Making Soy Milk

Find innovative production technology for making soy milk and connect directly with world-leading specialists

First mentioned on a stone slab of the Eastern Han dynasty in ancient China, soy milk has survived centuries and spread from Asia to Global consumption due to the rising popularity of plant-based alternatives. To produce soymilk, raw materials must be harvested, prepared, and blended with water and desired ingredients, such as flavors and vitamins, in soymilk processing equipment.

Tell us about your production challenge

The first steps in soymilk production: from soybeans to okara and jun

Soy is a fairly simple plant to grow; it can thrive in a variety of climates and soils. Once harvested, soybeans are brought to the production plant, cleaned in a grain elevator and dehulled by steaming the hull.

The grain elevator also measures the moisture content of the soybeans, which is typically from 45% to 55%. The clean beans must be soaked or cooked in the enzyme invalidator using high pressure and temperature to eradicate a specific enzyme indigestible for humans.

Ready soybeans are then transferred to grinders for two types of grinding – rough and finer grinding. It is firstly roughly ground with water, however, it requires further grinding as soybeans are still coarse, regardless of being cooked previously. This results in a white slurry that is passed through a large centrifuge pressing the slurry against the surface of a drum that extracts waste (fibers), known as okara, which remains on the outside of the drum, from the liquid forced inside the drum, which, at this point of production, is called jun.

Final production processes and soymilk processing equipment – Jun’s journey

Once okara is extracted from jun, the liquid is boiled in a soymilk cooking machine. The beverage-in-making is then stored in a soymilk storage tank, a mechanism ensuring production quality management. For commercial soymilk, the next step is the addition of sugars, flavors, and vitamins.

In order to disperse flavors properly, all the ingredients are blended, adding them from a smaller tank to raw soymilk in a larger tank. Once sterilized, jun is passed to a homogenizer to break down fat particles and prevent them from separating from the liquid. The temperature then must be decreased to room temperature in the cooling tanks. The final step is aseptic packaging without exposing the product to air.

Soy milk quality: food safety and foam reduction

The quality of soy milk starts with choosing the perfect raw materials: the ideal soybean has a white or colorless hilum. Furthermore, due to the low acid medium, which is the ideal environment for the development of bacteria and germs, the product must be meticulously controlled during the whole production, which in many factories means over 206 quality control checkpoints which entail controlling the temperature of water, steam, and pressure. Additionally, samples are taken every 10 minutes and checked for pH, temperature, and bacterial growth.

Another critical characteristic of high-quality soy milk is the absence of foam. Namely, soy contains a substance called saponin, which tends to foam in addition to protein. A practical solution is the use of defoamers, chemical additives that curb the formation of foam. The most effective defoamers for soy products are based on glycerin fatty acid ester, although defoamers can also be silicone-, water- or oil-based, etc.

Zero waste production – what to do with okara?

As a soybean byproduct, okara is associated with environmental problems due to large quantities of insoluble fiber. However, the industry has found ways to use the waste. Namely, it is used in agriculture as food for cattle and manure. Okara can also be used as a non-gluten flour alternative in baking goods.

In Singapore, scientists found a way to ferment okara and transform it into a tasty, nutritious food ingredient by adding natural microorganisms and enzymes. Furthermore, scientists have recently tried to produce novel biodegradable plastics from soya beans (Glycine max L.) with improved elasticity and plasticity.

The currently available soy plastic is mainly used as disposable food packaging, which is safe for temperatures below zero but sensitive to high temperatures. All in all, the production of soy plastic is less hazardous to the environment and animals than traditional types of plastic.

Methods for elimination of disagreeable soy odor

Soymilk has a specific “beany” odor resulting from the oxidation of specific unsaturated fatty acids by the enzyme lipoxygenase during the seed grinding process. This odor is repulsive for many consumers; therefore, manufacturers are trying to eliminate it as much as possible.

There are several ways to go about it, such as disabling the LOX enzyme with heat by boiling or blanching the beans in hot water. Nevertheless, it is possible to eliminate the odor without a heat treatment by blending soybeans in water free of dissolved oxygen. It is achieved by adding glucose and glucose oxidase to water to consume oxygen.

An environmentally friendly alternative to dairy

It is well-known that plant-based milk alternatives are not consumed exclusively by vegan and lactose-intolerant individuals but also by those aware of the dairy industry’s environmental impact. Making plant-based milk generates about one-third of the greenhouse gases compared to dairy milk, in addition to using far less land and water.

Soymilk especially stands out in this regard as it uses the least amount of water among all plant-based milk alternatives. Namely, 1L of produced soymilk requires 27.7L of water, which is nearly half compared to oat milk and more than 20 times less than dairy. In addition, soymilk performs well in the metric of eutrophication – the pollution of ecosystems with excess nutrients, resulting in the least pollution with 1,06 grams of waste per produced liter.

Processing steps involved in soy milk making

Which soy milk technology do you need?

Pasteurizer for extended shelf-life (esl) milk

Extend the shelf life of milk while maintaining its taste and nutritional i...

Milk pasteurizer for whey and cream

Ensure optimal product safety and quality with advanced heat exchange technology, reduc...

Milk skimming separators for dairy applications

Enhance dairy production with high-efficiency skimming separators that opt...

Milk standardization system

Achieve precise milk and cream fat standardization with this advanced inline system, optimizing ...

Membrane filtration for whey concentration

Enhance your liquid processing with advanced membrane filtration designed to im...

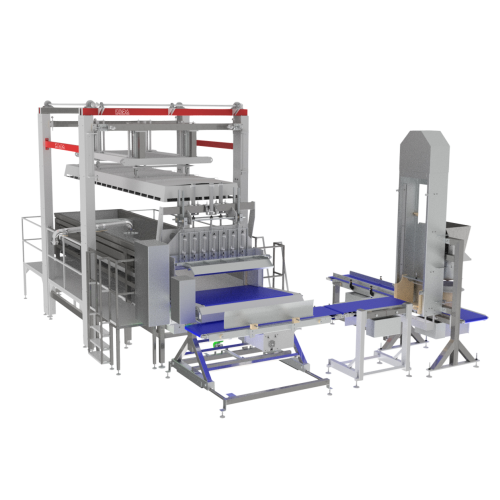

Cheese forming units for hard and semi-hard cheeses

Optimize your cheese production process with advanced moulding and pr...

Uht sterilization for milk

Enhance your production line with advanced UHT sterilization, ensuring extended shelf-life and un...

Complete milk processing lines

Optimize liquid product quality with a comprehensive processing line that integrates pasteuri...

High-performance decanter centrifuge for dewatering

Achieve efficient and reliable dewatering by integrating a decanter c...

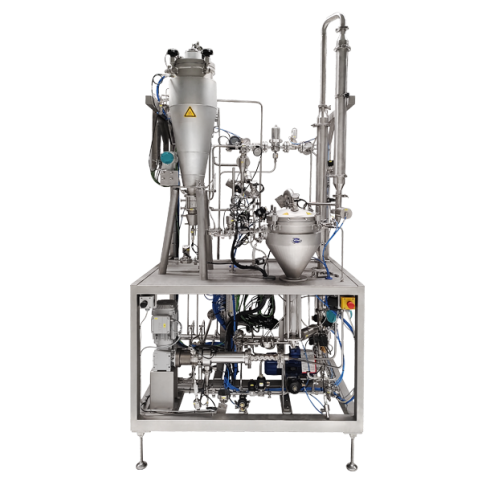

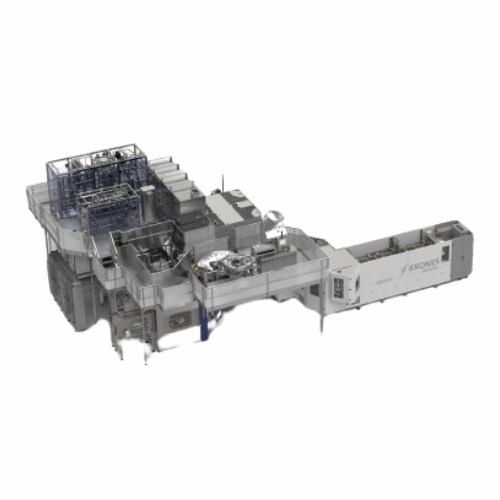

Soya milk production system

Efficiently transform soybeans into high-quality, non-beany soy milk with advanced processing te...

Dairy alternative production technology

Transform your production line with efficient dairy-alternative technology, enablin...

Milk powder processing plant

Achieve precise powder formulations with our state-of-the-art milk powder processing plant, ide...

Perforated disc mill for food and chemical processing

Streamline your processing workflow with a versatile solution that ...

Perforated disc mill for pre-comminution and mashing

Achieve precise granulating and mashing of diverse materials with th...

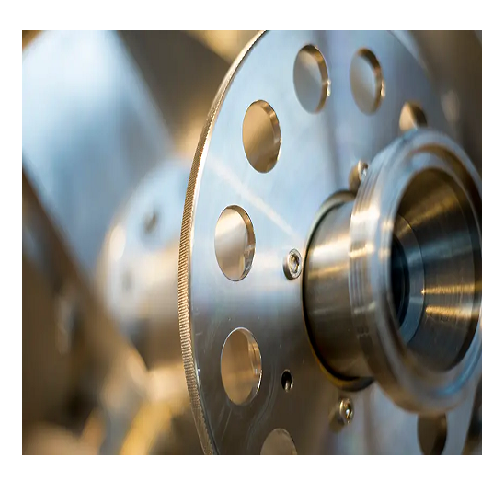

Industrial homogenizers for dairy products

Maximize consistency and quality in your production of milk products and bevera...

Stainless steel process vessels for biopharmaceutical applications

Ensure seamless mixing and sterilization with engine...

Mayonnaise production system

Ensure precise emulsification for low to full-fat mayonnaise and similar cold emulsions with a ...

Pig systems for product recovery in food and beverage industry

Maximize yield and minimize waste with advanced PIG syste...

Hygienic fluid storage tanks for food industry

Ensure impeccable hygiene in fluid storage with our customizable tanks, des...

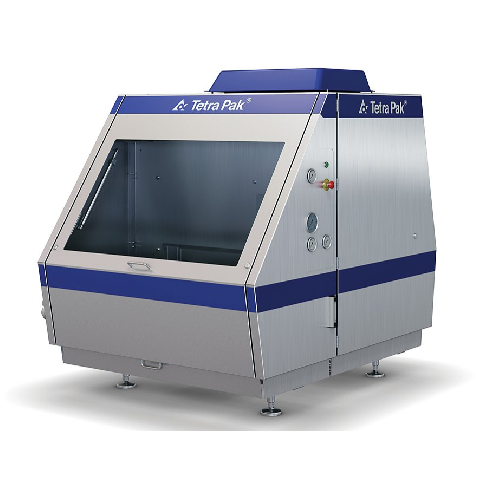

Aseptic buffer tanks for pilot scale process lines

Ensure seamless production flow and quality control in sterile environ...

Batch food processing cookers

Achieve precise temperature and pressure control for small-scale food production with modular ...

Atmospheric blending vessel for r&d activities

Optimize your liquid blending processes with this versatile vessel, designe...

Laboratory in-line sterilization system

Ensure precise temperature control and rapid cooling for diverse liquid application...

Direct steam injection Uht pilot system

Elevate your production capabilities with a sanitary UHT pilot system designed for ...

Direct steam infusion for high spore kill rate in sensitive food products

Achieve rapid, efficient sterilization and m...

Lab-scale water bath blending vessel for product preparation

Ensure consistent flavor and quality across diverse small-s...

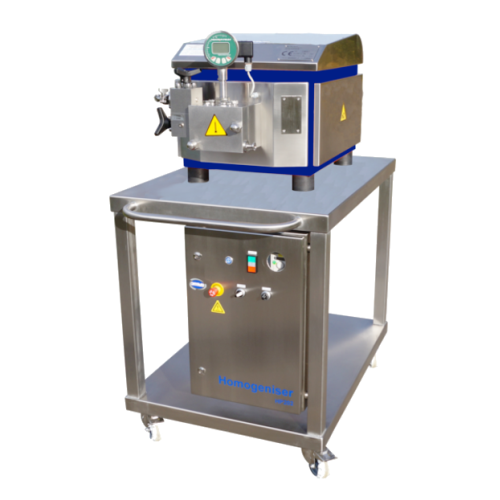

Lab-scale high-pressure homogenization solution

Optimize your lab-scale production with precision homogenization, ensuring...

Pilot homogenizer for high-pressure inline homogenization

Achieve precise homogenization and emulsification across vario...

Direct steam injection system for heat treatment

Achieve precise thermal processing and enhance product quality for comple...

Manual Cip unit for lab and pilot plant cleaning

Need thorough cleaning without disassembling your pilot plant? This compa...

Customized process plants for plant-based beverages

Efficiently scale your production of plant-based beverages with modul...

Lab-scale carbonation system for beverage filling

Streamline your beverage development with precision carbonation and ver...

Large insulated oil storage tank

Ensure optimal temperature control for sensitive liquids like oils, sauces, and creams with...

Compact tunnel pasteuriser for beverages

Ensure beverage safety with precise pasteurisation in a compact design that integr...

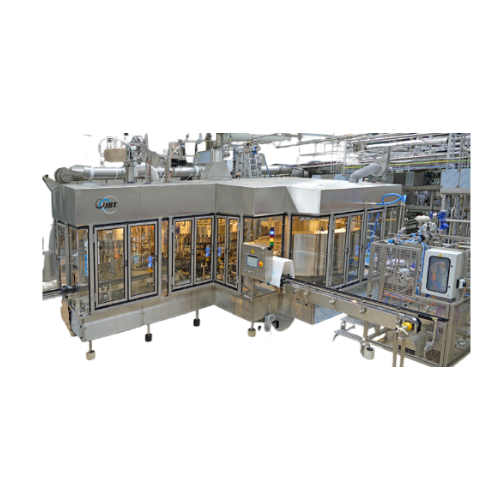

Ultrahygienic block for aseptic filling

When handling sensitive beverages, ensuring microbiological safety and quick produc...

Syrup room for customized beverage ingredient preparation

Achieve unparalleled flexibility in beverage production with a...

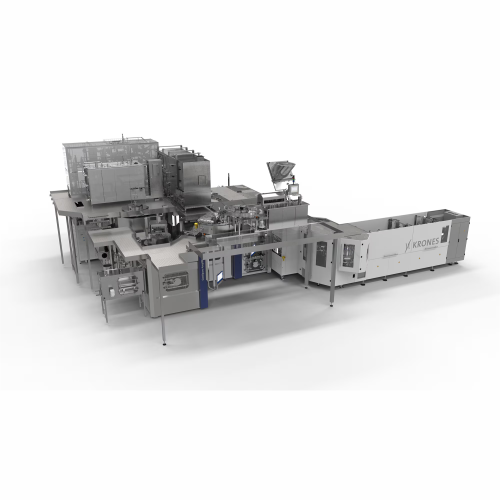

Flexible packaging line for beverage production

Streamline your beverage production with a flexible system capable of hand...

Innovative beer filling and capping technology

Revolutionize your filling process with an integrated system that combines ...

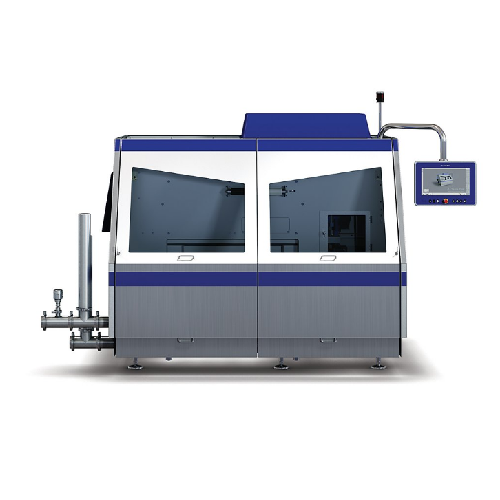

Aseptic bottle sterilisation system for Pet containers

Ensure aseptic integrity and high-speed efficiency in beverage pro...

Mixer for carbonated and non-alcoholic drink production

Efficiently mix and carbonate a variety of beverages while optimi...

Aseptic filling system for Pet containers

Ensure your beverage products maintain sterility and longevity with a high-speed...

Filter system for beverage stabilization and clarification

Ensure your beverages are crystal clear and stable with a ver...

Robotic layer grouping system for container distribution

Streamline your packaging line with precise, high-speed containe...

Bottle filler for beer and soft drinks in glass bottles

Achieve precision in bottling with reduced CO2 emissions and low ...

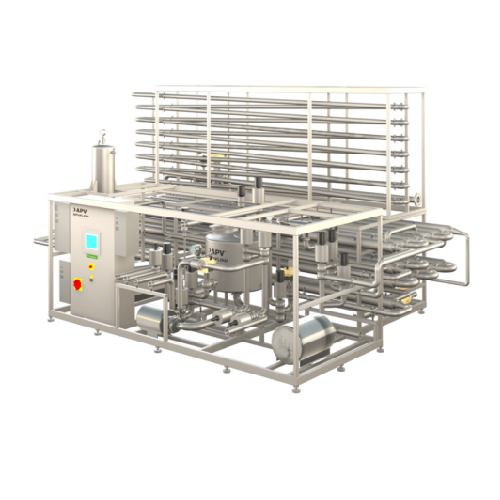

Htst pasteurization system for liquid foods

Ensure your liquid products are safe and long-lasting with high-temperature-sh...

3 phase decanter centrifuge for industrial separation

Optimize your production line with efficient three-phase separation...

Industrial belt press for fruit and vegetable processing

Optimize your juice yield and reduce drying costs in starch and ...

Inline high shear mixing unit for low to medium viscosity products

Achieve precise emulsification and size-reduction wi...

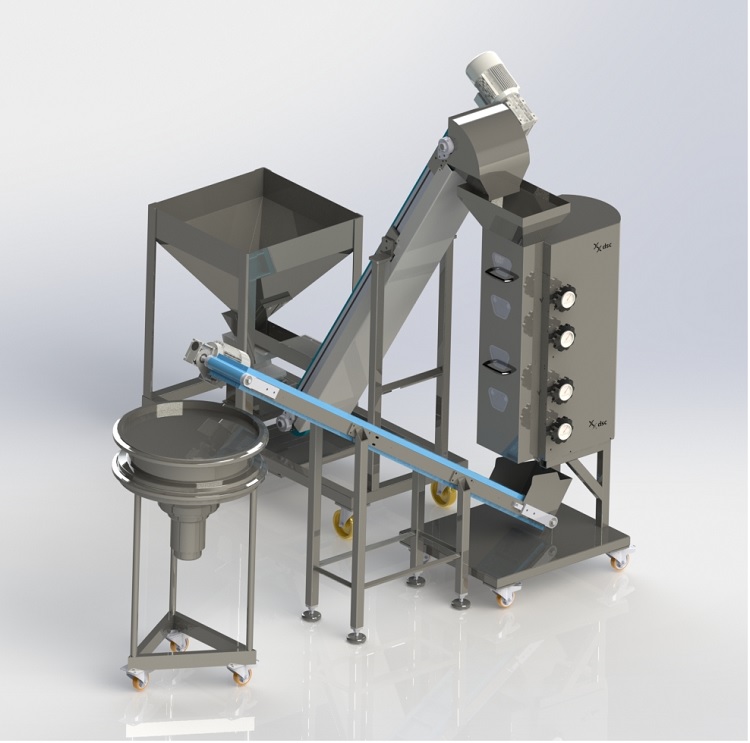

Bigbag filling system for powder and bulk materials

Ensure precise and dust-free bigbag filling with this versatile syste...

Manual filling system for bag-in-box packaging

Streamline your liquid filling process with a manual system designed for pr...

Semi-automatic aseptic filler for single bags

Ensure aseptic integrity and flexibility for your liquid and semi-liquid pro...

Premixer for confectionery masses

Achieve consistent ingredient blending with precision-premixing for candy and baked goods...

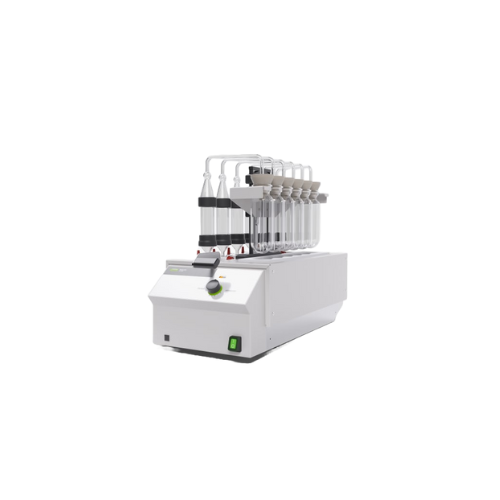

Industrial fat extraction system for food and feed analysis

Optimize your laboratory workflow with a versatile fat extra...

Acid hydrolysis system for total fat determination

Streamline your laboratory workflow with a powerful hydrolysis system ...

Industrial pasteurizer for juice, dairy, and vegetable purees

Ensure product safety and extend shelf life with this comp...

Industrial homogenizer for high pressure applications

Achieve consistent product texture and stability for your emulsions...

Laboratory homogenizer for dairy and biotech applications

Ensure precise particle size reduction and consistent texture ...

Decanter centrifuge for food industry separation

Achieve precise separation and ensure optimum product quality with our ad...

Plant-based protein extraction technology

Achieve optimal purity in plant-based milk, yogurt, and cheese production with c...

Gasketed plate heat exchangers for hygienic applications

Ensure optimal hygiene and thermal efficiency in your processing...

Cleaning in place system for beverage production

Ensure maximum hygiene and efficiency in beverage production with a modul...

R&d vessels for research and development centers

Optimize your R&D operations with versatile vessels designed to hand...

Balance tank for pasteurization systems

Ensure consistent product quality with precise liquid holding and heating capabilit...

Flavor vats for ice cream and food production

Maximize your product line versatility with customizable flavor vats, design...

Coil heat exchanger for dairy and beverage processing

Quickly sterilize and retain product quality with this coil heat ex...

Uht sterilizer for dairy and high-viscosity products

Optimize your production of dairy alternatives and fruit-based drink...

Dual heating coil for dairy and beverage processing

Achieve precise temperature control for your liquid products with a s...

High temperature short time (HTST) dairy pasteurization system

Ensure precise pasteurization with advanced heat transfer...

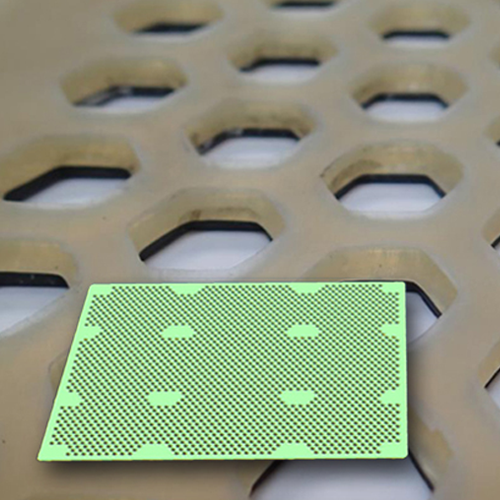

Layer pad for agitating retorts in food processing

Efficiently secure and process irregularly shaped containers in retort...

Expandable high pressure processing system

Optimize your production line with an expandable high-pressure processing syste...

Rotary level filler for low to high viscosity liquid products

Ensure precise fill levels and enhance production efficien...

Aseptic filler for packaged dairy and beverages

Ensure product sterility and extend shelf life efficiently with high-speed...

High shear test mixers for developing new products

Streamline product development with high shear test mixers, allowing y...

Industrial high-pressure homogenizer

Achieve precise homogenization with superior flow rates and efficiency, ensuring optim...

Hygienic filling system for short shelf life milk

Optimize your cold-chain distribution with a filling system engineered ...

Reverse osmosis dealcoholization technology for beer

Achieve consistent flavor profiles in your non-alcoholic beer produc...

Reverse osmosis beer dealcoholization technology

Achieve precise alcohol removal from beer while preserving flavor integri...

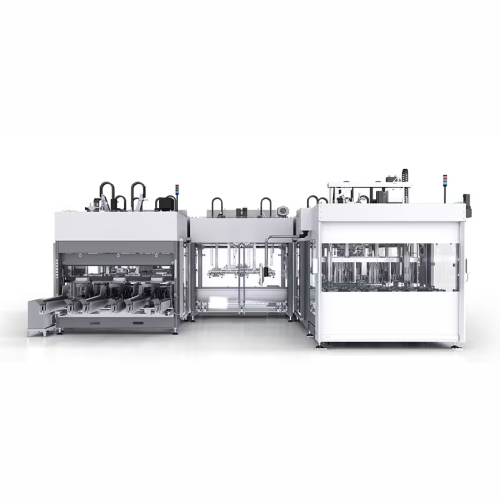

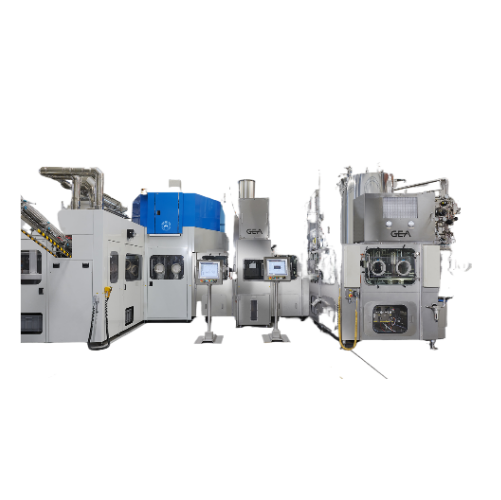

Aseptic blow fill system for beverage bottling

Designed for high-speed aseptic bottling, this system ensures sterility thr...

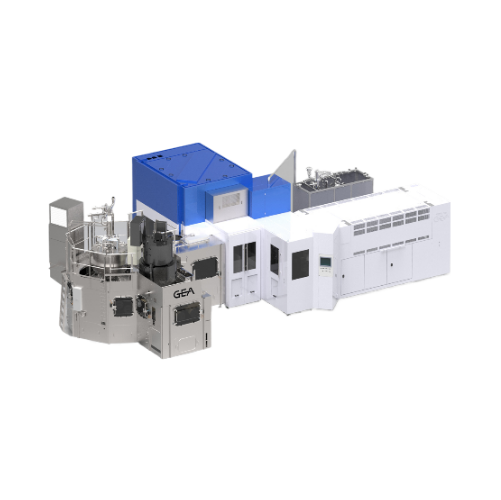

Decontamination blow fill system for beverages

Optimize your beverage production with a technology that integrates preform...

Aseptic filling for high and low acid beverages

Ensure aseptic integrity while maximizing operational efficiency with a co...

Aseptic filling system for milk-based drinks

Ensure sterile bottling of milk-based and sensitive beverages with this syste...

Decanter for plant-based beverage extraction

Ensure high-yield extraction and optimal purity from plant-based ingredients ...

Fermentation and storage solutions for breweries

Enhance your brewing process with robust fermentation and storage tanks d...

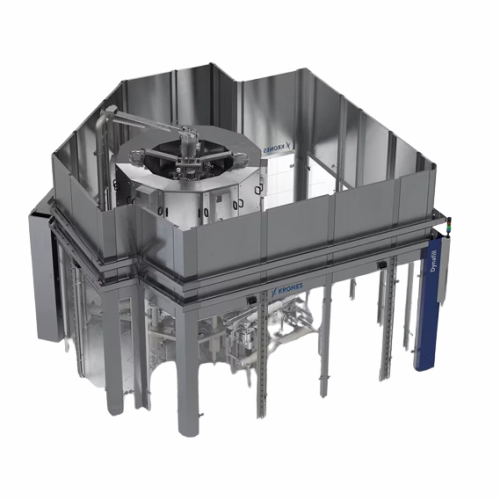

Continuous mash filtration system for breweries

Optimize your production line with continuous mash filtration that revolut...

Horizontal stand-up pouching for beverages, dairy, and pet care

Optimize your liquid product packaging with rapid, high-...

Continuous stand-up pouching solution for up to 1000ml

Maximize efficiency in high-speed production lines with precise st...

Automatic rotary premade pouch filler for various industries

Streamline your pouch packaging process with precision fill...

Industrial particle size reduction processor

Optimize your production line with high-capacity, continuous particle size re...

Viscous and liquid product processor

Optimize your production of viscous slurries and liquid formulations with a versatile ...

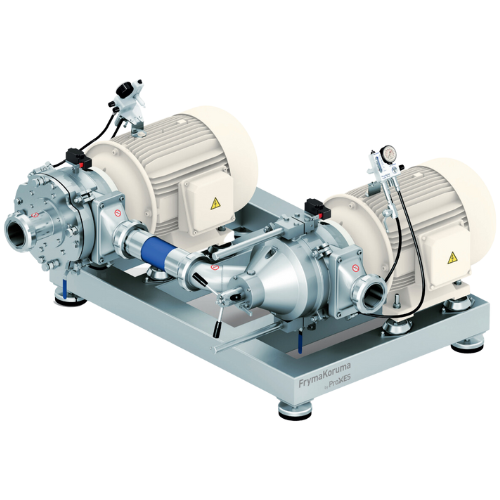

Industrial homogenizers for liquid processing

Achieve consistent product quality and energy efficiency in liquid processin...

High-speed blender for commercial use

Designed for high-performance blending tasks, this solution integrates vacuum technol...

Bottle filling system for diverse specifications

Optimize your bottle-filling operations with a modular system that seamle...

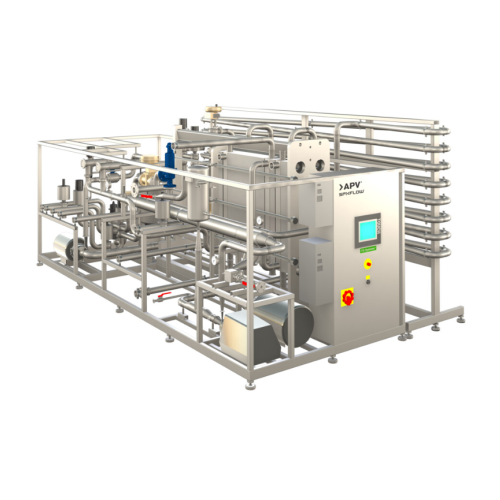

Direct Uht treatment for liquid foods

Optimize aseptic production with advanced UHT technology to preserve nutritional valu...

Indirect Uht treatment for dairy products

Ensure your beverages achieve extended shelf life with consistent quality using ...

Direct Uht processing for heat-sensitive liquid products

Achieve optimal taste and nutritional value in liquid foods thro...

Milk skimming separator

Achieve superior separation efficiency and reduced energy consumption in dairy processing with seamle...

Efficient dairy product separator

Achieve precise fat separation and enhance product quality while reducing energy consumpt...

Air jet cleaning system for powder production

Eliminate water and chemical use while maximizing production efficiency with...

Industrial clarifier for dairy and plant-based products

Optimize your production line with cutting-edge clarification tec...

Beverage preparation system for large-scale production

Ideal for producers looking to scale up, this versatile system eff...

High-speed liquid mixing solution

Optimize your beverage mixing operations with a system that ensures even ingredient distr...

Plate heat exchanger for food products

Achieve precise temperature control in your processing line with this plate heat exc...

Tubular heat exchanger for food processing

Optimize energy consumption and ensure unparalleled food safety during heat tre...

Industrial homogenizer for liquid food applications

Achieve unparalleled product consistency and quality with high-speed ...

Homogenizer for high-capacity food processing

Achieve superior emulsification and suspension handling with this high-press...

Autonomous ingredient dissolver for high-volume dry ingredient mixing

Efficiently mix multiple high volumes of dry ingr...

Lid unscrambler for unstackable lids in round containers

Streamline your packaging process with this lid unscrambler, eff...

Double decanter for plant-based beverages

Optimize your plant-based beverage production by achieving high protein yield an...

Industrial grinder for plant-based beverages production

Achieve optimal particle size for seamless integration with your ...

Hydrolysation tank for plant-based beverage production

Ensure optimal hydrolysis conditions for plant-based beverages wit...

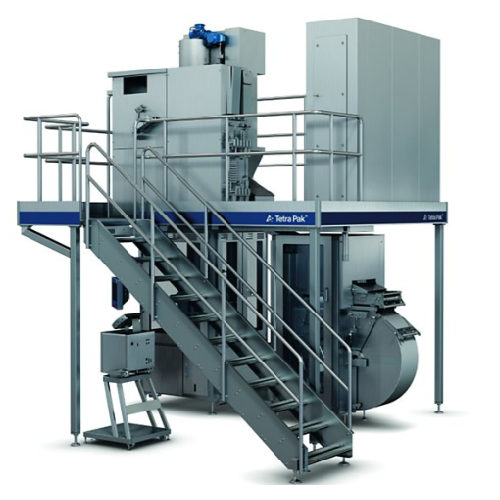

Continuous soya extraction unit

Enhance your plant-based beverage production with a unit that maximizes protein yield and re...

Thermal deactivation unit for plant-based base creation

Efficiently deactivate enzymes in plant-based beverages with prec...

High-precision decanter for plant-based beverages

Enhance your plant-based beverage production with a decanter engineered...

Aseptic tank with blending function for liquid food storage

Achieve seamless integration of aseptic buffering and in-lin...

Liquid ingredient reception tank

Optimize your liquid processing with versatile tanks designed for efficient storage and han...

Indirect Uht treatment for high viscous products with particles

Optimize your production line with a unit that ensures h...

Direct Uht processing system for dairy and plant-based beverages

Achieve ultra-high temperature treatment with minimal i...

In-line blender for beverage production

Enhance beverage production with a versatile solution that offers precise blending,...

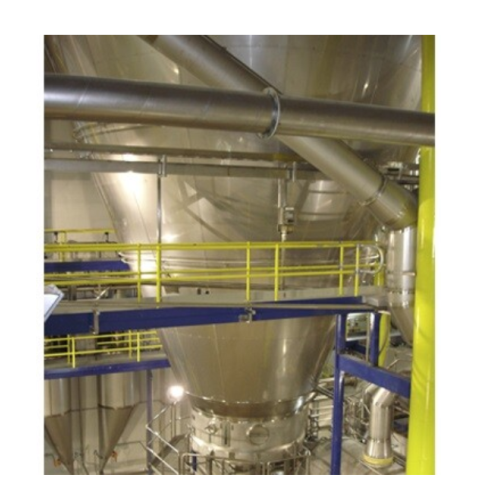

Spray dryer for dairy, whey, and plant-based powders

Achieve precise control over powder attributes with our versatile sp...

Ultra-high temperature processor for premium liquid foods

Achieve superior product quality and flexibility with advanced...

Uht processing unit for dairy products

Optimize your liquid food production with continuous, high-capacity UHT treatment th...

Indirect Uht processing for dairy products

Enhance your dairy and beverage operations with state-of-the-art ultra-high tem...

High capacity milk separator with polynode technology

Achieve unprecedented milk skimming efficiency and reduced environm...

Clarifiers for dairy and plant-based beverages

Ensure optimal product purity and versatility by efficiently removing impur...

High shear mixer for emulsification and powder dissolving

Achieve seamless mixing and emulsification for high and low vi...

High shear mixer for smooth or particulate food products

Achieve consistent quality in diverse food products with precise...

Batch mixer for soft drinks ingredients

Effectively manage diverse ingredient formats with a high-performance mixing system...

Mid-range capacity homogenizer for dairy and beverage

For operations demanding consistent product quality and high uptime...

High-pressure homogenizer for dairy and beverage products

Achieve optimal product consistency and extend shelf life with...

Autonomous ingredient dissolver for high volume dry ingredient mixing

Streamline your production by seamlessly mixing d...

Batch dissolver for sugar or dextrose

Efficiently dissolve crystalline substances like sugar and dextrose with precision, e...

Double decanter for plant-based beverage extraction

Maximize protein yield and enhance extraction efficiency in your plan...

Industrial grinder for plant-based beverages

Ensure optimal particle size for hydrolysis in plant-based beverage productio...

Hydrolysation tank for plant-based beverages

Optimize your plant-based beverage production with a hydrolysation tank that ...

Continuous soya protein extraction system

Optimize plant-based milk yield and reduce waste with a versatile extraction sys...

Thermal deactivation unit for plant-based beverages

Enhance your plant-based beverage production by effectively reducing ...

Coiled heat exchanger for viscous and particulate products

Optimize heat treatment of viscous and particulate foods with...

Tubular heat exchanger for food products

Achieve precise temperature control and energy efficiency with this innovative tub...

Storage tank for food liquid storage

Ensure seamless liquid product handling with precision-engineered storage tanks design...

Evaporation system for dairy products

Optimize product quality with continuous evaporation, ensuring efficient moisture rem...

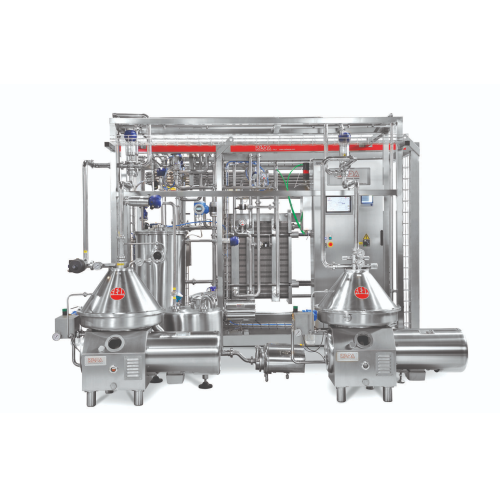

Plant-based beverage extraction system

Maximize yield and product quality in plant-based and dairy beverages with high-effi...

Ingredient reception tank for liquid storage and processing

Ensure efficient storage and processing of liquid ingredient...

Liquid sugar storage tank

Ensure seamless liquid sugar management in your production line with advanced storage solutions de...

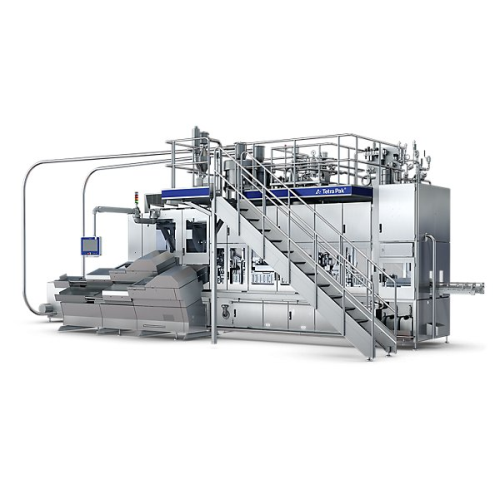

High-speed aseptic carton filling solution

Maximize production efficiency and meet growing demand with this high-output fi...

Filling system for gable top packages

Achieve precise, cost-effective filling with reduced energy consumption for chilled l...

Filling solution for water packaging

Achieve efficient packaging for a variety of beverages with this high-speed filling so...

Filling system for gable top cartons chilled products

Achieve precise filling and reliable sealing for chilled beverages ...

Dual filling solution for tetra top packages

Boost production flexibility by simultaneously filling different liquid produ...

Filling system for tetra brik 100 slim packages

Optimize your chilled product packaging with a high-speed filling system d...

Aseptic carton filling system for tetra fino packaging

Elevate your production efficiency with a high-speed aseptic filli...

Filling system for tetra wedge aseptic packages

Optimize your production line with a reliable filling system designed to e...

Compact aseptic filling solution for versatile production

Maximize production line efficiency with a compact filling sys...

Versatile filling system for aseptic packaging

Achieve seamless integration in high-speed aseptic packaging with this flex...

Aseptic filling solution for liquid food packaging

Optimize liquid food production with advanced aseptic filling, ensurin...

Stainless steel peanut butter grinder

Optimize your production line with high-speed emulsification and grinding, achieving ...

Commercial tofu making system

Enhance your tofu production capabilities with our integrated grinding, cooking, and forming s...

Industrial autoclave food sterilizer for retort pouch and canning

Preserve the integrity and shelf life of your food pr...

High-capacity sleeve filters for silo dedusting

Optimize your production with filtration systems that ensure efficient dus...

Industrial stainless steel filters and strainers

Optimize your liquid processing with precision filtration and straining, ...

Side entry mixer for industrial tank applications

Ensure optimal mixing and blending of liquids and slurries with high ef...

Self-cleaning clarifiers for liquid-solid separation

Optimize your production line with high-performance self-cleaning cl...

Self-cleaning separator for industrial liquid/solid separation

Optimize your production line with self-cleaning separato...

Tubular juice pasteurizer

Ensure optimal safety and quality of liquid products with precise temperature control and high hea...

High pressure homogenizers for dairy and pharmaceutical applications

Optimize your production line with high-pressure h...

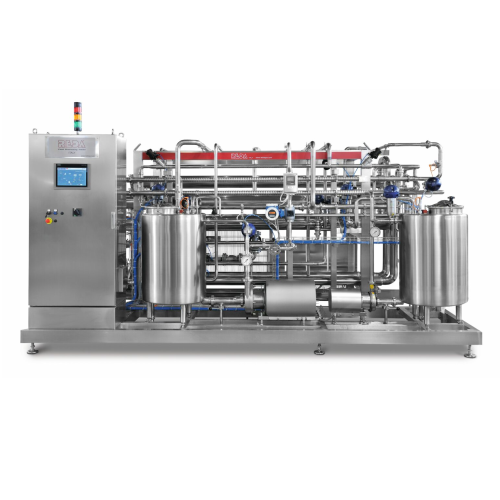

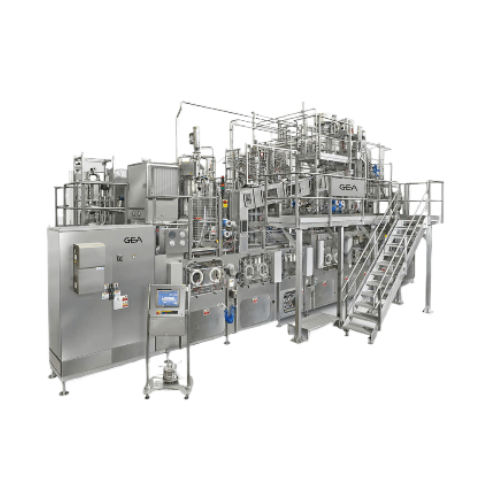

Soymilk processing plant

Enhance your plant-based production with our tailored soymilk processing plants, designed to efficie...

Instant infusion Uht for baby food or milk concentrate processing

Achieve exceptional product quality with ultra-short,...

Microfiltration system for dairy and plant-based applications

Enhance your production capacity and reduce waste with adv...

Milk pasteurizer system

Ensure your dairy and plant-based beverages achieve optimal safety and quality with precise temperatu...

Multipurpose ultra high temperature (uht) pilot plants

Optimize liquid food production with a versatile pilot unit design...

Plate juice pasteurizer system

Ensure optimal pasteurization with precise temperature control and high heat recovery, reduci...

Sanitary gasketed plate heat exchangers for clean applications

Ensure product purity and maintain hygienic standards wit...

High pressure homogenizer for food and beverage processing

Optimize your production line with a versatile high-pressure ...

Spray dryers for producing free-flowing dustless powders

Achieve consistent product quality with customizable spray dryer...

Aseptic storage tank for aseptic products

Ensure uninterrupted aseptic product storage with this advanced tank system, des...

Clean in place (cip) system for industrial cleaning

Ensure optimal hygiene and production efficiency with a system that s...

Laboratory scale powder/liquid mixer

Easily integrate powders into complex liquid formulations at a laboratory scale, ensur...

Chilled water milk can cooler for small farms

Ensure milk quality and safety with rapid cooling from 35°C to 8°C in under ...

Energy efficient grinder for plant-based milk

Buying pre-processed materials, such as flour, and handling and dispersing t...

Linear automatic bottling machine for liquids

Autonomous filling systems are a very widely utilized solution for the consi...

Sugar dissolving system for beverages

In the beverage industry, production of sweet drinks requires the addition of sugar s...

Pasteurizer machine for sensitive beverages

When you want to expand your beverage production line, following a new global ...

Water treatment for beverage preparation

Water is one of the main ingredients in producing juices and other beverages. If i...

Continuous sterilizer for milk beverages

An important goal of heat processing in the manufacturing of milk beverages is to ...

Nut and cheese grater

Smearing, clumping and crumbling are common problems when cheese and other soft textured foodstuffs are...

Automatic bottling machine for beverage

One of the biggest challenges when bottling beverage drinks is that many of the bot...

Industrial bottle washing machine

Polyethylene terephthalate (PET) and glass bottles are widely used in the beverage indust...

Industrial bottle sterilizer

Sterilization is an important process in the beverage industry to kill microorganisms. It is im...

Air knife system for bottling lines

Wet containers are unacceptable and can be problematic in the food and beverage industr...

CIP system for beverage

Clean-in-place operations are a mandatory part of food and beverage processing which cannot fail. How...

Tunnel pasteurizer for beverage

In the beverage industry, beverages need to be pasteurized in order to destroy pathogens, an...

High pressure electric laboratory homogenizer

It’s vital that small units for experimentation can scale up with 100% accur...

High pressure pilot homogenizer

Biotech and pharmaceutical development programs often require a mixing method that achieves ...

High pressure industrial homogenizer

For any industrial pharmaceutical process that relies on high pressure homogenization ...

Pilot high pressure homogenizer

For maximum value, a high-pressure homogenizer that’s suitable for both laboratory and pilot...

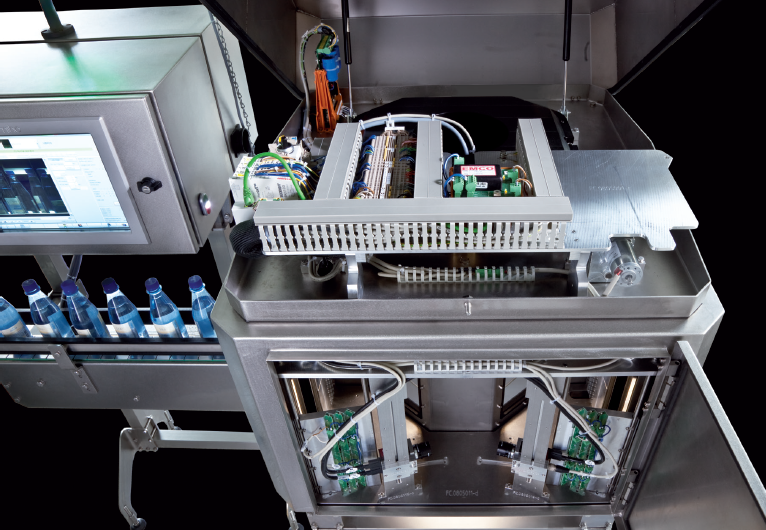

Metal detector for bottles

For metal contamination detection in finished products that are bottled, traditional solutions re...

Air knife dryer for bottles

When filling glass bottles during beverage production, the cleaning and filling processes often ...

Small scale linear sieve for nuts

Removing dust and grading grains is an important part of producing a high quality chopped...

Vibrating sieve for liquid solid separation

Many industrial processes require the efficient separation of solids from a sl...

Versatile bottle sorting system

Quality bottle sorting machine and inspection system which can be put to use not only after ...

High-end empty bottle inspection system

If you are looking for a system with empty bottle inspection; base, residual liquid...

High-precision X-ray fill level controller

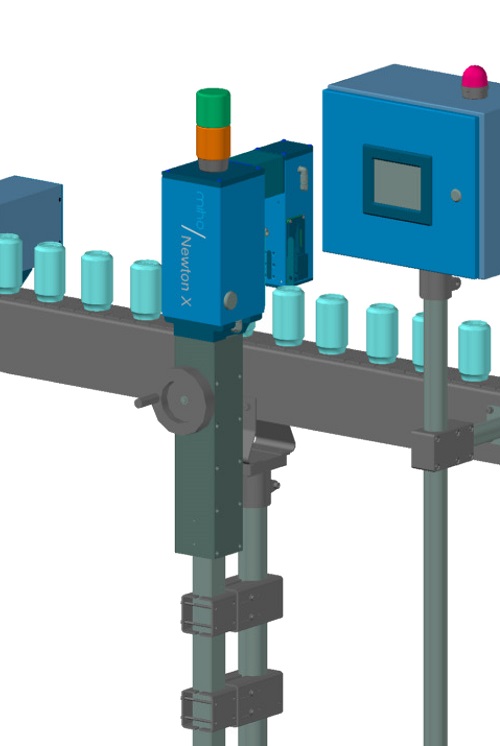

High-speed, high precision X-ray system to inspect containers that are difficul...

X-ray fill level controller

For containers that are difficult to see through, such as cans or cartons lined with aluminium, ...

Optical fill level controller

Accurate fill level inspection for transparent, opaque and foaming liquids, that makes sure th...

High-frequency fill level controller

In terms of high-frequency technology, the fill level detection is considered a standa...

Empty bottle shape, colour and size sorting system

Accurate bottle sorting system that differentiates between the bottles...