Eft chargers for industrial applications

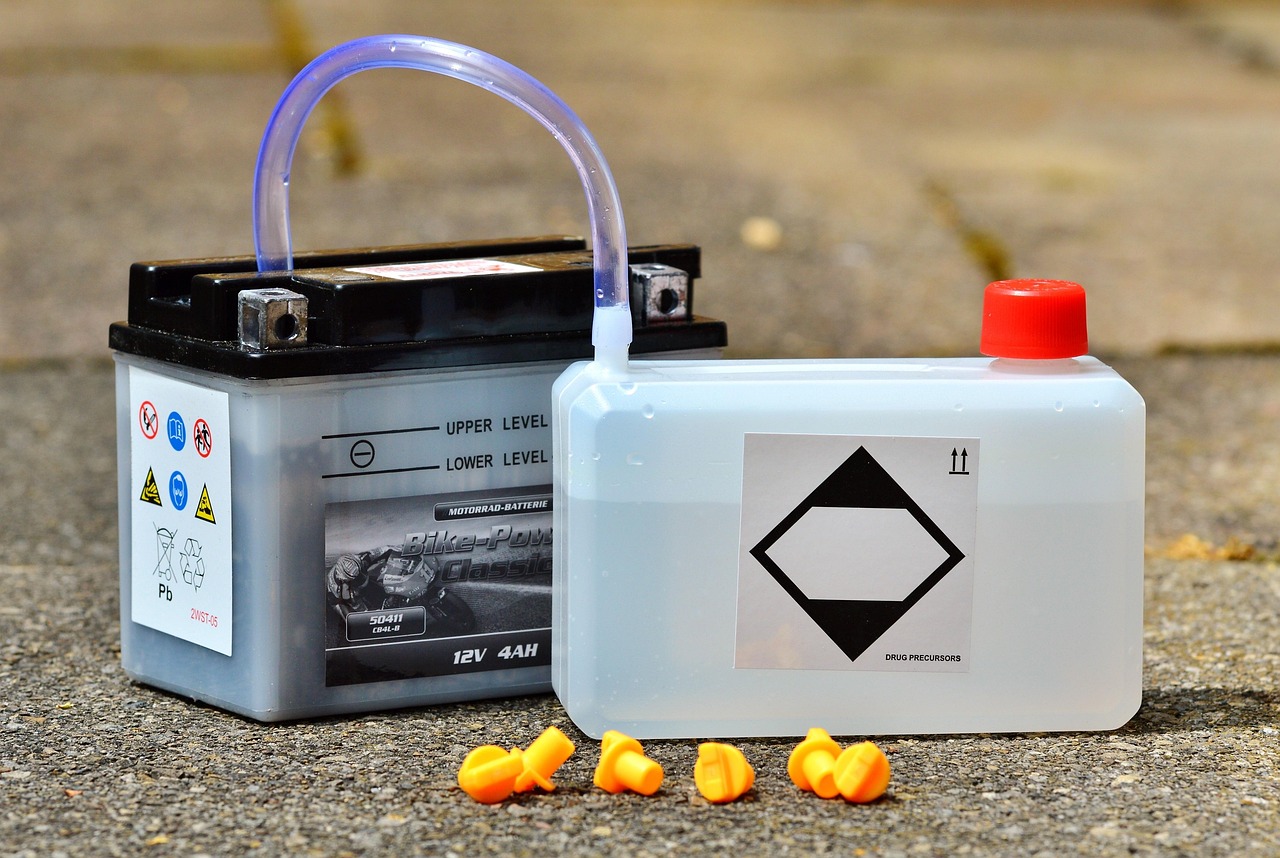

Ensure optimal performance and longevity of lead-acid batteries with precise dry charging in your final conditioning process, enhancing battery life and reliability.

Prepares Batteries for Optimal Charge Retention

The Dry Charge Oven from Sovema Group is engineered to optimize the conditioning phase of battery production. This oven is crucial for preparing lead-acid, automotive, industrial, deep cycle, AGM, and gel batteries by effectively enhancing their initial charge acceptance. Utilizing precise temperature control, it drives off residual moisture, ensuring superior performance and longevity of the batteries. This oven seamlessly integrates into the final conditioning department, offering scalable processing capacity tailored to your production needs. Featuring state-of-the-art automation, it supports remote monitoring for efficient operation and maintenance. The Dry Charge Oven’s robust construction ensures durability and reliable operation, making it a vital component in any high-performance battery manufacturing setup.

Benefits

- Enhances battery performance by optimizing charge retention.

- Minimizes energy usage through precise temperature management.

- Reduces operational costs with automated, remote monitoring.

- Ensures consistent product quality with reliable moisture removal.

- Integrates seamlessly into existing production lines for streamlined operations.

- Applications

- Batteries

- End products

- Agm batteries, Lead-acid batteries, Industrial batteries, Automotive batteries, Gel batteries, Deep cycle batteries

- Steps before

- Steps after

- Input ingredients

- Output ingredients

- Market info

- Sovema Group is known for its expertise in manufacturing advanced equipment for lead-acid battery production, offering turnkey solutions and innovative technology to enhance battery manufacturing efficiency and quality.

- Batch vs. continuous operation

- Batch

- Cleaning method

- Manual

- Automation level

- Manual / PLC

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm