Lithium-Ion Battery Manufacturing Equipment

Find innovative production technology for making lithium-ion batteries and connect directly with world-leading specialists

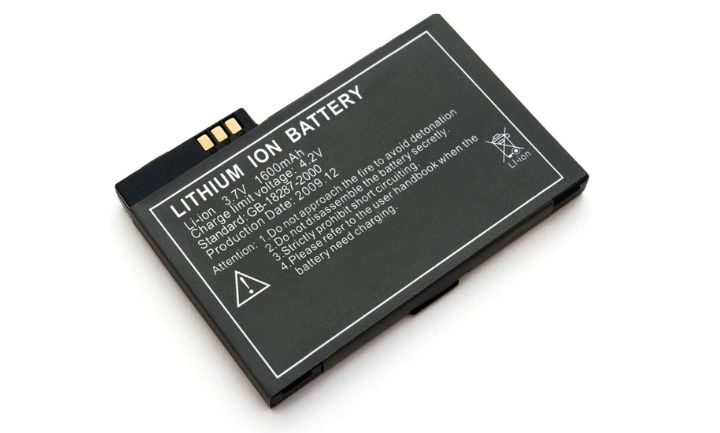

Landline telephones in the 1980s were minimalist gadgets that kept getting slimmer in the 1990s. In contrast, cell phones in the same period were bulky and cumbersome. And once they lost their charge, they turned into a giant paperweight. Then came a revolution in batteries and automation with lithium-ion battery manufacturing equipment. Mobile phones packed more power, recharged faster, and endured more recharge cycles. Above all, they were light and small, making cell phones the inseparable companions they are today. But Lithium-ion batteries power much more than phones. As a result, the world is seeing steady growth in battery manufacturing equipment and lithium-ion production lines.

Tell us about your production challenge

Dry and refine lithium before processing the metal

The crucial element in lithium-ion battery production is, of course, lithium. The lightest material on earth is highly reactive, making it a prime candidate for this exchange of electrons.

The metal is obtained either from ore mines or extracted from lithium-rich pools. The former method is quarried and refined; in the latter, the water is removed by evaporators, and the metal is filtered from the remaining deposits.

Stabilize lithium with a metal oxide

Lithium is a chemically unstable material, and it is worked into matrices with other metals to stabilize it. Engineers use multiple compounds to form these metal oxides for the cathode chamber. Nickel, manganese, cobalt, aluminum, and iron are the most widely used metals in the cell manufacturing process.

The anode chamber is typically made from graphite, a stable mineral that can hold the lithium ions discharged from the metal oxide.

Enlarge the surface area of lithium particles with fine milling technology

Before starting the formulation process, the raw metals need to be treated with a dryer to remove all moisture content.

Your dry materials are now ready for ultra-fine milling. Grind the metals into a powder to achieve a uniform particle size distribution that allows them to be worked more smoothly. Meanwhile, reducing particle size increases their surface area and produces a higher performance in batteries.

Form the lithium-ion mechanism into a battery cell

The graphite and metal oxides are coded onto current collector sheets, usually made of copper and aluminum on an assembly line. An electrolyte sheet sandwiched between them keeps them from coming into contact. It also serves as a barrier to electrons traveling from cathode to anode and back. Welding techniques, such as laser welding, are used to seal the battery cells, ensuring that they are safe and durable.

The pouch cell design is becoming increasingly popular, as it is lightweight and flexible, making it ideal for portable devices. Cell assembly is the process of assembling the different components of the battery cell, including the anode, cathode, and electrolyte.

The sheets are pressed together and wound around a steel cylinder, forming a compact cell. A typical battery pack module for electric vehicles consists of several lithium-ion battery cells packed together in an integrated unit. The whole is greater than the sum of its parts, and this solution generates electricity more efficiently than a large battery would.

Lithium-ion technology is changing electricity distribution methods

Advances in lithium-ion battery materials and technologies are fast-tracking electric mobility and promise to remodel electricity grids. The basic principle of the battery is that ions and electrons travel from a positive electrode (anode) to a negative electrode (cathode), creating an electric current on the way.

When the anode discharges all its ions, the current is interrupted, and the battery goes flat as the energy storage has been depleted. When you plug your battery-operated device into the wall socket, the positive charge pulls the ions to the anode again. With the development of advanced coater technology, battery manufacturers can now achieve a more efficient assembly line, with the ability to coat multiple layers of materials onto the current collector sheets in a single pass. This not only increases production speed but also improves product quality and consistency.

Which lithium-ion batteries technology do you need?

Automatic bag folding solution for bulk packaging

Enhance your production line efficiency and product protection by integ...

Specific surface area & pore size analyzer for materials

Achieve unparalleled precision in material characterization by m...

Laser diffraction particle size analyzer

Achieve precise particle size analysis with laser diffraction technology, ensuring...

Stability analyzer for emulsions, suspensions, and foams

Accurately detect and quantify changes in dispersibility and sta...

Multi-sample stability analyzer for emulsions and suspensions

Achieve precise, non-destructive stability analysis of emu...

Gas pycnometer for true density measurement of solids and powders

Achieve highly precise density measurements of solid ...

Flexible powder recipe formulation system

Streamline your batch production with efficient, dust-tight formulation and blen...

Powder packing module for consistent flow

Enhance your production efficiency with streamlined powder packing that ensures ...

Ibc cleaning equipment for hygienic powder handling

Optimize cleaning efficiency and maintain hygiene standards with a ve...

Laboratory ploughshare mixer for small-scale production

Achieve precise mixing and granulation for R&D and small-bat...

High-precision palletizing robot for industrial applications

Maximize efficiency and reduce floor space in your producti...

Flexible industrial robot for medium payloads

Optimize your production line with a versatile robotic solution that adapts ...

High payload industrial robot

Optimize your production with high payload robots designed to enhance flexibility and reduce o...

Spot welding robot for confined spaces

Optimize spot welding efficiency in tight manufacturing spaces with a compact robot ...

Automotive assembly and leak testing systems

Optimize your production line with versatile assembly and testing systems, en...

Cylinder block leak testing system

Ensure reliability and quality by detecting and addressing leaks in cylinder blocks with...

Function test for electro-hydraulic control units (ehs)

Ensure precise functionality and reliability in your production l...

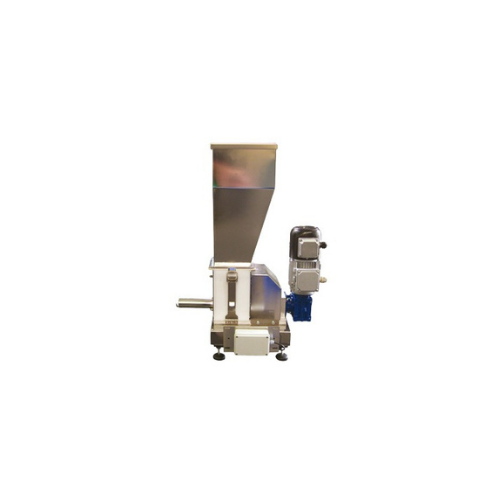

Industrial powder grinder

Achieve precise particle size reduction and classification with advanced equipment designed for co...

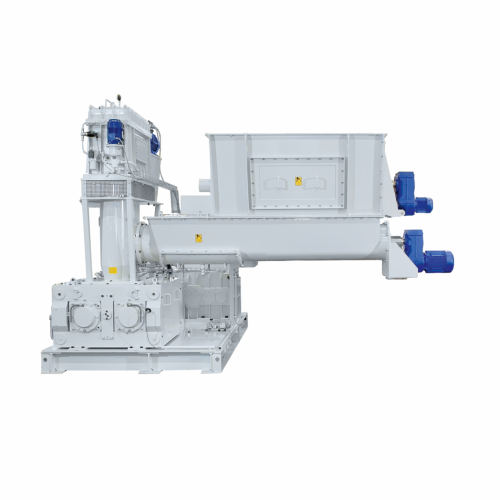

Powder mixing systems

Optimize your production line with precision powder mixing systems that ensure uniformity, enhance prod...

Gear pelletizer for stable cylindrical pellets

Achieve uniform pellet size and stability in your production line with a lo...

Pneumatic conveying system for bulk material handling

Efficiently transport bulk materials with precision through pneumat...

Industrial pre-crusher for coarse crushing

Optimize your production line by efficiently transforming clumped materials int...

Table roller mills for mineral raw material comminution

Achieve precise mineral raw material comminution and energy-effic...

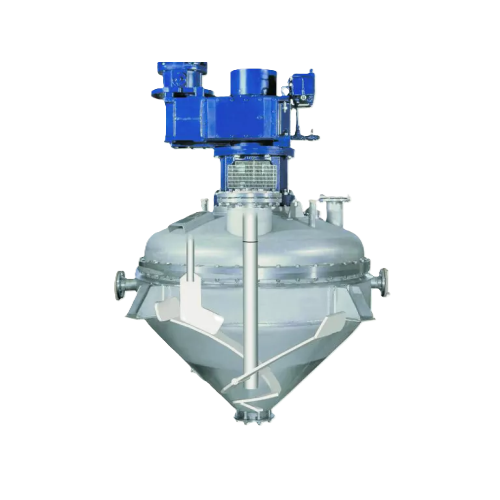

Conical screw mixer for powder blending

Achieve precise and homogeneous blending with the conical screw mixer, ensuring uni...

Ultra-fine powder flash drying system

Achieve rapid moisture removal and particle refinement with this integrated system, d...

Spiral jet mill for ultrafine micronisation

Optimize your powder processing with precision-driven micronisation that ensur...

Fluidised bed opposed jet mill for fine particle processing

Achieve precise and consistent particle sizes with high-spee...

Jet mill for toner and pigment industries

Optimize particle size and distribution for high-demand applications with this h...

Roller press for fine-grained material compaction

Achieve optimal density and stability in your solid press agglomerates ...

Compactor for powder processing

Designed for transforming powdered materials into uniform granules, this compactor enhances ...

High-pressure roller compactors for chemical, food, and minerals industries

Achieve precise particle compaction and br...

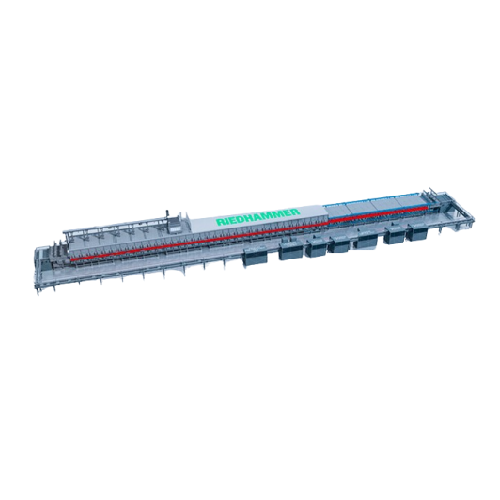

Mechanical conveying systems for bulk solids

Optimize your bulk material processes with advanced mechanical conveying syst...

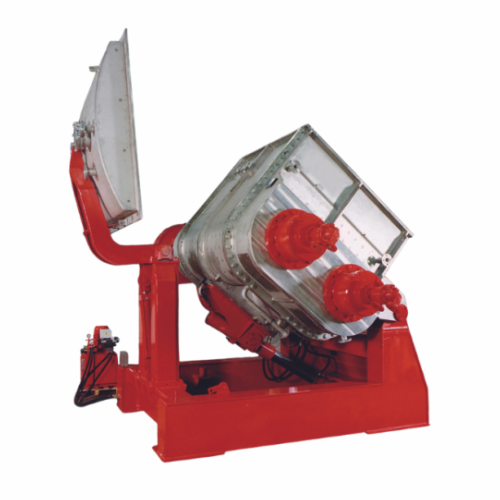

Multiprocessing system for flexible research and production

Optimize your process development with a versatile system th...

Pelleting and spheronizing equipment for chemical granulates

Optimize your production line with versatile pelleting and ...

Industrial granulator for high-throughput plastic recycling

Facing challenges in efficiently recycling high-volume plast...

High-speed hammer mill for continuous operation

Achieve precise particle size reduction with high-speed hammer milling, id...

High pressure roller mill for medium-fine crushing

Achieve precision in particle size with high-pressure roller mills, id...

High-pressure roller mill for medium-fine crushing

Achieve precise granule distribution in medium-fine crushing applicati...

Spiral jet mill for superfine powder production

Achieve consistent ultra-fine powder with precise particle size control, c...

Fluidised bed opposed jet mill for ultrafine powder production

Achieve contamination-free ultrafine powder milling with ...

Sugar grinding and recrystallization system

Optimize your sugar production with a system that integrates grinding and recr...

Versatile fine impact mill for soft materials

Achieve precision grinding with flexibility for a wide range of materials, e...

Flake crushers for gentle crushing of brittle materials

For processes needing precise granule control, our equipment ensu...

Flake crusher for hygroscopic substances and lumped salts

Efficiently turn fragile, aggregated materials into manageable...

Industrial granulators for plastic recycling

Streamline your recycling operations with a solution that not only reduces en...

Fine cutting mill for soft to medium-hard plastics

Achieve precise size reduction and smooth particle shapes in plastic p...

Compact granulator for plastic comminution

Optimize your plastic recycling operations with a compact granulator designed t...

Heavy-duty shredder for difficult materials

Struggling with stubborn materials that resist conventional shredding? This ro...

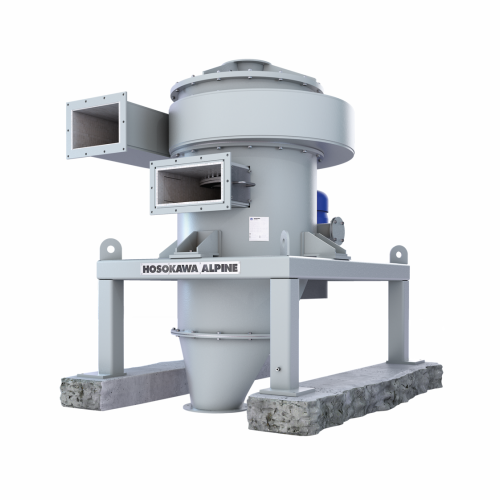

Air classifier for fine powder processing

Enhance your production line with precise particle size control and energy-effic...

Ultrafine classifier for precise particle separation

Gain precise control over particle size with this ultrafine classifi...

Gravity classifier for precise particle separation

Achieve sharp separations in particle processing with minimal maintena...

Ultrafine classifier for toner and pigments

Achieve unparalleled precision in classifying fine powders essential for high-...

Ultrafine air classifier for powder separation

Achieve precise particle separation with technology designed to enhance you...

Ultrafine classifier for soft to medium-hard mineral processing

Achieve exceptional particle precision with an ultrafine...

Discharge systems for difficult bulk materials

Achieve seamless bulk material discharge with our advanced systems that eff...

Automatic bulk material filling system

Ensure precise, contamination-free filling of various bulk materials with an advance...

Ultrafine grinding mill for calcium carbonate slurries

Achieve precise particle size distribution in your mineral slurrie...

Ultra-fine dry grinding mill for glass and ceramics

Achieve ultra-fine particle sizes and energy savings with a dry grind...

Ball mill for dry comminution of hard materials

Achieve ultrafine particle sizes and precise material breakdown with this ...

Classifier mill for ultra-fine grinding and precise particle size control

Achieve consistent ultra-fine particle distr...

Air classifier for classifying industrial minerals

Achieve precise particle separation with advanced air classifiers, par...

Air classifier for fine to medium-fine separation

Reduce energy consumption and wear while achieving high precision in th...

Air jet sieve for particle size analysis

Achieve precise particle size distribution effortlessly for your powders, ensuring...

Laboratory system for powder and particle processing

When precision in powder processing is crucial, this versatile labor...

High-viscosity continuous industrial kneader for small volumes

Achieve consistent high-viscosity material processing wit...

Double z-arm industrial extrusion kneader for high-viscosity processes

Optimize high-viscosity material processing with...

Powder synthesis reactors for nanometer and micrometer particles

Achieve precise particle control and enhance material p...

Vacuum dryer for free-flowing and pasty solids

Achieve precise drying and mixing with this vacuum dryer, optimizing heat t...

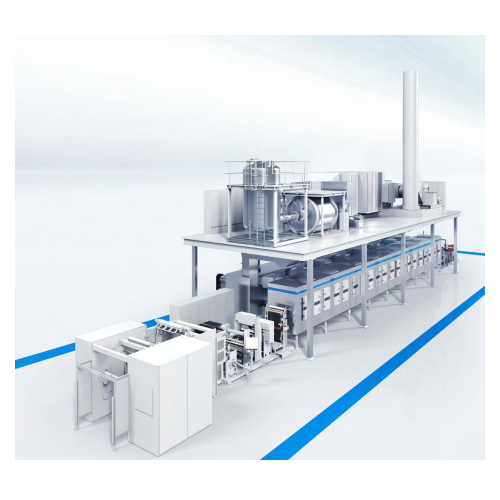

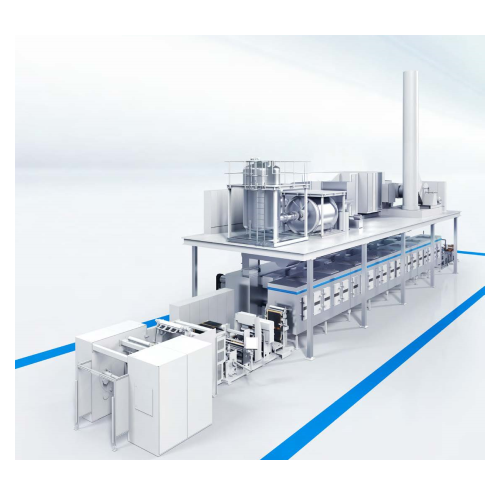

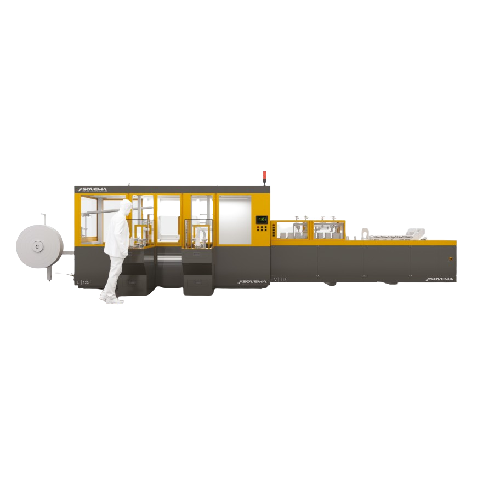

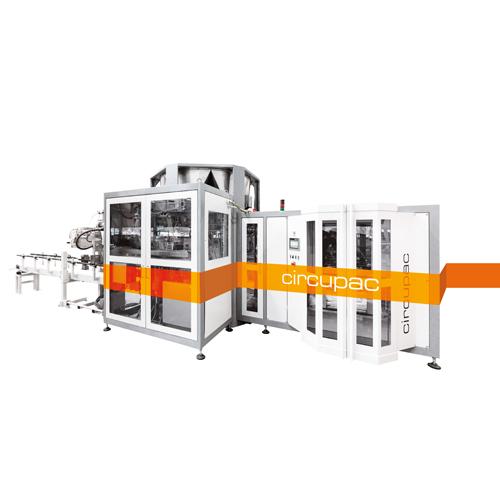

Production systems for battery cells with end-of-line testing

Optimize battery cell production with a flexible system of...

Roll support dryers for web transportation

Eliminate web curl issues and enhance drying precision for diverse materials wi...

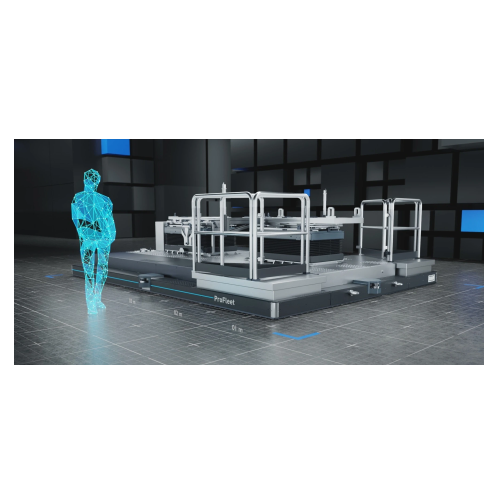

Compact Agv for trolley towing and load transport

Streamline your intralogistics operations with agile load transporters ...

Battery electrode coating line

Optimize your battery production with a comprehensive coating line that enhances throughput a...

Electrode coating system for lithium-ion batteries

Achieve high-volume, precision electrode coating for lithium-ion batte...

Solvent recovery systems for battery electrode manufacturing

Efficiently recover and purify solvents in battery electrod...

Spray dryers for lithium iron phosphate powder production

Optimize your lithium battery and electric vehicle production ...

Precision feeders and mixers for plastics processing

Achieve precise blending and feeding for plastics processing with mo...

Sanitary bulk solids receiver for food and pharma

Ensure precise control over bulk solid transfer with a system designed ...

Complete packaging lines for various containers

Streamline your packaging process with versatile equipment capable of hand...

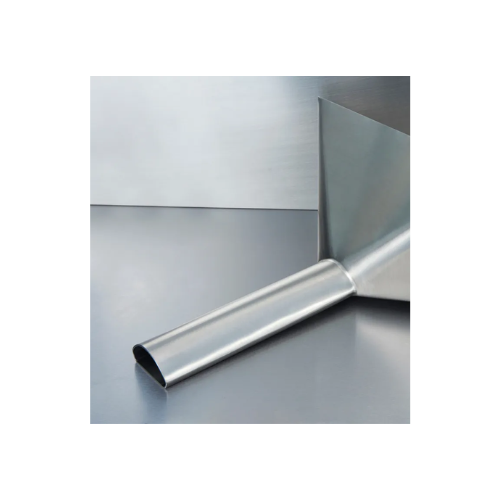

Powder dispensing funnel

Enhance powder handling accuracy while minimizing product loss with a precision-engineered dispensin...

Bottle cleaning station for controlled environments

Ensure high-level decontamination of passive units and containers wit...

Bulk powder transfer safety device

Ensure stable and secure docking by minimizing equipment damage during powder transfer p...

Controlled atmosphere oven for high-temperature applications

Achieve precise atmosphere control and uniform heating for ...

High temperature clean room ovens

Achieve precise environmental control for heating, drying, and sterilizing sensitive mate...

Chain conveyor for grain and floury products

Ensure seamless material handling with a versatile chain conveyor designed fo...

Four-roller and eight-roller mill for wheat and grain grinding

Optimize your grinding operations with this versatile rol...

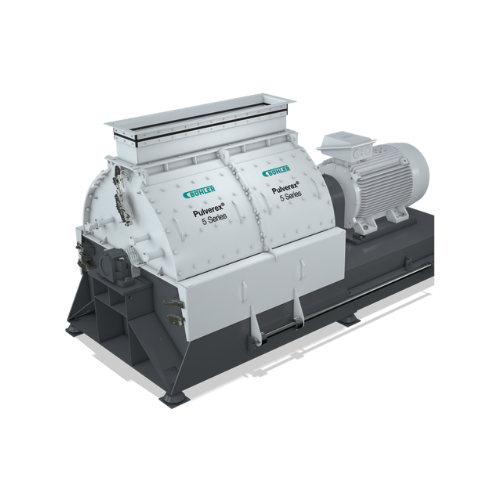

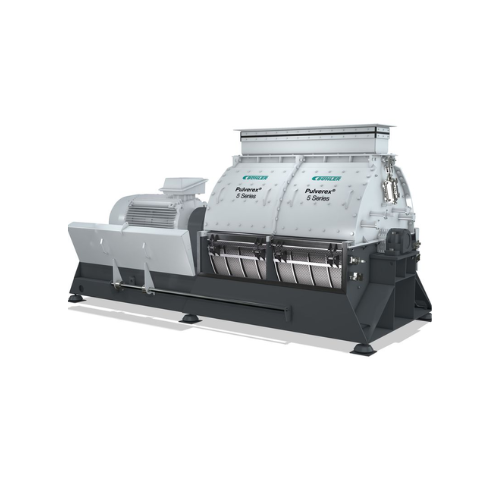

Pulverizer for fine grinding applications

Achieve optimal particle size distribution and enhance throughput with this adva...

High-throughput hammer mill for animal feed production

Ideal for high-throughput operations, this hammer mill ensures pre...

Heavy-duty trough chain conveyor for high throughput applications

Optimized for high-capacity operations, this robust c...

Twin-screw extruder for breakfast cereals production

Enhance your product range with flexible twin-screw extrusion techno...

Discharge station for bags and big bags

Ensure consistent material flow and hygiene in your production line with a versatil...

Control systems for wet grinding industry

Enhance precision and efficiency in your production line with advanced control s...

Batch scale for high accuracy weighing of powdery products

Achieve unparalleled precision in powder dosing with our batc...

Fully automatic batch scale for powdery and granular products

Achieve precise and repeatable dosing for powdery and gran...

Industrial fine grinding pulverizer

Achieve consistent fine granulation at high capacity with reduced energy consumption, u...

Planetary ball mill for powder material mixing and alloying

Achieve precise control in particle size reduction and homog...

Table-top bottom loading furnace for high-temperature applications

For precise thermal processing and advanced experime...

24-ton laboratory pellet press

Achieve precise pellet formation with reliable 24-ton pressing power, ideal for compaction of...

Rotary tablet press for abrasive powders

Achieve precise tablet sizing and bilayer production, even with abrasive powders, ...

Heavy-duty tablet press for single & double-layer tablets

Maximize your tablet production with a high-speed solution cap...

Industrial rotary press for single-layer tablet production

Optimize your tablet production with precision-engineered rot...

Battery production facilities with precision weighing

Achieve maximum product purity and precision in your production pro...

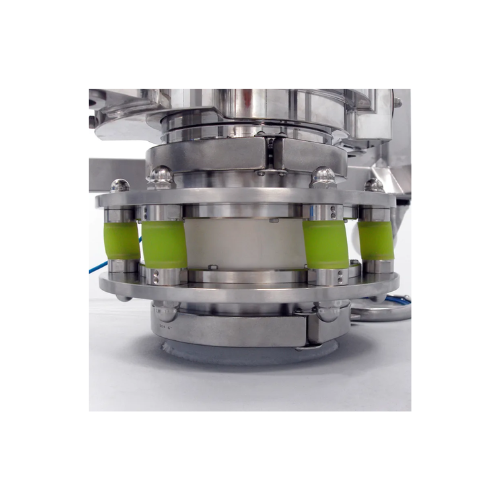

Inline disperser for lithium-ion electrode slurry mixing

Achieve highly efficient dispersion and homogeneity for battery ...

High-speed mixer for industrial mixing applications

Achieve rapid, consistent mixing and dispersion across diverse materi...

Double cone mixer for free-flowing material blending

Optimize your production with precision blending and gentle drying o...

Industrial mixers for hire

Optimize your production line with versatile mixers designed for precision blending, heating, and...

External electric motovibrators for hazardous environments

Ensure safety and efficiency in explosive environments with t...

Loss-in-weight screw feeder for precise powder dosing

Achieve high precision in continuous dosing with this advanced scre...

Explosion-proof production disperser for paint manufacturing

Ensure safe and efficient dispersion in volatile environmen...

Explosion-proof dissolver for chemical processing

Ensure safe and efficient dispersion in volatile environments with this...

Vacuum dispersion system for high-viscosity products

Eliminate air inclusions during production with a modular vacuum sys...

Vacuum basket mill for high viscosity products

Achieve efficient fine grinding of high-viscosity products while minimizing...

Vacuum dissolver for high viscosity products

Optimize your production with a vacuum dissolver designed to efficiently prev...

Vacuum dissolver for large batch production

Optimize your mixing processes with a versatile vacuum dissolver designed for ...

Rotary homogenizer for high shear mixing

Achieve precise homogenization of various viscosities with advanced rotor-stator t...

Rotor-stator homogenizer for high shear batch processing

Achieve ultra-fine particle distribution and stable emulsions wi...

Explosion-proof bead mill for industrial grinding applications

For manufacturers seeking precise particle size control, ...

Explosion-proof horizontal bead mill

For manufacturers seeking precise particle sizing, this explosion-proof bead mill ensu...

Horizontal bead mill for industrial production

Ensure ultra-fine particle size reduction in high-demand processes with thi...

Horizontal bead mill for fine grinding in continuous process

Achieve ultrafine particle dispersion and consistent mixing...

Horizontal bead mill for ultrafine particle grinding

Achieve precision in ultrafine grinding with a system that allows fo...

High-capacity dissolvers for industrial mixing

Enhance your production line with precision mixing, achieving consistent di...

High shear batch process homogenizer for production

Achieve efficient emulsifying, homogenizing, and dispersing with prec...

High-efficiency immersion mill for medium viscosity products

Achieve precise particle size reduction and superior disper...

High-efficient industrial immersion mill

Achieve rapid, efficient dispersion and fine grinding in demanding production envi...

High-performance dissolver for industrial dispersion processes

Optimize your dispersion processes with this advanced dis...

High-performance production dissolver for large batches

Achieve precise and repeatable dispersion for complex formulation...

Production dissolver with scraper for high-viscosity products

Efficiently tackle high-viscosity material processing with...

Explosion-proof dissolver for high-viscosity products

Optimized for safely processing high-viscosity products, this explo...

Vacuum basket mill for highly viscous products

Achieve precision in fine milling under vacuum to prevent air inclusions in...

ATEX vacuum dissolver for high viscosity products

Ensure safe and efficient dispersion of high-viscosity materials under...

Explosion-proof vacuum dissolver for high-viscosity products

Optimize your production by eliminating air inclusions and ...

Explosion-proof vacuum dissolver for high viscosity products

Achieve precise dispersion of high-viscosity products under...

Vacuum dispersion system for single-walled containers

Optimize your production line with an adaptable vacuum dispersion s...

Laboratory vacuum dissolver

Experience precision vacuum processing for your high-viscosity formulations, ensuring optimal di...

Vacuum dissolver for laboratory and pilot plant operations

Perfect for developing intricate formulations, this vacuum di...

Dissolver for high-volume industrial dispersion

Achieve precise and efficient mixing with this dissolver, designed for sea...

Explosion-proof basket mill for fine grinding

Achieve efficient and safe fine grinding with this innovative explosion-proo...

Explosion-proof immersion mill for paints and varnishes

Optimize high-performance coatings production with an explosion-p...

Laboratory dissolver for multiple applications

Efficiently streamline your laboratory processes with this versatile dissol...

Lab and pilot plant dissolver for dispersion and fine grinding

Achieve efficient dispersion and fine grinding in laborat...

Industrial dissolver for high-viscosity materials

Efficiently disperse and mix high-viscosity materials with precision, e...

Explosion-proof horizontal bead mill for fine grinding

Ensure precise, explosion-proof grinding in hazardous environments...

Atex horizontal bead mill

Ensure precision and safety in explosive environments with a robust solution that finely grinds an...

Explosion-proof dissolver for hazardous area mixing

When operating in hazardous environments, maintaining consistent and ...

Explosion-proof dissolvers for laboratory use

Ideal for safely dispersing and mixing chemical substances in potentially ex...

Efficient high-volume dissolver with scraper

For high-viscosity formulations, this advanced dissolver with integrated scra...

Lab stirrer for high-viscosity substances

Need precise, high-torque stirring for your complex formulations? This lab stirr...

Entry-level vacuum dispersion system for laboratory applications

Achieve precise dispersion and milling with this versat...

Laboratory and pilot plant horizontal bead mill

Achieve precision milling with minimal product waste, ensuring consistent ...

Laboratory disperser for small batch processing

Achieve precise dispersion and homogenization of high-viscosity mixtures w...

Precision 2k dispenser for automated systems

Achieve precise mixing and dispensing of two-component materials with minimal...

Glovebox for lithium-ion battery material processing

Ensure optimum material integrity with a solution designed to mainta...

Pasting line for e-bike plates

Ideal for ensuring precision and consistency, this pasting line enhances the efficiency of ba...

Pouch li-ion cell assembly line

Efficiently assemble high-performance lithium-ion pouch cells crucial for powering electric ...

Roll to roll notching equipment for battery production

Optimize battery component production with precision notching, ens...

End of line testing for industrial batteries

Ensure battery reliability and safety in your production line with advanced t...

Enveloping and stacking solution for battery manufacturing

Streamline your battery production line with precision techno...

High-density battery chargers

Ensure your battery production line maintains optimal charge levels with precision and efficie...

Industrial belt paster for battery manufacturing

Enhance battery production efficiency by precisely applying pastes to bat...

Industrial battery curing chamber

Achieve optimal battery performance with precise environmental control, ensuring the stab...

Industrial dry charge oven for battery manufacturing

Optimize your battery production with precision-engineered assembly ...

Eft chargers for industrial applications

Ensure optimal performance and longevity of lead-acid batteries with precise dry c...

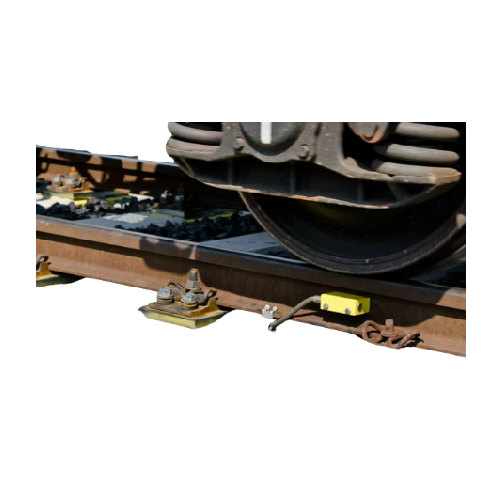

Dynamic weighing for solids and liquids

Ensure precision in rail transport with innovative dynamic scales that provide lega...

Scale hopper for bulk solid material handling

Ensure precise measurement and efficient transport of bulk solid materials w...

Crane scales for precise weighing in chassis

Optimize space with low-profile crane scales, ensuring accurate weight measur...

Crane weighing system for precision measurement

Ensure precise and temperature-resistant weighing during high-demand opera...

Industrial grinding mill replacement parts service

Optimize production efficiency with high-precision grinding solutions ...

Industrial weighfeeder for hygienic applications

Achieve precise mass flow control with a hygienic design, ideal for appli...

U-belt conveyor for bulk material transport

Optimize your high-speed bulk material transport with this space-saving convey...

Loss-in-weight feeder for battery cell production

In battery cell production, achieving precise dosing and safe handling ...

Optimal maintenance solution for industrial weighfeeders

Streamline your processing operations with a solution that minim...

Drop forged chain for drag chain conveyors

Enhance your material flow efficiency with a robust drop forged chain designed ...

Lithium-ion battery powder processing solution

Optimize your lithium-ion battery manufacturing with advanced powder treatm...

Ultrafine bead mill for battery materials

To facilitate the attainment of ultrafine particles and enhance electrode proper...

Inline solid-liquid mixer for battery production

In battery production, a critical phase entails mixing solids with liquid...

Compact Mixing Plant for Paints and Coatings

A smooth finish in paints and coatings depends on the grade of dispersal duri...

Single-use containment valves

From GMP and HSE perspective material transfer is critical for chemical and pharmaceutical for...

Self-cleaning candle filtration system

Separating solids from liquids by filtration requires frequent cleaning or replaceme...

Automatic centrifuge for lithium carbonate

The battery industry requires high purity components. To obtain more than 99.5%...

Continuous centrifuge for lithium hydroxide

Lithium hydroxide, a lithium compound used in making lithium batteries, is ind...

Open mouth bag filling machine for powders

The packaging of powdery products such as flour can be challenging as it is cru...

Robot palletizing system

If you are a relatively large-scale producer, packing and transporting large quantities of products ...

High containment split butterfly valve

Powder containment is the cornerstone of chemical and pharmaceutical manufacturing. ...