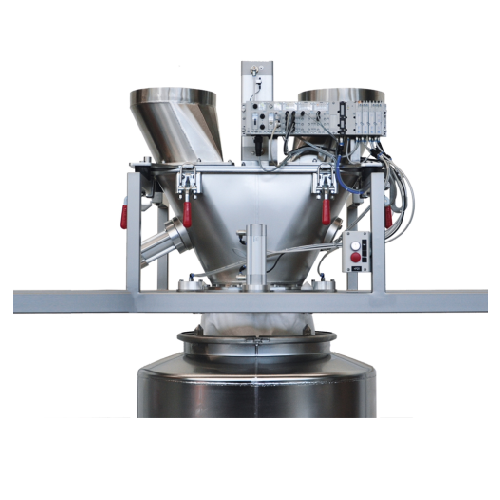

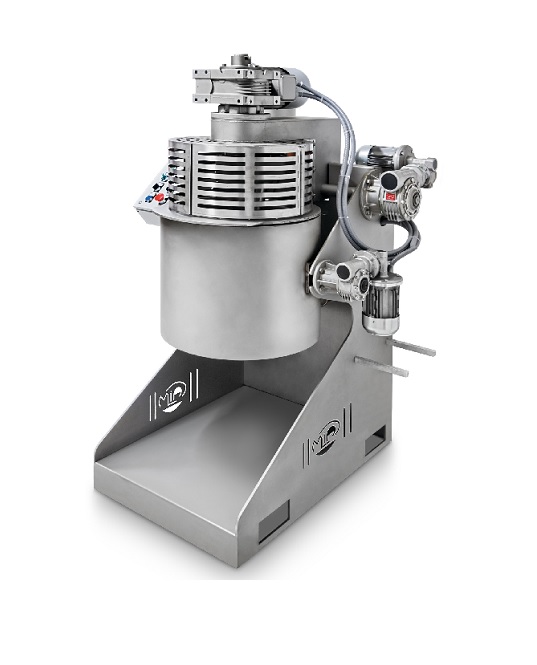

Extruder and depositor for protein bar manufacturing

Streamline your protein and energy bar production with an advanced e...

High shear mixer for dairy and personal care products

Achieve consistent emulsification and stable homogeneity with high ...

Dairy waste reduction with evaporator product recovery

Transform dairy processing by efficiently recovering valuable low ...

Pv processing vessels for liquid and cream mixing

Optimize your mixing operations with versatile processing vessels desig...

Industrial coating pan for food and pharmaceutical products

Optimize your production with precision mixing and coating, ...

Laboratory mixers for product development and research

Optimize your R&D efforts with advanced mixing solutions desi...

Industrial mixers for hire

Optimize your production line with versatile mixers designed for precision blending, heating, and...

Sanitary dryers for textured vegetable proteins

Optimize drying and sanitation for textured vegetable proteins and pet foo...

Conical twin screw extruder for pet food and aquatic feed

Precision-engineered for high-speed extrusion and drying proce...

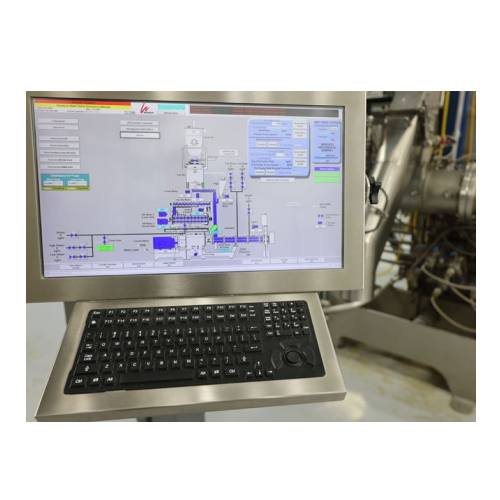

Automated process management system for industrial extrusion

Optimize your production line with precise control and moni...

Convection roaster for pet food and delicate food products

Achieve optimal texture and moisture control in delicate food...

Thermoforming packaging system for medium production volumes

Optimize your food packaging with high-speed, continuous op...

Laboratory batch mixer for small scale production

Achieve rapid and reproducible mixing results with this laboratory batc...

Container filling system for pasty and chunky products

Achieve precise, drip-free filling of diverse pasty and chunky pro...

Vacuum filling machines for cooked ham & sausages

Achieve precise portioning and enhanced product quality with this advan...

Side seal shrink packaging machine

Achieve seamless and efficient packaging for varied product sizes with continuous side s...

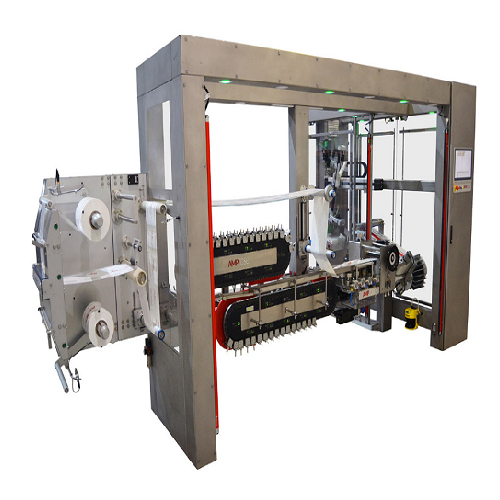

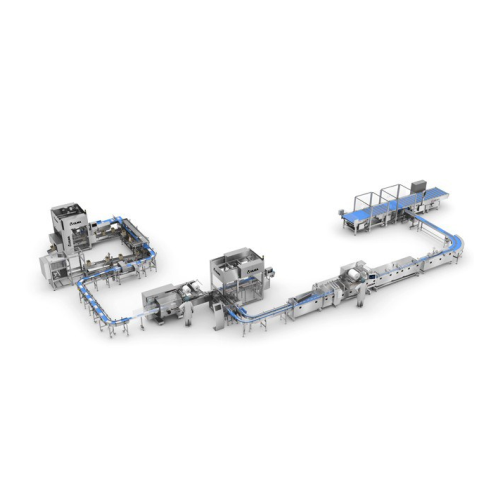

Complete primary and multipack packaging solution for bars

Enhance your bar production efficiency by seamlessly integrat...

Automated packaging and case packing for snack bars

Optimize your snack bar production line with this high-speed solution...

Ultrasonic food cutting

Optimize your production line with precision ultrasonic cutting technology, designed to enhance consi...

Industrial steam peeler for potatoes

Optimize peeling efficiency while minimizing waste and energy usage with this high-spe...

Compact high-torque extruder for customizable extrusion tasks

Ensure precise control over your extrusion processes with ...

Dry granulation system for pharmaceutical powders

Streamline your powder processing with a dry granulation system that en...

Laboratory extruders for feasibility studies and r&d

Optimize your testing with laboratory extruders designed for precise...

Single screw extruder for chemical catalysts and sealants

Optimize material ingestion and processing with a versatile si...

Spray dryer for heat-sensitive powders

Ensure high-quality drying of heat-sensitive powders, producing non-caking and non-h...

Pure water generation system for pharmaceutical manufacturing

Ensure high-purity water and steam production with precisi...

Horizontal flow wrapper for food packaging

Simplify your packaging process with our high-speed horizontal flow wrapper tha...

Paper forming technology for sustainable packaging

Elevate your product’s sustainability with advanced paper formin...

Vffs packaging solution for diverse bag styles and high hygiene standards

Enhance your packaging operations with high-...

Small batch mixing rotosphere blender for food industry

Achieve precise mixing of small batch powders and granules with a...

Reliable cartoning solution for food and non-food products

Achieve seamless product packaging with a cartoning solution ...

Stationary grain dryer with biturbo system

Optimize your drying processes with a system that efficiently manages air flow ...

Layer dryer for food and pet food applications

Optimize drying efficiency with multi-layer technology that minimizes space...

Wet granulation system for pharmaceutical tablets

Optimize your tablet production with precise particle size reduction an...

Portable texture analysis for low force applications

Easily perform precision texture measurements on low-force applicati...

Texture analyzer for high force applications

Achieve precise texture measurement across a vast array of products with a so...

Entry-level texture analysis system for Qc applications

Perfect for quality control labs, this portable system streamline...

Texture analyser for food and cosmetics testing

Ensuring consistent product quality across diverse food and cosmetic appli...

Tubular ultra high temperature processing system for dairy products

Optimize your dairy processing with precise thermal...

Pilot plant homogenizer for immiscible liquids

Streamline your R&D with precise homogenization, allowing you to test ...

Small scale spin flash dryers for high-viscosity liquids

Optimize moisture control with cutting-edge spin flash dryers de...

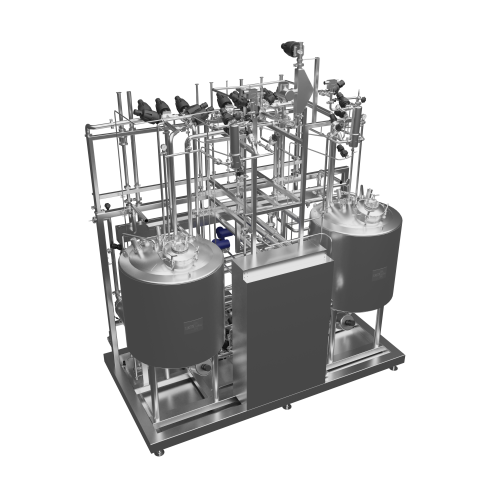

Clean in place (cip) system for industrial cleaning

Ensure optimal hygiene and production efficiency with a system that s...

Volumetric feeder for flowable ingredients

Ensure consistent and precise dosing of diverse materials in your production li...

Automated dissolution sample collection system

Double your testing efficiency with parallel dissolution sampling, ensuring...

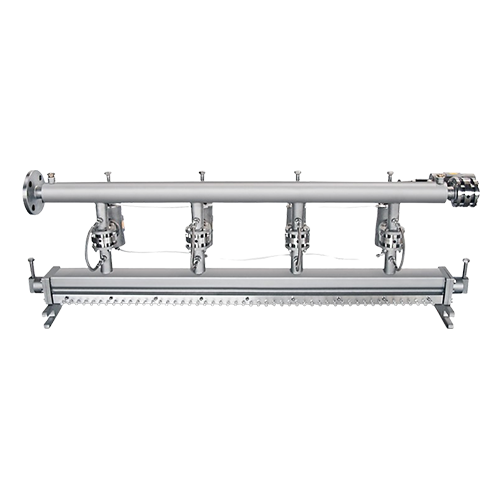

Lay-on systems for precise sprinkling and nut depositing

Optimize your confectionery production with precision sprinkling...

Sprinkling system for decorating confectionery products

Enhance your confectionery line with precision sprinkling systems...

Bulk chocolate storage for confectionery production

Maximize space efficiency while maintaining product quality with our ...

Chocolate storage tanks for confectionery production

Optimize your confectionery production with state-of-the-art storage...

Sieving system for chocolate processing

Ensure product purity and consistency by seamlessly removing unwanted particles fro...

Decrystallization for tempered chocolate

Ensure your chocolate is perfectly smooth and free of fat crystals with an advance...

Confectionery rework tempering solution

Improve confectionery production efficiency by integrating a compact rework temperi...

Chocolate tempering solution for superior gloss and shelf life

Achieve consistent sheen and extend the shelf life of cho...

Z-conveyor for confectionery production

Ensure the gentle transport of delicate dry and granulated ingredients with a versa...

Automatic feeder for enrobing solid articles

Ensure seamless feeding for large-scale enrobing operations, enabling efficie...

Praline and bar product take-off system

Streamline your confectionery production with a versatile take-off system designed ...

Longitudinal slitting system for confectionery production

Achieve precise confectionery dimensions with our customizable...

Transverse cutting systems for confectionery production

Achieve precise cutting and slitting with high-speed transverse s...

All around sprinkling systems for confectionery

Enhance your confectionery production with a system that ensures precise a...

Chocolate decoration systems for confectionery production

Enhance your confectionery production with precision chocolate...

Automated chocolate decoration system

Elevate your confectionery production with precision chocolate decoration, seamlessly...

Continuous bar production line for confectionery

Streamline your confectionery production with a seamless system for craft...

Chocolate shell molding system

Optimize your confectionery production with precision shell formation, enabling diverse and i...

Manifold system for producing weight-accurate ropes of chocolate or fruit masses

Achieve precise weight and shape in c...

Forming solution for candy and cereal bars

Achieve precision in bar production with a system that ensures minimal weight v...

Volume-precise moulding for chocolate and fat masses

Achieve precise and consistent moulding for chocolate and confection...

Continuous mixer for confectionery and bakery ingredients

Maximize production efficiency by seamlessly integrating mixin...

Sugar and fondant coating solution

Achieve precise, multi-color or single coat applications with thin, uniform layers, seam...

Retractable mass carriage enrober for chocolate coating

Improve production flexibility with a versatile enrober that allo...

Ice cream coating system for enrobing applications

Achieve seamless chocolate and nut coatings on ice cream bars and conf...

Enrobing system for full, half, and bottom coating of chocolates

Achieve precise and consistent chocolate coating with a...

Enrobing system for biscuits and baked goods

Achieve consistent and precise chocolate coatings with the versatility you ne...

Integrated tempering enrober for chocolate coatings

Enhance your chocolate production line with an integrated solution fo...

Bucket sheeter for confectionery masses

Efficiently form thin, precise layers of flowable confectionery masses with ease, e...

Industrial spreading systems for sticky products

Effortlessly manage the spread of sticky confectionery products with prec...

Cooling tunnel for center cooling in confectionery production

Efficiently manage center cooling in confectionery product...

Advanced cooling tunnel for confectionery production

Optimize your confectionery production with a cooling system that en...

High-precision biscuit sandwiching system

Efficiently align, fill, and sandwich high-speed biscuit rows while ensuring pre...

Bottom coating system for confectionery production

Optimize your confectionery line with precision bottom coating, ensuri...

Dosing system for bakery and convenience food

Achieve precise dosing and filling of liquids and slurries with this versati...

Refrigeration jacket for triple roller bar mixers

Enhance dough mixing performance by efficiently managing temperature co...

Professional chocolate tempering system for chocolatiers

Achieve precise chocolate tempering with advanced digital contro...

Chocolate tempering solution for small scale production

Efficiently temper chocolate for diverse confectionery creations ...

Continuous extruder for protein bars and super foods

Optimize your snack production with a continuous extrusion solution ...

Wall chocolate fountain for continuous chocolate flow

Create a mesmerizing ambiance with a seamless chocolate waterfall, ...

Flow-wrapping machine with quick format changeovers

Optimize your packaging flexibility with a flow-wrapping machine desi...

Top loader robots for precision packaging

Optimize packaging operations with versatile robotic top loaders that achieve hi...

Production system for molecular diagnostics

Eliminate bottlenecks in molecular diagnostics production with a versatile sys...

Horizontal cartoning system for coffee pods

Enhance your packaging line efficiency with a system designed for gentle handl...

Sequentially automated case packer for small products

Efficiently pack diverse small products into large cases with preci...

Standardized modular tray former for secondary packaging

Optimize your packaging line efficiency with this modular tray f...

Guillotine cutter for confectionery

Confectionery products such as marshmallows, licorice candies, and fudges come out of e...

Entry-level cereal bar making machine

Cereal and grain bars are increasingly popular, both as snack foods and as functional...

Industrial vacuum cooker

Batch cookers can be highly inflexible and inefficient, relying on maximum fill levels to operate we...

Display tray cartoner machine

Packaging products usually require a great deal of flexibility to comply with demand from mark...

Medium-speed flexible wrapping machine for chocolates

Larger scale wrapping of individual chocolate products demands gent...

Strand forming machine for 2 masses

Form two-ingredient mixes into the shapes and layer combinations required for your fina...

Strand forming machine for 3 masses

Form three ingredient mixes into the shapes and layer combinations required for your fi...

Strand forming machine for creamy mixtures

Turn your ingredients mixture into strands and slabs for further processing int...

Strand cutting machine

Cut continuous strands and slabs of your ingredient mix into bars, strips, and other final product sha...

High-speed strand cutting machine

Cut continuous strands and slabs of your ingredient mix into bars, strips, and other fina...

Longitudinal strand cutting machine

Cut continuous slabs of your ingredient mix into spaced strands for further processing ...

Entry-level automatic cereal bar machine

Start up your manufacturing of cereal bars or produce smaller batches to test and ...

Slab forming machine

Turn the mixture of your ingredients, into continuous slabs for processing into bars, stands, or other s...

Strand forming machine

Form ingredient mixes into strands and slabs for further processing into bars, and other final product...

Small scale nut grinder

Many confectionery and bakery processes rely on the uniform grinding of raw ingredients such as nuts,...

Entry level cereal bar cutting table

The small-scale manual production of crunchy cereal bars, brittles, and similar produc...

Entry level cooker for cereal bar production

The creation of high-quality, flavourful crunch bars, brittles and similar pr...

Automatic stretch wrapping machine for medium speed

For secure, automated stretch wrapping at medium speeds, the key is e...