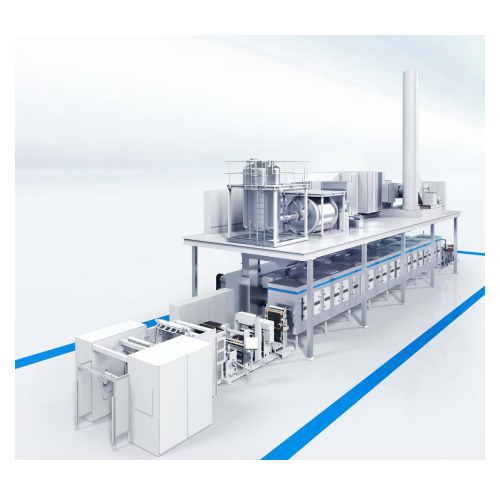

Electrode coating system for lithium-ion batteries

Achieve high-volume, precision electrode coating for lithium-ion batteries, optimizing both coating uniformity and drying efficiency in your production line.

Coats and Dries Electrode Surfaces Efficiently

The Electrode Coating and Drying System by Dürr offers a complete solution for manufacturers of lithium-ion batteries, featuring simultaneous two-sided coating and a non-contact drying process ideal for high-volume production runs in the automotive and energy storage industries. This system employs slot-die coating techniques on a backing roll, enabling precise coat weight control of 70-300g/m², with less than ±1% variation, ensuring consistent quality of EV battery electrodes and modules. The system integrates seamlessly into existing production lines, utilizing air flotation dryers to preserve foil integrity, and offers flexibility with both roll support and flotation drying options. With 24/7 service and parts support, this equipment enhances efficiency while maintaining a compact footprint, addressing challenges related to manufacturing space and productivity. Additionally, its robust design is suitable for continuous operation, and it provides engineering support for customized configurations to meet specific production requirements.

Benefits

- Enhances productivity with simultaneous two-sided coating, reducing production time.

- Minimizes material waste through precise coat weight control of less than ±1%.

- Lowers operational costs with flexible drying options and a compact manufacturing footprint.

- Provides reliable performance in continuous, high-volume manufacturing environments.

- Customized engineering support ensures seamless integration into existing production lines.

- Applications

- Energy storage, Batteries, Lithium-ion battery, Electrode manufacturing

- End products

- Ev battery electrodes, Lithium-ion battery packs, Lithium-ion battery cells, Lithium-ion energy storage modules

- Steps before

- Material Preparation, Foil Quality Check, Raw Material Handling

- Steps after

- Drying, Solvent Recovery, Refining, Quality Inspection, Packaging

- Input ingredients

- foil, coating materials, lithium-ion battery components

- Output ingredients

- coated foil, electrode films, dry coating

- Market info

- Dürr is known for its expertise in industrial engineering and manufacturing solutions, specializing in automotive painting technology, environmental technology, and production efficiency systems. It has a strong reputation for innovation and quality in engineered-to-order equipment.

- Coat weight

- 70-300g/m² dry

- Coat weight precision

- < ±1%

- Sharp edges

- < 3mm

- Dimensions,register

- ± 0.5mm

- Coating Method

- Slot-die / Tandem

- Process Type

- Simultaneous Two-Sided / Tandem

- Drying Process

- Air Flotation

- Integration Level

- Turnkey / Single-Source OEM

- Production Line Type

- Basic / Fully Integrated

- Footprint

- Compact / Straight-path

- Drying Process Contact

- Non-contact drying

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Compact design

- Discharge method

- Slot-die coating on a backing roll

- Coating method

- Slot-die coating

- Control panel type

- Automation and monitoring systems

- Integration possibilities

- Turnkey coating lines

- Customization for volume

- High-volume and basic market needs

- Drying integration

- Air flotation dryer

- Support services

- 24/7 service and parts support