Production systems for battery cells with end-of-line testing

Optimize battery cell production with a flexible system offering comprehensive end-of-line testing, ensuring your cells meet stringent quality standards while adapting to varying output demands and specifications.

Performs Comprehensive Battery Cell Testing and Packaging

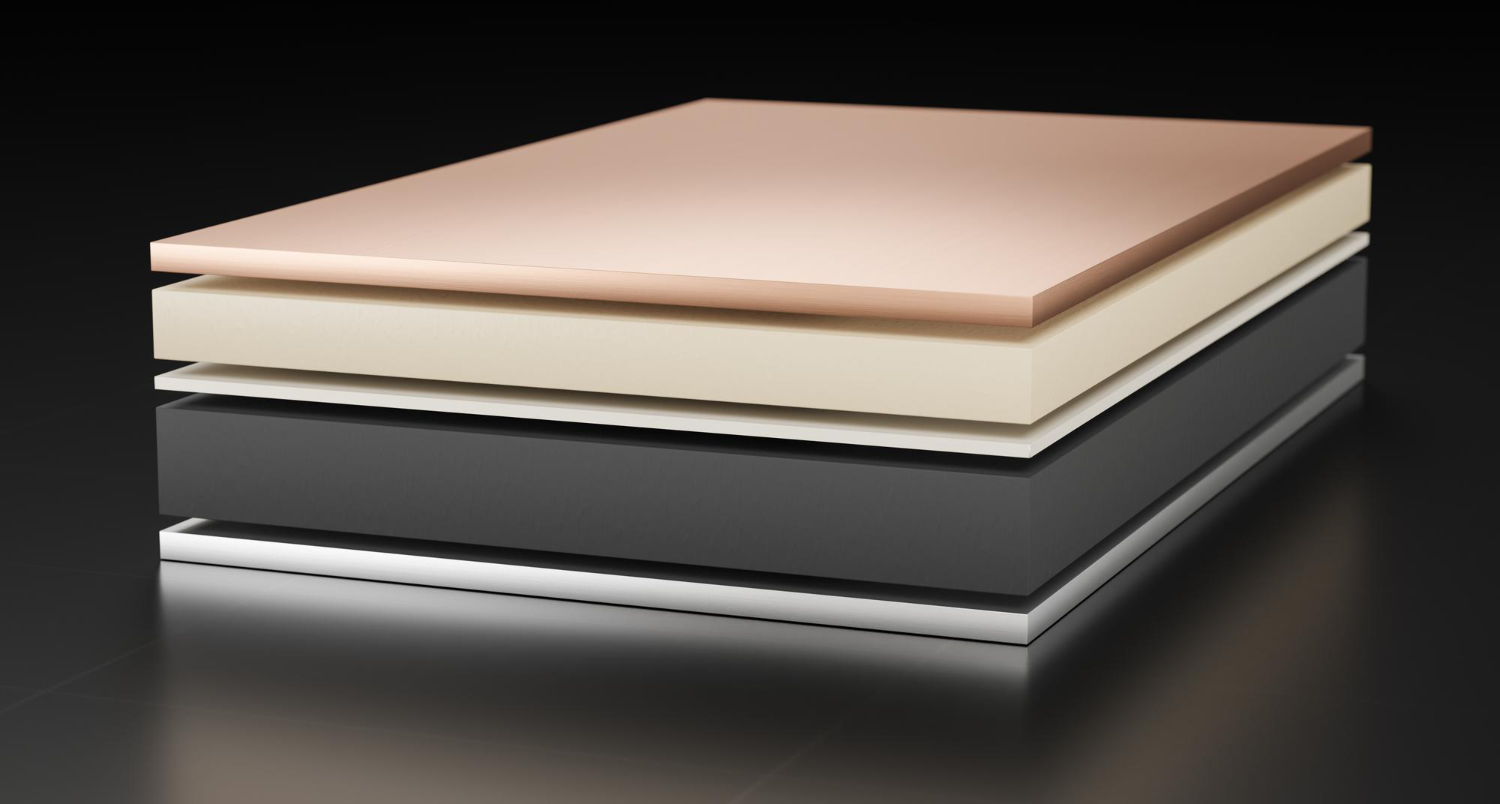

The TEAMBATT platform from teamtechnik provides a fully automated solution for battery cell production and testing. This system excels in integrating extensive electrical testing with visual inspections, making it ideal for automotive and renewable energy industries. Specially crafted to optimize process flow, it performs tasks such as cell infeed, weighing, applying insulating film, and heat-shrink tubing applications. It further includes plasma activation, pressing, and packaging, ensuring high-quality end products like round cells (18650 to 46XX) and prismatic cells. With its flexible and scalable structure, TEAMBATT adapts to varying production outputs while incorporating advanced testing methods, including ACIR, DCIR, and HV tests, to ensure thorough quality control. The system’s continuous operation is supported by PLC-controlled software, offering seamless integration with existing production lines and remote monitoring capabilities. Built for efficiency, it provides significant energy savings through optimized motor controls and can be customized to meet specific engineering needs, facilitating specialized production requirements.

Benefits

- Enhances product quality through comprehensive end-of-line testing.

- Increases production efficiency with seamless integration into existing lines.

- Adapts to changing production demands with scalable design.

- Minimizes energy usage through optimized motor controls.

- Decreases operational costs with fully automated, continuous processes.

- Applications

- Battery modules, Fuel cells, Battery packs, Battery cells, Batteries

- End products

- Round cells 32700, Round cells 46xx, Round cells 18650, Round cells 21700, Round cells 26650, Prismatic cells

- Steps before

- Formation, Aging

- Steps after

- Packaging, Palletizing

- Input ingredients

- round cells, prismatic cells, heat-shrink tubing, insulating film, cells for packaging

- Output ingredients

- tested cells, packaged cells, insulated cells, marked cells

- Market info

- Dürr is known for its expertise in industrial engineering and manufacturing solutions, specializing in automotive painting technology, environmental technology, and production efficiency systems. It has a strong reputation for innovation and quality in engineered-to-order equipment.

- End-of-line testing

- Integrated visual inspections and electrical EOL tests

- Cell types

- Round cells (18650, 26650, 21700, 32700, 46XX) and prismatic cells

- Process steps

- Visual inspections, electrical testing, cell infeed, cell weighing

- Flexibility

- Extendable and scalable platform

- Packaging solutions

- Turnkey solutions for packaging processes

- Cell production processes

- Heat-shrink tubing application, cell marking, visual inspections, electrical tests

- Electrical testing

- OCV, inner resistivity, ACIR, DCIR, Pulse output

- HV test

- Available

- Leakage test

- Available

- End-of-line testing

- Visual and electrical tests

- Automation level

- Standardized assembly and test lines

- Integrated steps

- Heat-shrink tubing, cell marking, visual inspection

- Scalability

- Flexible and adjustable production system

- Turnkey solution

- Packaging and testing processes

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine Footprint

- Compact/Miniaturized

- Control Panel Type

- Integrated/Touchscreen

- Discharge Method

- Automated/Conveyor

- Scalability

- Modular/Expandable

- Heat-shrink Tubing Application System

- In-line

- Control panel type

- HMI/PLC/Touchscreen

- Integration possibilities

- Scalable/Modular Design

- Platform flexibility

- TEAMBATT

- Output scalability

- Adjustable Output Quantity