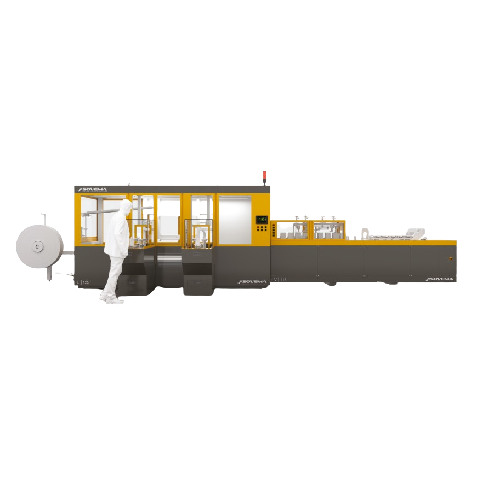

Enveloping and stacking solution for battery manufacturing

Streamline your battery production line with precision technology designed for seamlessly enveloping and stacking battery components, enhancing efficiency and consistency across various battery types.

Envelopes and Stacks Battery Components

The Enveloping & Stacking Machine E-125 from Sovema Group is engineered for battery manufacturing, facilitating precise and efficient assembly of lead-acid, lithium-ion, nickel-cadmium, and nickel-metal hydride batteries. Designed to enhance production lines, this machine automates the enveloping and stacking of battery components, ensuring seamless flow and reduced manual intervention. It integrates easily with existing systems, featuring PLC-controlled operations for streamlined production and remote monitoring capabilities. The E-125 demonstrates energy efficiency, optimizing motor functions to minimize power usage while maintaining high throughput. Constructed with durable materials, it withstands the demands of rigorous manufacturing schedules, requiring minimal maintenance and offering customizable options to meet specific production needs.

Benefits

- Enhances production efficiency by automating component assembly.

- Minimizes labor costs with integrated PLC control.

- Increases energy savings through optimized motor operation.

- Adapts easily to existing production lines for seamless integration.

- Supports multiple battery types, increasing production versatility.

- Applications

- Batteries

- End products

- Lead-acid batteries, Nickel-metal hydride batteries, Nickel-cadmium batteries, Lithium-ion batteries

- Steps before

- Steps after

- Input ingredients

- Output ingredients

- Market info

- Sovema Group is known for its expertise in manufacturing advanced equipment for lead-acid battery production, offering turnkey solutions and innovative technology to enhance battery manufacturing efficiency and quality.

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- Cleaning method

- CIP / Manual

- Energy efficiency

- 0.5–2 kWh/kg moisture