Roll to roll notching equipment for battery production

Optimize battery component production with precision notching, ensuring consistency and streamlined integration into your existing roll-to-roll manufacturing process.

Precisely Notches Battery Electrode Materials

The Roll to Roll Notching Machine from Sovema Group is engineered to meet the exacting demands of battery electrode production. This specialized machine features precision alignment and roll-to-roll processing to notch lithium-ion, nickel-cadmium, and solid-state battery components with unparalleled accuracy. Its operational design supports customizable electrode sizes, ensuring seamless integration into your existing production line. The system operates efficiently with automated control systems, capable of high throughput without compromising dimensional stability. Constructed with durable, corrosion-resistant materials, the notching machine is designed for longevity in high-demand environments. Simplify maintenance with its user-friendly interface and modular components, which allow for quick replacements and reduced downtime. Configurations are available to suit diverse production needs, providing the flexibility required for evolving industry standards.

Benefits

- Enhances electrode precision to ensure optimal battery performance.

- Integrates smoothly with existing production lines for streamlined operations.

- Minimizes operational costs with energy-efficient automated processes.

- Reduces wear and maintenance needs due to durable materials.

- Customizable to meet specific production demands and future market needs.

- Applications

- Batteries

- End products

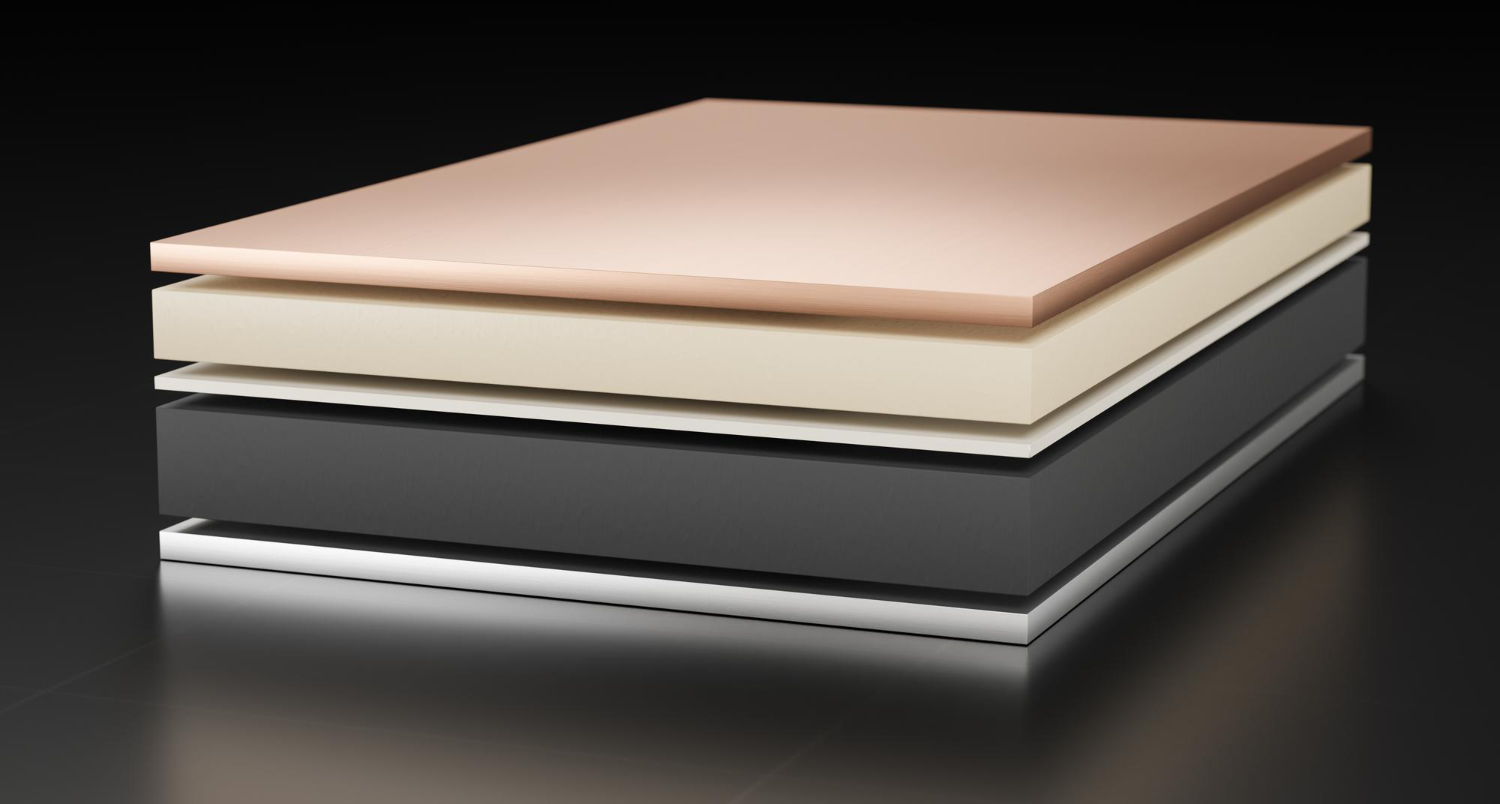

- Lithium-sulfur cathodes, Lithium-ion battery electrodes, Solid-state battery layers, Nickel-cadmium cell components, Anode and cathode sheets

- Steps before

- Steps after

- Input ingredients

- Output ingredients

- Market info

- Sovema Group is known for its expertise in manufacturing advanced equipment for lead-acid battery production, offering turnkey solutions and innovative technology to enhance battery manufacturing efficiency and quality.

- Working mechanism

- Roll to roll notching

- Automation level

- PLC

- Batch vs. continuous operation

- Inline Continuous

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine Type

- Roll to Roll Notching Machine

- Manufacturer

- Sovema Group

- Control Panel Type

- Digital