Making Pharmaceutical Syrup

Find innovative production technology for making cough syrup and connect directly with world-leading specialists

Your earliest memory of medicine is probably a jar of cough syrup with a plastic dosing spoon attached. Although widely produced as remedies for children, medicated syrups are also available for adults. Making cough syrup starts by dissolving active ingredients into a purified water and sugar solution. But it is the distinct flavorings and colorants that persist in people’s minds long after the illness is cured.

Select your cough syrup process

Tell us about your production challenge

Apply heat progressively to prevent caramelization of sucrose

Sucrose acts as both a sweetener and a thickener for making cough syrup. The solution with heat method heats the combination of sucrose and purified water until the sugar is completely dissolved. Top up the mixture with distilled water to add volume.

Heating, however, must be performed gently and gradually. One of the benefits of sucrose is its purity of color, but excessive temperatures cause it to caramelize, turning it brown.

Offset low sugar concentrations with preservatives

The solution of water and sucrose is fertile ground for colonies of microorganisms, raising risks for the product. But the hydrophilic properties of sugar also make them resistant to microbial growth. The syrup medium needs to strike a balance between viscosity and pathogen resistance.

A sucrose concentration of 85% or higher in cough syrups is considered microbe-resistant. In cases where the concentration is lower, you can counter pathogenic development with preservatives. A range of compounds such as glycerin, sorbic acid, and butylparaben are effective.

Processing pharmaceutical syrups with tolu balsam as the main ingredient

Tolu balsam is emerging as a critical ingredient in medicated formulas. Rich in benzyl and cinnamyl esters, it is frequently used in cough recipes to dissolve mucus. Tolu balsam is suspended in magnesium carbonate in a mixing tank. The mixture is then combined with the water and sucrose syrup and filtered repeatedly until the solution is clear.

Active pharmaceutical ingredients are then prepared into the solution by heating. In general, higher final temperatures result in thicker syrups and lower final temperatures in thinner ones.

A spoonful of flavorings makes the medicine go down

Most drugs in solution are unpalatable. There are two strategies to cancel out the offensive tastes: mask them or reduce their potency.

Bitterness can be covered by aromatic flavors such as mint, ginger, and cherry. Citrus flavors and raspberry work well against sour ingredients. Saltiness can be tempered with rich flavors like butterscotch, peach, or apricot. Ingredients that result too sweet can be mellowed with vanilla, fruit, and berry.

Processing steps involved in cough syrup making

Which cough syrup technology do you need?

Centrifugal pumps for food & beverage and biopharmaceutical applications

Optimize your liquid transfer processes with p...

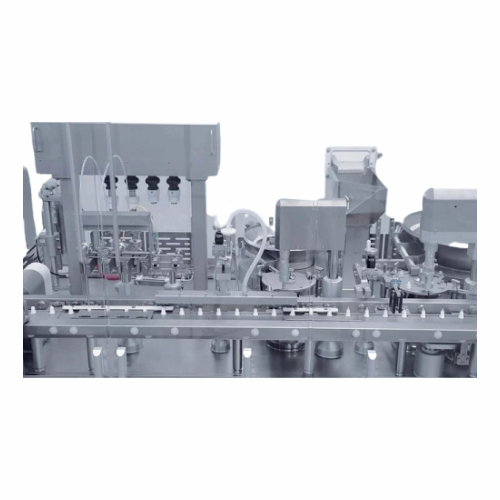

Filling and capping solution for oral liquid products

Achieve precise, high-speed filling and capping of oral liquids wit...

Gravimetric filling and capping system for chlorine solutions

Optimize your filling and capping processes for chlorinate...

Marking solutions for traysealers

Ensure precise labeling and data printing on tray-sealed packages with integrated solutio...

Dished end for optimized mixing in small-volume vessels

When space constraints challenge vessel design, this solution eli...

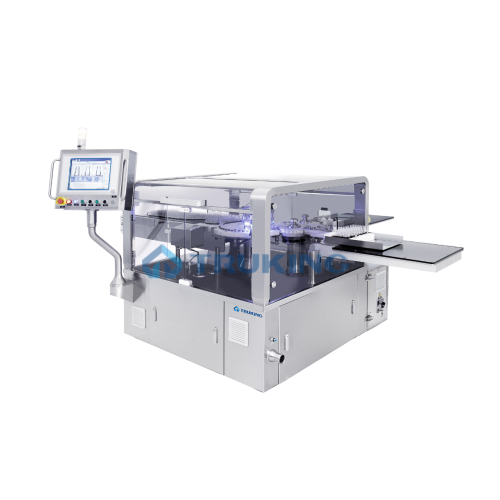

Automatic bottle and vial blower

Ensure purity and compliance in your liquid bottling line with this integrated blowing syst...

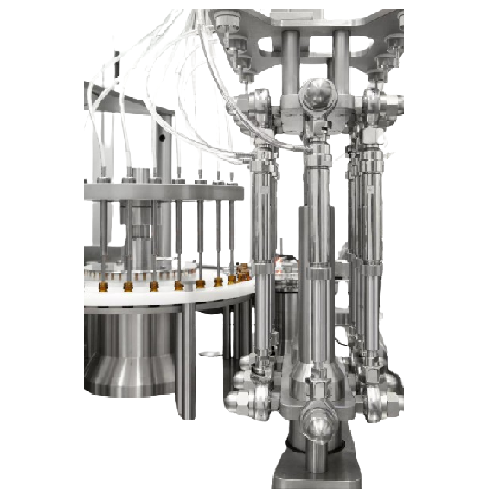

Bottle filler and capper

Achieve precise liquid filling and secure capping with high-speed, intermittent motion, ensuring con...

Filling and capping solution for bottles

Optimize your bottling efficiency with a robust solution designed to streamline fi...

Stickpack filling and closing system

Optimize your stickpack production with precise dosing, uniform sealing, and seamless ...

Film coater for Otc and food supplements

Achieve optimal film coating for tablets and capsules with precision-engineered so...

Volumetric filling system for cosmetic products

Streamline your production line with precise volumetric control, ensuring ...

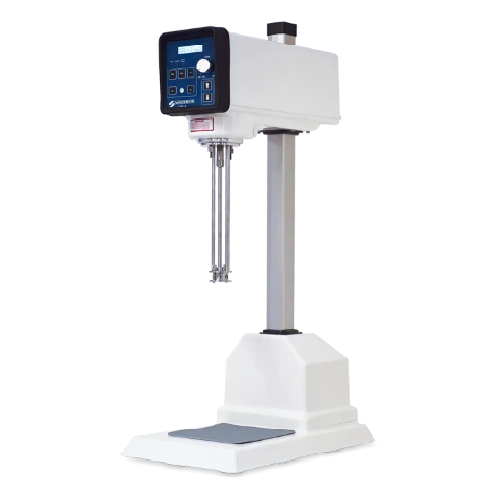

Laboratory mixer for intensive sample preparation

For precise and efficient preparation of both liquid and dry formulatio...

Industrial skids for liquid processing

Efficiently manage large-scale liquid and solid processing in your production line w...

Powder blender for liquid mixing applications

Optimize your process with a compact blender designed to efficiently dissolv...

Powder liquid blender for food processing

Achieve seamless integration of solids into liquids with precision-engineered bl...

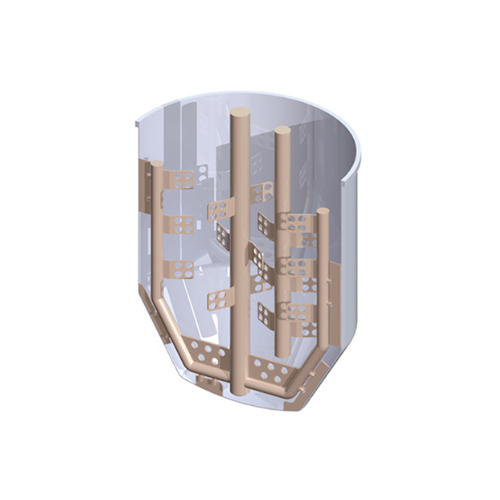

Agitators for mixing tanks

Optimize mixing operations with versatile agitators designed for various viscosities and fluid ty...

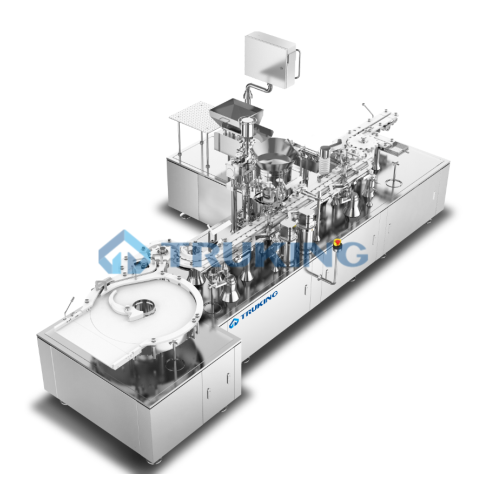

In-line filling system for pharmaceutical products

Ensure precise and flexible filling of liquids, from sterile saline to...

Thermoforming solution for clinical trials

Designed for precision and flexibility, this compact thermoforming machine stre...

Pure steam generation and distribution system

Ensure reliable sterilization with pure steam that’s free from contami...

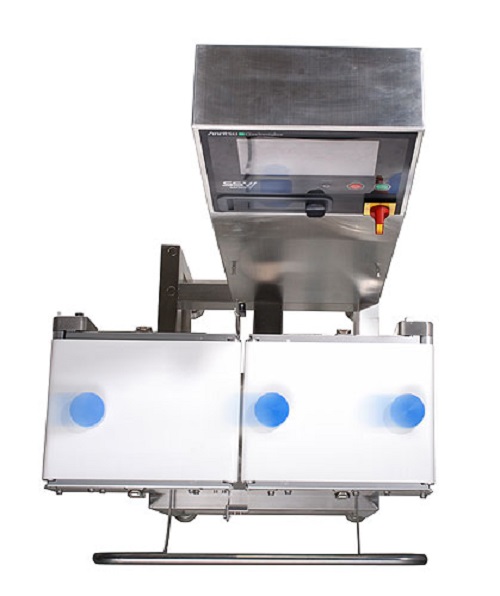

Leak detection for pharmaceutical containers

Ensure the integrity of your liquid products in high-speed production by dete...

Top-down x-ray inspection for pharmaceutical packages

Ensure product safety by detecting minute foreign particles and pac...

Empty container inspection for pharma packaging

Ensure ultra-clean packaging by detecting glass faults and contaminants be...

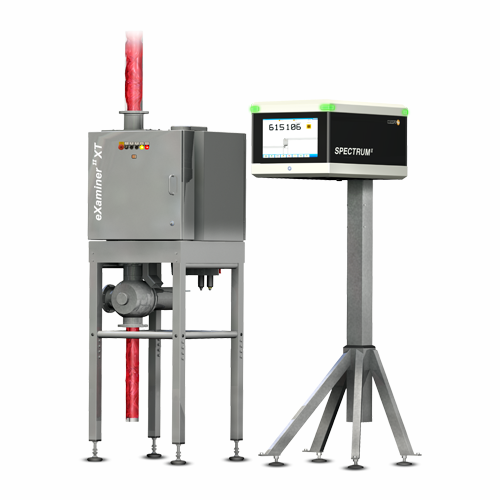

Pipeline inspection for liquid and paste-like products

Ensure your liquid and paste-like products are free from foreign o...

Foreign matter detection for syrup and medicine bottles

Ensure the quality and safety of your liquid products with precis...

Full container inspection for pharma and food industries

Ensure precise fill levels and secure closures in your productio...

Checkweigher for packaged goods inspection

Ensure precision and compliance with this high-speed checkweigher, perfect for ...

Side entry mixer for industrial fluid mixing

Optimize your fluid mixing processes with high-speed side entry mixers, desig...

Filling system for consumer healthcare products

For small to medium productions needing versatile filling and sealing, thi...

Filling solution for consumer healthcare products

Navigate complex liquid product formulations with a versatile filling s...

Filling solution for non-injectable pharmaceutical products

Streamline your pharmaceutical production with a versatile s...

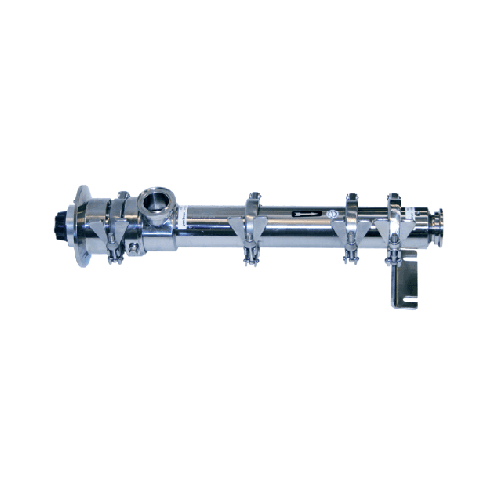

Sampling valve for secure sample extraction

Ensure product quality by safely extracting representative samples without hal...

Planetary stirrer for creams and ointments mixing

Achieve homogeneous mixing of creams, ointments, and pastes efficiently...

Precision ointment filling and dosing system

Achieve precise filling of liquid formulations with a versatile system capabl...

Intermittent stick pack machine for pharma and healthcare

Looking to streamline your packaging operations with high-spee...

Intermittent stick pack packaging system for pharma products

Achieve precise dosage and packaging of pharmaceutical and ...

Intermittent stick pack system for pharmaceuticals

Effortlessly streamline your packaging process with a high-speed, mult...

Vacuum processing units for high-viscosity products

For manufacturers seeking to streamline production of high-viscosity ...

Large-scale industrial freeze dryer

Achieve precise moisture control and preserve product integrity with a large-scale free...

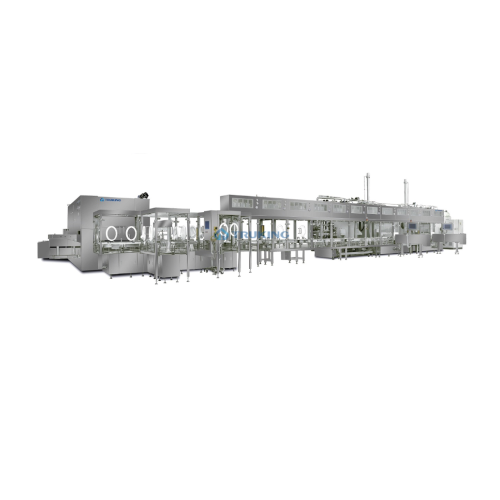

Continuous motion liquid filling and capping monobloc

Optimize high-speed liquid filling with seamless transitions from f...

Linear intermittent motion filling system for high-density liquids

Ensure precise dosing of high-density liquids like c...

Industrial recirculating chiller for laboratory applications

For consistent distillation results, maintain accurate temp...

Industrial tanks for diverse applications

Efficiently manage your liquid production processes with customizable storage, m...

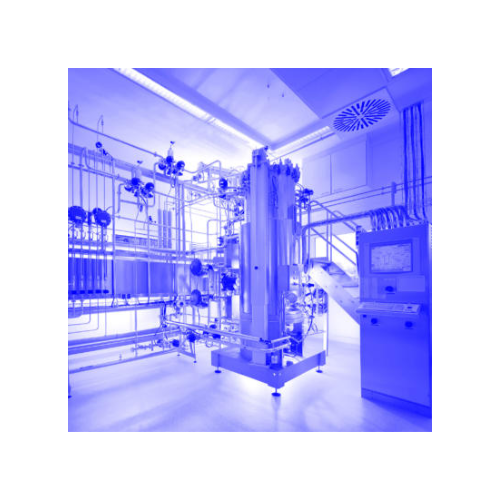

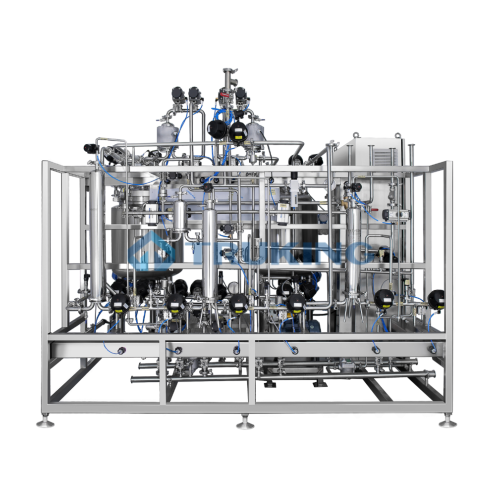

Clean-in-place systems for biotechnology and pharma

Ensure seamless transitions between production batches with efficient...

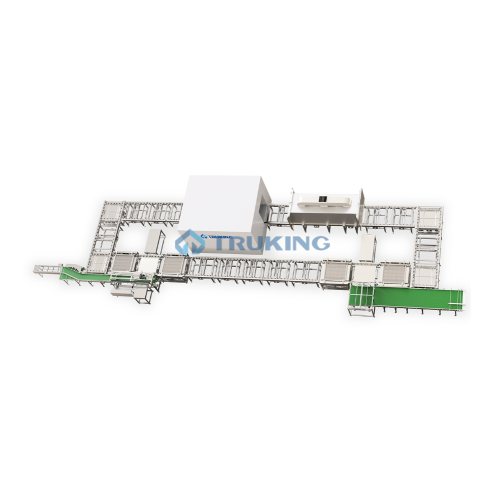

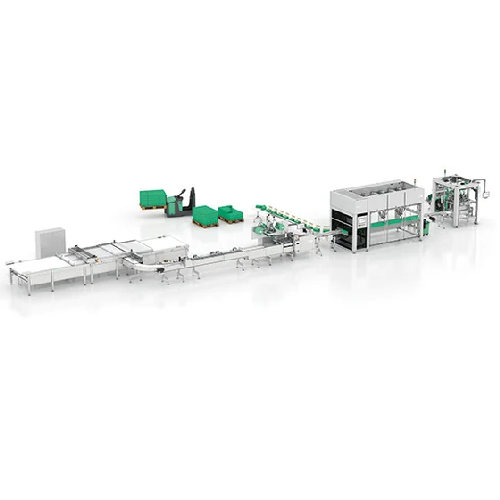

High-speed vertical and horizontal case packer

Enhance your packaging line efficiency with a versatile case packing soluti...

Lab-scale fermentors for microbial cultivation

Optimize microbial cultivation with lab-scale fermentors designed for preci...

Formulation vessel for biopharmaceutical homogeneity

Achieve precise homogeneity in liquid formulations with vessels opti...

Industrial bottle cap closer for various caps

Ensure seamless closures for liquid products with versatile equipment design...

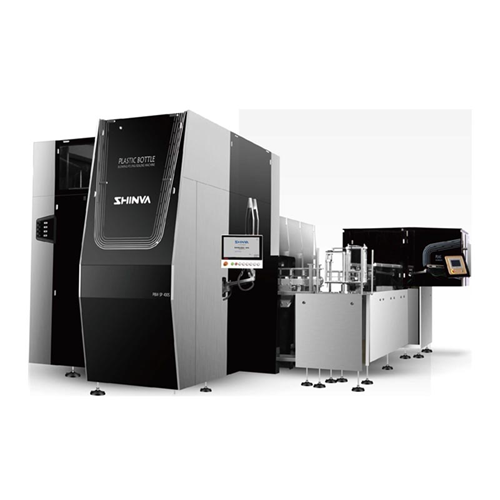

Filling and closing solution for plastic bottles

Efficiently sort, fill, and close a variety of plastic bottles with preci...

Filling and closing solution for vials and stable bottles

Optimize vial and bottle processing with a seamless solution d...

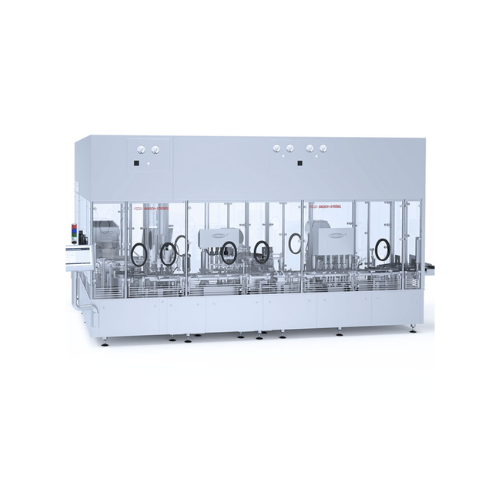

Automated filling and closing system for vials and bottles

Optimize your vial and bottle filling line with precise liqui...

Cleaning system Cip for internal equipment maintenance

Ensure optimal hygiene and production efficiency with this portabl...

Alternate movement bottle filling and capping system

Enhance your production line with a versatile filling and capping so...

Sterilisable isolator workstation for aseptic containment

Ensure precise contamination control and sterile conditions du...

Sterile liquid preparation system for pharmaceutical use

Ensure the sterility and precision of your liquid formulations w...

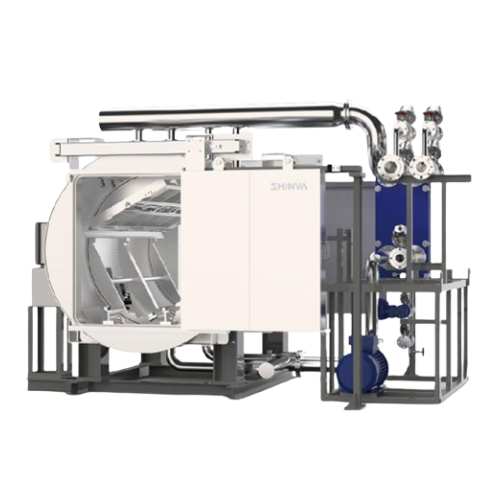

Vertical vacuum dryer and mixing reactor

Achieve precise control over drying and mixing processes with a versatile unit des...

Large batch gyraton® mixer for homogenizing moist and poorly flowing materials

Optimize your production line with this...

Automatic single side adhesive labeling solution

Streamline your packaging line with precision; this solution offers effic...

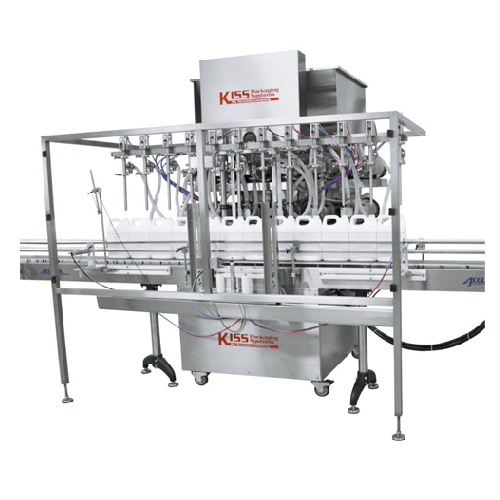

Automatic detergent shampoo filling solution

Streamline your filling process with precise volume control, achieving consis...

Automatic edible oil filling & capping solution

Streamline your liquid packaging operations with precise, high-speed filli...

Automatic food cooking oil bottling solution

Ensure precise volumetric filling for a range of liquid products, enhancing y...

In-line filling system for various container sizes

Streamline your production with versatile in-line filling solutions th...

Single seat valve for hygienic applications

Ensure optimal hygiene and safety with a versatile pneumatic valve designed to...

Benchtop mixer for lab-scale product development

Easily scale up your formulations with precise and repeatable lab-scale m...

Inline continuous mixer for dairy and beverage processing

Achieve precise emulsification and particle size reduction for...

Low-shear portable mixer

For processes demanding strict hygiene, this mixer eliminates rust and chipped coatings by offering ...

Filler and capper for bottles and jars

Optimize your production with a compact filling and capping solution that delivers f...

Benchtop screw capper for diverse bottle sizes

Ensure precision and efficiency in your capping process with this adaptable...

Semi-automatic flowmeter boom filler for large volume containers

Effortlessly handle large volume liquid filling with pr...

Analytical balance for precise laboratory measurements

Achieve unparalleled precision and reliability in your lab’s...

20l glass reactor for crystallization and isolation processes

Optimize your lab’s crystallization and isolation pr...

Dual-jacketed reactor for decarboxylation processes

Streamline your decarboxylation process with a dual-jacketed reactor ...

Dual-jacketed reactor for botanical extraction winterization

Optimize your production with precise temperature control a...

Large capacity jacketed glass reactor

Achieve precise control over temperature and vacuum conditions with this versatile re...

2l single jacketed glass reactor system

Enhance your laboratory’s efficiency with a versatile reactor system, ideal f...

Full body sleeving systems for packaging applications

Achieve seamless, high-speed labeling precision for diverse contain...

Automatic induction sealer for cap sealing

Achieve precise and reliable cap sealing with our advanced induction technology...

Rotary bottle rinser for high-speed production lines

Ensure thorough cleaning and preparation of containers with a high-s...

High precision automatic mini dose filler

Achieve unparalleled precision when filling small volumes, from 0.1 ML to 200 ML...

Automatic positive displacement filler for various liquids

Achieve precision and versatility in liquid filling operation...

Automatic positive displacement bottle filler

Streamline your liquid filling operations with precision and flexibility, id...

Automatic labeler for low profile containers

Optimize container labeling with precision and efficiency, addressing the cha...

Tabletop labeler with integrated thermal printer for round containers

Efficiently label and print variable data on roun...

Roll-on bottle capping solution for aluminum caps

Ensure precise threading and sealing of aluminum caps on diverse bottle...

Inspection-rejection station for bottled products

Ensure your bottled and packaged products ship defect-free by automatic...

Automatic capper for dual head o-ring chuck

Ensure precise cap application with dual-head precision, handling various bott...

Accumulation turntable for bottling lines

Optimize your production line’s efficiency with a 42-inch diameter accumul...

Clean-in-place system for diverse processing needs

Ensure the precision and consistency of your cleaning cycles with a ro...

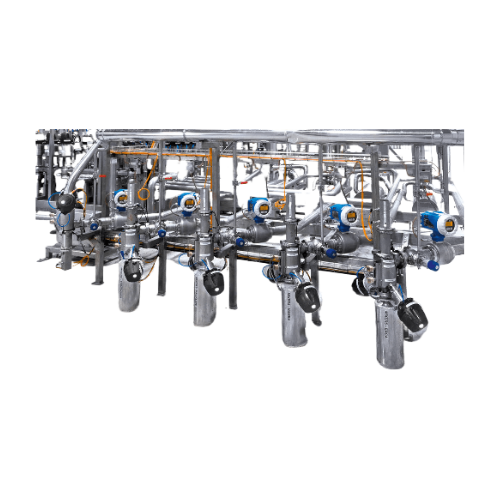

Automated valve manifolds for clean-in-place solutions

Optimize your production efficiency with automated valve manifolds...

On-food traceability technology for produce

Enhance your product authenticity with a revolutionary traceability technology...

Rotary level filler for low to high viscosity liquid products

Ensure precise fill levels and enhance production efficien...

3a certified product recovery system for food and pharmaceuticals

Optimize your production line with a system designed ...

Industrial high-pressure homogenizer

Achieve precise homogenization with superior flow rates and efficiency, ensuring optim...

Wash-off-line system for pharmaceutical plants

Optimize your production with a versatile wash-off-line system, ensuring pr...

Inline disperser for homogeneous emulsions and suspensions

Achieve precise control over particle size and distribution w...

Industrial jetstream mixer for homogeneous mixing

Achieve consistent product quality with precise micro and macro mixing ...

Serialisation system for medicine bottles

Optimize your packaging line with high-speed serialisation and labeling designed...

Efficient ribbon mixers for precise powder blending

Achieve consistent and uniform blending with this advanced U-Trough m...

Industrial sigma mixer extruder for homogeneous mixing and extrusion

Achieve precise mixing and seamless extrusion of d...

Blow/fill/seal packaging for large bottles

Need a high-speed solution for producing sterile liquid formulations in large v...

Omnidirectional inspection system for bottles and vials

Ensure precise serialization and aggregation with a 360° inspecti...

Vibratory hopper for bulk solids discharge

Ensure consistent material flow and prevent bridging in storage silos with this...

Vacuum basket mill for high-viscosity product milling

Achieve refined particle size and smooth texture in your high-visco...

Dosing and filling pump for liquids and pastes

Achieve precise dosing and filling of liquids and pastes with compact, hygi...

Dosing and filling pump for hygienic applications

Optimize your production line with this dosing and filling pump, design...

Side-mount agitator for large tank mixing

Achieve efficient mixing in large tanks with reduced energy consumption by lever...

Laboratory stirrer for high-viscosity materials

Streamline your laboratory mixing processes with a powerful stirrer design...

Laboratory stirrer for small batch mixing

Achieve consistent mixing and blending in small-scale environments with minimal ...

Continuous motion liquid packaging system

Achieve precise and clean liquid packaging with advanced servo-driven squeegee s...

Cartoning solution for pharmaceutical products

Ensure accurate and efficient packaging of pharmaceutical products with pre...

Vial powder dispensing system

Optimize your aseptic fill process with high-precision powder dispensing that minimizes contam...

Stainless steel craft tanks for biopharmaceuticals

Ensure precise temperature control and customized capacity for your fo...

Robotic sterilization logistics system

Ensure seamless aseptic transfers across production stages with this robotic logisti...

Superheated water sterilizer for pharmaceutical applications

Ensure precise sterilization with real-time monitoring and ...

Pharmaceutical autoclave for terminal sterilization

Optimize your sterile production with high-precision terminal sterili...

Vertical ultrasonic washing for pharmaceutical containers

Ensure immaculate cleanliness and sterilization of pharmaceuti...

Sterilizing and depyrogenization tunnel for ampoules

Ensure sterile and pyrogen-free ampoules with precision control in d...

High-speed ampoule filling unit

Ensure precision and speed with this cutting-edge solution designed for efficient filling an...

Vial filling and stoppering system for aseptic production

Streamline aseptic production by integrating high-speed vial f...

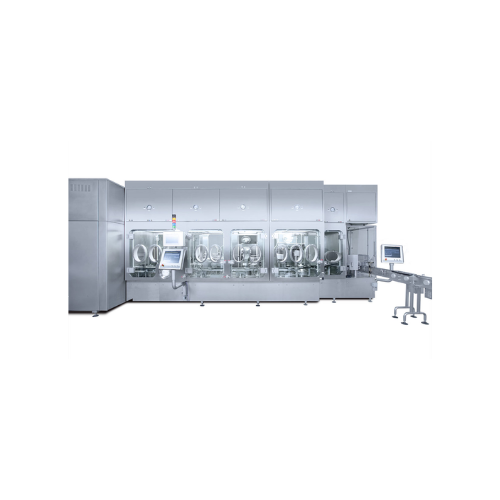

Pharmaceutical isolator system for aseptic production

Ensure aseptic conditions and operator safety with a robust isolati...

Autoclave unloading isolator for sterile assembly

Ensure aseptic conditions and prevent microbial contamination during th...

Ultra-pure water preparation system for pharmaceutical industry

Ensure your pharmaceutical production line meets stringe...

Aseptic blow fill seal system

Ensure sterile, high-speed production of liquid pharmaceuticals by integrating a cutting-edge ...

Automatic chromatography column for biopharmaceutical separation

Ensure high-purity monoclonal antibodies and herbal ext...

Pharmaceutical preparation system

Achieve seamless integration in pharmaceutical processes with a preparation system that o...

Comprehensive auxiliary system for online cleaning and temperature control

Ensure reliable and precise control in phar...

Sanitary vessels for pharmaceutical applications

Ensuring the highest standards of aseptic processing, these sanitary vess...

Bioreactor system for protein and enzyme reaction

Ensure precise control in biopharmaceutical production with a bioreacto...

Automatic inspection system for ampoules and vials

Ensure precision in pharmaceutical production with a comprehensive ins...

X-ray inspection for pharmaceutical vials

Ensure product purity by detecting contaminants in pharmaceutical vials with adv...

Automatic inspection system for sealing defects in ampoules

Ensure flawless ampoule sealing with a high-precision inspec...

Automatic inspection and leak test for pharma containers

Ensure container integrity for injectables with high-speed inspe...

Automatic leak detection system for pharmaceutical containers

Ensure the integrity of pharmaceutical containers with pre...

Sterilizing and drying tunnel for pharmaceutical vials

Ensure precise sterilization and depyrogenation of pharmaceutical ...

Sterilization and drying tunnel for glass bottles

Ensure aseptic integrity and regulatory compliance in injectable produc...

Non-pvc film large infusion compact line

Streamline your infusion production with a compact line designed for high-speed, p...

High capacity automatic blister packaging system

Streamline your production line with a high-speed blister packaging syste...

Secondary packaging cartoner for ampoules and vials

Optimize your aseptic production with efficient high-capacity carton ...

Pharmaceutical drops and sprays filling system

Streamline your liquid formulation process with precision filling and seali...

Industrial freeze dryer for pharma

Optimize moisture removal in lyophilized products with precise thermal conduction and ef...

Auto loading & unloading system for freeze dryers

Efficiently manage vial handling in freeze-drying processes with automa...

Ultrasonic pre-washing system for large infusion glass bottles

Optimize your cleaning process with an ultrasonic pre-was...

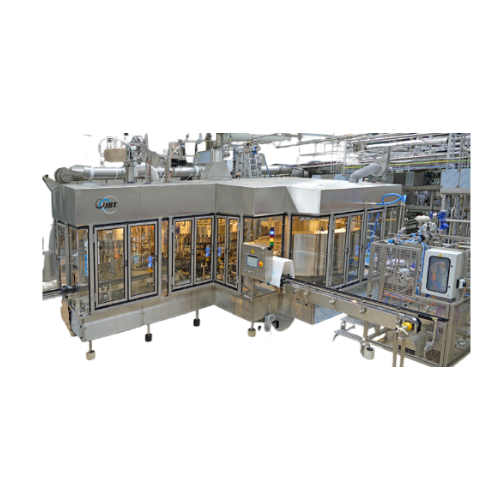

Aseptic rotary cup filling and closing solution

Maximize your production capacity with this cutting-edge aseptic solution,...

Pneumatic dosing syringes for precise liquid dispensing

Achieve precise and reliable liquid dosing with pneumatic syringe...

Volumetric piston fillers for dense liquid products

Ensure precise filling of liquids and dense products with versatile i...

Manual monoblock for filling and capping spouted pouches

For those handling liquid or semi-dense products, this manual mo...

Manual dosing and capping for semi-dense products

Enhance your production line efficiency by seamlessly integrating manua...

Manual system for filling and capping jars

Ideal for efficiently handling liquid and semi-dense products, this manual syst...

Manual filling and capping for spouted pouches

Optimize your production line with a versatile solution for filling and cap...

Pneumatic syringe dosing system

Streamline your liquid dosing process with precision and efficiency, ensuring each applicati...

Accurate volumetric filler for liquid and semi-dense products

Achieve precise dosing and filling of various liquid and s...

Bench-top piston filler for liquid and semi-dense products

Optimize your filling precision with a versatile piston fille...

Vacuum bottling equipment for wineries and breweries

Optimize your bottling process with a vacuum solution that fills up ...

Automatic line for filling and capping spouted pouches

Streamline your production line with high-speed filling and cappin...

Jacketed kettle for porridge and sauce cooking

Efficiently heat and mix diverse liquid and slurry products with precise te...

Automated visual inspection for pharmaceutical products

Ensure the integrity and safety of your parenteral products with ...

Pharma r&d equipment for solid dosage forms

Optimize your pharmaceutical production with cutting-edge equipment designed f...

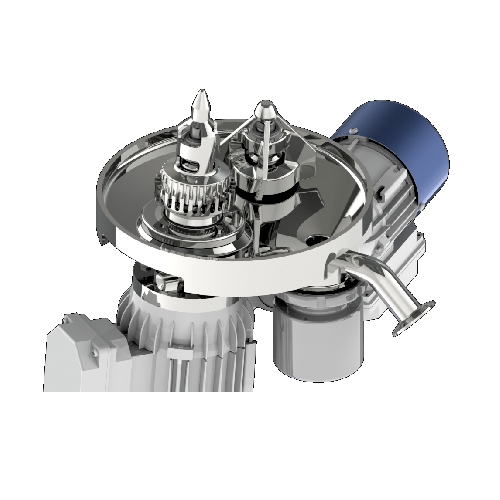

High-shear mixer for emulsions, dispersions, and foams

Achieve precise emulsions and dispersions effortlessly with high-s...

Line blender for continuous flow mixing

Achieve instantaneous mixing with minimal space and maintenance using a continuous ...

Micro-line vial filling solution for biopharmaceuticals

Ensure batch consistency and sterility in fill-finish operations ...

Motorized cap torque tester for bottle closures

Ensure precise seal integrity and compliance with bottle cap torque measur...

Laboratory in-line mixer for precise mixing and reproducibility

Achieve precise laboratory-scale mixing with rapid proce...

High shear mixer for efficient particle size reduction

Achieve rapid and precise blending and particle reduction in your ...

High shear lab mixer for laboratory work and r&d

Achieve unparalleled precision and consistency in laboratory and pilot-sc...

Reciprocating plastic bottle blow-fill-seal system

Achieve seamless integration of bottle forming, filling, and sealing w...

Moist heat sterilizer for liquid preparation

Ensure precise sterilization of pharmaceutical liquids and injectable biologi...

Basic moisture analyzer for laboratory weighing

Optimize moisture analysis tasks with precision and efficiency. Designed f...

Hygienic Cartoning Machine For Pharma and Health Products

When packing single or multiple vials, ampoules or devices int...

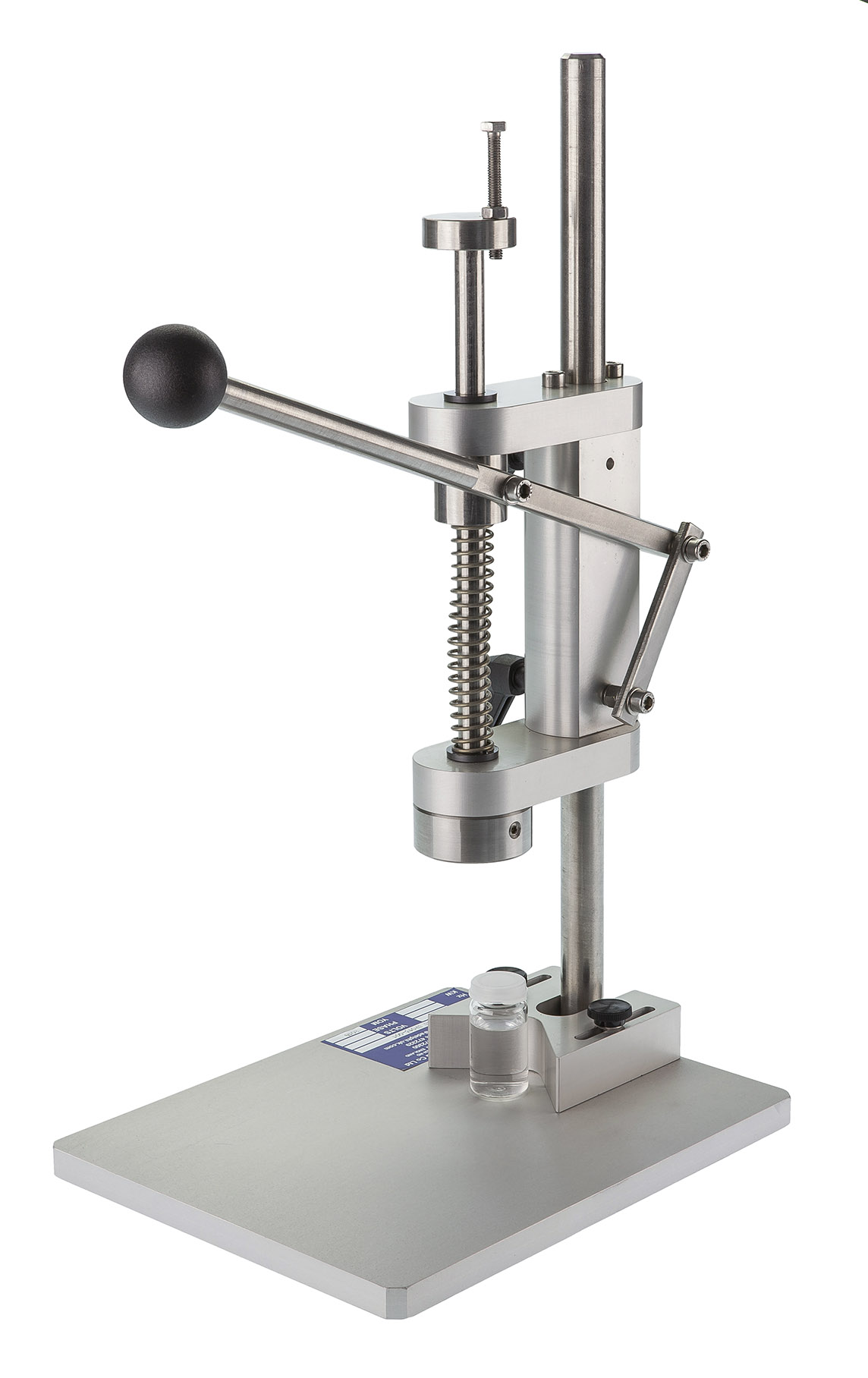

R&D bottle cap press

When you are a small-scale producer of liquids contained in bottles with press-on lids and caps you need...

Pharmaceutical formulation and mixing tanks

Preparation lines for formulating pharmaceuticals include fixed and mobile tan...

Syrup preparation tank

Syrups and suspensions are typically produced under the same high-quality conditions as used for steri...

Cleaning and sterilization systems

An increasingly vital part of high quality pharmaceutical production is a dedicated Clea...

Ultra-fine dispersing machine for emulsions and suspensions

Producing the finest micro-emulsions and suspensions require...

Labeling machines for pharmaceutical bottles

Labels for ampoules, vials and bottles are typically applied at the end of th...

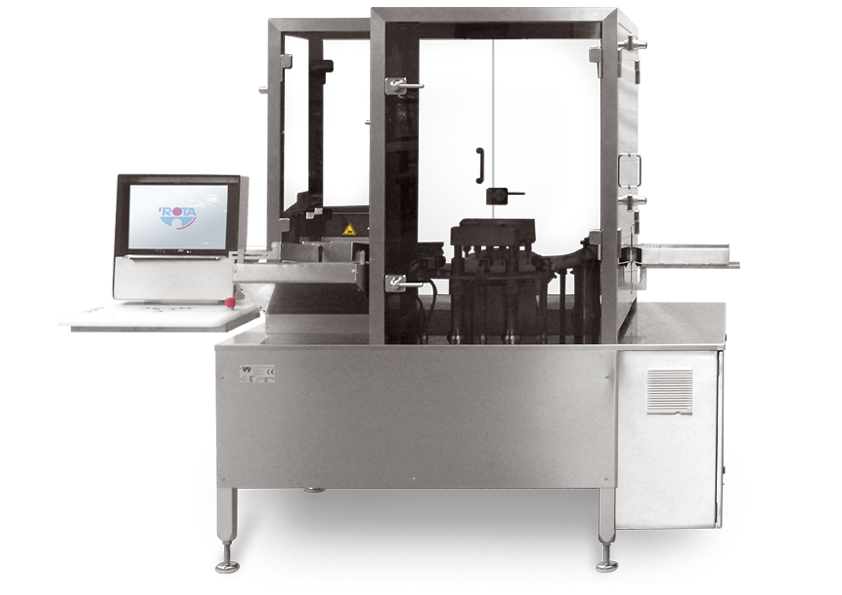

Pharmaceutical bottles inspection machine

For the visual inspection of small to medium batch-sizes of vials, ampoules or b...

Small bottle checkweigher

Any small-diameter bottle, containing prescription medication or cosmetic applications, can be pro...

Versatile checkweigher

This Versatile checkweigher is equipped with a highly versatile strain gauge load cell. It is also sui...