Automotive assembly and leak testing systems

Optimize your production line with versatile assembly and testing systems, ensuring precision in electric drive integration and leak-proof functionality for critical components.

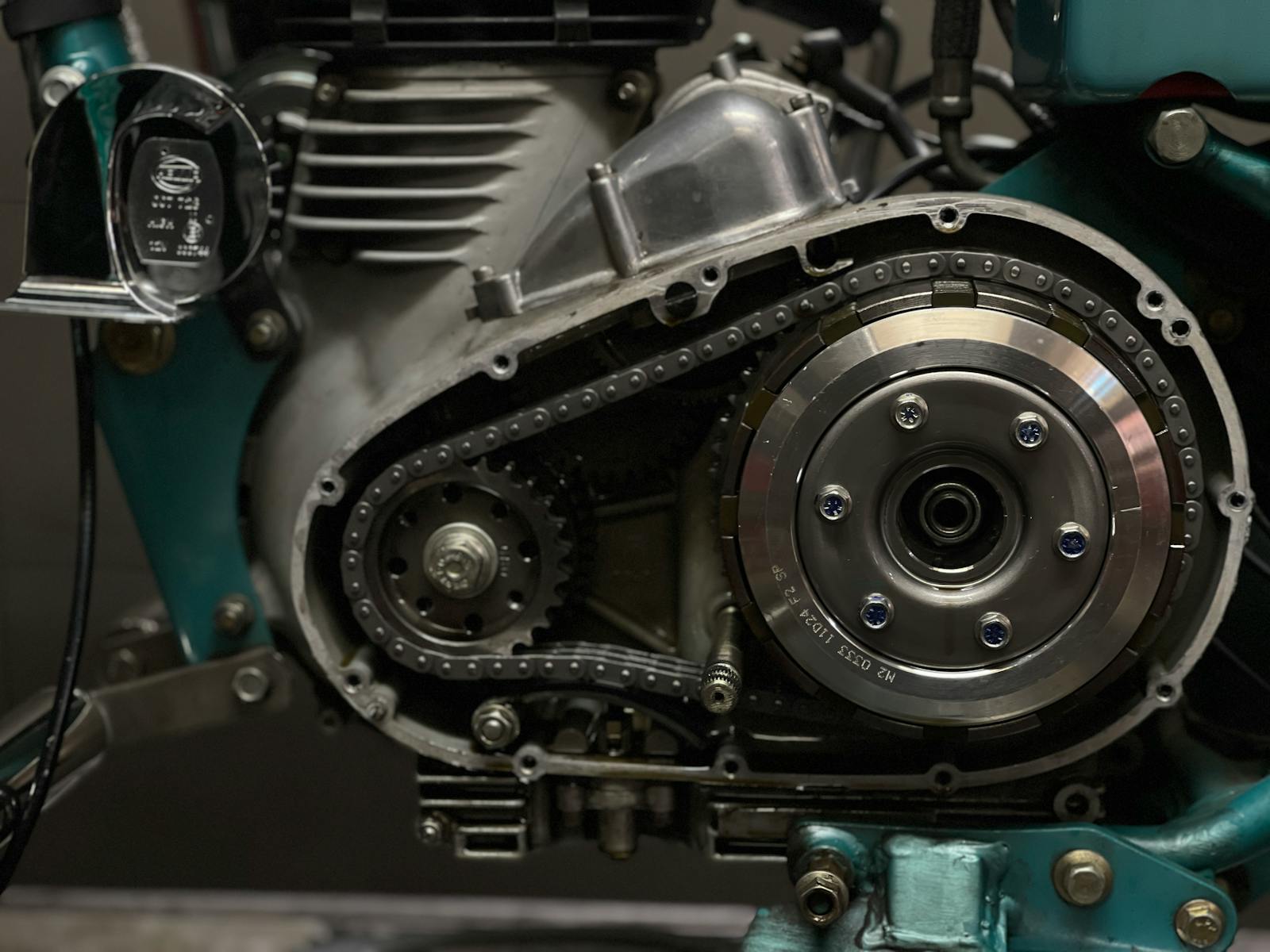

Assembles and Tests Electric and Hybrid Components

The assembly and testing systems from JW Froehlich Maschinenfabrik GmbH are engineered to optimize the production of electric drives, batteries, fuel cells, and hybrid engines. These systems are distinctive for their integrated leak and functional testing capabilities, accommodating a range of components from lithium-ion batteries to automation gearboxes. Featuring automated assembly processes, they ensure precision and compliance with industry standards for automotive and medical technology applications.

Configured for high-speed, continuous operations, these systems facilitate seamless integration into existing production lines. They are designed with advanced measurement and analysis software, enhancing accuracy in testing and diagnostics. Energy-efficient operations are achieved through smart motor controls, supporting sustainable production practices.

Constructed in durable materials to withstand the rigors of intensive use, JW Froehlich’s systems are available with various customization options to align with specific production needs. They adhere to rigorous safety standards and legal compliances, offering engineering support for tailored solutions. Maintenance is streamlined with dedicated service options and detailed guidance available in their comprehensive Leak Test Handbook.

Benefits

- Enhances production efficiency with seamless integration into automated lines.

- Ensures compliance with industry standards, reducing risk in critical testing.

- Minimizes operational costs through energy-efficient motor controls.

- Supports versatile component testing, from batteries to turbochargers.

- Offers customizable configurations for specific production challenges.

- Applications

- Transmissions, Hybrid combustion engines, Automotive, E-mobility, Engine components, Fuel cells, Hydrogen engines, Medical technology, Electric drives, Batteries

- End products

- Hydrogen power units, Hybrid drive systems, Fuel cell stacks, Inverters, Pistons, Electric motors, Automotive switching plates, Automatic gearboxes, Lithium-ion batteries, Electric compressors, Turbochargers, Crankshafts, Cylinder blocks, Medical diagnostic devices

- Steps before

- Component assembly, Pre-test preparation

- Steps after

- Leak testing, Functional testing, Data analysis, Final assembly

- Input ingredients

- electric drive unit (EDU), battery, fuel cell, short engines, complete engines, cylinder head, cylinder block, automatic transmissions, switching plate, turbocharger, leak test panels

- Output ingredients

- assembled systems, tested systems, leak tested components, functional tested components, user-oriented mounting systems, test systems for electric drives, test systems for hybrid combustion engines, test systems for hydrogen engines

- Market info

- JW Froehlich is known for manufacturing and supplying state-of-the-art testing and assembly systems for automotive and other industrial applications, renowned for precision, innovation, and expertise in tailor-made engineered solutions.

- Automation

- State-of-the-art technology

- Lead Time

- Short lead times

- Support

- Dedicated service

- Compliance

- Legally compliant technology

- Leak Testing

- Adherence to safety standards

- Functional Testing

- High precision

- Assembly

- Delivered in easily manageable sections

- Software

- User-oriented test and analysis software

- Product Range

- Electric drives, batteries, fuel cells

- E-Mobility Focus

- Innovation in electric and hybrid systems

- Working mechanism

- Leak test and functional test

- Automation level

- Manual / PLC / SCADA

- Integrated steps

- Assembly, leak testing, functional testing

- Batch vs. continuous operation

- Batch

- Changeover time

- Short lead times

- Cleaning method

- CIP / Manual

- Energy efficiency

- High efficiency standards

- Adherence to specifications

- High compliance

- Safety standards

- Highest safety standards

- High-temperature resistance

- Yes

- Corrosion resistance

- Suitable for Hydrogen and fuel cells

- Cleanability

- Meets industrial hygiene standards

- Electrical insulation

- Applicable for electric drive systems

- Mechanical strength

- Handles heavy load applications

- Density/particle size

- Compatible with integral components like inverters

- Footprint

- Compact, Easily Manageable Sections

- Control Panel Type

- User-oriented Interface

- Discharge Method

- High Precision Functional Testing

- System Flexibility

- Configurable for Various Applications

- Custom Configuration

- Tailored Solutions

- Integration with Existing Systems

- Yes

- HMI Type

- Touchscreen / PLC

- Module Configuration

- Customizable

- Software Interface

- User-centered software

- Machine Design

- Tailored solutions