Cell Culture Equipment

Find innovative production technology for making cell cultures and connect directly with world-leading specialists

Cell culture has been, over a little more than 100 years, an important method of research in laboratories. But medicine developments aside, we wonder if even the most positive of idealists could have also believed that cell cultures and tissue culture would possibly change the way – and what – we eat. From the lab to the dining table, there’s cell culture equipment to make even the unimaginable possible.

Technology picks for cell cultures

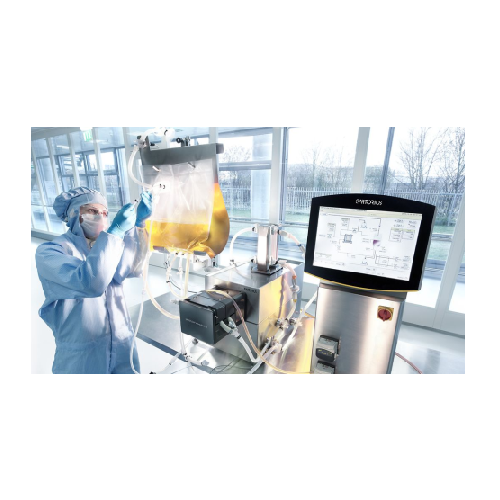

Automated cell culture clarification system

Efficient harvest from the bioreactor is essential to any successful cell cult...

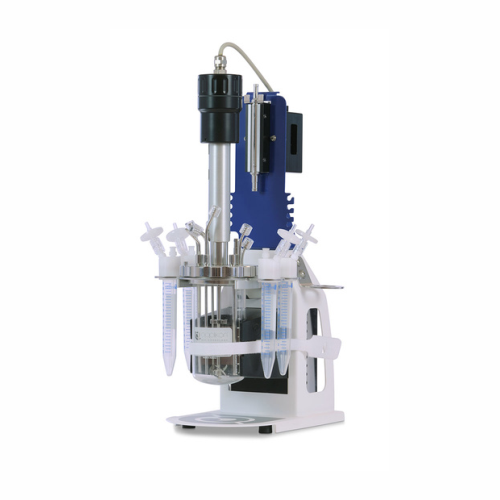

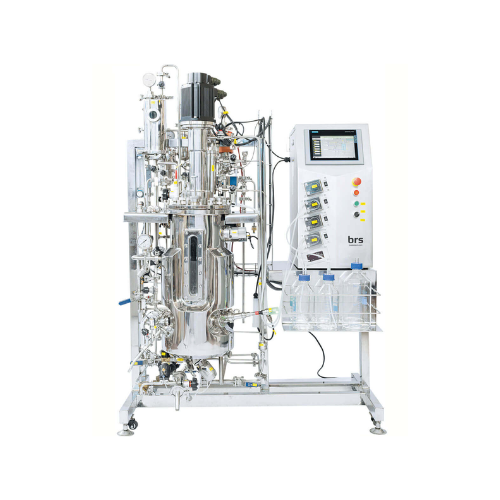

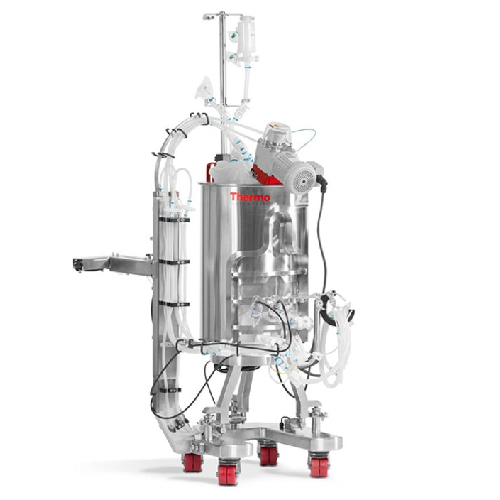

Bench top bioreactor for microbial and cell cultures

Optimize your bioprocessing workflow with this versatile bench top s...

Automated cell manufacturing system for stem cells

Revolutionize cell culture with a fully automated system designed to s...

Cell culture bioreactor for mabs and vaccines

Optimize your biopharmaceutical production with advanced cell culture capabi...

Stories about cell cultures

Tell us about your production challenge

Shakers, incubators, bioreactors – cell culture technology for your production

Cell culture manufacturing is largely used in the production of vaccines, treatments for cancer, and therapeutic proteins and antibodies. There are two sources where to obtain the cell material: through a cell stock, thawing the frozen cells and including them in the culture, and through the isolation of the cells of a donor tissue culture.

Before starting the culture technique, producers carry on cell seeding and observation. Cell seeding guarantees the right cell density, and observation defines if the cells are viable and not contaminated by foreign objects.

Shake flasks are usually the tool in these initial stages. If everything is correct, then you can place the flasks in a CO2 incubator. In it, the concentration of oxygen is lower compared to a non-controlled environment, so the cells can start culturing.

Some biotechnology producers may prefer to use an integrated incubator shaker instead of a flask and a separate incubator, to simplify the process in one place. In this case, you need to define which incubator shaker design fits best to your needs. In other cases, a centrifuge is used to allow the cells to spin down.

Apart from these options, it’s also possible to use a bioreactor as your cell culture equipment. It will help further control, in real-time, the biology of the cells, as well as to fulfill criteria related to quality and efficacy. The most common type that producers use is the stirred-tank bioreactor (STR), which can be easily adjusted for large scale production.

Culture conditions: preparing the environment for your cell lines

Choosing equipment is important. But, to promote cell growth, you need more than cell culture technology; you also need to provide an environment with good conditions for it to work. Researchers use cell lines to conduct different experiments because they can evaluate how a set of cells with the same characteristics respond when submitted to varied conditions and reagents.

When creating these lines, one essential part of the process is to set the culture media formulation that will help cell types to grow. Basic culture medium composition includes glucose, amino acids (the most prominent one being L-glutamine), vitamins, proteins, antibiotics, and inorganic salts. Other components, however, vary according to the outcome expected from those cell lines. The insect cells culture, for instance, benefit from TC-100, while many mammalian cells are supported by RPMI 1640.

Set the optimal conditions for your stem cells culture

Stem cell culture is a valuable asset for research. These cells are particularly interesting due to their nature, as what makes them unique is exactly their ability to differentiate themselves into any cell and self-renew. Nonetheless, it’s precisely because of this that culturing stem cells require extra care and attention in order to provide the right environment for their growth. Stem cells can easily differentiate if the optimal conditions are not reached, but they can also stop responding to growth stimuli, going through the phenomenon of cellular senescence.

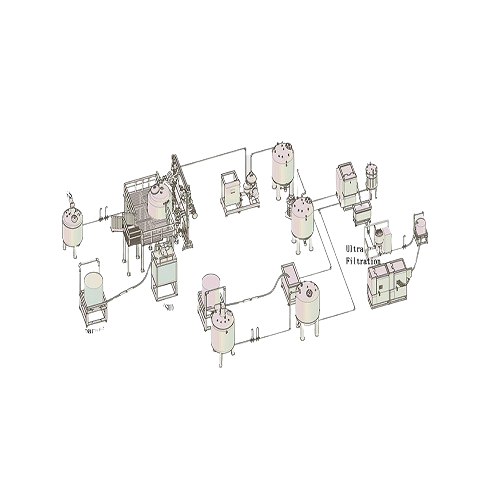

Processing steps involved in cell cultures making

Which cell cultures technology do you need?

Single-use separator for cell harvesting

Achieve maximum cell harvesting efficiency with single-use technology, streamlinin...

Pilot-scale bioreactor for cell cultivation and fermentation

Scale up your cell cultivation and fermentation processes s...

Laboratory homogenizer for nanoemulsions and dispersions

Elevate your laboratory capabilities with a bench-top homogenize...

15l vertical-wheel bioreactor for cell therapy scale-up

Accelerate your cell therapy scale-up with a bioreactor that offe...

Vertical-wheel bioreactor for cell therapy applications

Elevate your cell culture process with a bioreactor designed for ...

Large-scale bioreactor for cell therapy manufacturing

Tackle the challenge of scaling therapeutic cell production with a ...

Compact bioreactor for cell therapy process development

Quickly scale your cell culture processes with scalable mixing te...

Sterile filtration for cell culture media

Ensure sterility in cell culture and bioprocessing with advanced filtration solu...

Vacuum filtration for sterile media and buffer preparation

Achieve reliable sterilization and filtration of cell culture...

Bioprocessing liquid cell culture media

Streamline your bioprocessing with sterile liquid media solutions that ensure optim...

Compact fermentor for research and scale-up studies

Optimize your bioprocess development with a desktop fermentor that of...

Sterilization in place fermentor for bioprocess applications

Optimize your fermentation processes with seamless integrat...

Adherent cell expansion platform

Maximize adherent cell culture scalability and minimize operational costs with a platform d...

Controller for lab-scale bioreactors

Optimize your bioprocessing capabilities with a versatile controller that manages both...

Controller for pilot and production scale bioreactors

Optimize your bioprocess with a robust, configurable controller des...

Small size multi-use glass autoclavable bioreactor

Optimize your laboratory space with this compact bioreactor that reduc...

Single-use lab-scale bioreactor for upstream bioprocessing

Streamline your bioprocess development with a customizable, s...

Bench top bioreactor for microbial and cell cultures

Optimize your bioprocessing workflow with this versatile bench top s...

Turnkey bioreactor system for cell culture

Streamline your bioprocessing with a complete cultivation system; ideal for pro...

Stainless steel bioreactor for small-scale bioprocess production

Optimize your bioprocess development with a modular sta...

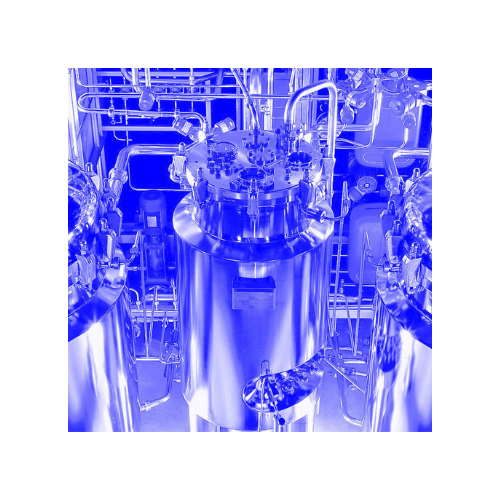

Stainless steel bioreactor for cgmp production

Achieve reliable and scalable production of life-saving medicines with a cu...

Bioreactor for mammalian and microbial cell cultivation

Optimize your bioprocesses with advanced temperature and heat tra...

Mini bioreactor for cell culture and microbial process development

Achieve precise control and reproducibility in small...

Single-use bioreactors for mammalian and insect cell cultivation

Optimize your bioprocesses with scalable, single-use bi...

Single-use bioreactors for microbial fermentation

Optimize high-density fermentation with advanced single-use bioreactor ...

High-speed centrifuge for laboratory applications

Maximize efficiency in high-volume centrifugation tasks with this versa...

Parallel bioreactor system for cell culture and microbiology

Optimize bioprocess development with a scalable system desi...

Bioreactor for cell culture yield optimization

Streamline complex cell culture processes with a bioreactor designed to enh...

Semi-automatic filling system for cell and gene therapy

Optimize your cell and gene therapy processes with a modular fill...

Cell & gene therapy isolator with integrated incubation

Enhance your cell and gene therapy workflow with a modular isolat...

Isolator for aseptic cell culture processing

Ensure sterility and reduce cross-contamination risks in your cell culture pr...

Incubation system for cell culturing in therapy labs

Optimize your cell culturing capabilities with a cutting-edge incuba...

Cell culture isolator for regenerative medicine

Ensure aseptic conditions for cell and gene therapy by maintaining a conta...

Autoclavable glass fermentor for biotech research

Optimize your fermentation processes with a versatile benchtop solution...

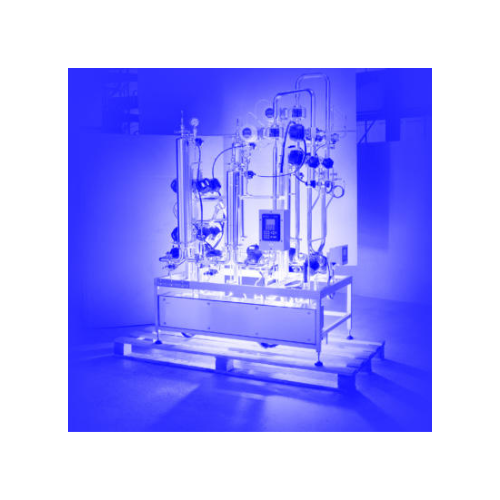

Pilot fermentors for biotech processes

Optimize your pilot-scale production with versatile fermentors and bioreactors desig...

Sterile media and buffer storage tanks

Ensure uninterrupted bioproduction with our tanks designed for secure storage and pr...

Media and buffer preparation solution for bioprocessing

Achieve seamless media and buffer preparation with precise dosing...

Autoclavable and in-situ sterilizable lab-scale fermentors

For researchers seeking precise control in bioprocessing, the...

Bioreactors for cell culture processes

Efficiently cultivate sensitive cell lines with customizable bioreactors designed to...

Filter stations for sterile filtration in biopharmaceuticals

Ensure sterility and precision in your biopharmaceutical pr...

Hybrid bioprocess system for cell culture and purification

Streamline your bioprocessing operations with a versatile sol...

Temperature-controlled bath for tissue sample freezing

Achieve rapid and reliable tissue freezing for precise histologica...

Aseptic filling line for biopharmaceuticals

Streamline your aseptic filling process with precision dosing and minimal spac...

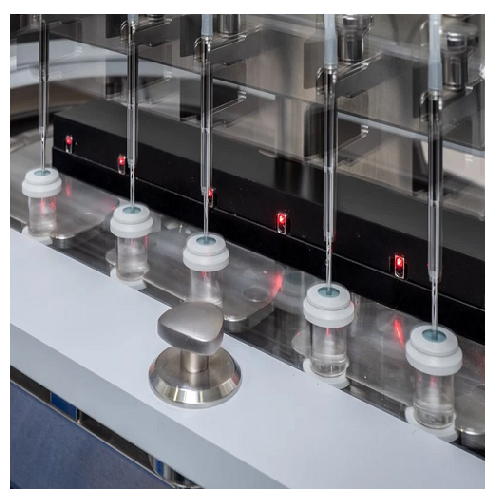

Aseptic filling line for biopharmaceutical products

Achieve precision and sterility in high-speed liquid filling operatio...

Aseptic filling solution for small cgmp batches

Ensure sterile and efficient filling of small-volume parenterals while mai...

Microbial cell clarification solution

Achieve high-yield, foam-free microbial cell clarification with minimal shear stress ...

Biopharma cell centrifuge for gentle protein recovery

Ensure gentle cell harvesting and enhanced yield in bioprocessing w...

Rotary homogenizer for laboratory and pilot plant

For achieving optimal dispersion in complex formulations, this solution...

Automated cell culture system for ipscs

Streamline your stem cell culture operations with a system that automates seeding, ...

Automated cell manufacturing system for stem cells

Revolutionize cell culture with a fully automated system designed to s...

Single use bioreactor for cell culture and fermentation

Optimize your cell culture processes with scalable, single-use bi...

Cell expansion system for antibody drug production

Enhance your biopharmaceutical production with efficient cell expansio...

Stainless steel container for bioprocessing

Optimize the containment and handling of large-volume biopharmaceutical liquid...

Large-volume sterile liquid storage solution

Efficiently store and transfer large volumes of sterile process liquids with ...

Microcarrier separation system for adherent cell cultures

Enhance your production efficiency with a scalable, single-use...

Microcarrier separation system for adherent cell culture

Enhance cell culture production efficiency by integrating a seam...

Single-use bioreactor for protein expression

Optimize your biopharmaceutical production with an advanced single-use biorea...

Single-use bioreactor for cell culture applications

Achieve optimal cell growth and product yield with a single-use biore...

Single-use bioreactor for high volume cell cultures

For optimizing cell culture efficiency, this advanced bioreactor revo...

Single-use bioreactor for cell culture processes

Optimize your cell culture productivity with advanced mixing dynamics tha...

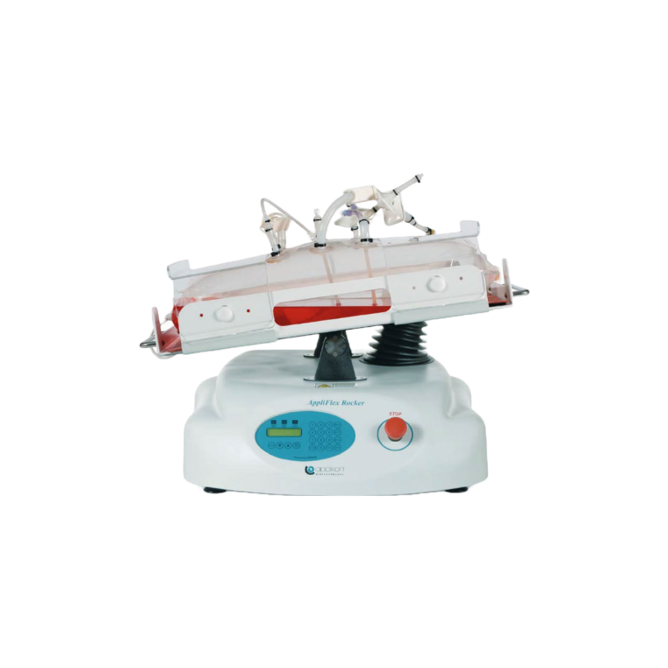

Rocker bioprocess container for cell culture processes

Optimize your bioprocessing with a container designed to enhance c...

Rocker bioreactor for cell culture processes

Achieve precise control over cell culture conditions with this rocker bioreac...

Glass bioreactor for mammalian cell culture

Optimize your bioprocessing with advanced mixing and cooling capabilities, des...

Glass bioreactor for cell culture processes

Optimize your cell culture and fermentation processes with a high-efficiency b...

Single-use bioreactor for cell cultures

Enhance your cell culture efficiency and minimize contamination risks with a state-...

Benchtop bioreactor for research and development

Achieve precise control over fermentation and cultivation processes with ...

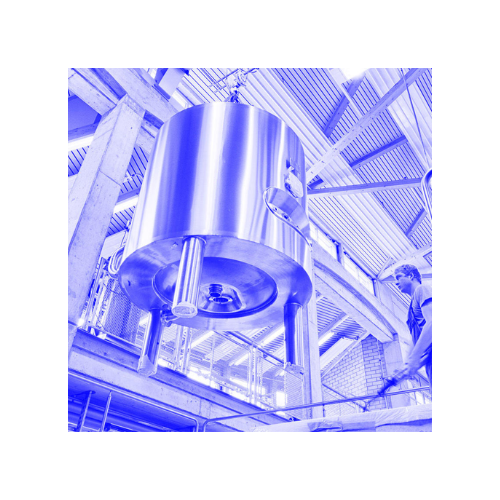

Industrial-scale bioreactors for large-scale biomanufacturing

When producing at large volumes, efficient and reliable bi...

Lab-scale microalgae cultivation system

Achieve precise control of microalgae cultivation with optimized growth conditions ...

Desktop bioprocessor for continuous biomanufacturing

Shrink your biotech facility to a bench-top unit, achieving seamless...

Benchtop stirred fermenter for precise fermentation control

Optimize your fermentation and cultivation processes with pr...

Tangential flow filtration system for cell harvesting

Optimize your biopharmaceutical production by integrating a versati...

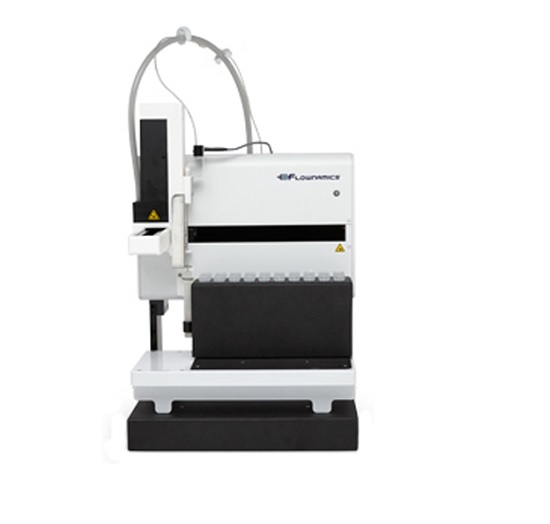

Automated single cell and colony picking system

Streamline your cell selection and retrieval processes with a high-precisi...

Multi-parallel bioreactors for cell line selection and process development

Enhance your biopharmaceutical production w...

Benchtop bioreactors for microbial fermentation

Optimize your bioprocessing with scalable benchtop bioreactors, ideal for ...

Single-use bioreactors for mammalian cell culture

Enhance agility and cut costs with scalable, single-use bioreactors ide...

Wave-mixed bioreactor for shear-sensitive cell cultures

Optimize cell cultivation with a modular, wave-induced mixing sys...

Stainless steel bioreactors

Enhance your bioproduction capabilities with robust solutions designed for efficient fermentatio...

High-frequency vibratory mixer

Mixing liquid products by stirring method generates heat from friction and shear forces. This...

Automated bubble traps for chromatography

Radial flow chromatography processes require special attention and the right use...

Pre-packed and pre-validated chromatography columns

In chromatography, you must always take into account the apparatus th...

Lab-scale radial chromatography columns for virus validation

In the food industry, as an example, during lab-testing and...

Compact H2O2 disinfection system

Dry fogging provides safe, effective microbiological cleaning of critical areas in biotech,...

High pressure electric laboratory homogenizer

It’s vital that small units for experimentation can scale up with 100% accur...

High pressure pilot homogenizer

Biotech and pharmaceutical development programs often require a mixing method that achieves ...

High pressure industrial homogenizer

For any industrial pharmaceutical process that relies on high pressure homogenization ...

Pilot high pressure homogenizer

For maximum value, a high-pressure homogenizer that’s suitable for both laboratory and pilot...

High pressure air powered laboratory homogenizer

Offering lab-scale to small pharmaceutical production scale output for in...

Laboratory test tube filling machine

Test tube filling needs to be accurate and efficient. Moreover, large laboratories tes...

Industrial petri dish filling machine

High throughput petri dish filling machines are traditionally slow and require a larg...

Fast printer for petri dishes

Adding a rotary edge printing facility to a petri dish filling system can be complex and expen...

Online sampling system for larger scale bioprocesses

Accurate sampling is vital for improving a wide variety of industria...

Online fraction collector for offline bioprocess analysis

Many bioprocesses require offline analysis of samples to monit...

Sampling probe for bioreactor samples

In biopharmaceutical and chemical industries, sampling is vital to develop, maintain,...

Sampling probe suitable for fermenter samples

Accurate, sterile sample collection is vital across a range of biopharmaceut...

Fluid sample-taking module for high cell density cultures

Automatic sampling of reactor vessels requires careful fluid m...

Accessory feed pump for various applications

In many biopharmaceutical or chemical development processes, lab work can be ...

Fluid sensor technology for flow rate measurement

For many bioprocesses, precise measurement of media flow rates is vital...

Fully Automated On-Line Sampling for Bioprocesses

Accurate sampling is a critical tool in the design and improvement of a...

Automatic sampling system for bioprocess monitoring

An accurate, automated sampling of cultures is a key requirement in t...

Entry-level automated online sampling system

An accurate and sterile sampling of cultures is vital throughout the biopharm...

Distributor of samples to different devices

The ability to expand your automatic sampling solution provides increased flex...

Disposable monolithic columns

Chromatographic monolithic columns for working with large proteins, viruses, VLPs and pDNA req...

Short bed monolithic columns for analytics

Samples taken at various process steps need to be analysed quickly and accurate...

Plasmid process pack for your pDNA purification process

When developing a pDNA purification process for eventual transfer...

Purification screening kit for large biomolecules

To purify a specific large biomolecule, for example IgM or a virus or v...

Disposable tank liners

Manufacturers in the bioprocessing industries are increasingly turning to single use solutions for the...

Compact horizontal laminar flow bench

HEPA filtered horizontal laminar airflow (cross-flow) creates an optimized free space...

Microbiological safety cabinet class II

This handy device offers the most advanced features in product-operator protection ...

Biosafety cabinet class II for cytotoxic medicines

For the manipulation of hazardous substances utilized during the prepa...

Positive pressure isolator

Ideal for products which have no biological risk but require high sterile conditions.

Biological safety cabinet class III

Specially designed for the handling of microbiological agents, when working with indige...

Single-use pressure sensor

Biopharmaceutical manufacturers are increasingly making use of Single-use pressure sensors to enh...

Automated single use tangential flow filtration system

Tangential Flow Filtration is an essential to the biopharmaceutica...

Single-use conductivity sensor

Biopharmaceutical manufacturers are increasingly making use of single-use conductivity sensor...

Single-use temperature sensor

Biopharmaceutical manufacturers are increasingly making use of single-use temperature sensors ...

Lab scale tangential flow filtration system

Tangential Flow Filtration is an essential to the biopharmaceutical processing...

Automated cell culture clarification system

Efficient harvest from the bioreactor is essential to any successful cell cult...

Disposable tubing for manifolds in bioprocesses

Manufacturers in the bioprocessing industries are increasingly turning to ...

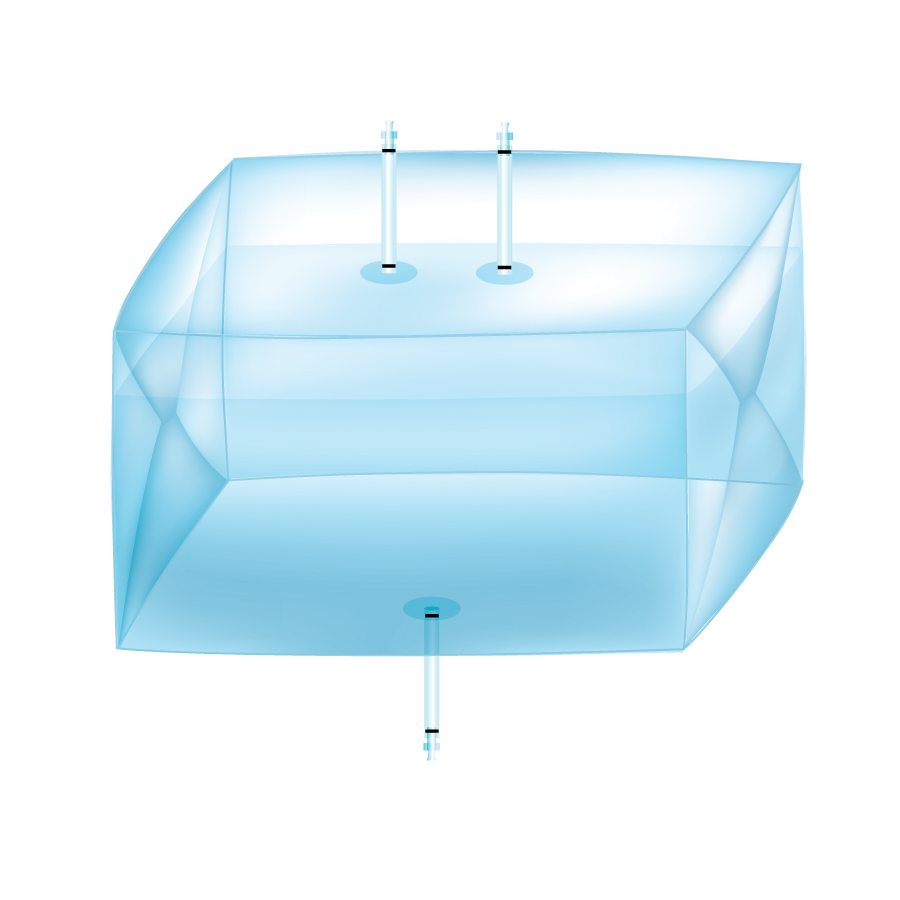

3D disposable bags for bioprocesses

Manufacturers in the bioprocessing industries are increasingly turning to single-use so...

Disposable manifold bags for bioprocesses

Manufacturers in the bioprocessing industries are increasingly turning to dispos...

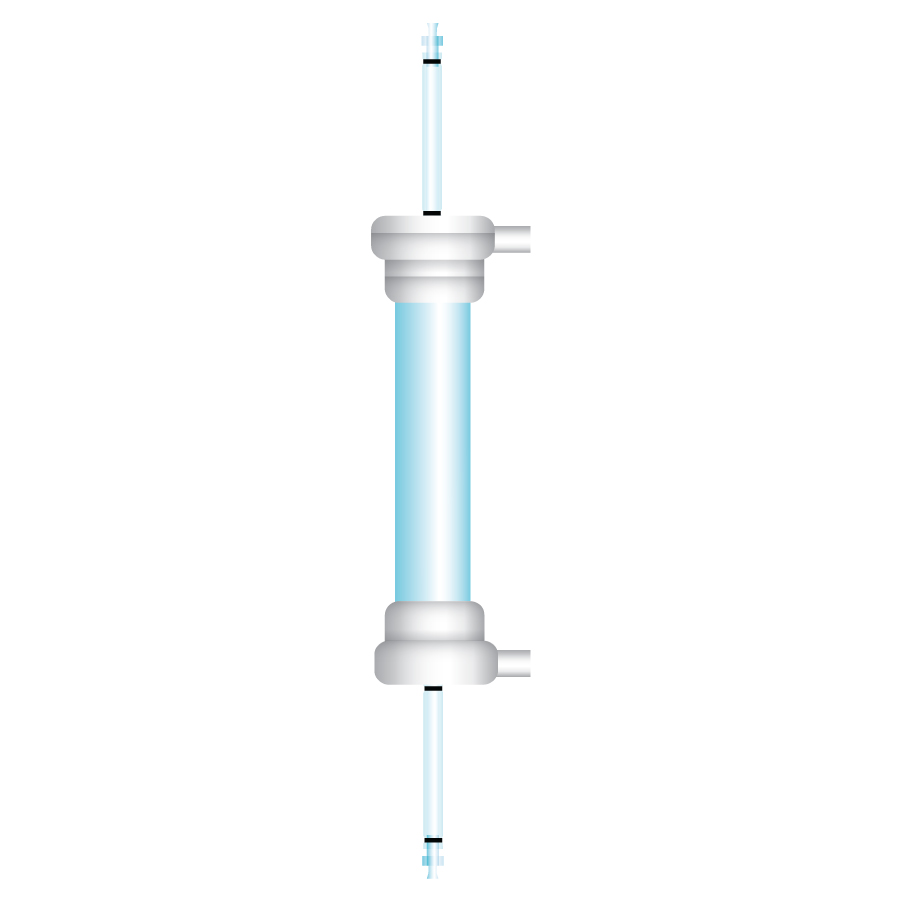

Normal flow filtration sets for bioprocesses

Bio-processors require reliable, high quality, easy to maintain, filtration e...

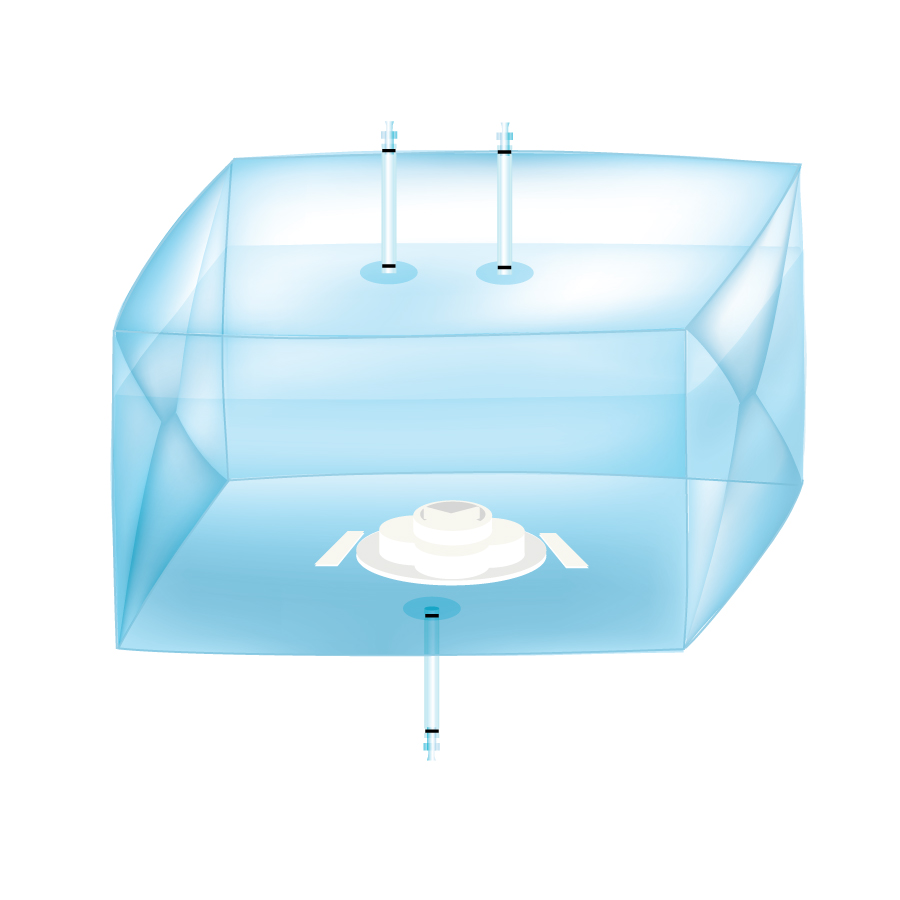

Disposable mixer bags for bioprocesses

Bioprocessors must use ingredients of known high quality and consistency. Inconsist...

Disposable pillow bags for bioprocesses

Manufacturers in the bioprocessing industries are increasingly turning to single us...

Biocompatible tubing for peristaltic pumps

Sensitive bioprocess applications requires equipment that will not interfere wi...

Y sets tubing for bioprocesses

Manufactueres in the bioprocessing industries are increasingly turning to single use solution...

Semi-automated tangential flow filtration system

Tangential Flow Filtration is an essential to the biopharmaceutical proce...

Semi-automated normal flow filtration system

Normal Flow Filtration is frequently used the biopharmaceutical processing in...

Bag holder and weighing platform for bioprocesses

Single use bags for biopharmaceutical process containment and liquid st...

Lab scale normal flow filtration system

Normal Flow Filtration is frequently used the biopharmaceutical processing industry...

Automated dispensing system for bioprocesses

Biopharmaceutical manufacturers require precisely known liquid quantities for...

Saturated steam GMP laboratory autoclave

For processing a wide range of products: solid, porous and liquids in a laboratory...