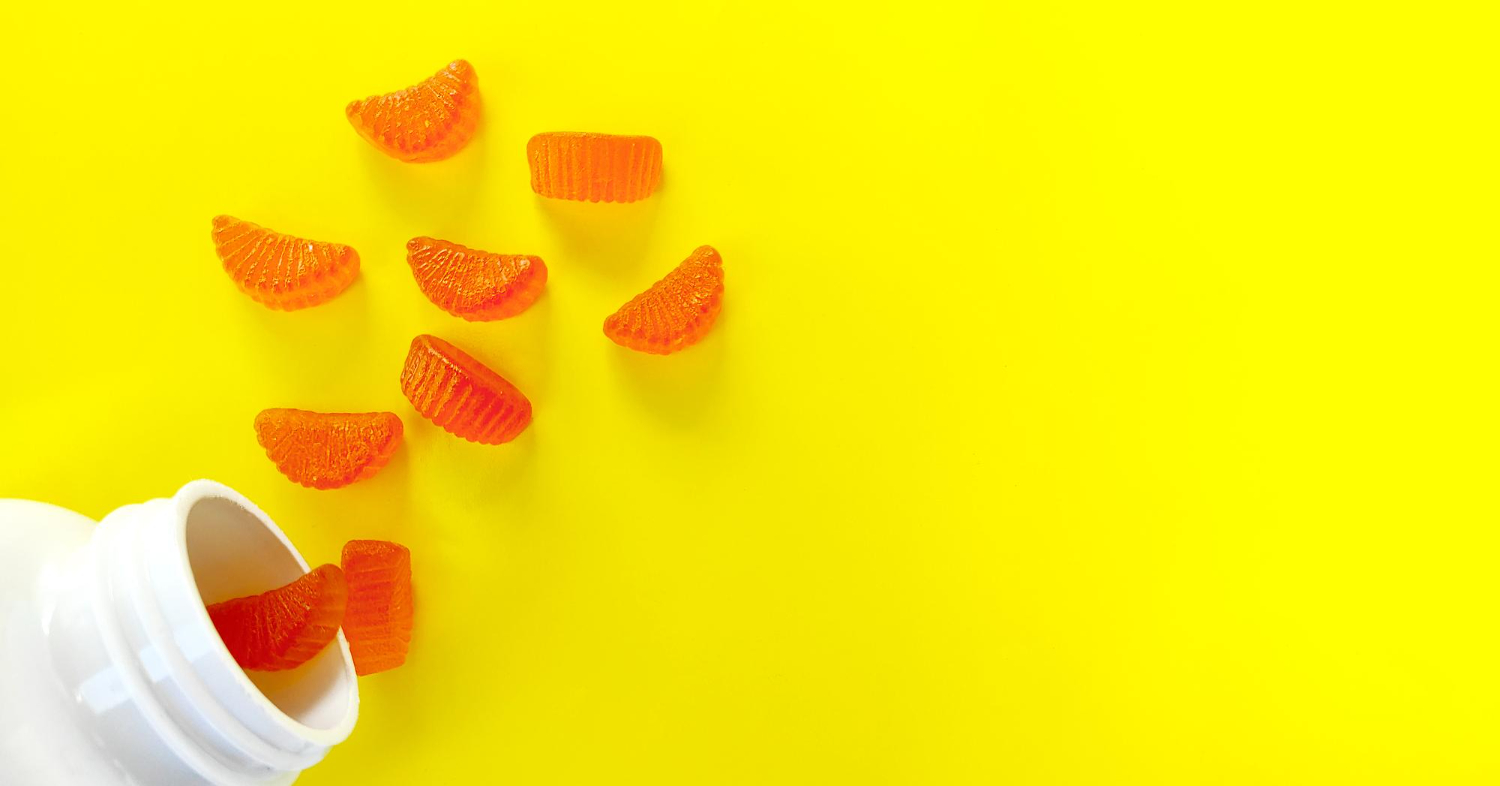

Gummy Bear Making Equipment

Find innovative production technology for making gummy bears and connect directly with world-leading specialists

Gummy bears are iconic confectioneries known for their playful shapes and fruity flavors. They have gained immense popularity worldwide due to their versatility and appeal to a wide variety of tastes. In addition to being delicious, gummy bears are also easy to produce, particularly in small quantities. For medium to large-scale production of gummies, there is a multitude of gummy manufacturing equipment to help ensure that you end up with a good product.

Innovative equipment for gummy bears

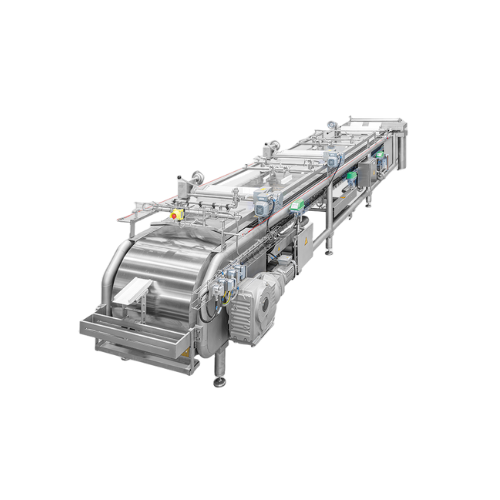

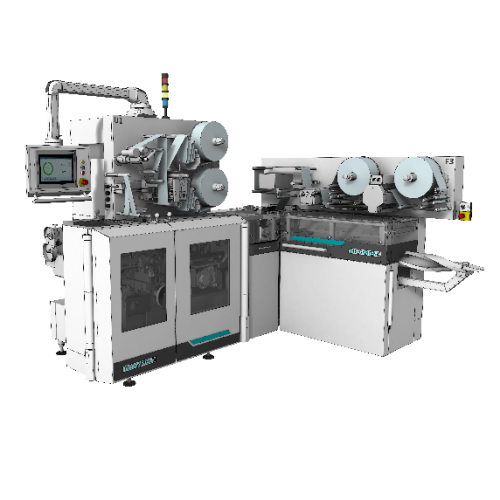

High-capacity non-starch gummy and jelly production line

Boost your gummy production efficiency with a seamless, high-cap...

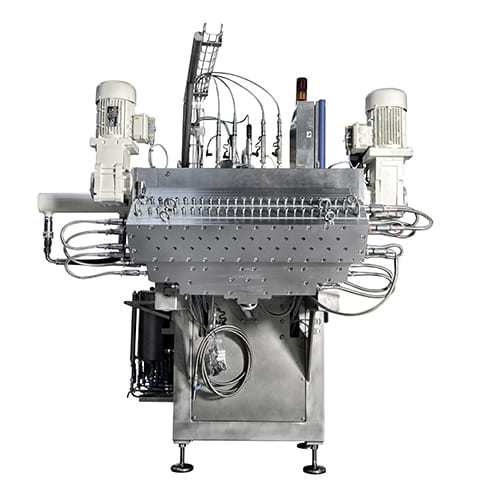

Mini candy depositor for gummy production

Optimize your confectionery production with a compact depositor, delivering prec...

Gummy candy depositor for precision manufacturing

Achieve consistent gummy size and shape while maintaining precise weigh...

Gummy counter for gusseted bags

Optimize your gummy production line with precise counting and packaging into re-sealable gus...

Stories about gummy bears

Starting up your OTC non-starch gummy production

Making healthier gummy formulations

Chew on this: craft gummies with pectin

Delving into the fungal fun of gummy goodness

How to turn a bag of sugar into a bag of scrumptious gummies

Preserving gummy texture in low or no sugar confectionery

How to craft gummy bears in 8 simple steps

Exploring the artistry of candy-making

Giving aerated jelly some bite

Tech is [was] keeping vitamin gummy manufacturers from cutting starch

Tell us about your production challenge

All the ingredients you need to produce gummy bears

Gelatin is the most important ingredient in gummy bear production, as it helps hold gummies together and gives them their texture. In addition to gelatin, you need water and a sweetener, which could be fruit flavors or just plain sugar. Corn syrup, citric acid, and starch help extend the gummy bear’s shelf life.

Gelatin, however, contains collagen, which is obtained from animals. As such, it’s a non-starter for people looking for a vegan or vegetarian jelly candy. Beeswax can be an alternative, but again, it’s derived from an animal, which is the case with shellac as well. The best ingredient for making vegan gummy bears is agar-agar powder. It comes from plants (seaweed), and offers the same consistency as gelatin. You’ll probably be unable to tell the difference between gummy bear’s made with gelatin and ones made with agar-agar. The taste doesn’t take a hit either.

Controlling the temperature with gummy making equipment and processes

Temperature is an important determiner of the texture of gummy bears during production, so you need to be careful with it in order to maintain a high quality end product.

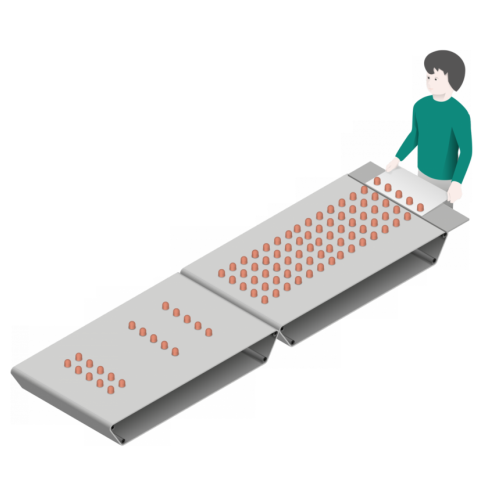

For medium to large scale production, a gummy bear making machine automates the process, reducing the chances for error. After gathering the ingredients in specific quantities, load them into the equipment’s stainless steel mixing and melting tanks. Set the heat to around 60° C (140° F) and let the gummy making equipment compound the ingredients for about 3 hours.

Test a sample to ensure that it fulfills quality standards, then pump the mixture to the machine’s molding station. At this stage, the mixture takes the shape of the molds and then solidifies. Finally, conveyors move the gummies to the packaging stage and allow them to dry for about 72 hours.

How about gummy bears with vitamins?

Apart from a few additional steps, the process of making vitamin gummies is similar to that of regular ones. Depending on how healthy or loaded with vitamins you want your gummy to be, you need to add a few extra ingredients to your base. In that case, a stand mixer can help get a good blend, if you’re making gummies manually. The next step would then be to cook the mixture until it nearly boils and then stir in vitamin C powder.

If you’re using gummy making machines, introduce the vitamin C powder to your ingredients and load them into the equipment’s mixing and melting tanks, then continue with the same general process. When adding supplements to your gummies, check the recommended daily dosage for each so you don’t exceed them.

Processing steps involved in gummy Bears making

Which gummy bears technology do you need?

Rotary indexing sealer for cup filling

Streamline your production line with precise cup filling and sealing, ideal for a wi...

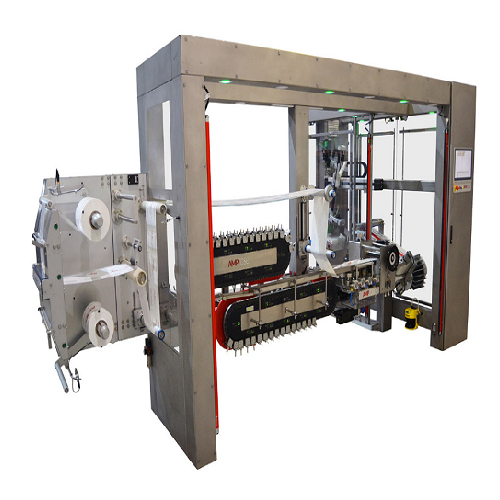

Intermittent pick and place solution for stackable items

Optimize your production line with high-speed, intermittent oper...

Centrifugal bowl feeder for high-speed bulk item feeding

Optimize your production line with high-speed feeding of diverse...

Invert sugar and glucose storage tank

Optimize your sweet and confectionery production by efficiently storing and resting g...

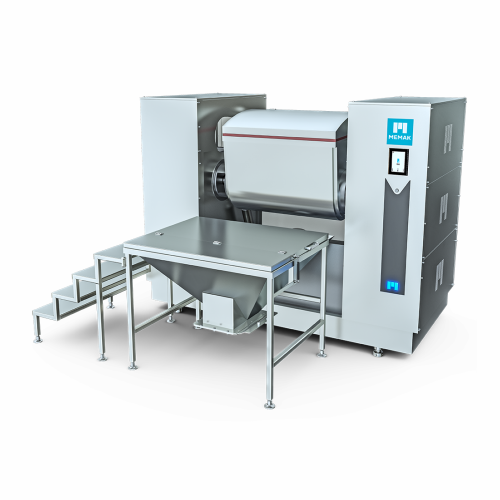

High viscosity material mixer for bakery and chocolate

Efficiently mix and knead high-viscosity materials for premium cho...

Entry-level moulding machine for small to medium production

Ideal for scaling new product lines, this versatile moulding...

Packaging solution for bulk vegetables and fruits

Ensure precise, high-speed packaging for diverse product sizes with a f...

Vibratory conveyor for efficient bulk material transportation

Optimize your processing line with robust vibratory convey...

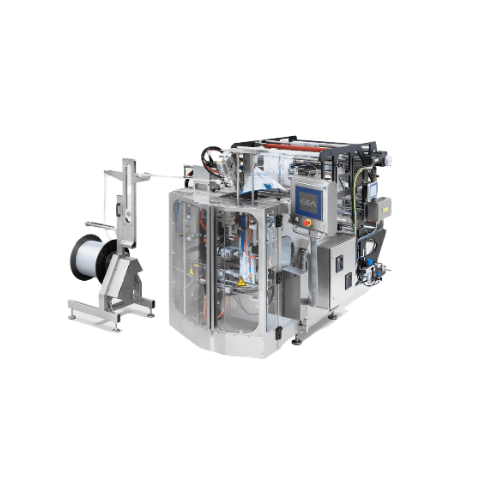

Vertical dosing and filling solution for confectionery packaging

Optimize your confectionery and nutraceutical packaging...

Stand-up pouch making system

Efficiently transform pre-printed reels into customizable stand-up pouches with precise unwindi...

Vertical cartoning system for confectionery products

When you need high-speed, versatile cartoning capabilities for varie...

Intermittent vertical form fill seal for confectionery packaging

Optimize your packaging operations with this versatile ...

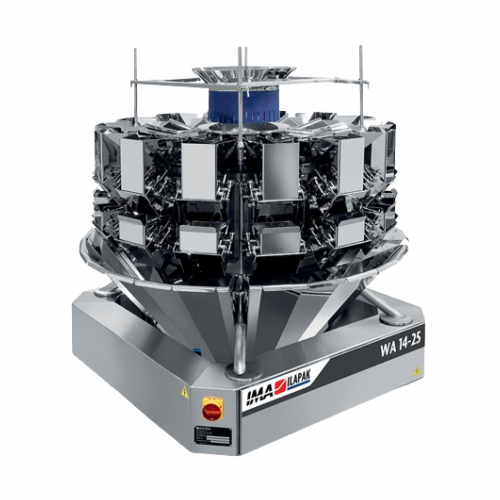

High precision multihead weigher for confectionery production

Achieve precise weighing and counting for varied product c...

Vertical baggers for confectionery packaging

Streamline your packaging operations with high-performance vertical baggers d...

High-speed flow wrapper for candies and gums

Achieve top-speed packaging with unparalleled flexibility for diverse confect...

Flow wrapping for bulk confectionery products

Efficiently orient, feed, and wrap bulk confectionery items with seamless in...

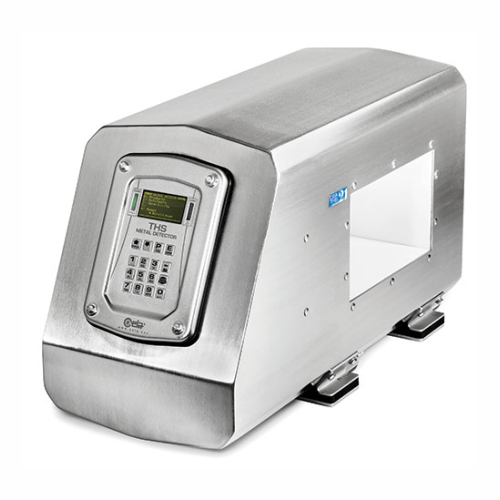

Industrial metal detector for gravity feed applications

Ensure the purity of your products by detecting and removing both...

Checkweigher for packaged goods inspection

Ensure precision and compliance with this high-speed checkweigher, perfect for ...

Multi-spectrum metal detector for food industry

Achieve unmatched detection accuracy in your food processing line with thi...

Multi-lane checkweigher for mixed-application production lines

Achieve precise weight verification across multiple lanes...

X-ray inspection system for detecting foreign objects in food products

Ensure product safety and quality by detecting e...

On-machine seasoning system for potato chips

Achieve uniform seasoning coverage for various snack foods with minimal wasta...

Multihead weigher for precise bulk product weighing

Optimize your weighing operations with highly accurate multihead tech...

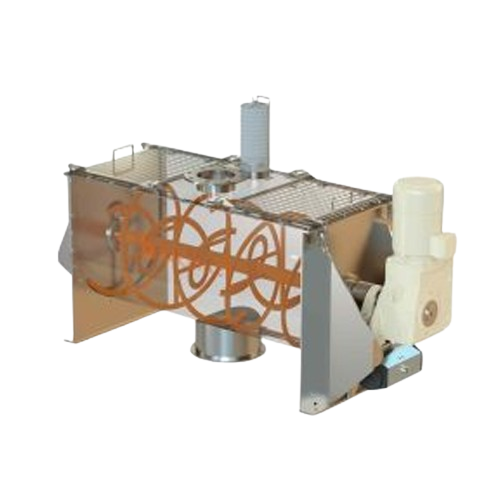

High-viscosity continuous industrial kneader for small volumes

Achieve consistent high-viscosity material processing wit...

Batch cooker for confectionery production

Achieve consistent confectionery texture and flavor with a flexible cooking solu...

Adjustable weighing system for raw materials

Optimize your confectionery and nutraceutical production with precise weighin...

Continuous production fondant beater

Achieve consistent fondant quality by gently controlling crystallization and temperatu...

Dosing unit for automated mixing in of ingredients

Achieve precise ingredient integration for confectionery and nutraceut...

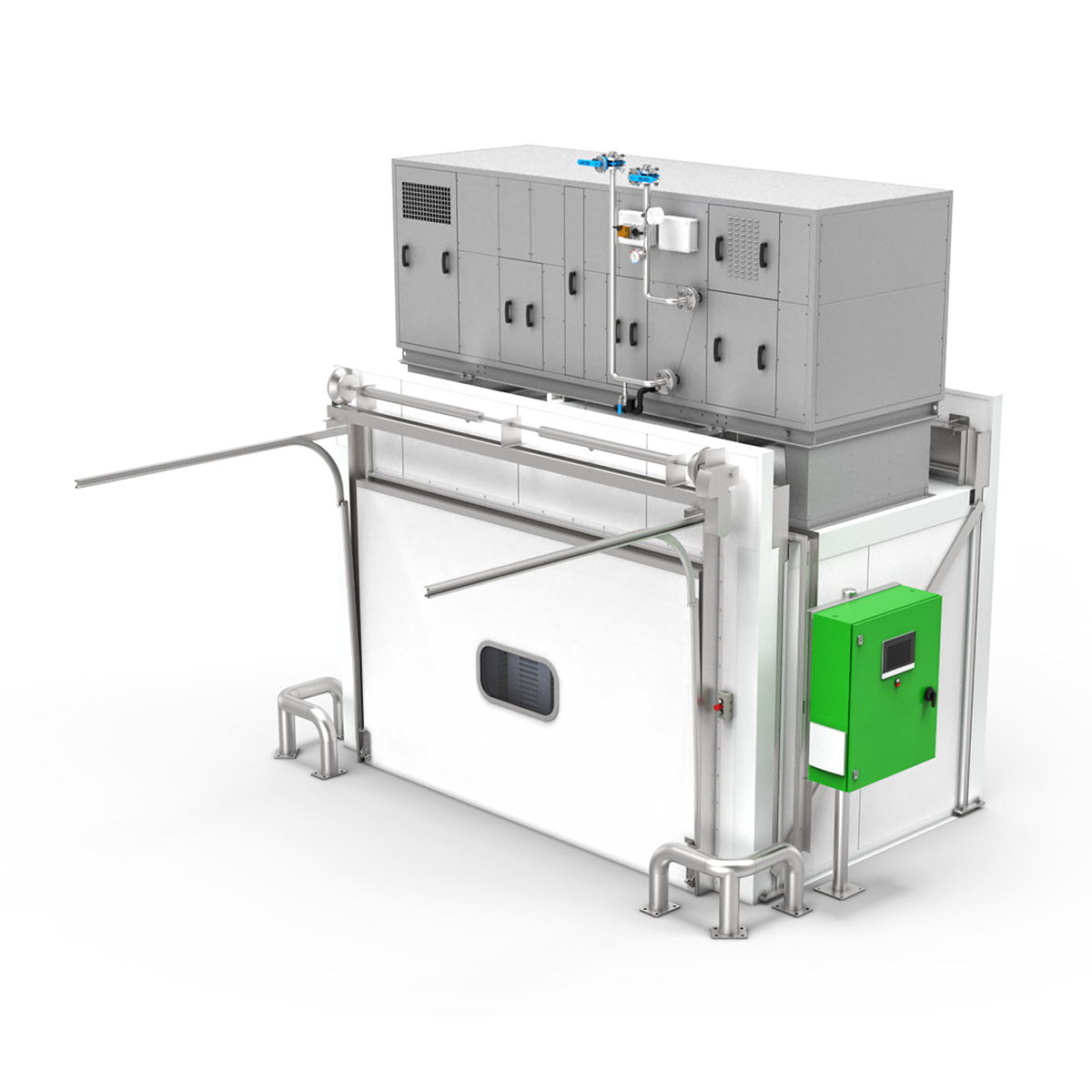

Cooker for jelly and gummies production

Experience efficient gummy and jelly production with precise heating and mixing, en...

Laboratory unit for small quantity production and r&d

For product developers needing precise control and flexibility, thi...

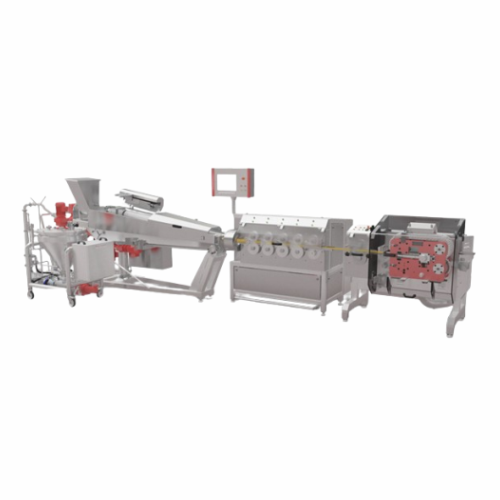

Hard candy forming line for manufacturing

Experience seamless candy production with advanced forming technology, ensuring ...

Automatic gummy production system

Achieve precise control in gummy production with systems that cater to diverse formulatio...

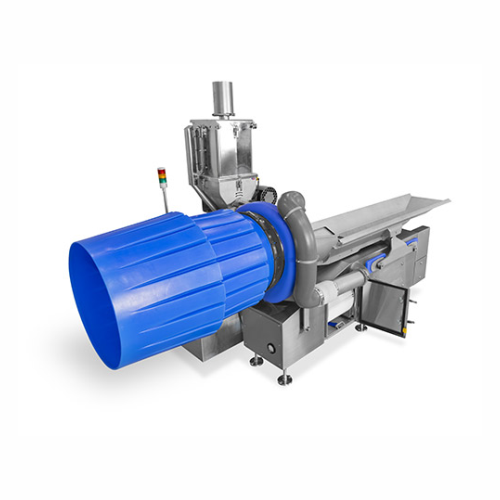

Powder and oil coating system for gummies

Enhance your gummy production with precise powder and oil coating, achieving con...

Oil coater for gummies

Optimize your gummy production with high-speed oil coating for consistent, flavorful finishes, ensurin...

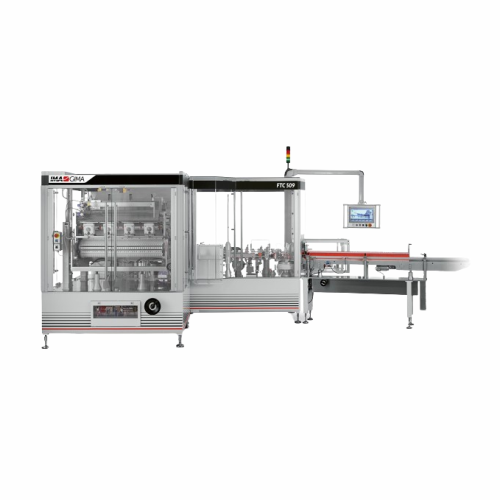

Packaging system for gummy products

Optimize your gummy production with a flexible packaging system that safeguards product...

Rapid gummy channel counter

Ensure accurate gummy counts and streamline your production process with a solution designed to ...

Sugar coating system for gummies

Achieve a flawless sugar coat on up to 240,000 gummies per hour, seamlessly integrating int...

Automatic tray washer for gummy production cleanup

Eliminate gummy residue efficiently with high-pressure tray washing, e...

Portable water activity meter for gummy production

Ensure consistent gummy quality and extended shelf life by precisely m...

Gummy counter for gusseted bags

Optimize your gummy production line with precise counting and packaging into re-sealable gus...

Automatic gummy manufacturing system

Efficiently streamline your candy production with a system capable of producing up to ...

Small automatic gummy line

Streamline your gummy production with a compact system designed to deliver precision deposits and...

High-capacity gummy production system

Optimize your gummy production with a starchless system that deposits up to 240,000 g...

Waxing station for confectionery products

Optimize your product’s final presentation and quality by applying a preci...

Cooling tunnel for confectionery extrusion

Optimize your production line with a versatile cooling tunnel capable of effici...

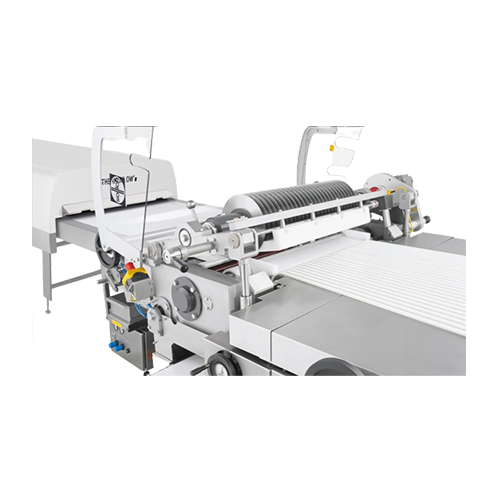

Confectionery cutting system for accurate results

Achieve precision and flexibility in modern confectionery production wi...

Multi-color and flavor confectionery production system

Maximize production flexibility with a single extruder that seamle...

Confectionery forming extruders for viscous masses

Efficiently transform viscous ingredients into uniform, high-quality c...

Screen changer for extrusion lines

Prevent clogs and maintain quality with this screen changer, designed to filter out soli...

Slurry preparation for licorice production

Ensure a continuous and homogeneous feed of licorice slurry to your extruder, o...

Stainless steel fermentation tanks

Optimize your fermentation efficiency with stainless steel tanks that provide precise te...

Flow pack packaging for irregularly shaped products

Achieve precise packaging for irregularly shaped and delicate items w...

Vertical form fill seal packaging for high washdown environments

Ensure optimal packaging in demanding environments with...

Bigbag filling system for powder and bulk materials

Ensure precise and dust-free bigbag filling with this versatile syste...

Basic checkweigher for weight control in low to medium performance

Ensure accurate weight control with a versatile chec...

Liquid confectionery metering system

Effortlessly integrate precision and flexibility in candy production by accurately met...

Industrial chocolate tempering belt

Achieve precise mass tempering for diverse confectionery textures with a stainless-stee...

Continuous cooking system for jelly and marshmallow production

Elevate your confectionery production with a system desig...

Batch weighing system for precise raw ingredient mixing

Optimize your confectionery production with a precise batch weigh...

Continuous caramel cooker for candy production

Achieve perfect caramel consistency with precise control as this solution c...

Crystallization process for chewy candy production

Optimize your confectionery production with precision crystallization,...

Hygienic pressure dissolver for high heat exchange

Efficiently dissolve and cook a wide range of confectionery masses wit...

Batch cooker for lab or small test production runs

Optimize your lab-scale confectionery trials with a versatile batch co...

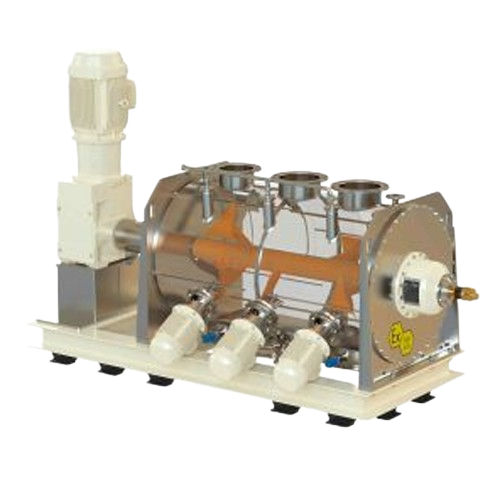

High shear mixer system for hydrocolloids

Streamline your confectionery production with a high-shear mixer designed for pr...

Mixing and metering system for candy production

Achieve precise ingredient integration and optimal blending for diverse co...

Batch cooker for confectionery masses

Effortlessly cook a variety of confectionery masses, like caramel and jelly, with pre...

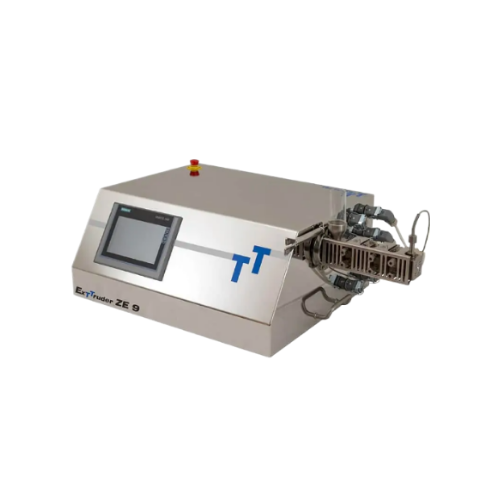

Food and confectionery twin-screw extruder

Enhance your confectionery production with a versatile twin-screw extruder desi...

Cut and flow pack system for cylindrical and rectangular pieces

Enhance your confectionery production with a high-speed ...

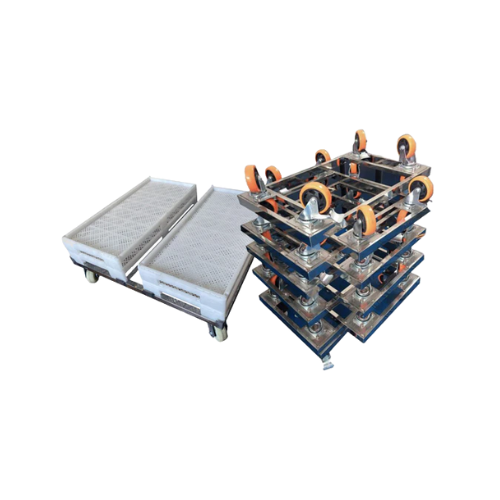

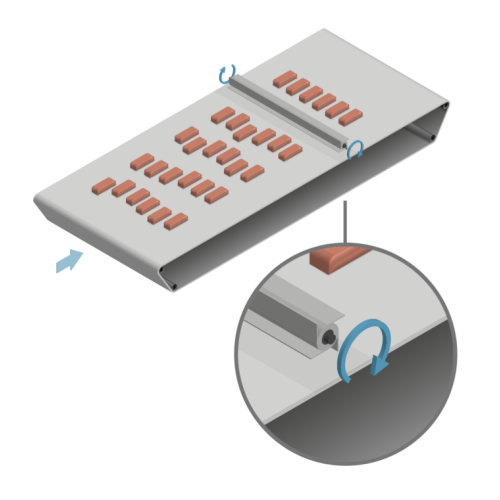

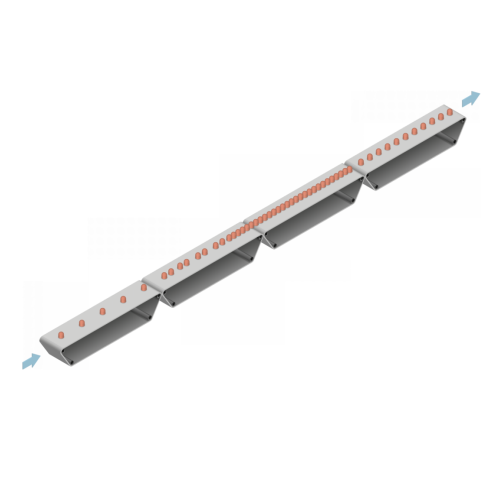

Drying trays for gummy candy production

Ensure proper drying and setting of your gummy candies and gelatin-based products w...

Sugar drum for coating gummy candy

Achieve a uniform sugar or wax layer on your gummy candies with precision and reliabilit...

Dissolving tilt kettle for gummy candy production

Optimize your gummy candy production by melting and dissolving ingredie...

Gummy candy depositor for precision manufacturing

Achieve consistent gummy size and shape while maintaining precise weigh...

Small-scale gummy candy depositor

Optimize your confectionery production with this manual depositing machine, capable of pr...

Premixer for confectionery masses

Achieve consistent ingredient blending with precision-premixing for candy and baked goods...

Batch cooker for confectioneries

Achieve consistent texture and flavor in every batch with this precision-driven cooker desi...

High-efficiency cooling tunnel for confectionery production

Optimize your product cooling process with high-efficiency t...

Twin-screw extruder for breakfast cereals production

Enhance your product range with flexible twin-screw extrusion techno...

V shape mixer for solids and powders

Ideal for preserving the delicate structures of fragile materials, this mixer ensures ...

Horizontal ploughshare mixer for solids and powders

Achieve uniform blends of diverse solids and powders with precision a...

Horizontal ribbon blender for solids and powders

Efficiently achieve uniform blending of bulk solids and powders, ensuring...

Checkweighers for medium and small products

Ensure precise weight control in high-speed production lines with advanced che...

Multipack flowrapping system

Streamline your packaging process with a multipack flowrapping system that effortlessly handles...

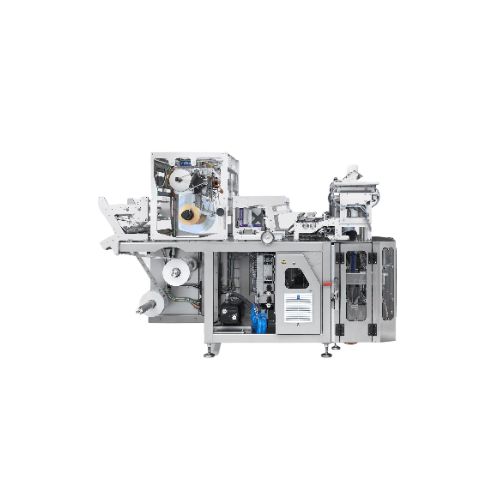

Pillow bag horizontal form-fill-seal solution

Optimize production efficiency with seamless integration of continuous, high...

4-side seal horizontal form-fill-seal packaging system

Streamline your confectionery and snack packaging with high-speed,...

Double twist wrapping machine for sweets

Optimize your confectionery packaging line with high-speed double twist wrapping, ...

Double twist wrapping solution for candy packaging

Enhance your candy and gum production with high-speed wrapping that en...

Extruder and depositor for confectionery production

Ideal for producing sophisticated confectionery and bakery items, thi...

Depositor and extruder for confectionery production

Enhance productivity with precision depositing and flexible extruding...

Vertical form-fill-seal for pillow bag packaging

Looking to enhance the speed and reliability of your packaging process? T...

Vertical pouch packaging system for food products

Achieve high-speed, precise packaging with our vertical pouch system, i...

High-speed vertical packaging system for candy and snacks

Achieve up to 500 pillow bags per minute with our high-speed p...

Vertical form fill sealer for high-speed packaging

Achieve consistent, high-speed packaging with flexible bag styles, per...

Vibratory buffer system for line efficiency

Enhance your production line by efficiently managing downstream stoppages and ...

Horizontal flat pouching solution for foods and chemicals

Achieve precision in pouching liquids and powders with high-sp...

Continuous motion liquid packaging system

Achieve precise and clean liquid packaging with advanced servo-driven squeegee s...

Continuous motion vertical form fill seal packaging system

Achieve high-speed, consistent packaging for diverse products...

High-speed vertical form fill seal for various packaging needs

Streamline your packaging process with an advanced vertic...

Vertical form fill seal for large bag packaging

For operations requiring precise, large bag packaging, this equipment ensu...

Automatic rotary premade pouch filler for food products

Enhance your packaging line with a high-speed solution designed t...

Automated infeed and outfeed systems for packaging lines

Streamline your production line by integrating reliable infeed a...

Support structures for packaging lines

Enhance safety and efficiency in your production line with robust support structures...

Industrial product fillers for precise packaging

Achieve consistent package weights and volumes with precision filling sol...

Industrial milling systems for food processing

Streamline your food production line with robust milling and cutting soluti...

Vertical packaging system for medium-high speed applications

Optimize your packaging line with a system that delivers pr...

Side seal shrink packaging machine

Achieve seamless and efficient packaging for varied product sizes with continuous side s...

Flow pack wrapper for shrink and film wrapping

Optimize your packaging operations with a versatile solution capable of hig...

Horizontal flow wrapper for bakery and chocolate

Achieve seamless integration in high-speed production lines with a horizo...

Automated bagging system for confectionery products

Achieve seamless integration in your confectionery packaging line wit...

Mini extruder for small batch processing

Ideal for precise control in experimental formulations, this mini extruder streaml...

Metal detector for packaging lines

Ensure product purity and safety with precision metal detection, seamlessly eliminating ...

Overflow conveyor for efficient product handling

Streamline your production with overflow conveyors that manage excess pro...

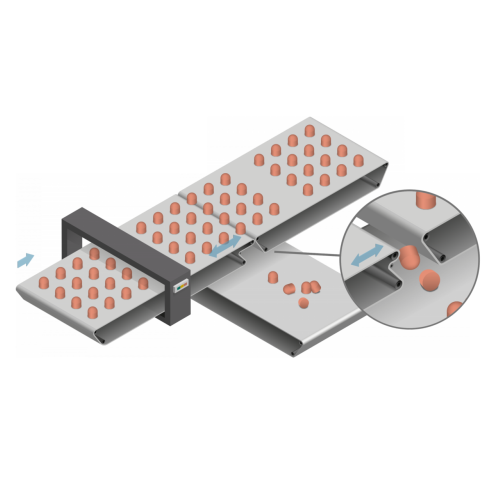

Row aligner for product packaging

Optimize your packaging line with precise alignment and high-speed product handling, ensu...

High-speed double twist packaging system for soft caramels

Streamline your confectionery packaging process with a high-s...

High-speed forming, cutting, and wrapping for side and bottom folds

Streamline your confectionery production with a mac...

High speed packaging system for fold wrap and stick packs

Streamline your confectionery production with a versatile syst...

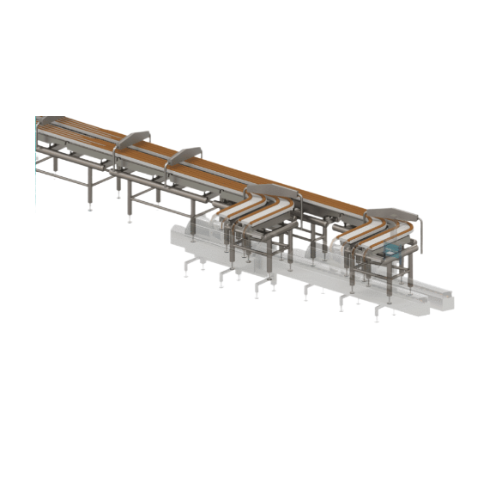

Accumulation conveyor for controlled feeding in packaging lines

Ensure seamless product flow and enhance efficiency in y...

Gondola storage system for efficient product handling

Manage production line inconsistencies with precision by employing ...

Flexible high-speed wrapping machine for chocolate products

Optimize your confectionery production line with a flexible ...

Wrapping system for preformed products in double twist

Achieve precise packaging with our high-speed double twist wrappin...

High-speed forming and cutting for soft caramels and chewy sweets

Efficiently streamline your confectionery production ...

High speed fold wrap and stick packs packaging system

Enhance your confectionery production line with a packaging system ...

High speed forming, cutting, and wrapping for side fold packaging with comic strip

Maximize your output with high-spe...

High-speed chocolate wrapping system

Optimize your confectionery packaging process with a versatile, high-speed wrapping so...

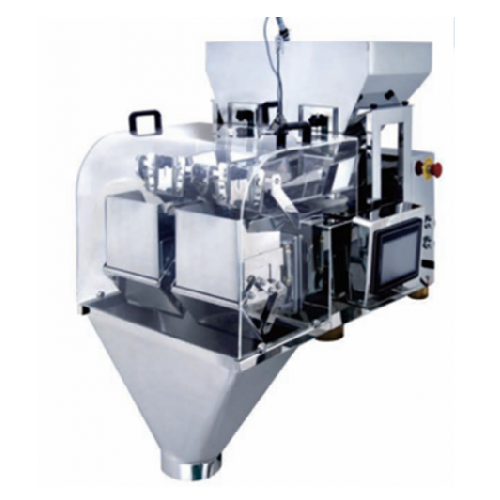

Twin product multihead weighing system for mixing and sorting

Optimize your production line with precision mixing and hi...

Multihead weighing system for dry free flowing products

Optimize your packaging line with precise weight measurements for...

Multihead weighers for food production

Optimize your food production line with precision and speed by integrating advanced ...

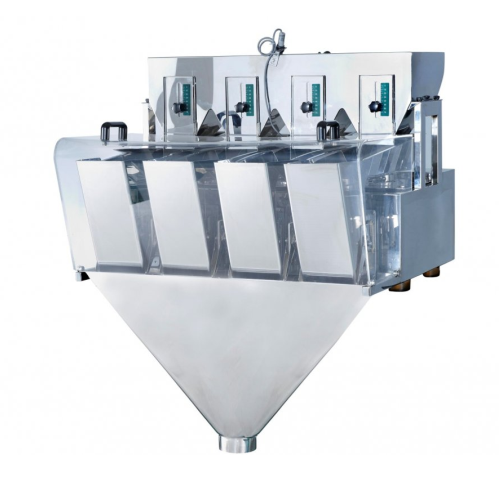

Linear weigher for dry free flowing products

Streamline your packaging process with precise weighing capabilities, ensurin...

Linear weigher for accurate food portioning

Ensure precise weight control for snacks and confectioneries with our advanced...

Linear weigher for dry free-flowing products

Optimize your packaging line with precise weighing for snacks, sweets, and gr...

10 head multihead weigher for dry products

Optimize your weighing and packaging operations with precise and rapid handling...

Rotary pouch filling system

Looking to efficiently manage pouch filling for diverse products? This rotary system seamlessly ...

Cooking extruders for continuous food processing

Optimize your extrusion processes with cooking extruders designed for con...

Belt dryers for gelatin processing

Efficiently transform liquid gelatin into high-quality solids with precise moisture cont...

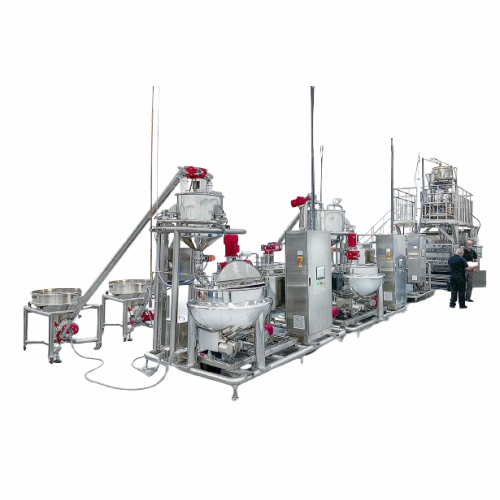

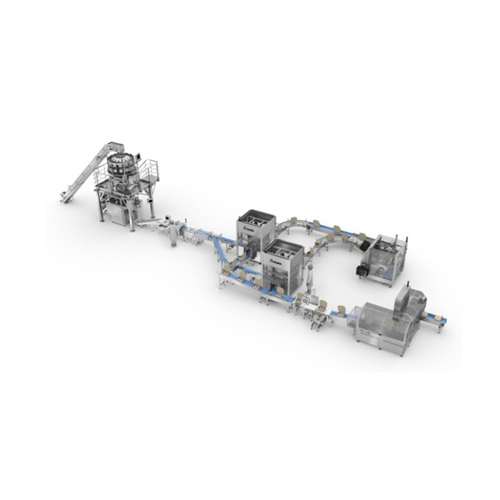

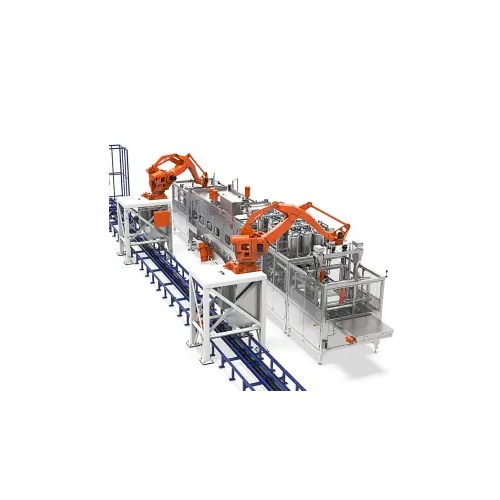

High-capacity non-starch gummy and jelly production line

Boost your gummy production efficiency with a seamless, high-cap...

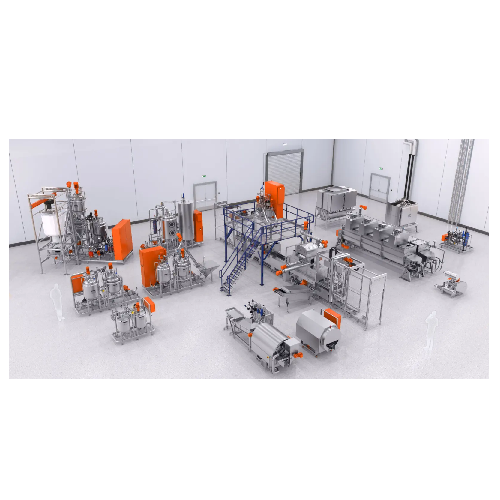

Industrial gummy and jelly production line

Optimize your gummy and jelly production with a system that streamlines operati...

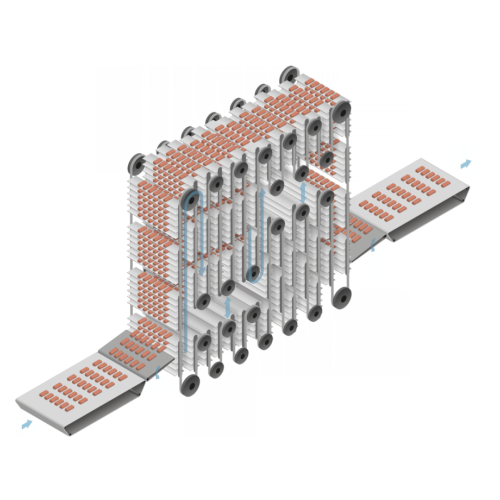

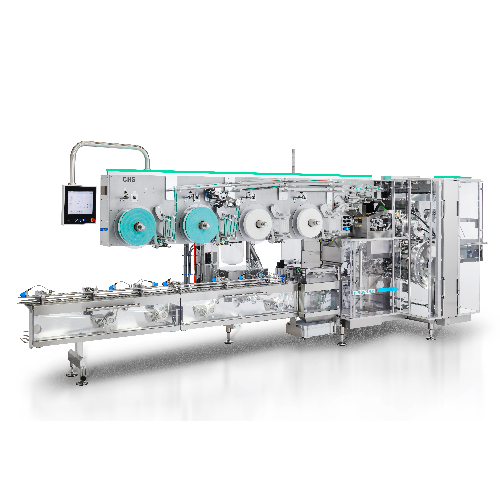

Automatic production line for gummies and nutraceuticals

Maximize the versatility and efficiency of your production space...

Mid-capacity gummy and jelly production system

Ideal for manufacturers aiming to integrate functional ingredients into gum...

Entry-level gummy and jelly production line

Looking to produce gummies and jellies with functional ingredients? This produ...

Automatic production line for gummies, jellies, and nutraceuticals

Optimize your production space with a compact line t...

Robotic production line for gummies and nutraceuticals

Streamline your gummy and nutraceutical production with a versatil...

Robotic high capacity production line for gummies and jellies

Optimize your gummy and jelly production with a high-capac...

High output confectionery kitchen technology

Elevate your confectionery production with seamless processes that ensure pre...

Candy packaging solution for gummies and hard candies

Maximize your confectionery efficiency with high-speed packaging so...

Texture analyser for food and cosmetics testing

Ensuring consistent product quality across diverse food and cosmetic appli...

Scraped surface heat exchangers for high viscosity products

Ideal for continuous processing, these heat exchangers effic...

Longitudinal slitting system for confectionery production

Achieve precise confectionery dimensions with our customizable...

All around sprinkling systems for confectionery

Enhance your confectionery production with a system that ensures precise a...

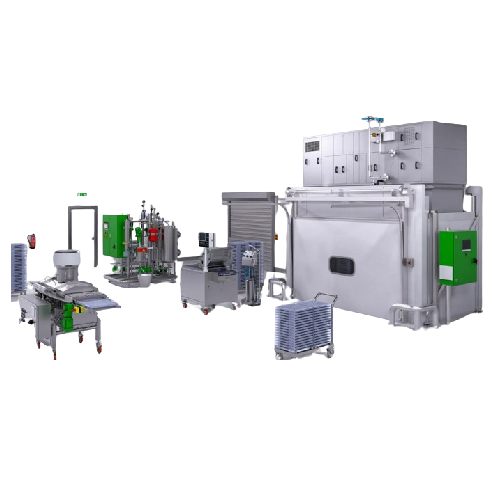

Start-up production line for CBD gummy production

High-value products like CBD gummies demand precision equipment such as...

Lab scale production line for nutraceutical gummy production

By gradually investing in the individual parts, a productio...

Small-scale demoulder for starchless functional gummy production

Removing vitamin or CBD gummies from the moulds by hand...

Entry-level conditioning system for drying nutraceutical gummies

The drying process demands specific environmental condi...

Entry-level starchless depositor for nutraceutical gummies

Manufacturing nutraceutical products such as vitamin, CBD ,or...

Entry-level cooking system for vitamin and CBD gummies

Producing functional gummies or jellies with functional ingredient...

Continuous mixer for pumpable media

In the food industry, mixing processes often involve solid and liquid combinations such...

High precision dosing system for liquid media

Producing confectionery and bakery products implies mixing large amounts of ...

Low Output Production Line for Gummies and Jellies

The original technique for making gums and jellies exploited the non-s...

Flexible Output Line For Gummies and Jellies

The traditional method for gummy and jelly production uses starch to keep the...

High Output Industrial Production Line for Gummies and Jellies

Mainstream technology for the preparation of gummies and ...

Emulsifier and mixer for gelling agent

When making jams and marmalades, gelling agents, such as pectin, are used to thicken...

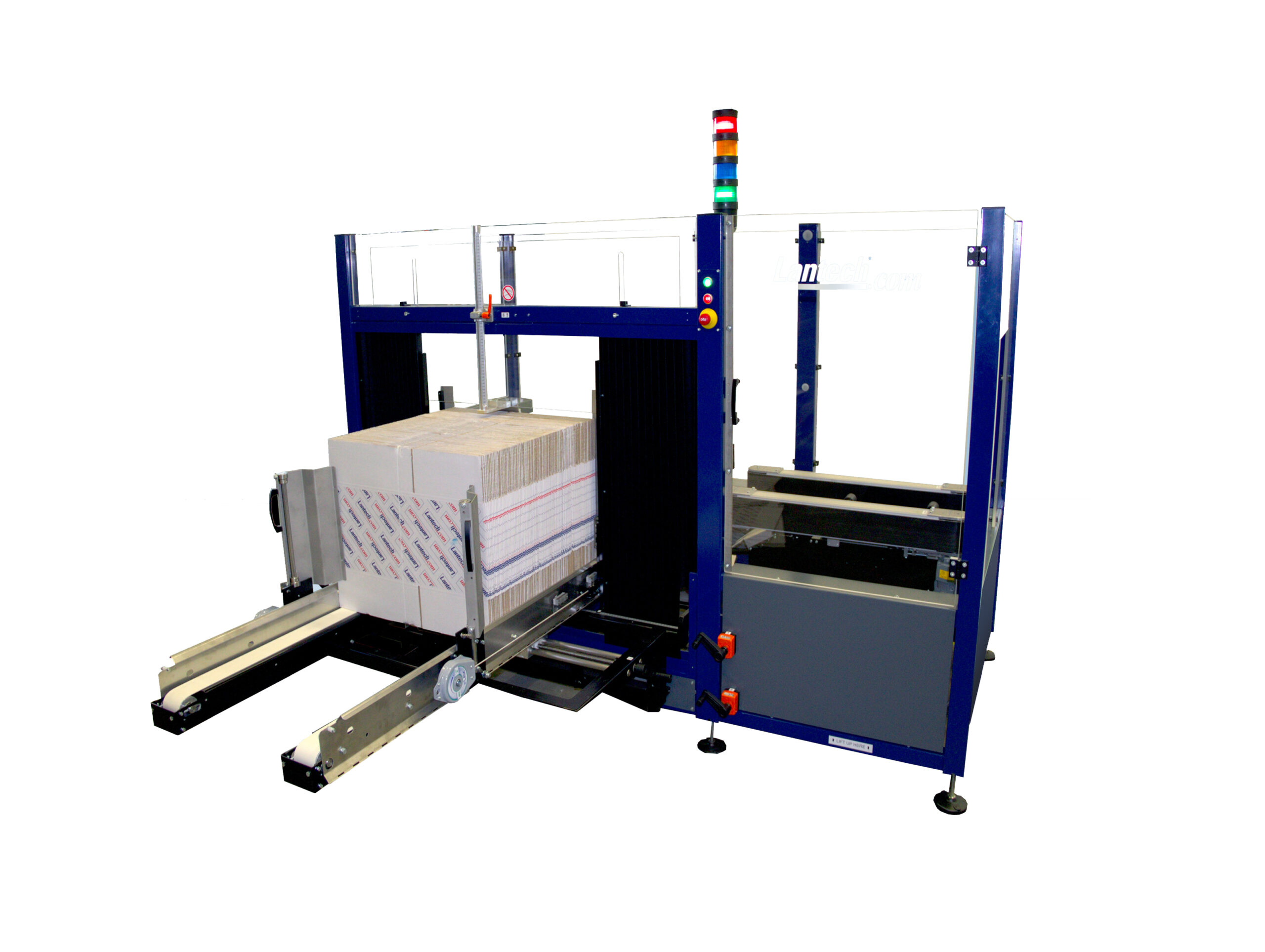

Endload cartoning machine

As demand for food production increases, so does that of packaging and sealing the product and mak...

Bagger with mechanical driven jaw actuation

If you want to pack into unique bag styles like Quad-seal and Doypack, but you...

Mini sugar coating machine

The coating of grains or nuts with sugar is a popular process in the manufacture of many bakery p...

Entry-level high volume package seal tester

Manufactured food products need to be packed in gas-filled pouches to ensure t...

High-Speed Pouch Packaging Machine

For large scale production of powders and liquids in a wide range of industry sectors, a...

Small sugar mill for entry level production

Sugar powder is a key ingredient in a wide range of bakery, confectionery, and...

Small scale dragee coating machine

Coated dragée products such as Jordan Almonds or hard-coated candies are very popular, b...

Bag-in-Bag machine

If you are looking for a compact packing machine that packs multiple smaller packs in one master bag; this...

Case erector

To overcome common cases of manufacturing variations and optimize your packaging line, you need to be able to cou...

Cooker for gums and jellies

Prepare your ingredients for use in gummy and jelly products. This is a static cooking system de...

Whipping machine for soft candy

Prepare your ingredients for any whipped or aerated product component. This is a pressurized...

Batch cooker for hard candy

Prepare your ingredients for the production of hard candy. This is a line of universal candy coo...

Pressure cooker for caramel and soft candy

Prepare your ingredients for soft candy production. This is a highly flexible c...